Method for preparing PVDF-TrFE/graphene high performance composite material

A composite material, graphene technology, used in flat products, household appliances, other household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

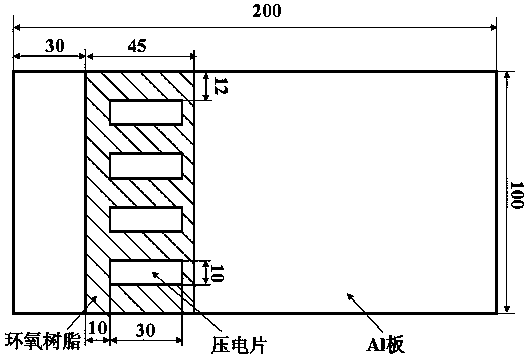

Image

Examples

Embodiment 1

[0025] The goal of this embodiment is to make a PVDF-TrFE / graphene composite film, the content of graphene is 0.05wt%, the film length is 3cm, the width is 1cm, the thickness before stretching is about 300 μm, and the thickness after stretching is about 100 μm .

[0026] The materials used are PVDF-TrFE powder, commercial graphene, and the solvent is DMF solution (purity>99%). The material parameters are shown in the table below:

[0027] Table 1 Properties of PVDF-TrFE

[0028] molecular weight

350000

153℃

Curie temperature

118℃

Composition: VDF / TrFE

75 / 25 (mol%)

form

[0029] Table 2 Properties of Graphene

[0030] density

>1g / cm 3

1TPa

tensile strength

130GPa

10 6 S / cm

About 5000W / mK

specific surface area

2630m 2 / g

[0031] The specific production steps are as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com