Long glassfiber reinforced nylon composite material and preparation method thereof

A nylon composite material and long glass fiber technology, which is applied in the field of long glass fiber reinforced nylon composite material and its preparation, can solve the problems of large production equipment loss, serious glass fiber flying, and large environmental pollution, so as to improve the modulus and increase the Effects of reducing mechanical properties and molding shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

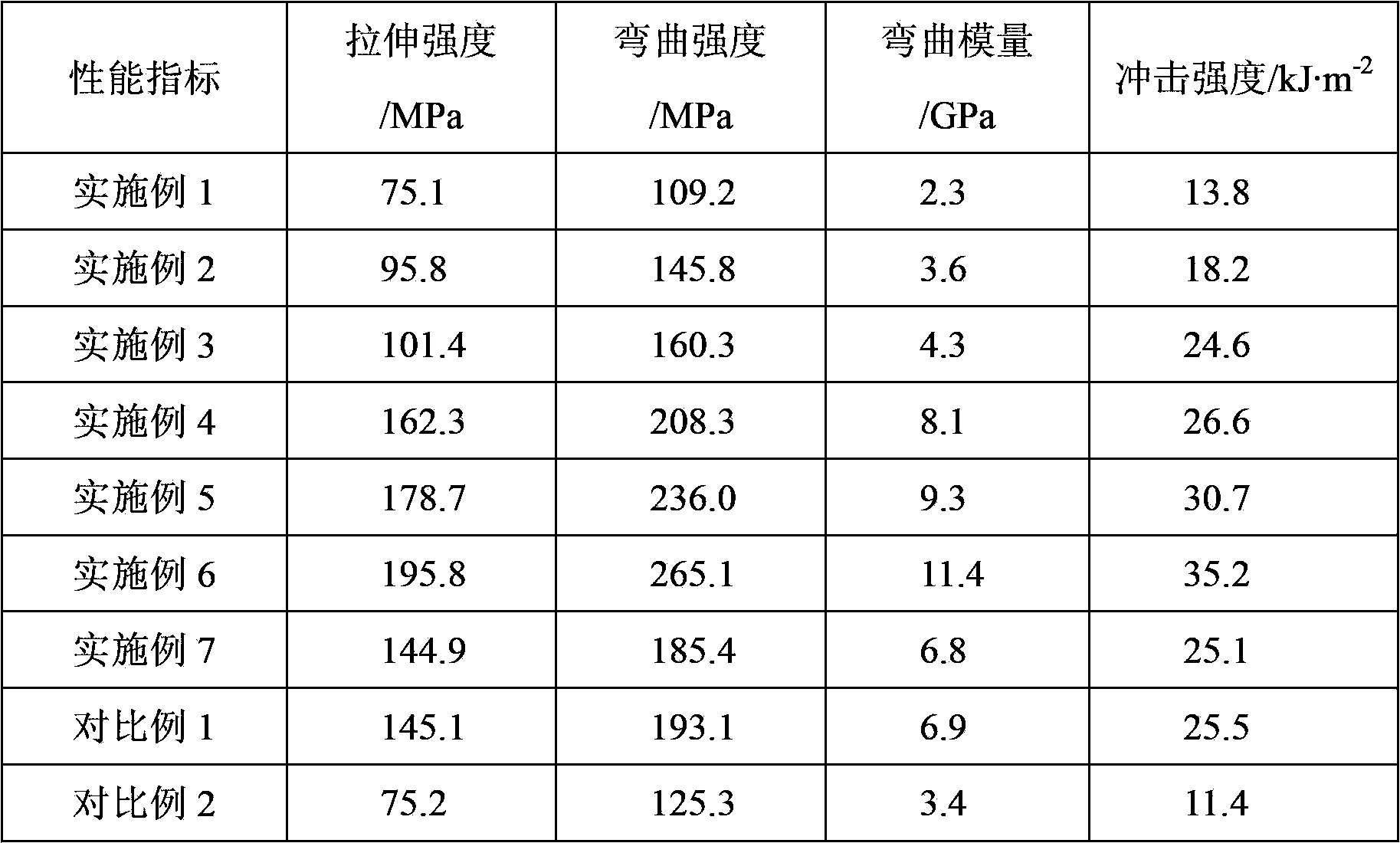

Examples

Embodiment 1

[0040] (1) First dry nylon 6 in an oven at 90°C for 10 hours, take 100 parts of dried nylon 6, 2 parts of compatibilizer PP-g-MAH, 0.1 part of antioxidant 1010 and 0.2 parts of lubricant silicone powder , mixed in a high-speed mixer for 3 minutes;

[0041] (2) Glass fiber surface treatment: First mix absolute ethanol and deionized water at a mass ratio of 95:5, and use acetic acid to adjust the pH of the solution to 3.5, and then add coupling agent KH550 (the content of effective substances is 98%) Dissolve in the above solution, prepare a glass fiber surface treatment agent with a coupling agent mass concentration of 0.5wt%, and then immerse a continuous long glass fiber with a diameter of 13 μm in the above solution for 20 minutes. Dry for 48 hours, then dry in an oven at 80°C for 4 hours;

[0042] (3) Send the mixture in the above (1) into the twin-screw extruder through the upstream feeding port, and at the same time, send the continuous long glass fiber in the above (2) ...

Embodiment 2

[0045] (1) First dry nylon 6 in an oven at 100°C for 8 hours, take 100 parts of dried nylon 6, 4 parts of compatibilizer POE-g-MAH, 0.2 parts of antioxidant 168 and 0.4 parts of lubricant TAF (modified Ethylene bis fatty acid amide, Suzhou Xingtai Photochemical Auxiliary Co., Ltd.) mixed in a high-speed mixer for 4 minutes;

[0046] (2) Glass fiber surface treatment: First mix absolute ethanol and deionized water at a mass ratio of 95:5, and use acetic acid to adjust the pH of the solution to 4.0, and then add coupling agent KH560 (the content of effective substances is 97%) Dissolve in the above solution, prepare a glass fiber surface treatment agent with a coupling agent mass concentration of 1.0wt%, and then immerse a continuous long glass fiber with a diameter of 12 μm in the above solution for 30 minutes. Dry for 42 hours, then dry in an oven at 90°C for 3 hours;

[0047](3) Send the mixture in the above (1) into the twin-screw extruder through the upstream feeding port,...

Embodiment 3

[0050] (1) First dry nylon 6 in an oven at 110°C for 6 hours, take 100 parts of dried nylon 6, 5 parts of compatibilizer EPDM-g-MAH, 0.25 parts of antioxidant 1076 and 0.45 parts of RH-313A (pentaerythritol Stearate, Dongguan Jianxing Plastic Products Co., Ltd.) was mixed in a high-speed mixer for 5 minutes;

[0051] (2) Glass fiber surface treatment: first mix absolute ethanol and deionized water at a mass ratio of 95:5, and use acetic acid to adjust the pH value of the solution to 4.5, and then add coupling agent KH570 (the content of effective substances is 97%) Dissolve in the above solution, prepare a glass fiber surface treatment agent with a coupling agent mass concentration of 1.25wt%, and then immerse a continuous long glass fiber with a diameter of 11 μm in the above solution for 40 minutes. Dry for 38 hours, then dry in an oven at 100°C for 2 hours;

[0052] (3) Send the mixture in the above (1) into the twin-screw extruder through the upstream feeding port, and at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com