A method for remelting and freezing to purify mixed salt containing arsenic, sodium sulfite and sodium sulfate

A sodium sulfite and mixed salt technology, applied in the purification of alkali metal sulfite/sulfate, chemical instruments and methods, arsenic compounds, etc., can solve the problems of no market value, environmental pollution, and inability to store for a long time, and achieve important environmental protection Benefits, elimination of environmental hazards, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

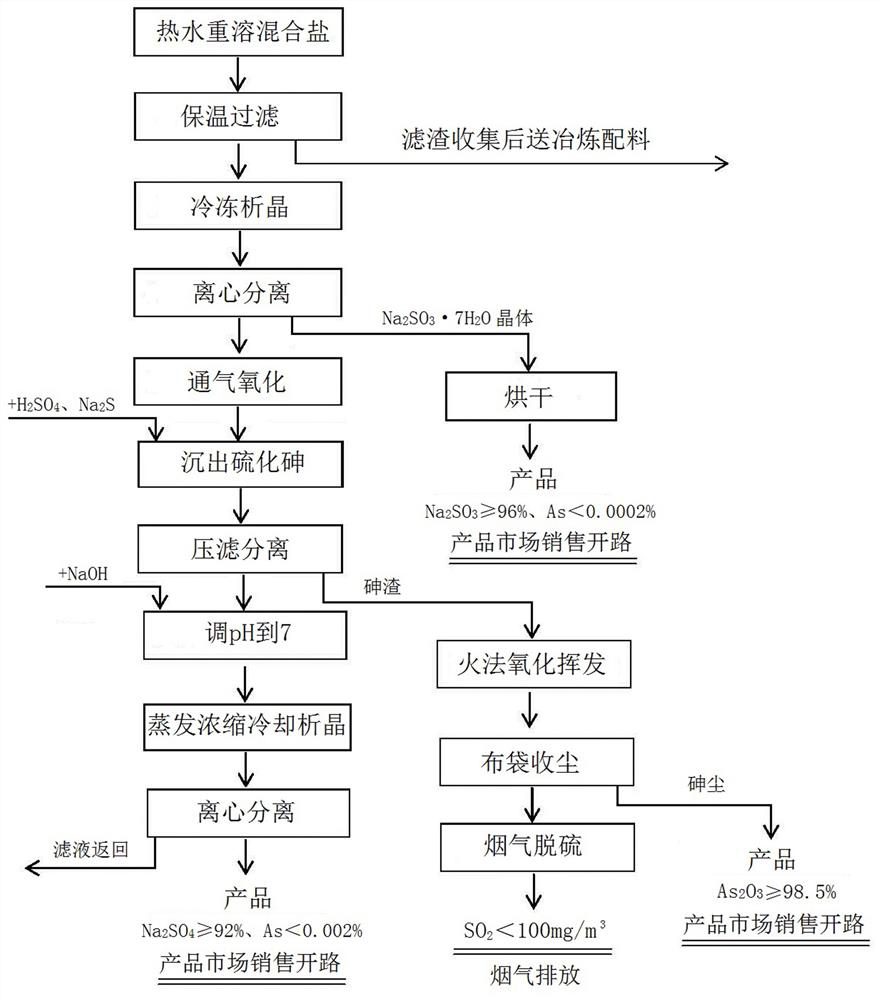

Method used

Image

Examples

Embodiment 1

[0019] Step 1: Redissolve the mixed salt, use a 1000ml beaker, fill 1000ml of water, place it on an electric heating magnetic stirring table, heat the water to above 50°C, slowly add 550g of mixed salt containing arsenic, sodium sulfite and sodium sulfate into the hot water , the typical composition of the mixed salt is: H 2 O 6%, Na 2 SO 3 70%, Na 2 SO 4 8%, As 0.6%; after complete melting, control the water temperature at 38°C to 42°C, and measure the specific gravity of the aqueous solution as 1.27, in the solution: Na 2 SO 3 The content is 38.5g / 100g H 2 O; Na 2 SO 4 The content is 4.4g / 100g H 2 O.

[0020] Step 2: Filter the heavy solution, use a 1500ml vacuum filter bottle, put a Φ120mm porous funnel on it, use a medium-speed filter paper, connect a vacuum pump, and filter the above heavy solution. Because the process time is short, the liquid temperature does not drop significantly, and the filtration is smooth.

[0021] Step 3: Put the above-mentioned filtr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com