Patents

Literature

35results about How to "Significant industrial application value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

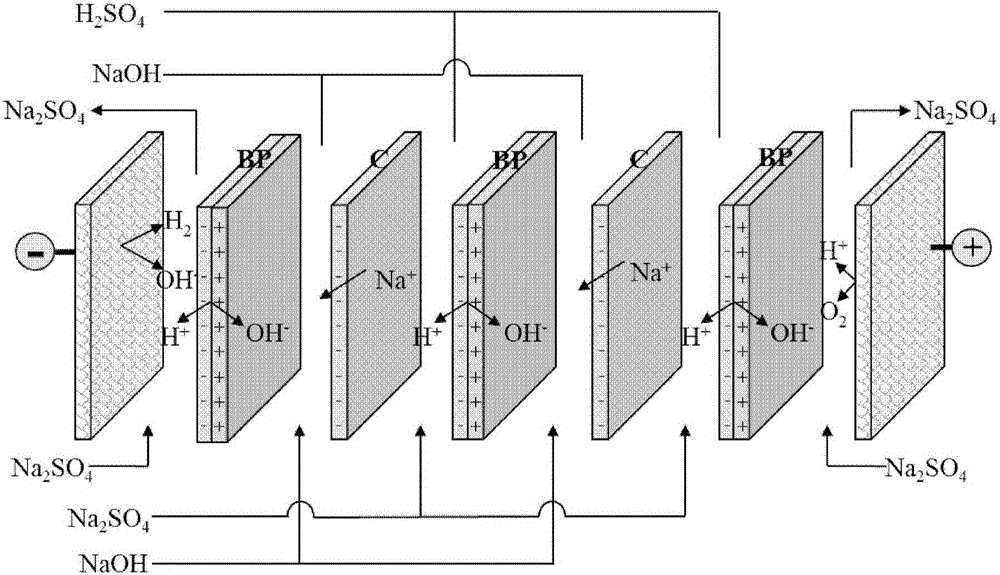

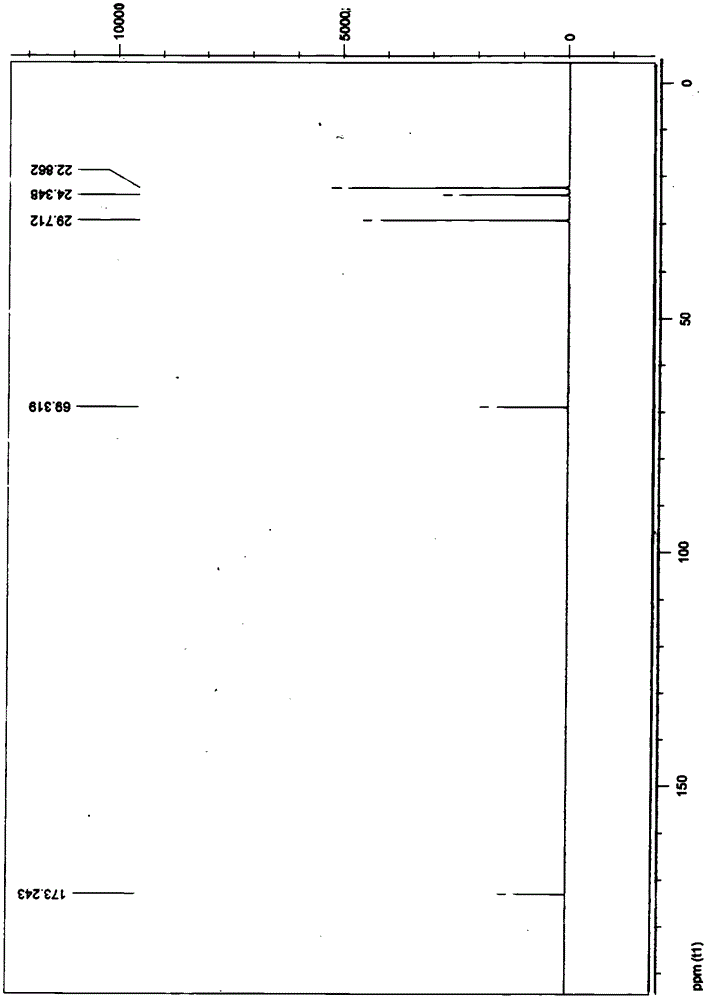

Method for preparing methionine and sodium hydroxide through bipolar membrane electrodialysis

