Method for preparing superparamagnetic Fe3O4 nano particle based on thermal decomposition of template

A superparamagnetic and nanoparticle technology, applied in ferrous oxide, iron oxide/iron hydroxide, etc., can solve the problems of wide particle size distribution, agglomeration, restricting the industrialization development of magnetic Fe nanoparticles, etc. Good dispersion, regular morphology and controllable morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

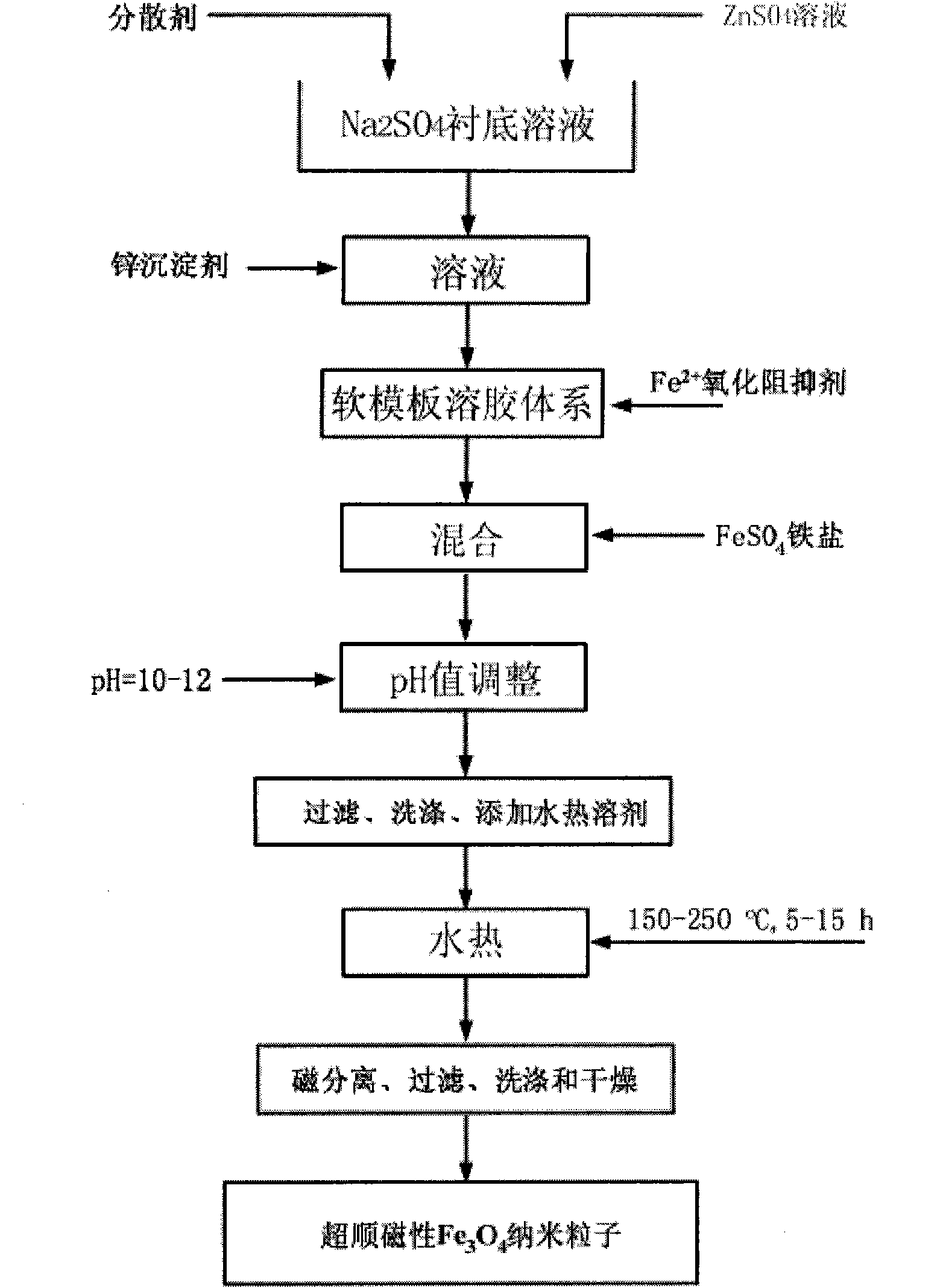

Method used

Image

Examples

Embodiment 1

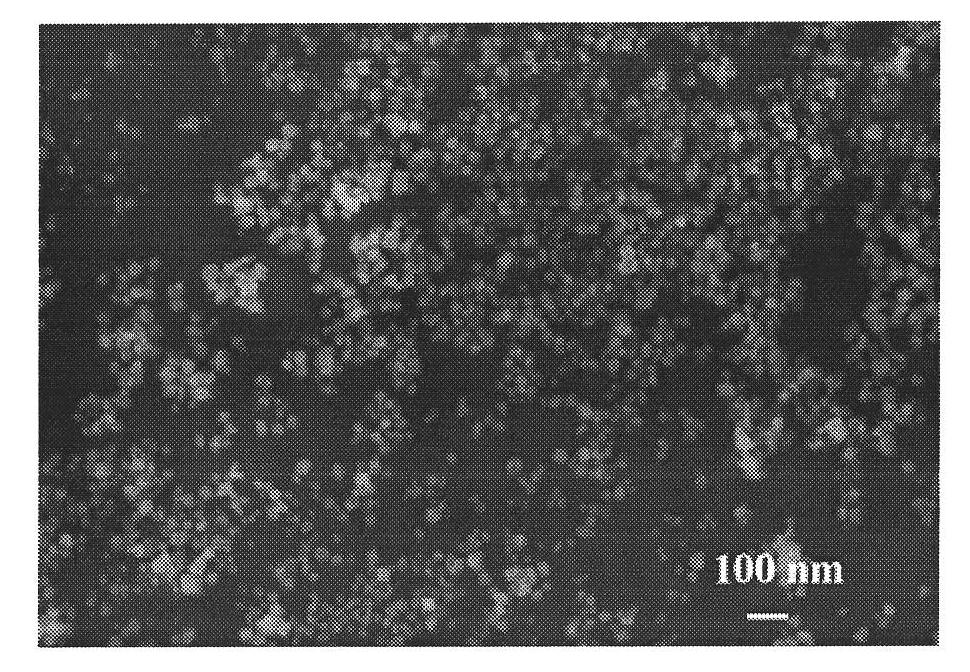

[0036] Configure 0.12 mol / L Na 2 SO 4 Substrate solution, at 25 ° C and 650 rpm stirring conditions, sequentially add 20 ml of 0.25 mol / liter ZnSO 4 solution, 8 ml of 0.05 mol / L cetyltrimethylammonium bromide solution and 35 ml of 0.34 mol / L sodium carbonate solution to obtain a white sol-like slurry, then add 0.15 gram of sodium ascorbate and 50 ml of 0.4 mol / L FeSO 4 solution. After the above solutions are fully mixed, the pH value is adjusted to 11.5 with 0.5 mol / L sodium hydroxide solution, and after the obtained solid is filtered and washed, add ethanol equal to the volume of the pre-filtered slurry, stir and transfer to a hydrothermal device. Heat at 200°C for 8 hours. After the hydrothermal suspension was separated by magnet, filtered, washed and dried in vacuum (40°C, 24 hours), a large amount of black superparamagnetic Fe with a particle size of about 25nm was obtained, which was monodisperse. 3 o 4 Nanoparticles.

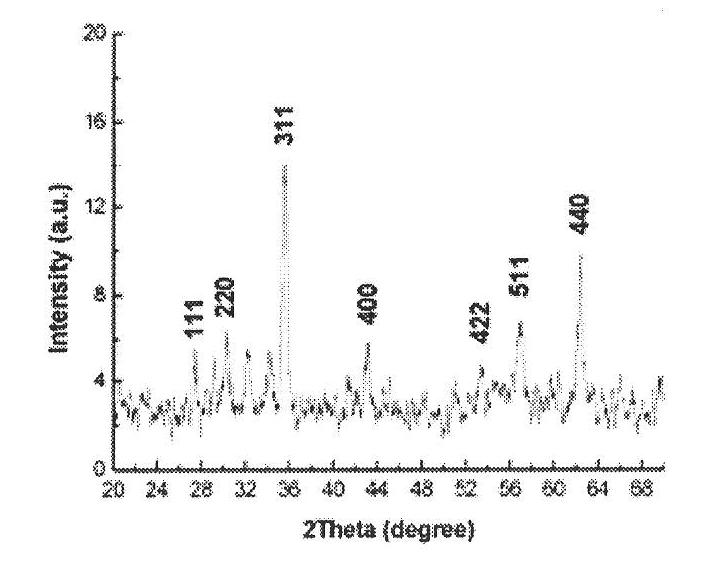

[0037] figure 2 Show the XRD diffraction...

Embodiment 2

