Amino plastic substrate, and preparation method and application thereof

A technology for plastic sheets and substrates, which is used in biochemical equipment and methods, determination/inspection of microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

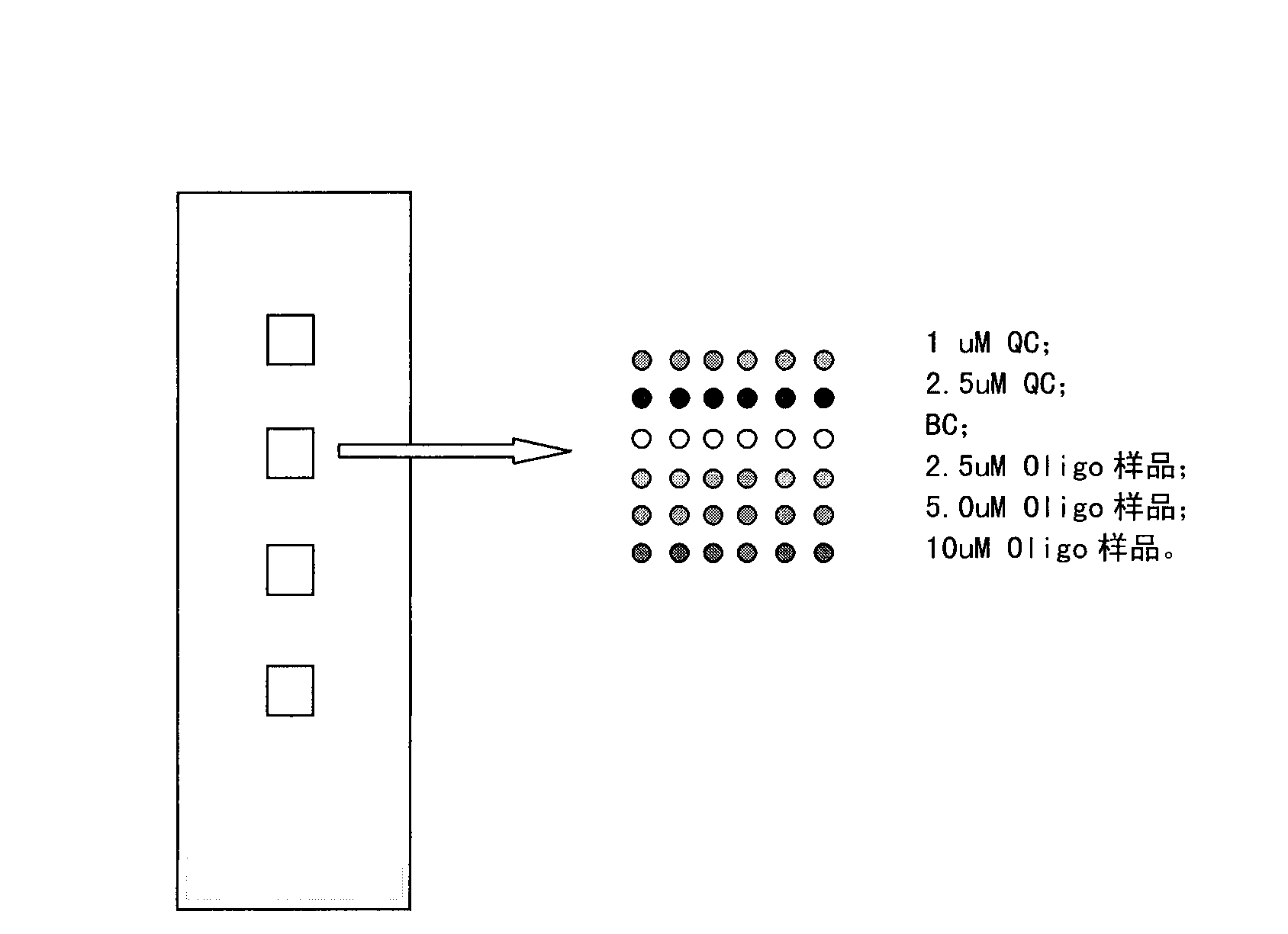

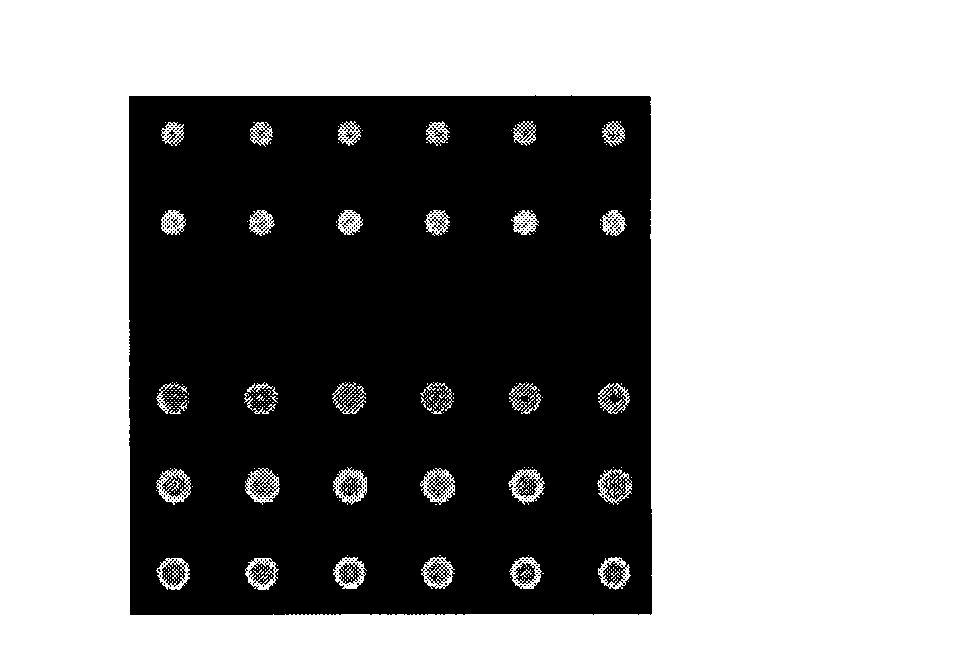

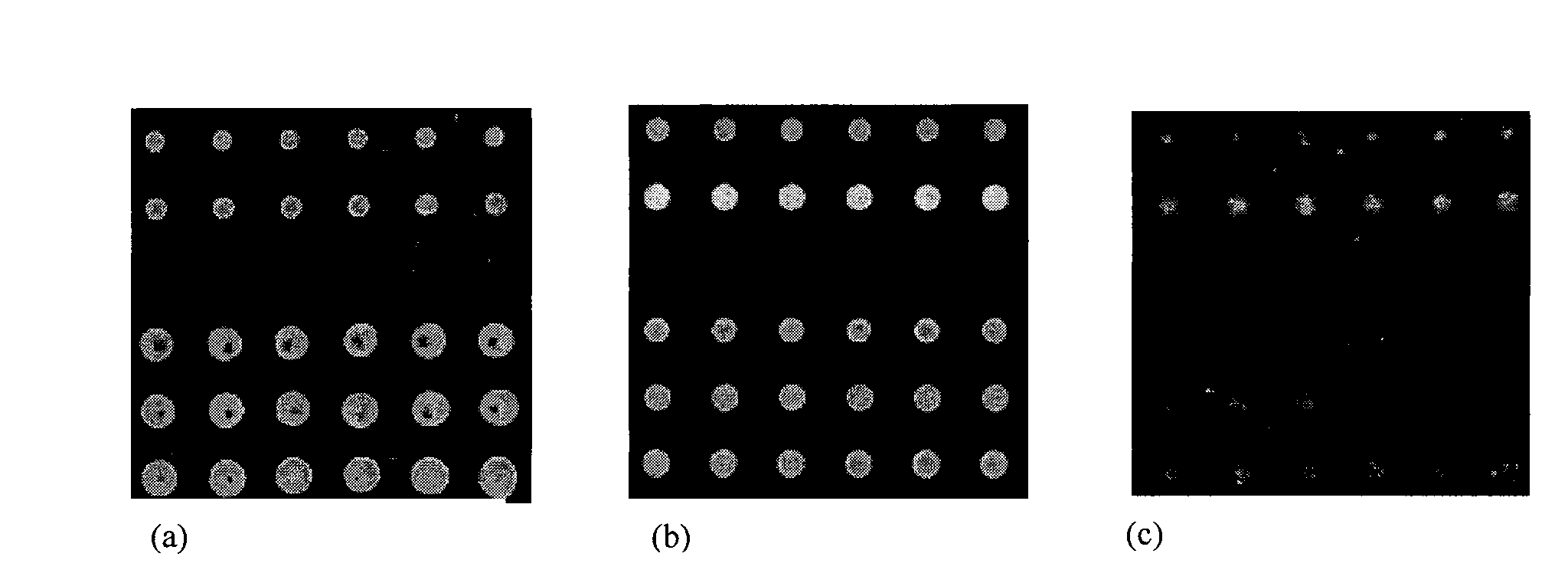

Image

Examples

Embodiment 1

[0056] Embodiment 1, prepare two-dimensional amino plastic substrate with aminosilanization method in aqueous solution

[0057] 1. Pretreatment of the film base: Wash the plastic film base with PS deionized water, dry it, and carry out O 3 Treat for 3h or Plasma treatment for 2min under aerobic conditions.

[0058] 2. Aminosilanization: place the plastic sheet base pretreated in step 1 in an aqueous solution of APTS, the concentration of APTS in the solution is 0.01% (volume percentage), and react at 70°C and 120rpm shaking conditions for 30 hours; wash with deionized water and dry to obtain a two-dimensional amino plastic substrate.

[0059] The surface of the plastic sheet is cleaned and modified, and the surface of the plastic sheet is distributed with amino groups by reacting with APTS to obtain an aminoplast substrate (two-dimensional aminoplast substrate).

[0060] The plastic substrate PS was replaced by PC or PMMA, and the above experiment was carried out, and a two-...

Embodiment 2

