Self-healing solid electrolyte film as well as preparation method and application thereof

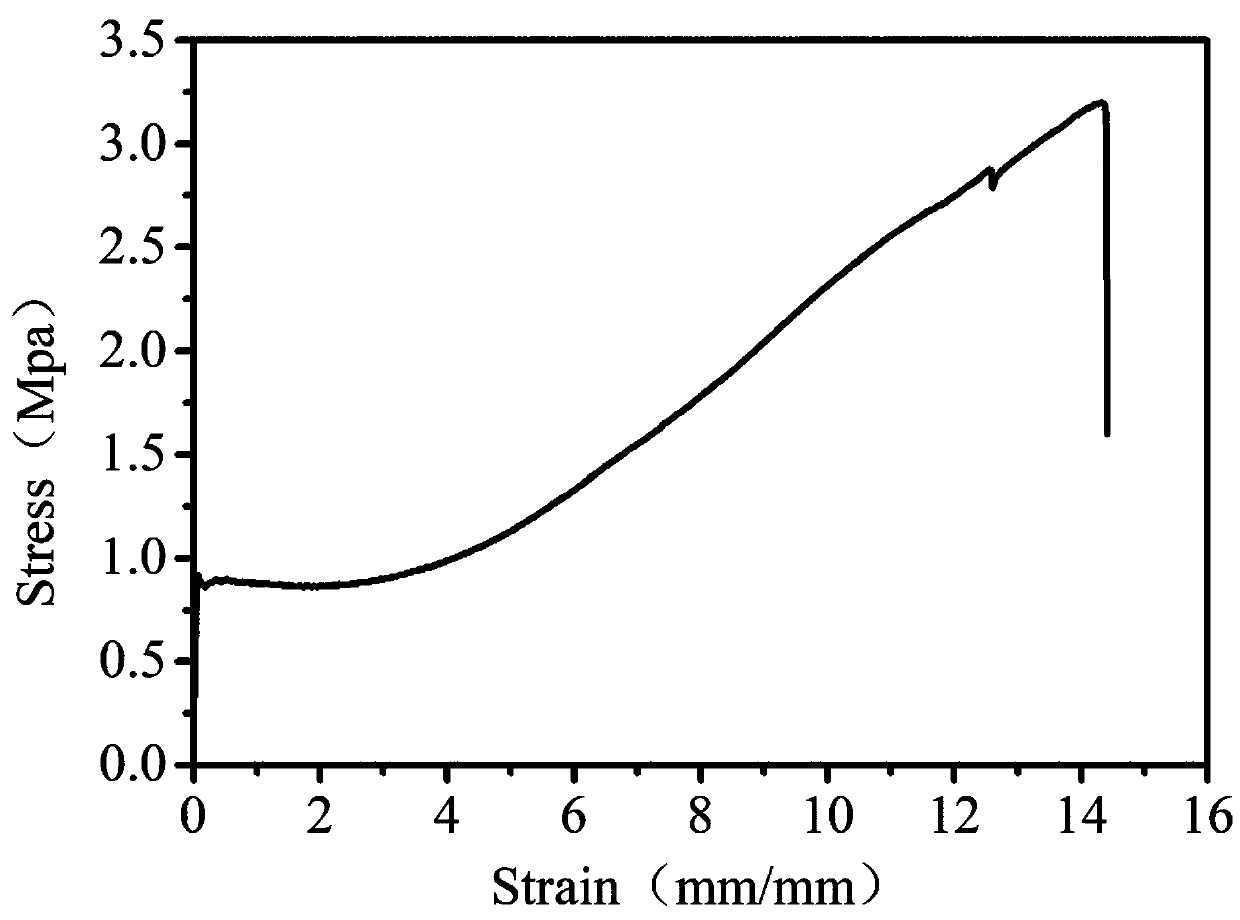

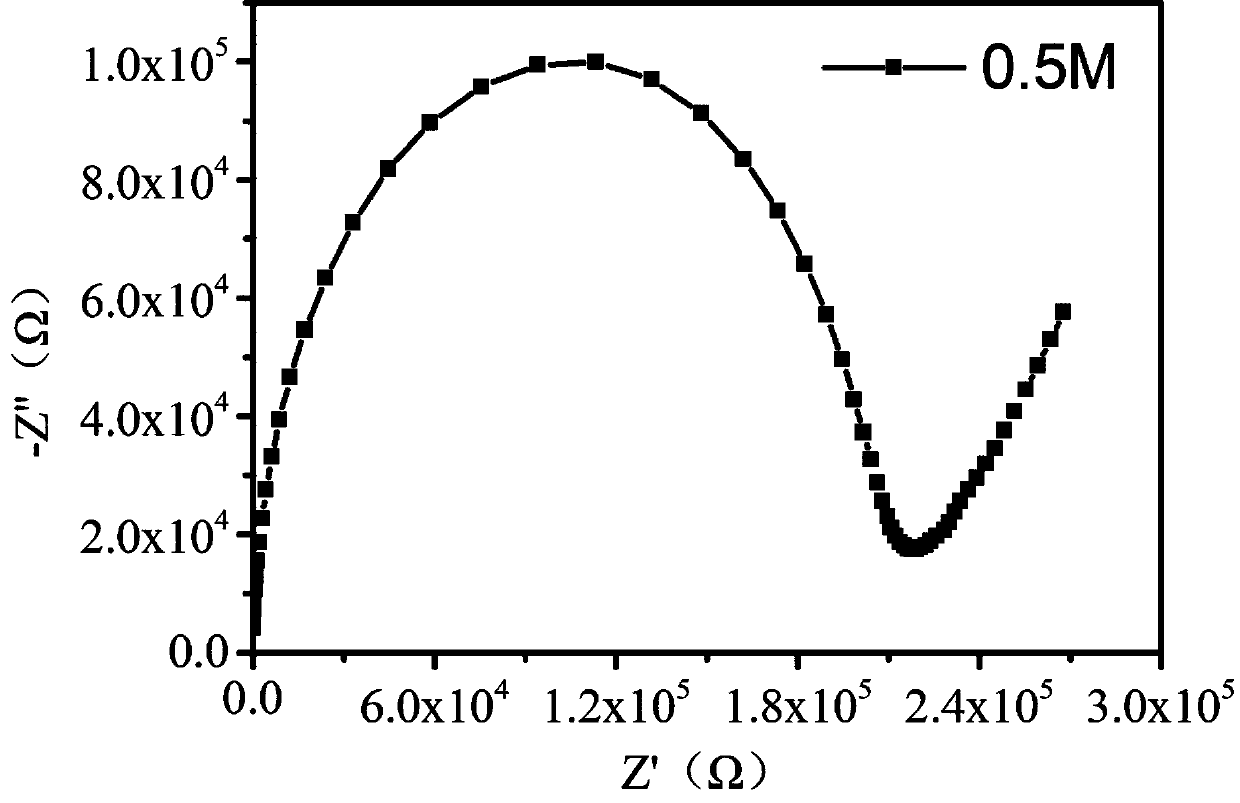

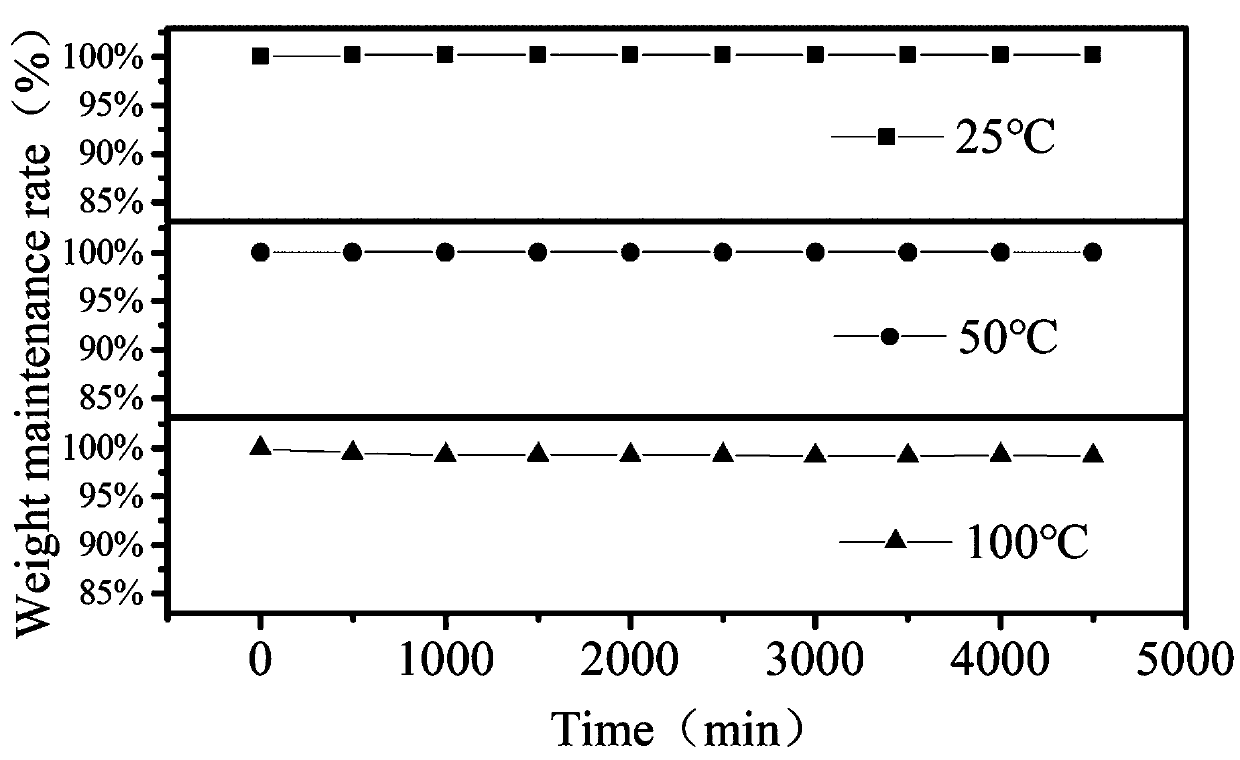

A technology of solid electrolyte and electrolyte salt, which is applied in the measurement of the property force of piezoelectric resistance materials, the use of electric/magnetic devices to transmit sensing components, material impedance, etc., can solve the problem of increasing the conductivity and stretchability of solid electrolyte films. , poor film formation, inability to introduce dynamic non-covalent bonds, etc., to achieve good sensitivity and the ability to distinguish different types of external stimuli, good flexibility and repeatability, and self-healing preparation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the self-healing solid electrolyte film comprises the following steps:

