Preparation method for formaldehyde catalyst through adopting iron molybdenum method and methanol oxidation

A catalyst, oxidation technology, used in the preparation of organic compounds, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor catalyst stability, low formaldehyde selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

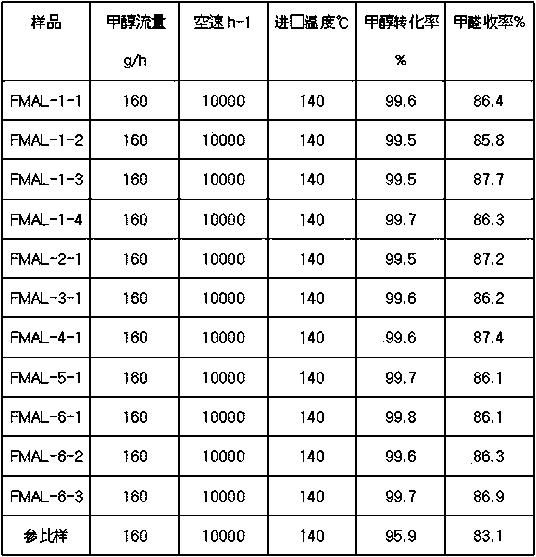

Examples

preparation example Construction

[0021] A method for preparing a formaldehyde catalyst by iron-molybdenum method methanol oxidation, the catalyst preparation method comprising the steps of:

[0022] (1) Step 1: Control the temperature of the reactor at 80°C-150°C, the pressure at 0.1MPa-0.8MPa, and the stirring speed at 100r / min-250r / min, and remove 1.2-1.5Kg molybdenum salt with 20Kg 50-90°C Ionized water is configured as 0.22-0.28mol / L molybdenum salt solution, 0.5-0.8Kg iron salt and 5Kg 50-90°C deionized water are configured as 0.56-0.89mol / L iron salt solution, and then added in parallel with a metering pump The precipitation reaction is carried out in the reaction kettle. During the reaction process, the pH of the system is controlled at 1.0-6.0, and the reaction time is controlled at 1h-3h. Stop after 2h-4h to obtain slurry;

[0023] (2) Step 2: Wash the slurry with deionized water, then filter with a filter press, and continue to wash the filter cake with deionized water for 2-7 times to obtain a qua...

Embodiment 1

[0036] Control the temperature of the reaction kettle at 110°C-135°C, the pressure at 0.15MPa-0.5MPa, and the stirring speed at 100r / min-250r / min, and add the prepared molybdenum salt solution and iron salt solution into the reaction kettle in parallel with a metering pump Carry out precipitation reaction, control the pH of the system at 1.8-3.5 during the reaction process, and control the reaction time at 1h-3h. After the co-current precipitation reaction is completed, continue to maintain the above reaction temperature, pressure and stirring speed for the crystallization reaction of precipitation, 2h-4h After stopping, a slurry was obtained. Filter the slurry with a stainless steel filter to obtain the filter cake and filtrate, wash the filter cake with deionized water 3 times to obtain the washed filter cake, dry the washed filter cake in a drying oven at 100-150°C for 8 hours to obtain the catalyst activity Precursor.

Embodiment 1-1

[0038] Mix 2-4% of the total amount of lubricant into the active precursor, pulverize and mix evenly, and the mixed material is pressed into shape with a rotary tablet press, and the size is (4.0-4.5mm*4.0-5.0mm*1.5- 2.5mm) hollow cylinder, the hollow cylinder was activated at 350°C-380°C for 4 hours to obtain the finished catalyst FMAL-1-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com