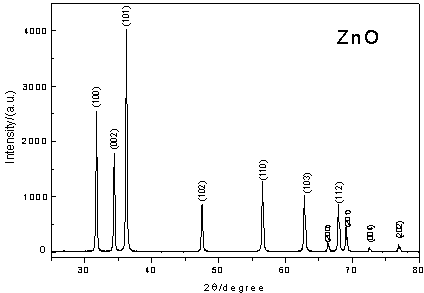

Method for preparing monodisperse spherical nano ZnO

A nano-zinc oxide, monodisperse technology, applied in zinc oxide/zinc hydroxide, nanotechnology, nanotechnology and other directions, can solve the problems of expensive equipment, high production cost, high temperature and high pressure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepare 0.4M zinc salt aqueous solution and 4M NaOH aqueous solution; dissolve 15g PEG-6000 in 20mL distilled water, heat and stir until completely dissolved; mix 20mL PEG-6000 solution with 30mL zinc salt solution, place in 250mL In a round-bottomed flask, heat in a water bath at 95°C and stir for 0.5 h; measure 50 mL of NaOH solution, quickly add it to the mixed solution, and at the same time adjust the stirring speed to 600 rpm, keep stirring in a constant temperature water bath at 95°C for 2.5 h, after the reaction is complete, Cool to room temperature, filter, wash with ethanol and distilled water several times, and dry in an oven at 60°C for 6 hours to obtain zinc oxide powder.

Embodiment 2

[0026] Prepare 0.4M zinc salt aqueous solution and 4M NaOH aqueous solution, dissolve 15g PEG-6000 in 20mL distilled water, heat and stir until completely dissolved, mix 20mL PEG-6000 solution with 30mL zinc salt solution, place in 250mL In a round bottom flask, heat in a water bath at 95°C, stir for 0.5h, measure 50mL of NaOH solution, quickly add it to the mixed solution, and at the same time adjust the stirring speed to 700 rpm, keep stirring in a constant temperature water bath at 95°C for 3.5h, after the reaction is complete, Cool to room temperature, filter, wash with ethanol and distilled water several times, and dry in an oven at 60°C for 6 hours to obtain zinc oxide powder.

Embodiment 3

[0028] Prepare 0.4M zinc salt aqueous solution and 4M NaOH aqueous solution, dissolve 8g PEG-6000 in 10.67mL distilled water, heat and stir until completely dissolved, mix 10.67mL PEG-6000 solution with 16mL zinc salt solution, set In a 250mL round bottom flask, heat in a water bath at 95°C, stir for 0.5h, measure 26.675mL of NaOH solution, quickly add it to the mixed solution, and at the same time adjust the stirring speed to 800 rpm, keep stirring in a constant temperature water bath at 95°C for 4h, until the reaction is complete Afterwards, cool to room temperature, filter, wash with ethanol and distilled water several times, and dry in an oven at 60°C for 6 hours to obtain zinc oxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com