Method for comprehensively recycling sodium, aluminum and iron from red mud

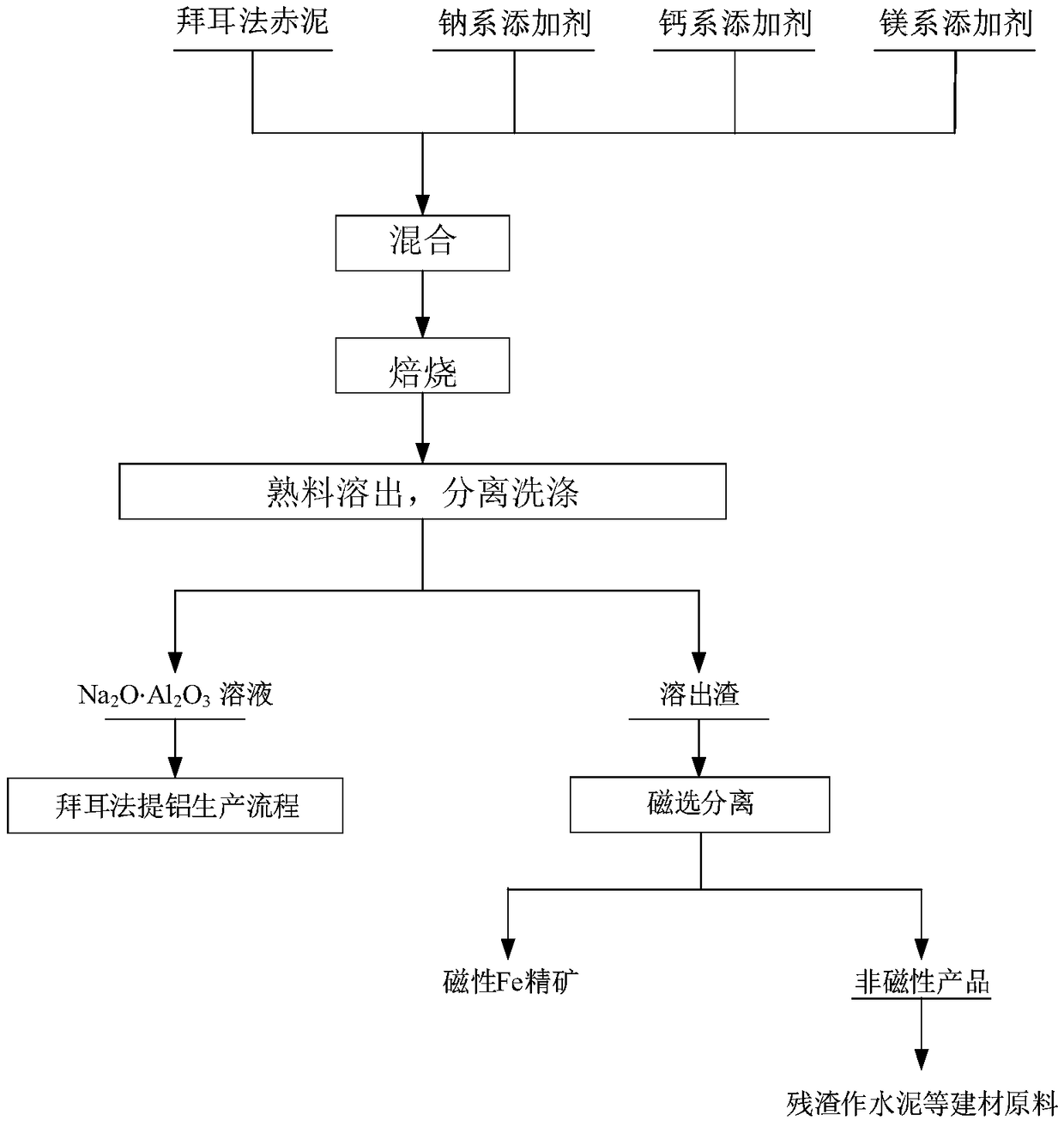

A technology for red mud and additives, applied in the field of comprehensive recovery of sodium and iron from aluminum and red mud, can solve the problems of secondary pollution and complex red mud treatment process, achieve elimination of environmental hazards, significant industrial application value, and simplify control conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The Bayer process red mud was taken from a place in Shandong. The raw material of the Bayer process was mainly boehmite. The composition of the processed Bayer process red mud was analyzed, and the main elements in the red mud were obtained as follows:

