Tin-based composite oxide material as well as preparation method and application thereof

A technology of composite oxides and tin compounds, which is applied in electrode manufacturing, structural parts, electrical components, etc., can solve problems such as uneven size, safety, and poor electrical contact performance of materials, and achieve simple synthesis methods, unique structures, and particle sizes. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of tin-based composite oxide: 3.1g SnCl 4 and 11.4 g Na 2 HPO 4 Add it into 40mL of deionized water, stir well, then add 10.6g of HF 10wt% solution. Dissolve 2.9g of sodium dodecyl sulfate (SDS) in 20mL of deionized water, then mix it with the above solution, stir thoroughly on a magnetic stirrer for 1h, and then transfer the resulting suspension to a 70mL polytetrafluoroethylene liner In a hydrothermal kettle, seal the lid tightly and react in an oven at 150°C for 12h. After the reaction kettle was cooled to room temperature, the obtained precipitate was filtered and washed repeatedly with distilled water. Finally, the reaction product was placed in a ceramic pot and directly heated in a muffle furnace at 300°C for 3 hours, then cooled and ground.

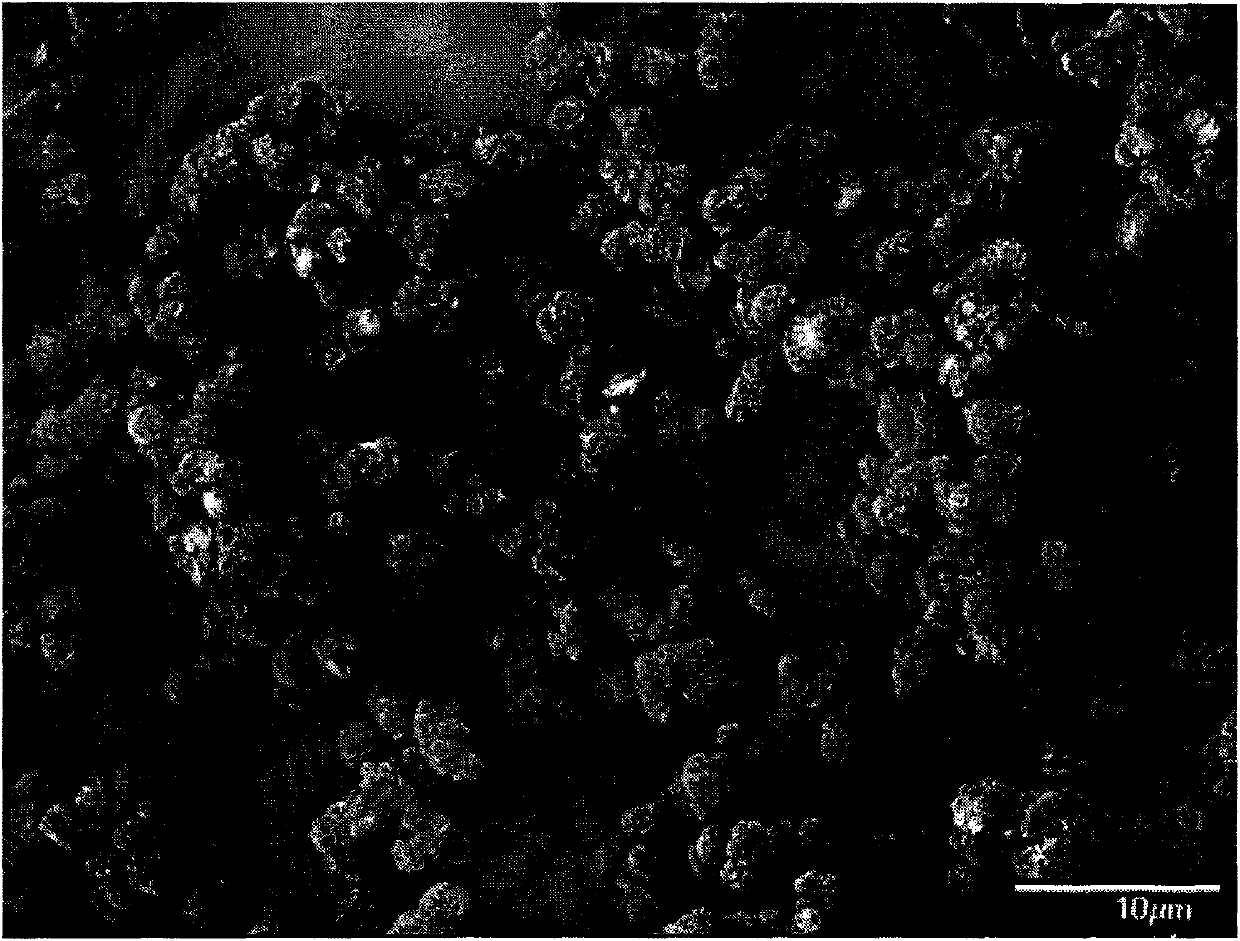

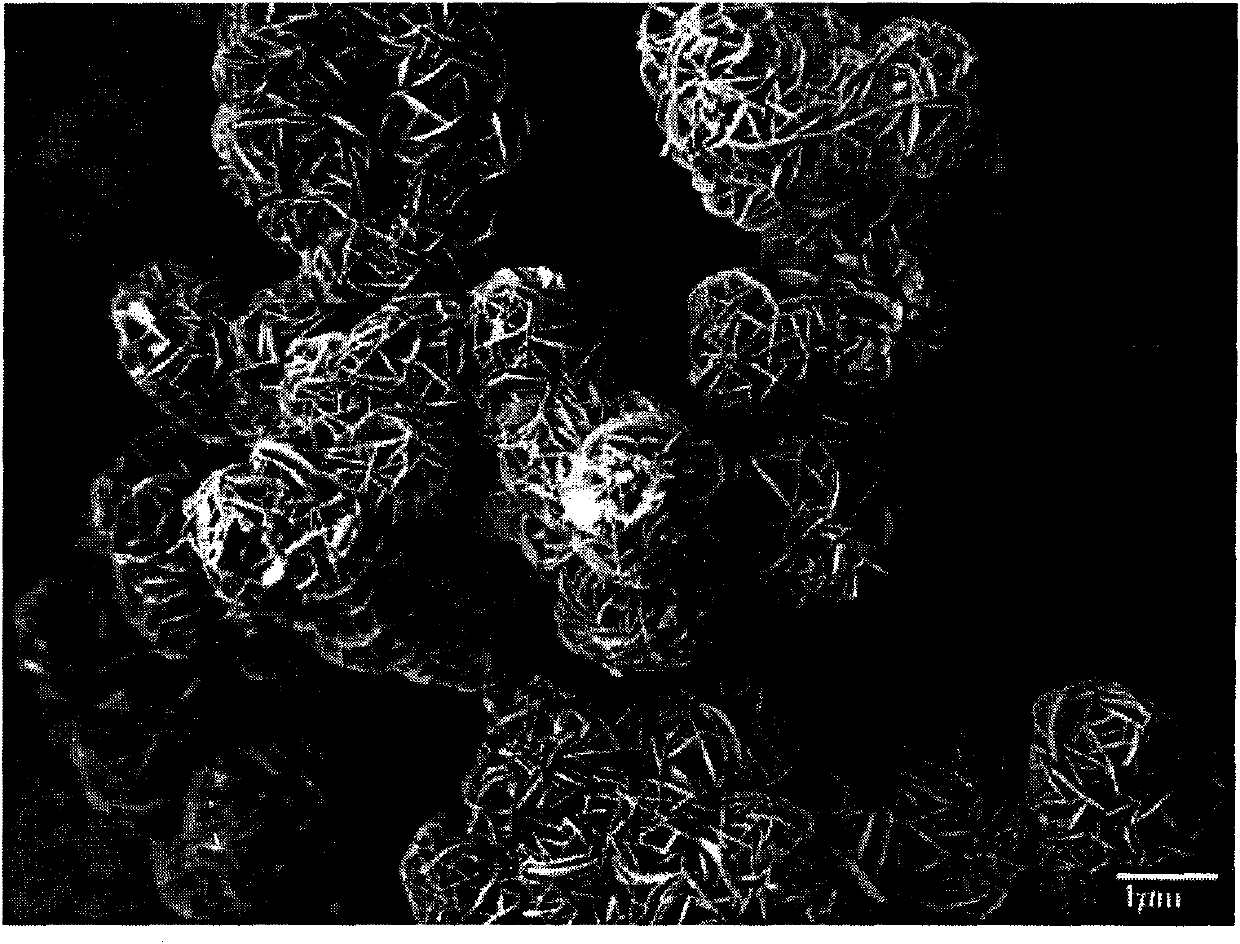

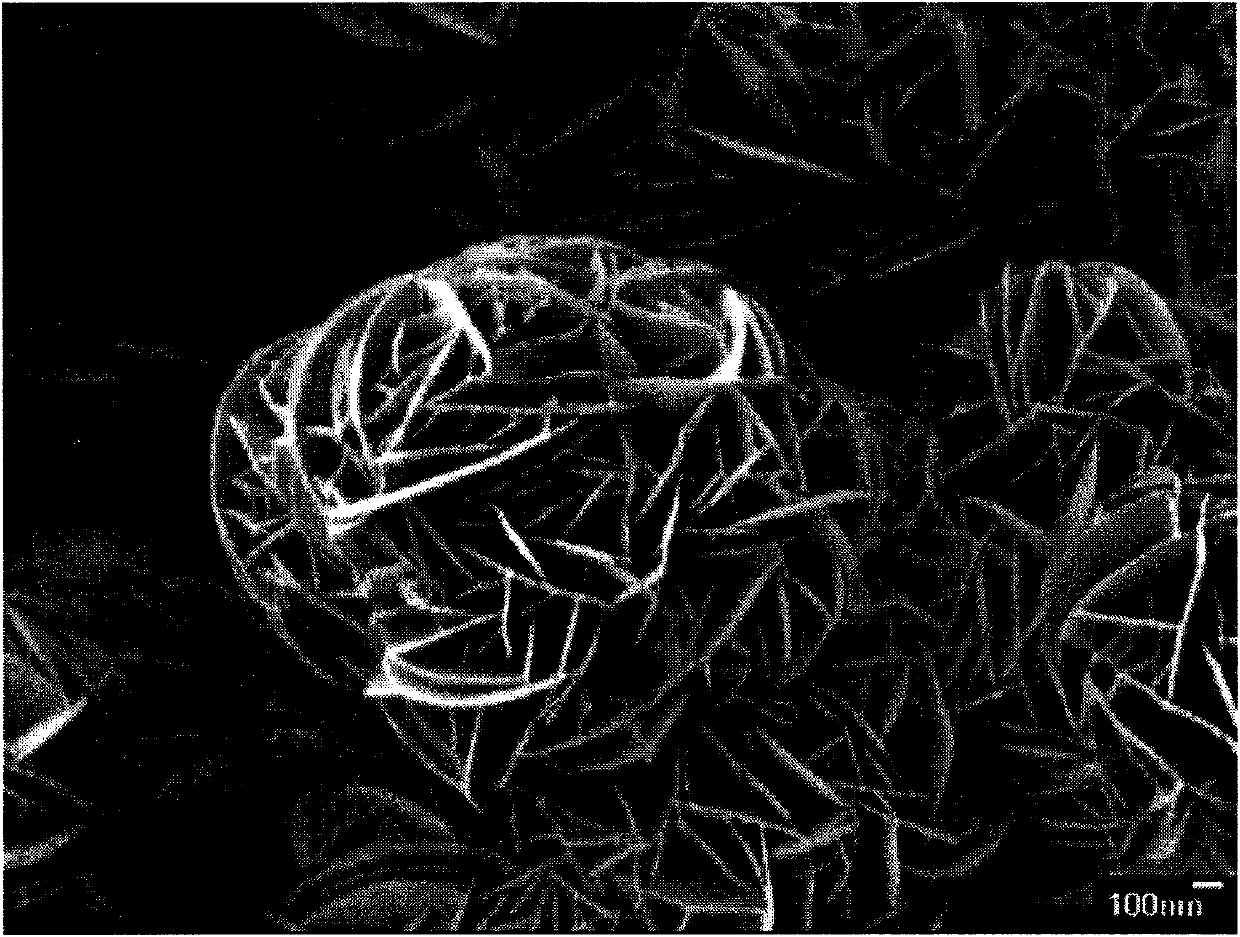

[0035] Scanning electron microscope test of the product: JSM-7401F field emission scanning electron microscope, the working voltage is 200kV, the scanning electron microscope picture is shown in Figure 1, the...

Embodiment 2

[0039] Preparation of tin-based composite oxide: 3.1g SnCl 4 and 11.4 g Na 2 HPO 4 Add it into 40mL of deionized water, stir well, then add 10.6g of HF 10wt% solution. Dissolve 2.9g of SDS in 20mL of deionized water, then mix it with the above solution, stir it fully on a magnetic stirrer for 1h, then transfer the resulting suspension to a 70mL polytetrafluoroethylene liner hydrothermal kettle, seal it tightly The lid of the kettle was reacted in an oven at 150°C for 6h. After the reaction kettle was cooled to room temperature, the obtained precipitate was filtered and washed repeatedly with distilled water. Finally, the reaction product was placed in a ceramic pot and directly heated in a muffle furnace at 300°C for 3 hours, then cooled and ground.

[0040] The scanning electron microscope test of the product: JSM-7401F field emission scanning electron microscope, the working voltage is 200kV, the scanning electron microscope picture is as follows Figure 4 As shown, each...

Embodiment 3

[0042] Preparation of tin-based composite oxide: 3.1g SnCl 4 and 11.4 g Na 2 HPO 4 Add it into 40mL of deionized water, stir well, then add 10.6g of HF 10wt% solution. Dissolve 2.9g of SDS in 2CmL of deionized water, then mix with the above solution, fully stir on a magnetic stirrer for 1h, then transfer the resulting suspension to a 70mL polytetrafluoroethylene liner of hydrothermal kettle, seal tightly The lid of the kettle was reacted in an oven at 150°C for 9h. After the reaction kettle was cooled to room temperature, the obtained precipitate was filtered and washed repeatedly with distilled water. Finally, the reaction product was placed in a ceramic pot and directly heated in a muffle furnace at 300°C for 3 hours, then cooled and ground.

[0043] The scanning electron microscope test of the product: JSM-7401F field emission scanning electron microscope, the working voltage is 200kV, the scanning electron microscope picture is as follows Figure 5 As shown, each build...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com