InactiveCN103933861ARealize cleaner productionSignificant industrial application valueOrganic compound preparationAlkali metal hydroxidesMethionine recyclingHydrolysate

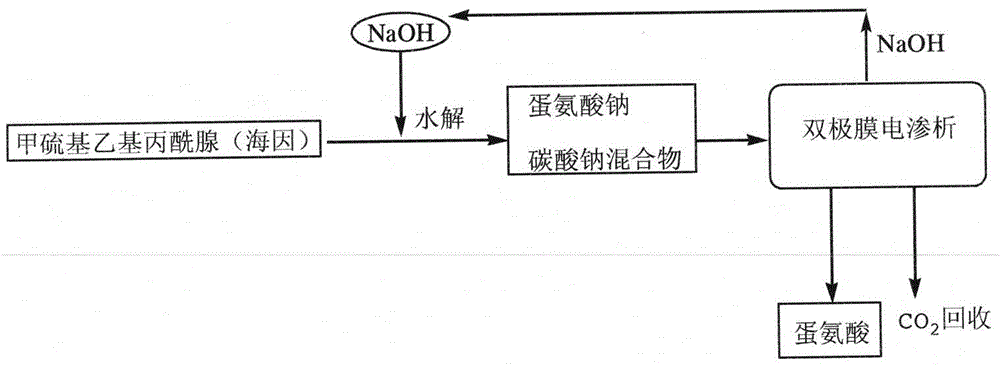

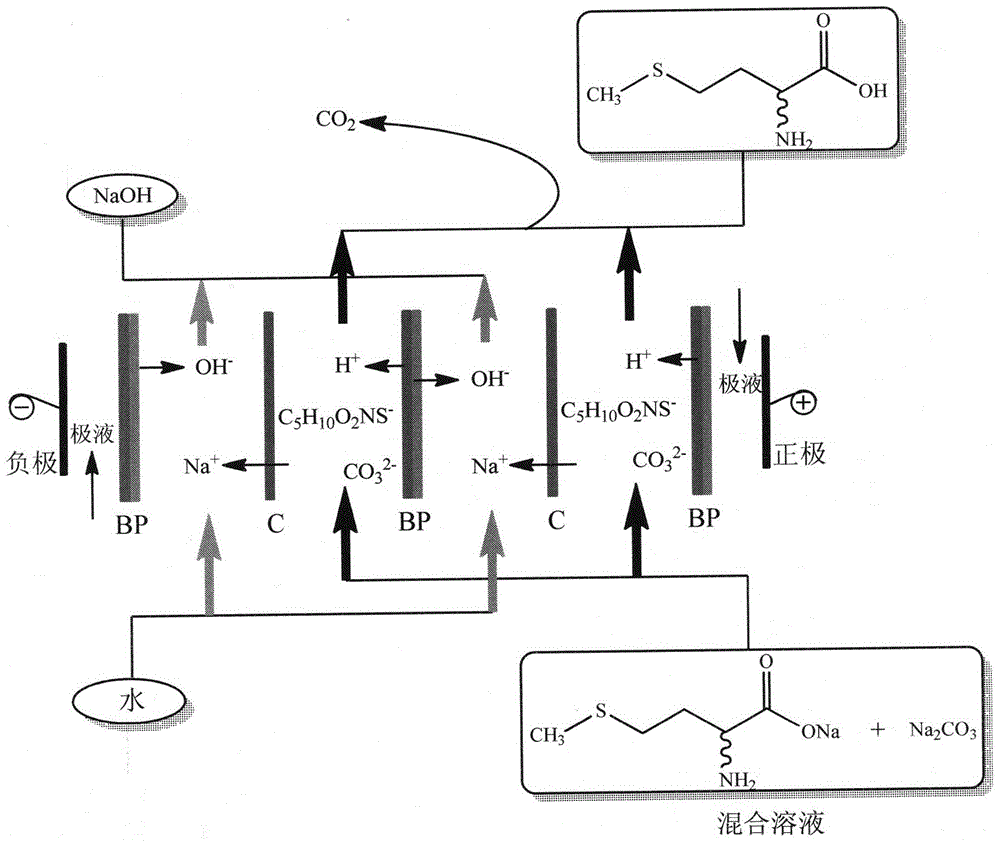

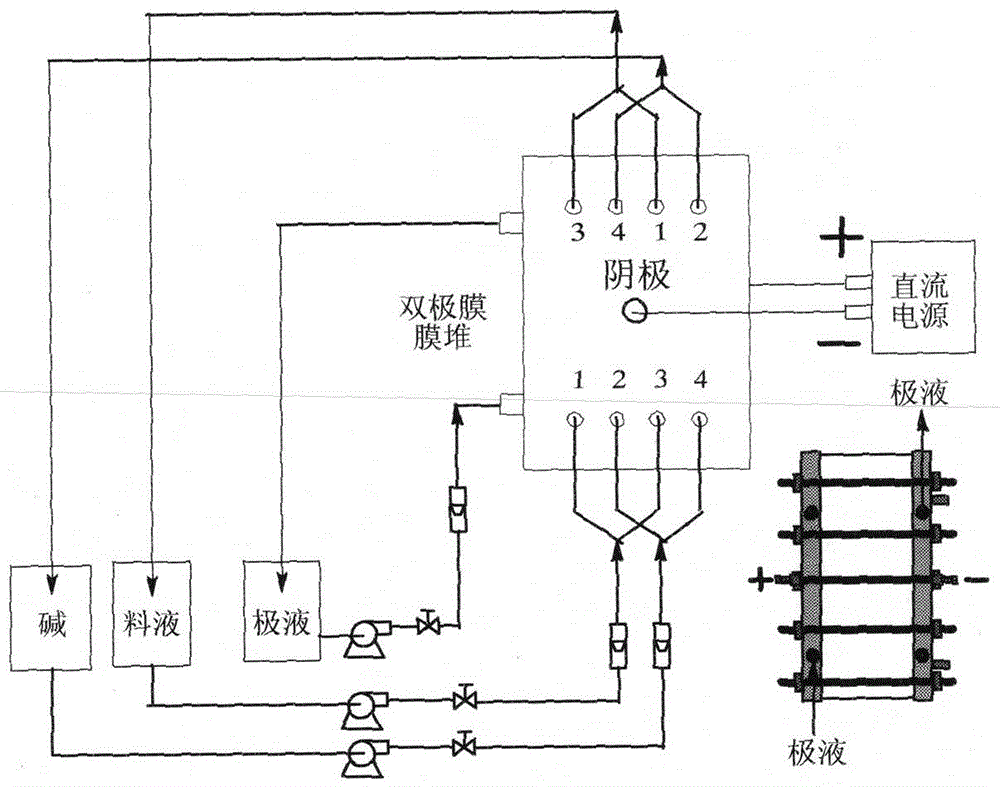

The invention discloses a method for preparing methionine and sodium hydroxide through applying a bipolar membrane electrodialysis technology. The method comprises the specific process: diluting a methylthioethyl hydantoin (hydantoin) hydrolysate to one-third to one-fifth of the original concentration, and filtering with a microporous filter; then pumping the hydrolysate into one of a salt chamber or a salt / acid chamber of a bipolar membrane electrodialysis device, and injecting a certain concentration of an electrolyte solution into other compartments; connecting a cathode and an anode of the bipolar membrane electrodialysis device respectively with a negative electrode and a positive electrode of a direct-current power source, starting the bipolar membrane electrodialysis device, controlling the current density of a direct-current electric field to be 50-150 mA / cm<2> and the temperature at 20-40 DEG C, and thus obtaining methionine with higher purity in an acid chamber, wherein the methionine recycling rate reaches more than 95% and the current efficiency reaches about 70%; and at the same time, collecting obtained carbon dioxide, and thus obtaining sodium hydroxide with the concentration of 4-6% in an alkali chamber. The method has the advantages of high yield, no pollution, less use of raw materials, and good application prospects.

Owner:ZHEJIANG CIRCLE TECH MEMBRANE TECH +1

A self-supporting catalyst having a core-shell structure, a preparing method thereof and applications of the catalyst