[0030] (1) Measure 2 mL of ethyl 2-[[(butylamino)carbonyl]oxo]acrylate, then add 0.0056 g of polydiacrylate or polyethylene glycol diacrylate, 0.02 g of 1-hydroxycycloacrylate Hexyl phenyl ketone and a certain amount of electrolyte salt lithium bistrifluoromethanesulfonylimide are stirred to fully dissolve to obtain a transparent solution A;

[0031] (2) Inject the solution A in step 1 into a glass mold with an interval of 500 μm to 1500 μm, and polymerize for 1-60 min under ultraviolet light irradiation to obtain a self-healing solid electrolyte film.

[0032] The self-healing solid electrolyte film of the present invention is used as an electrolyte for a flexible stretchable sensor, and the flexible stretchable sensor is composed of a self-healing solid state electrolyte film and metal electrodes connected at both ends of the self-healing solid state electrolyte film.

Embodiment 1

[0034] The preparation method of the self-healing solid electrolyte film of the present invention comprises the following steps:

[0035](1) Measure 2 mL of 2-[[(butylamino)carbonyl]oxo]ethyl acrylate, then add 0.0056 g of polydiacrylate or polyethylene glycol diacrylate, 0.02 g of 1-hydroxycycloacrylate Hexyl phenyl ketone and 0.0574 grams of electrolyte salt lithium bistrifluoromethanesulfonylimide were stirred to fully dissolve to obtain a transparent solution A;

[0036] (2) Inject the solution A in step 1 into a glass mold with an interval of 500 μm to 1500 μm, and polymerize for 1-60 min under ultraviolet light irradiation to obtain a self-healing solid electrolyte film.

Embodiment 2

[0038] The preparation method of the self-healing solid electrolyte film of the present invention comprises the following steps:

[0039] (1) Measure 2 mL of 2-[[(butylamino)carbonyl]oxo]ethyl acrylate, then add 0.0056 g of polydiacrylate or polyethylene glycol diacrylate, 0.02 g of 1-hydroxycycloacrylate Hexyl phenyl ketone and 0.1723 grams of electrolyte salt lithium bistrifluoromethanesulfonylimide were stirred to fully dissolve to obtain transparent solution A;

[0040] (2) Inject the solution A in step 1 into a glass mold with an interval of 500 μm to 1500 μm, and polymerize for 1-60 min under ultraviolet light irradiation to obtain a self-healing solid electrolyte film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com