[0053] Al 2 O 3 Content 21.21%, Fe 2 O 3 Content 26.01%, Na 2 O content 6.48%, TiO 2 Content 4.14%, SiO 2 The content is 18.50%, and the content of CaO is 13.94%.

[0054] According to the molar ratio of CaO / (SiO 2 +TiO 2 )(Calcium ratio) is 2.2, MgO / Fe 2 O 3 Is 0.6, (Na 2 O+K 2 O) / Al 2 O 3 (Alkali ratio) Add a certain amount of limestone (CaCO 3 ), magnesium oxide and sodium carbonate are mixed with Bayer process red mud; put the mixed raw meal in a high-temperature furnace at 1150℃ for 40min; after cooling to room temperature, grind to 80%≤0.074mm; sinter after fine grinding The clinker is Na 2 O k 15g / L, Na 2 O c 5g / L leaching in 80℃ adjusting solution, time is 20min; the ratio of alkaline adjusting solution to clinker liq...

Embodiment 2

[0057] The Bayer process red mud is taken from a place in Henan. The raw materials of the Bayer process are diaspore and boehmite. The composition of the treated Bayer process red mud is analyzed, and the main elements in the red mud are obtained as follows:

[0058] Al 2 O 3 Content 20.57%, Fe 2 O 3 Content 23.17%, Na 2 O content 9.79%, TiO 2 Content 2.55%, SiO 2 The content is 20.58%, and the content of CaO is 10.20%. According to the molar ratio of CaO / (SiO 2 +TiO 2 )(Calcium ratio) is 2.2, MgO / Fe 2 O 3 Is 0.8, (Na 2 O+K 2 O) / Al 2 O 3 (Alkali ratio) Add a certain amount of limestone (CaCO 3 ), magnesium oxide and sodium carbonate are mixed with Bayer process red mud; put the mixed raw meal in a high-temperature furnace at 1150℃ for 60min; after cooling to room temperature, it is ground to 80%≤0.074mm; the sintering after fine grinding The clinker is Na 2 O k 15g / L, Na 2 O c 5g / L leaching in the conditioning solution at 80°C for 20min; the ratio of alkaline conditioning solution...

Embodiment 3

[0061] The Bayer process red mud is taken from a certain place in Guangxi. The Bayer process raw material is mainly diaspore. The composition of the Bayer process red mud is analyzed, and the main elements in the red mud are obtained as follows:

[0062] Al 2 O 3 Content 18.68%, Fe 2 O 3 Content 24.72%, Na 2 O content 5.57%, TiO 2 10.25% content, SiO 2 The content is 22.20%, and the content of CaO is 15.20%.

[0063] According to the molar ratio of CaO / (SiO 2 +TiO 2 )(Calcium ratio) is 2.2, MgO / Fe 2 O 3 Is 0.8, (Na 2 O+K 2 O) / Al 2 O 3 (Alkali ratio) Add a certain amount of limestone (CaCO 3 ), magnesium oxide and sodium carbonate are mixed with Bayer process red mud; put the mixed raw meal in a high-temperature furnace at 1200℃ for 60min; after cooling to room temperature, it is ground to 80%≤0.074mm; after fine grinding, sintering The clinker is Na 2 O k 15g / L, Na 2 O c 5g / L leaching in the conditioning solution at 80°C for 20min; the ratio of alkaline conditioning solution to clin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com