[0061] Embodiment 2, prepare two-dimensional amino plastic substrate with aminosilanization method in aqueous solution

[0062] 1. Pretreatment of film base:

[0063] With experiment 1 in embodiment 1.

[0064] 2. Aminosilanization: Place the plastic sheet base pretreated in step 1 in an aqueous solution of APTS, the concentration of APTS in the solution is 10% (volume percentage), and react 0.5% at 15°C and 120rpm shaking conditions. hours; wash with deionized water and dry to obtain a two-dimensional amino plastic substrate.

[0065] The plastic substrate PS was replaced by PC or PMMA, and the above experiment was carried out, and a two-dimensional aminoplastic substrate was also obtained.

Embodiment 3

[0066] Embodiment 3, two-dimensional amino plastic substrate is prepared by aminosilanization method in aqueous solution

[0067] 1. Pretreatment of film base:

[0068] With experiment 1 in embodiment 1.

[0069] 2. Amino silanization: place the plastic sheet base pretreated in step 1 in an aqueous solution of APTS, the concentration of APTS in the solution is 0.5% (volume percentage), and react at 35°C and 120rpm shaking conditions for 5 hours; wash with deionized water and dry to obtain a two-dimensional amino plastic substrate.

[0070] The plastic substrate PS was replaced by PC or PMMA, and the above experiment was carried out, and a two-dimensional aminoplastic substrate was also obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com