Fixed bed biomass gasification process and equipment capable of collecting tar in steps

A biomass and fixed-bed technology, applied in fixed-bed gasification, petroleum industry, gas purification of condensed non-gaseous materials, etc., can solve the problems of waste of resources, difficult recycling of tar, secondary waste water pollution, etc., and improve the quality of gas. , the effect of alleviating the energy crisis and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

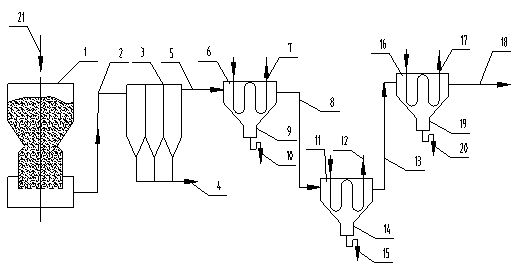

[0013] figure 1 Shown is the structural diagram of the downdraft fixed-bed gasification equipment. The equipment includes a cylindrical gasification furnace 1. The top inlet of the gasification furnace 1 is provided with a gasification air inlet pipe 21, and the bottom outlet is provided with a first air guide pipe 2. A high-temperature filter and dust collector 3 is connected through the first air guide pipe 2. The bottom of the high-temperature filter and dust collector 3 is provided with an ash discharge pipe 4. The upper part of the high-temperature filter and dust collector 3 is connected in series with three coke pools through the second air guide pipe 5. The three coke pools are respectively the first coke pool 9, the second coke pool 14 and the third coke pool 19. The first coke pool 9 is provided with a tar collector 6 and a first cooler 7 to control the temperature 600°C-250°C, the bottom of which is equipped with a first coke discharge tube 10; the second coke pool ...

Embodiment 2

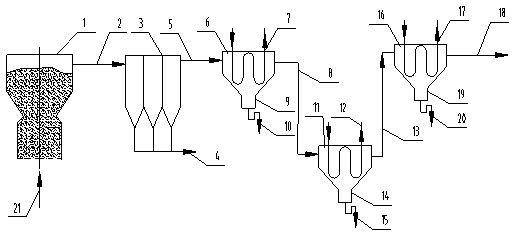

[0016] figure 2 Shown is the structure diagram of updraft fixed bed gasification equipment. It is basically the same as the first embodiment, except that a gasification air inlet pipe 21 is arranged at the bottom inlet of the gasifier 1 , and a first gas guide pipe 2 is arranged at the top outlet of the gasifier 1 . The same parts are omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com