Method for promoting separation of valuable metals and calcic gangue minerals in waste residue

A technology for valuable metals and gangue minerals, applied in the field of environmental engineering, can solve problems such as poor crystal quality, difficulty in effectively separating valuable components from gangue components, small grain size, etc., to achieve easy control conditions and reduce leaching Low toxicity and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

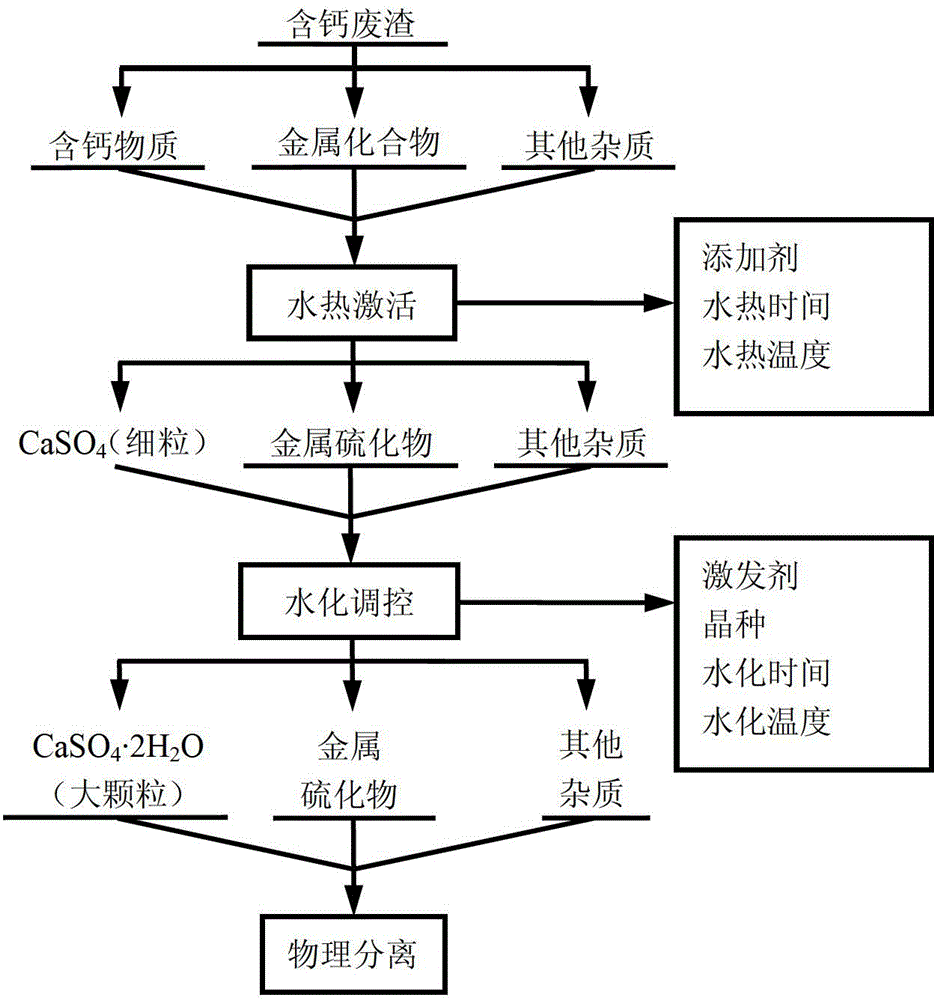

Method used

Image

Examples

Embodiment 1

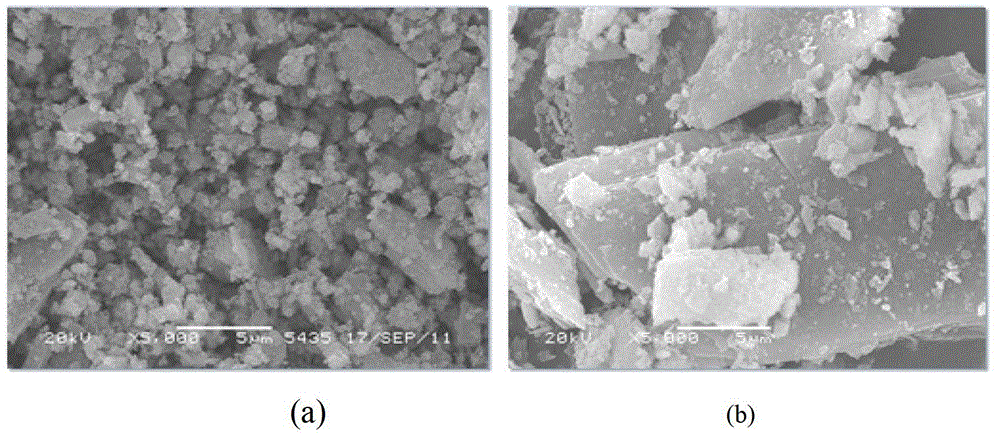

[0027] Hydration Regulation of Calcium Sulfate Pure Compounds

[0028] Step 1, weigh 100 grams of anhydrous calcium sulfate and 10 grams of sodium sulfate and place them in a 1-liter autoclave, then add 300 milliliters of water, seal the autoclave, set the speed at 200 r / min, start the motor, heat up to 100 ° C, and keep the temperature constant Leave on for 2 hours.

[0029] Step 2, turn off the stirring device and the heating switch, let the material in the autoclave be naturally cooled to 80°C, open the autoclave, add 0.5 g of calcium sulfate dihydrate crystals (over 200 mesh) as a seed crystal, seal the autoclave, and wait for the material in the autoclave to Continue to cool naturally to 60°C.

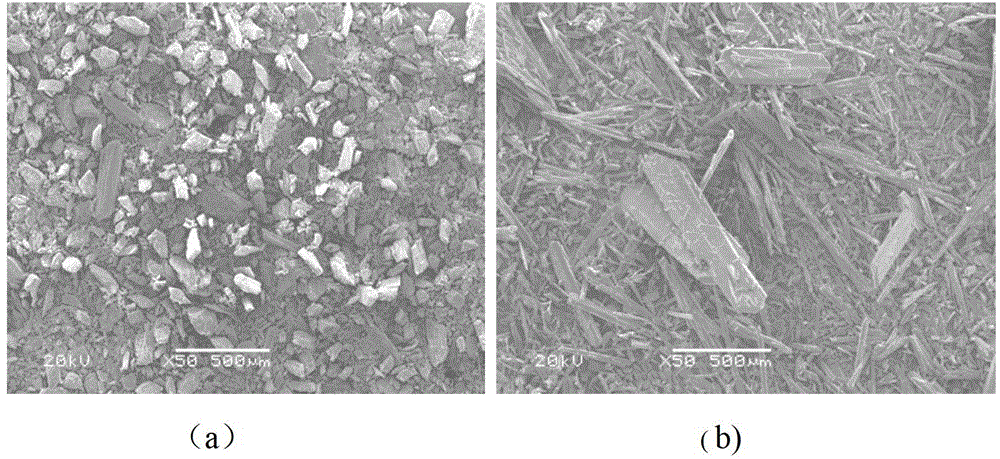

[0030] Step 3, the material in the autoclave is lowered to 60°C and kept at a constant temperature for 2 hours, then the heating switch is turned off, and the material is cooled to room temperature naturally. Open the autoclave to take out the material, filter and rinse with wat...

Embodiment 2

[0033] Hydrothermal activation-hydration control of zinc-containing waste residue in a smelter

[0034] Step 1, mix the zinc-containing waste slag and sulfur produced by a smelter according to the ratio of M:S=1:1.2, where M represents the amount of all heavy metals in the dry waste slag, and S represents the amount of added sulfur . Add water according to the liquid-solid ratio of 3:1, mix the materials and put them into the autoclave, and seal the autoclave.

[0035] Step 2, turn on the motor, set the speed to 200r / min, raise the temperature to 200°C for 4 hours for hydrothermal activation, turn off the stirring device and the heating switch after the reaction, let it cool down to 100°C naturally and add 10 grams of anhydrous sodium sulfate to make Activator, keep stirring at 100°C for two hours, then turn off the heating and stirring device, let it cool naturally to 80°C, add 5 grams of calcium sulfate dihydrate crystals as seed crystals, stir for ten minutes, and age when...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com