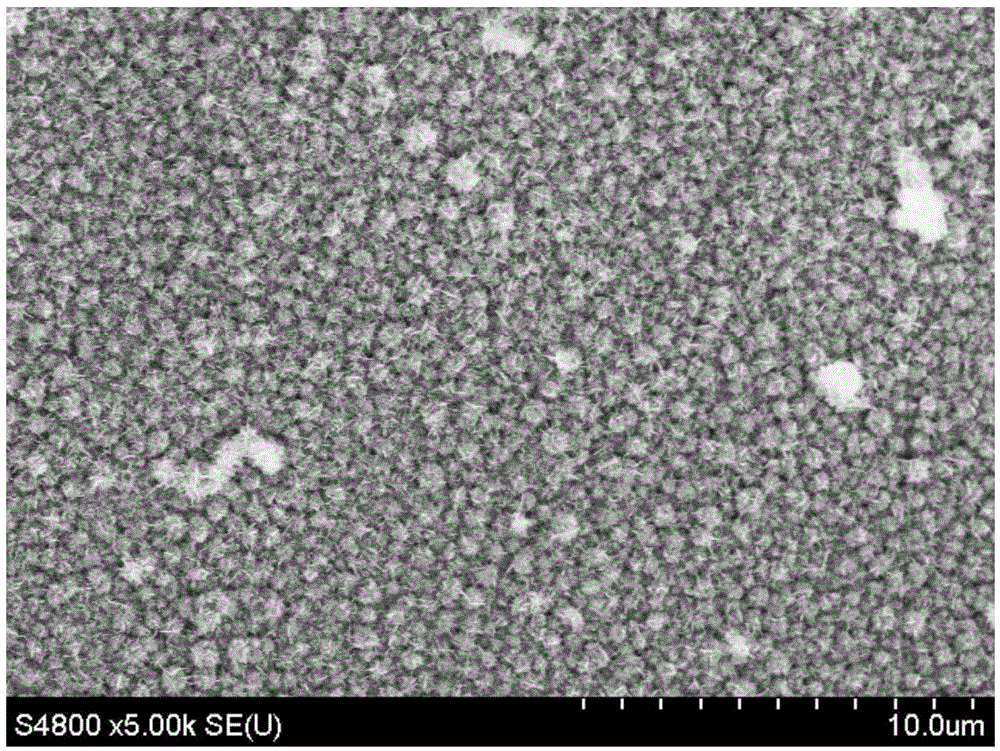

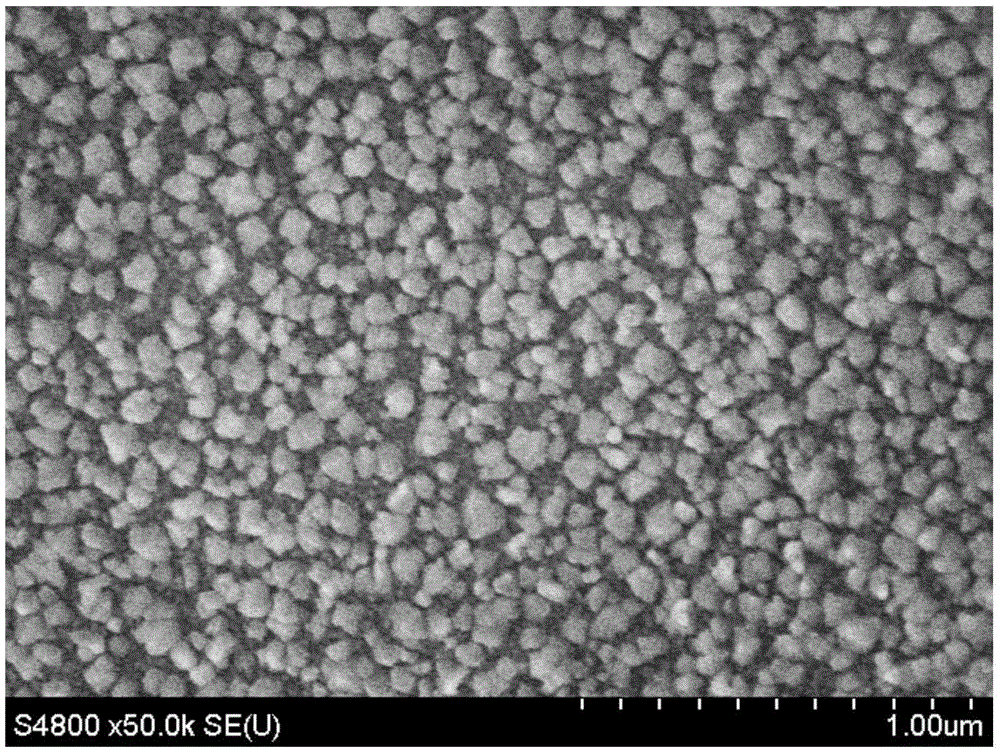

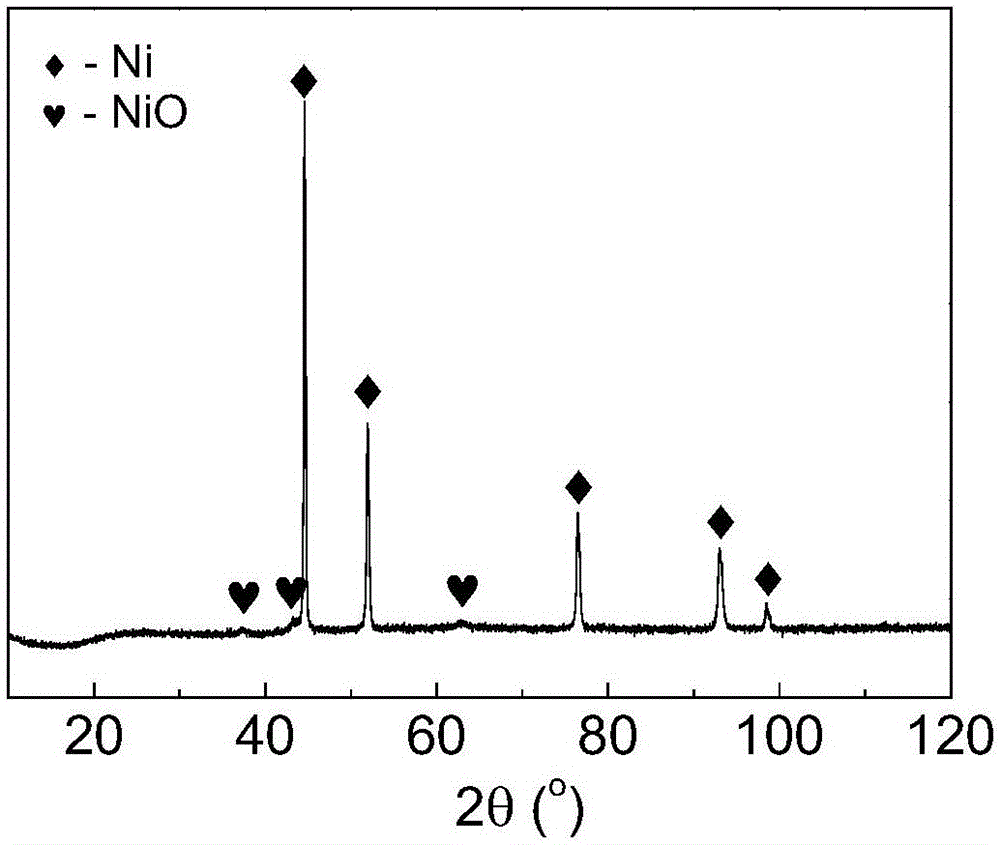

PendingCN107537478AOptimal Control StructureStable structureHydrogenDispersed particle separationCatalytic oxidationCalcination

A self-supporting metal or metal oxide catalyst having a core-shell structure is disclosed. The general formula of the catalyst is xM-yMO@zShell / mAlO / ZT, wherein the x is 0-5% by mass, the y is 0-10%by mass, the z is 0.5-20% by mass, the m is 0.1-20% by mass, and the catalyst includes the M, the Mo, the Shell and the AlO, with the balance being the ZT. The catalyst is prepared by a method including (1) a step of subjecting the ZT to hydrothermal treatment and / or thermal treatment in pure water or an aqueous solution containing an aluminum source and an alkali source to prepare a self-supporting AlO / ZT composite carrier, and (2) a step of soaking the prepared AlO / ZT carrier by utilizing an organic solution containing at least one metal M ion and coordinated with a coupling agent, and performing drying, calcination and reduction to prepare the catalyst. The catalyst can be used for catalytic oxidation of low-concentration methane and volatile organic compounds (VOCs), catalytic oxidation of carbon monoxide, lower olefin preparation from synthetic gas (FTO), and methane conversion to prepare synthetic gas.

