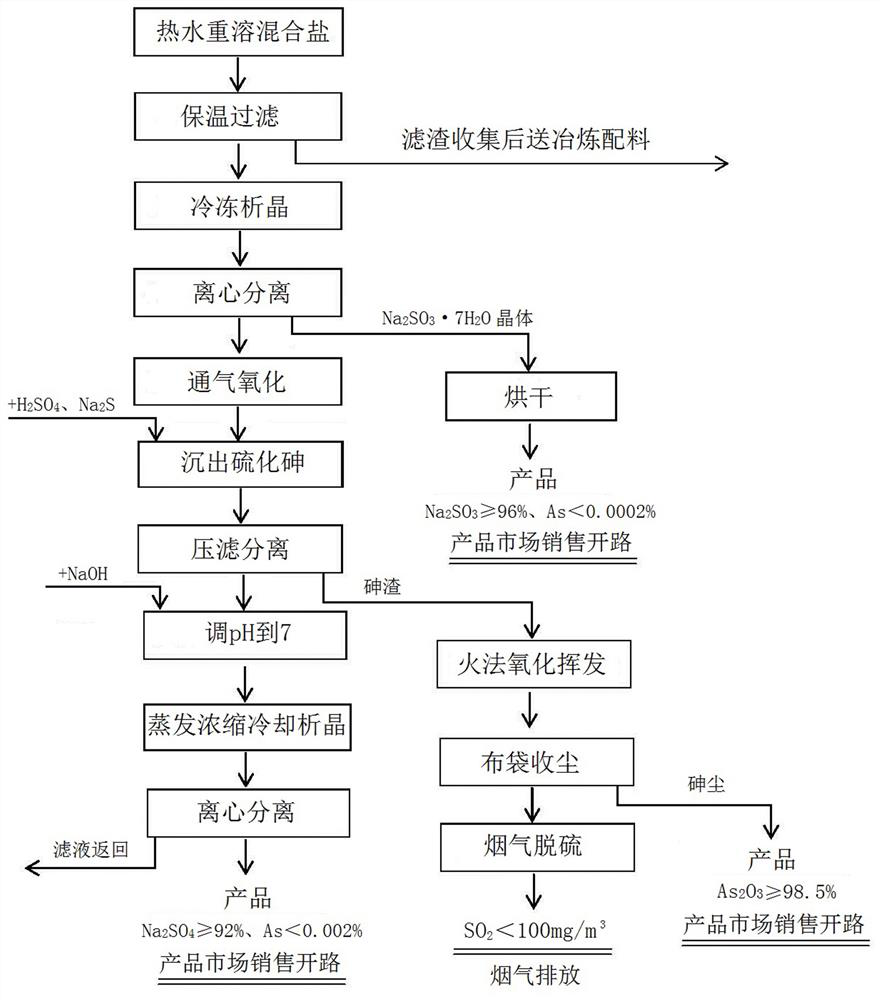

Method for redissolving, freezing and purifying mixed salt containing arsenic, sodium sulfite and sodium sulfate

A sodium sulfite and mixed salt technology, which is applied in alkali metal sulfite/sulfate purification, chemical instruments and methods, arsenic compounds, etc., can solve the problems of no market value, environmental pollution, low main content of sodium sulfite, etc., and achieve important environmental protection Effectiveness, high economic benefits, and the effect of eliminating hidden dangers of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Step 1: Redissolve the mixed salt, use a 1000ml beaker, fill 1000ml of water, place it on an electric heating magnetic stirring table, heat the water to above 50°C, slowly add 550g of mixed salt containing arsenic, sodium sulfite and sodium sulfate into the hot water , the typical composition of the mixed salt is: H 2 O 6%, Na 2 SO 3 70%, Na 2 SO 4 8%, As 0.6%; after complete melting, control the water temperature at 38°C to 42°C, and measure the specific gravity of the aqueous solution as 1.27, in the solution: Na 2 SO 3 The content is 38.5g / 100g H 2 O; Na 2 SO 4 The content is 4.4g / 100g H 2 O.

[0020] Step 2: Filter the heavy solution, use a 1500ml vacuum filter bottle, put a Φ120mm porous funnel on it, use a medium-speed filter paper, connect a vacuum pump, and filter the above heavy solution. Because the process time is short, the liquid temperature does not drop significantly, and the filtration is smooth.

[0021] Step 3: Put the above-mentioned filtr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com