Method for preparing hollow fiber nanofiltration membrane by using thermally induced phase separation/interface cross linking synchronization method

A thermally induced phase separation and interfacial cross-linking technology, which can be used in semi-permeable membrane separation, hollow filament manufacturing, fiber chemical characteristics, etc. It can solve the problems of poor uniformity, unsuitable hollow fiber nanofiltration membrane, and many defects. , to achieve the effect of high requirements to avoid stickiness, simple and easy performance, and easy control of thickness and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

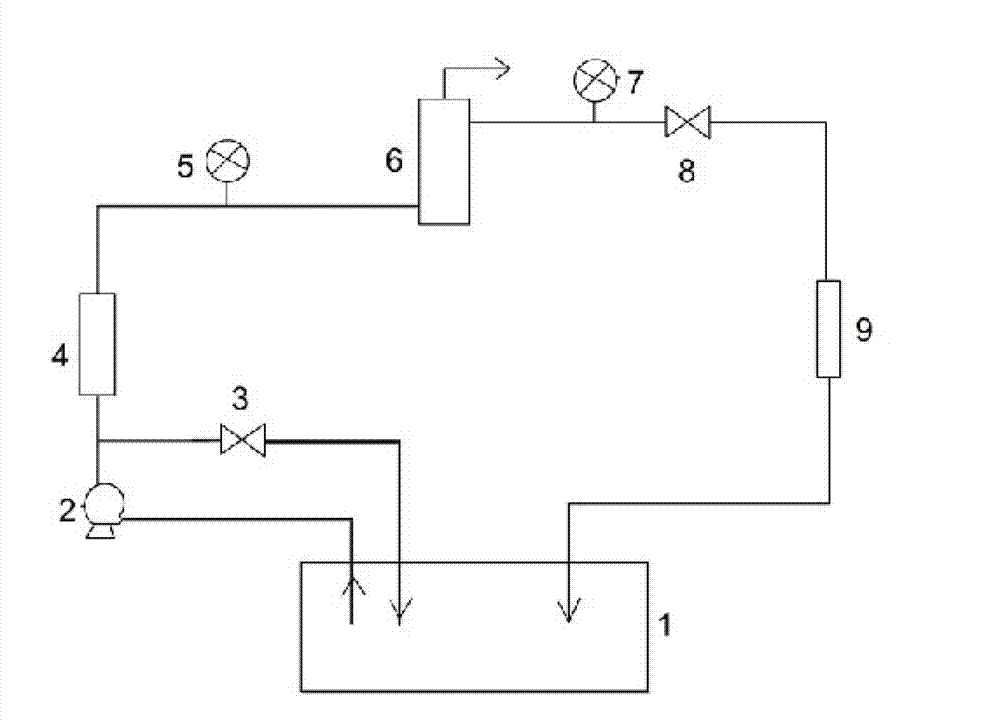

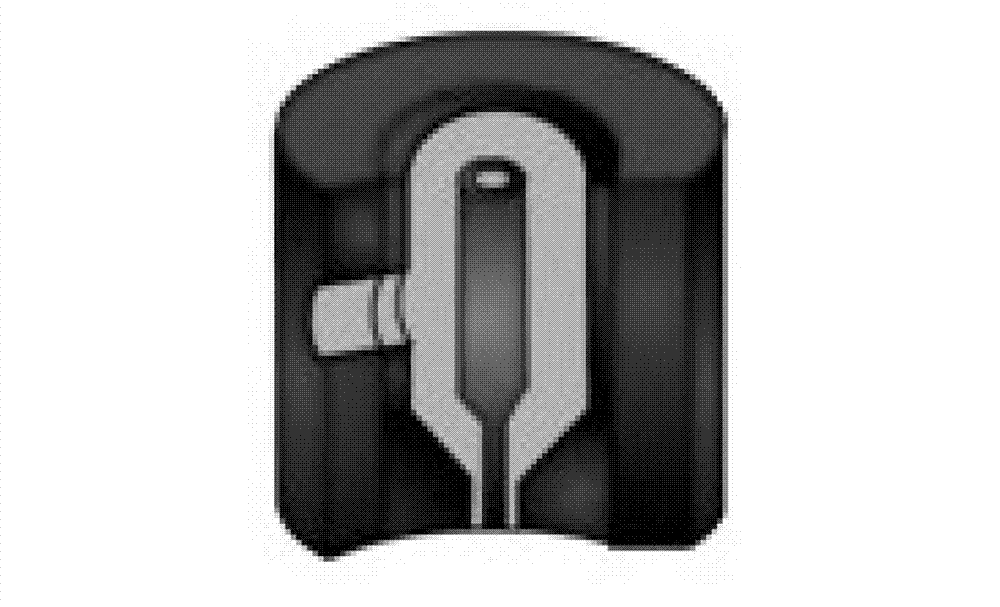

Method used

Image

Examples

Embodiment 1

[0025] Select polyacrylonitrile, dimethyl sulfone and p-dichlorobenzyl with a mass ratio of 10:90:1, add them into the stirring tank and mix evenly, heat to 160°C, stir well until the mixed system becomes a homogeneous solution, then let it stand for defoaming , to obtain the casting liquid; select glycerol as the core liquid; extrude the casting liquid and the core liquid through the outer hole of the ring spinning head at a speed of 3 m / min at 160 ° C and a pressure of 0.2 MPa, and then immerse the In an air bath at 30°C, a hollow primary membrane was obtained. The hollow nascent membrane was soaked in polyethyleneimine aqueous solution with a polyethyleneimine concentration of 5 g / L at 40° C. for 8 hours, and taken out to obtain a polyacrylonitrile hollow fiber nanofiltration membrane.

[0026] After the above-mentioned hollow fiber nanofiltration membrane is made into a membrane module, a nanofiltration membrane performance evaluation instrument is used to measure the volu...

Embodiment 2