Owner:EAST CHINA NORMAL UNIV

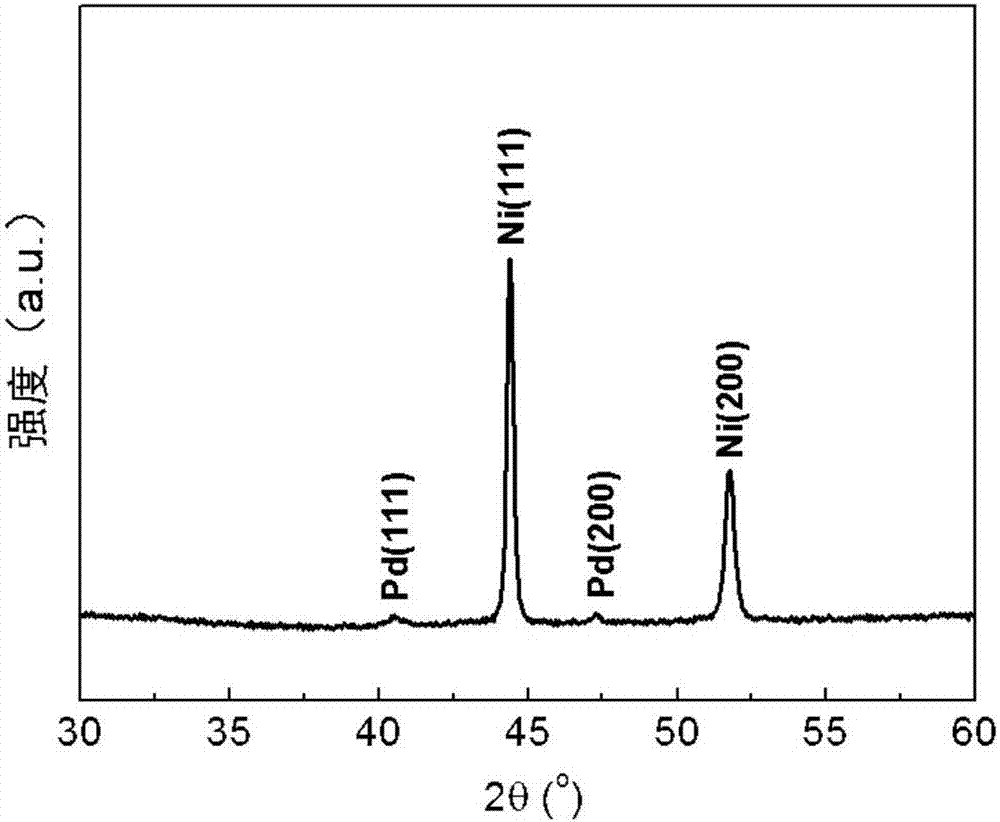

