Rare earth cerium-added high-strength dispersion-strengthened copper, and preparation method thereof

A dispersion-strengthened copper and high-strength technology is applied in the field of high-strength dispersion-strengthened copper added with rare earth cerium and its preparation. , The effect of improved corrosion resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

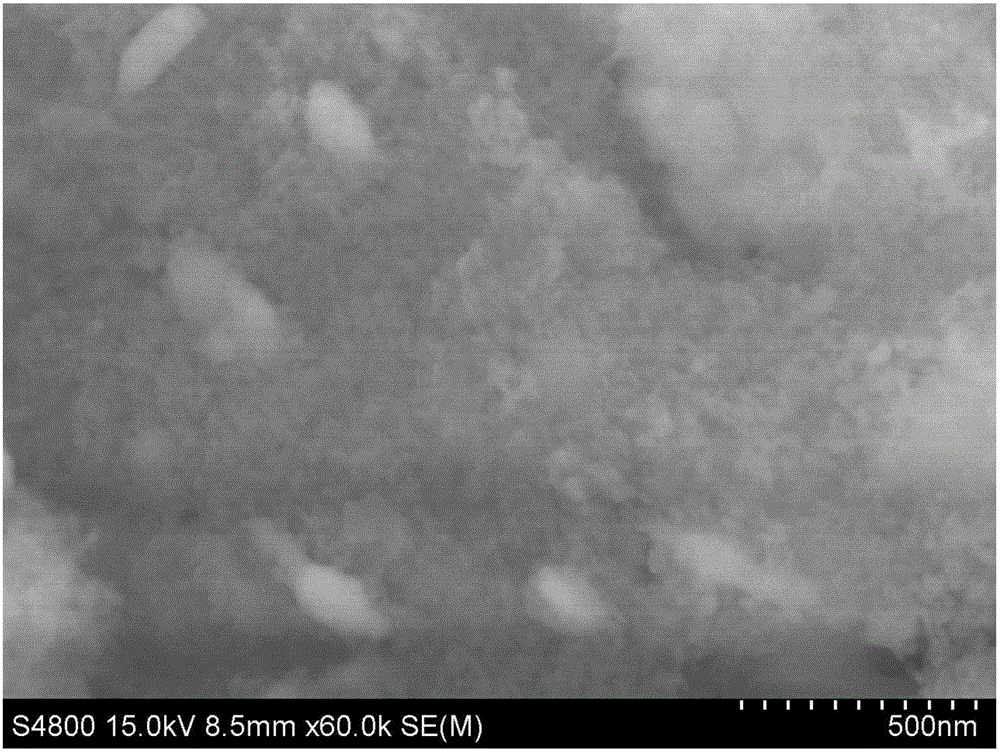

Image

Examples

Embodiment 1

[0017] The present invention is described in detail below in conjunction with embodiment.

[0018] In the embodiment of the present invention, the process flow of dispersion strengthened copper with rare earth cerium and its preparation method is as follows: composition design, including copper powder, nano-Al 2 o 3 and cerium, the ratio of each component is: copper 98.20wt.%, nanometer Al 2 o 3 : 0.88wt.%, cerium: 0.88wt.%, impurity elements include iron, chromium oxide, etc., iron ≤ 0.01wt%, zirconia ≤ 0.02wt%, impurity elements less than 0.04wt.%.

[0019] Rare earth cerium and nano-alumina are mixed in equal proportions. The particle size of rare earth cerium is about 1 mm. Put it into a planetary ball mill for grinding with copper powder for 6 hours at a speed of 200 rpm and a ball-to-material ratio of 5:1. Obtain a mixed powder with uniform composition, and sinter it with a plasma device at a pressure of 30 MPa and a high temperature of 870°C to obtain a high-temperat...

Embodiment 2

[0021] The present invention is described in detail below in conjunction with embodiment.

[0022] In the embodiment of the present invention, the process flow of dispersion strengthened copper with rare earth cerium and its preparation method is as follows: composition design, including copper powder, nano-Al 2 o 3 and cerium, the ratio of each component is: copper 98.46wt.%, nanometer Al 2 o 3 : 0.75wt.%, cerium: 0.75wt.%, impurity elements include iron, chromium oxide, etc., iron ≤ 0.01wt%, zirconia ≤ 0.02wt%, impurity elements less than 0.04wt.%.

[0023] Rare earth cerium and nano-alumina are mixed in equal proportions. The particle size of rare earth cerium is about 1mm. Put it into a planetary ball mill for grinding with copper powder for 5.5 hours at a speed of 195 rpm and a ball-to-material ratio of 5:1. Obtain a mixed powder with uniform composition, sinter it with a plasma equipment at a pressure of 30MPa and a high temperature of 860°C to obtain a high-temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com