[0036] Select polyacrylonitrile, propylene carbonate and p-dichlorobenzyl with a mass ratio of 20:80:1, add them into the stirring tank and mix evenly, heat to 160°C, stir well until the mixed system becomes a homogeneous solution, then let stand for defoaming, Obtain the casting liquid; select glycerol as the core liquid; the casting liquid and the core liquid are extruded through the outer hole of the ring spinning head at 160 ℃ and 0.2 MPa pressure at a speed of 3 m / min, and then immersed in 30 In an air bath at ℃, a hollow nascent membrane was obtained. Soak the hollow nascent membrane in a polydimethylaminoethyl methacrylate ethanol solution with a polydimethylaminoethyl methacrylate concentration of 5g / L at 40°C for 8 hours, take it out, and obtain a polyacrylonitrile hollow fiber nanofiltration membrane .

[0037] After the above-mentioned hollow fiber nanofiltration membrane is made into a membrane module, test the water flux and the rejection rate of magnesium sulfat...

Embodiment 3

[0039] Select polyvinylidene fluoride, cyclohexanone and p-dichlorobenzyl with a mass ratio of 30:70:3, add them into the stirring tank and mix evenly, heat to 140°C, stir well until the mixed system becomes a homogeneous solution, then let it stand for defoaming , to obtain the casting solution; select polyethylene glycol with a number average molecular weight of 200 as the core solution; pass the casting solution and the core solution through the ring spinning head at a speed of 5 m / min at 140° C. and a pressure of 0.2 MPa The outer hole was extruded and then immersed in an air bath at 20°C to obtain a hollow nascent membrane. Soak the hollow nascent membrane in a polyethyleneimine ethanol solution with a polyethyleneimine concentration of 15 g / L at 60°C for 12 hours, and take it out to obtain a polyvinylidene fluoride hollow fiber nanofiltration membrane.

[0040] After the above-mentioned hollow fiber nanofiltration membrane is made into a membrane module, test the water f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com