[0039] Configure 0.12 mol / L Na 2 SO 4 Substrate solution, under 25 ℃ and 800 rpm stirring conditions, add 15 ml of 0.23 mol / L ZnSO 4 solution, 12 milliliters of 0.06 mol / liter cetyltrimethylammonium bromide solution and 30 milliliters of 0.27 mol / liter sodium carbonate solution to obtain a white sol-like slurry, then add 0.2 gram of sodium ascorbate and 60 milliliters of 0.4 mol / L FeSO 4 solution. After the above solutions are fully mixed, the pH value is adjusted to 11.5 with 0.5 mol / L sodium hydroxide solution, and the obtained solid is filtered and washed, and 1,3 butanediol is added with the volume equal to that of the pre-filtered slurry, stirred and transferred to Put it into a hydrothermal device, and heat it at 200°C for 10 hours. After the hydrothermal suspension was separated by magnet, filtered, washed and dried in vacuum (40°C, 24 hours), a large amount of black superparamagnetic Fe with a particle size of about 15nm was obtained, which was monodisperse. 3 o ...

Embodiment 3

[0041] Configure 0.12 mol / L Na 2 SO 4 Substrate solution, under 25 ℃ and 700 rpm stirring conditions, add 15 ml of 0.23 mol / L ZnSO 4 solution, 0.01 mol sodium oleate and 30 ml 0.27 mol / l sodium carbonate solution to obtain a white slurry, then add 0.2 g sodium ascorbate and 50 ml 0.4 mol / l FeSO 4 solution. After the above solution is fully mixed, the pH value is adjusted to 11.0 with 0.5 mol / liter sodium hydroxide solution, and the obtained solid is filtered and washed, and isopropanol of the same volume as the slurry before filtration is added, stirred and transferred to hydrothermal device, heated at 200°C for 12 hours. The hydrothermal suspension was separated by magnet, filtered, washed and dried in vacuum (40°C, 24 hours), and a large amount of black magnetic Fe with a particle size of about 80nrn was obtained, which was monodisperse. 3 o 4 Nanoparticles, synthesized magnetic particles with -COO- groups on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com