Oxidation preparation method of fluorobenzene formaldehyde

A technology of fluorobenzaldehyde and fluorotoluene, which is applied in the field of preparation of fluorobenzaldehyde, can solve the problems of affecting development and large power consumption, and achieve the effects of low production cost, elimination of environmental hazards, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

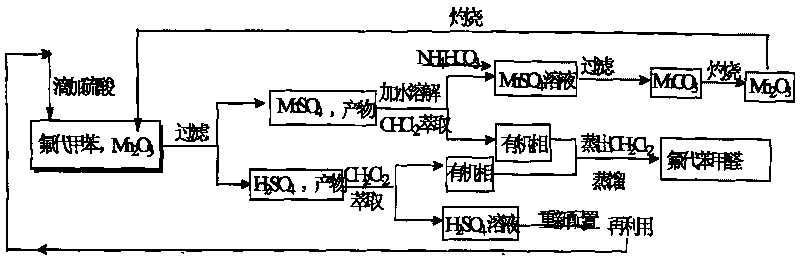

[0011] In conjunction with the accompanying drawings, the oxidation preparation method of fluorobenzaldehyde of the present invention mainly utilizes Mn 2 o 3 Realize the oxidation of p-fluorotoluene in sulfuric acid medium to synthesize fluorobenzaldehyde. For the by-product heavy metal salt manganese sulfate, it is converted into manganese carbonate by adding ammonium bicarbonate, and then converted into Mn by burning. 2 o 3 , Realize the recycling of solid oxidant, no waste residue is generated, and it will not cause harm to the environment. Include the following steps:

[0012] In the first step, add Mn to the reaction device 2 o 3 and fluorotoluene. Wherein fluorotoluene refers to p-fluorotoluene, o-fluorotoluene or m-fluorotoluene. Fluorotoluene and Mn 2 o 3 The molar ratio is 1:2~3.

[0013] In the second step, the reaction device is heated, and sulfuric acid is started to be added dropwise. The heating temperature is 40-80 DEG C, and the mass concentration of...

Embodiment 1

[0022] mn 2 o 3 Oxidative synthesis of m-fluorobenzaldehyde

[0023] 20g of m-fluorotoluene and 60g of Mn 2 o 3 Place in a 500mL four-necked flask, and install a thermometer, a mechanical stirrer, and a condenser. Heat with a water bath to adjust the reaction temperature to 50°C. 70% (wt) 200mL sulfuric acid was dropped into the flask, and the drop was completed within 1 hour, and the reaction was maintained at 50° C., and the reaction was detected by GC control for about 8 hours.

[0024] After the reaction is finished, cool and filter the product directly, the filtrate is mainly a mixed solution of sulfuric acid and manganese sulfate, and extract the product in the filtrate with 50mL dichloromethane; Extract the product in the filtrate, after separation, the water phase is manganese sulfate solution, the oil phase is mixed with the former, and the product at 66-68°C / 20mmHg is collected by vacuum distillation to obtain 21.3g, the purity of GC analysis is 99.6%, and the y...

Embodiment 2

[0026] mn 2 o 3 of recycling

[0027] The manganese sulfate solution of embodiment 1 (concentration is 150g L -1 ) to adjust the reaction temperature to 30°C. Under the condition of stirring, adjust its pH to 6.0 by adding ammonia solution dropwise, slowly add ammonium bicarbonate (concentration is 150g·L -1 ), to pH=6.8 as the end point, placed for aging, filtered, washed with deionized water, washed with Ba 2+ Detected to no SO 4 2+ . Place the filter cake in a muffle furnace, adjust the temperature to 370°C, and burn for 6h. Ignite at 650°C for 1 hour, take it out and cool to obtain 49.3g of manganese trioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com