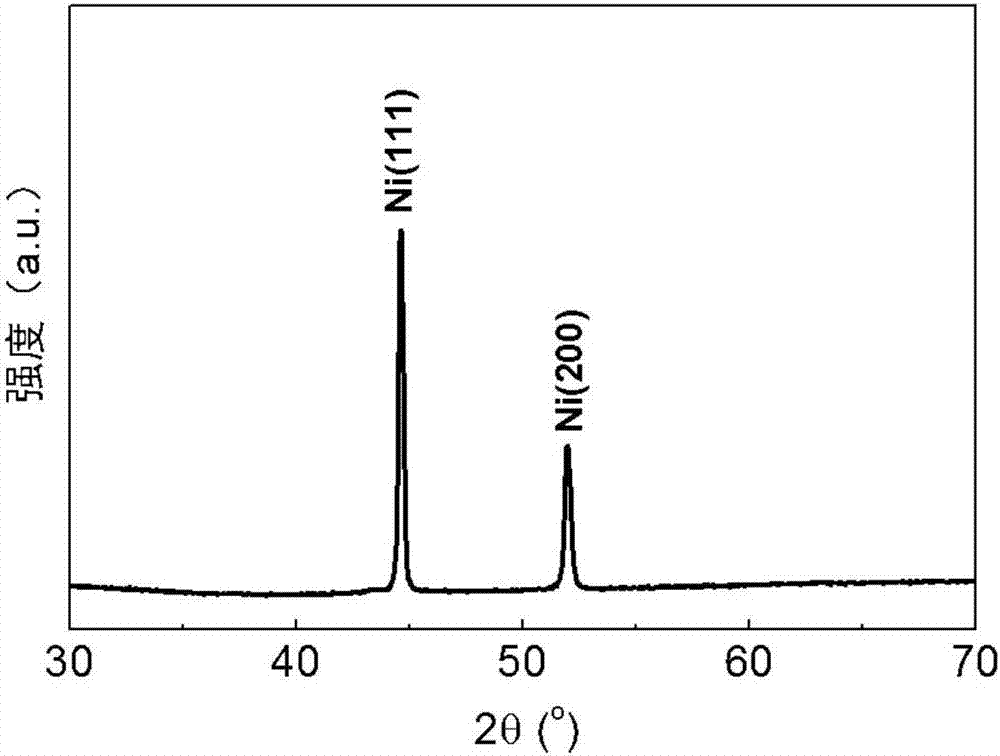

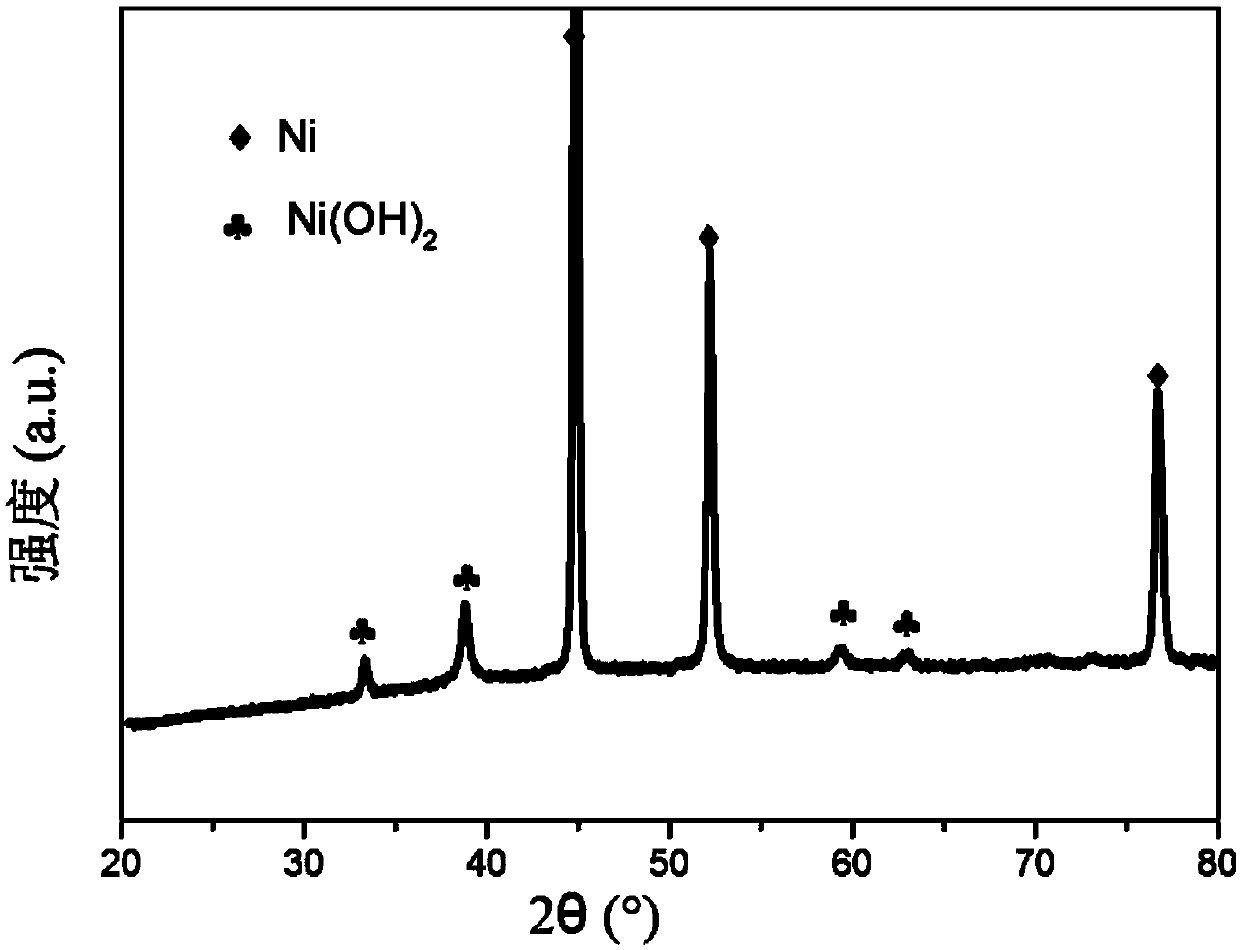

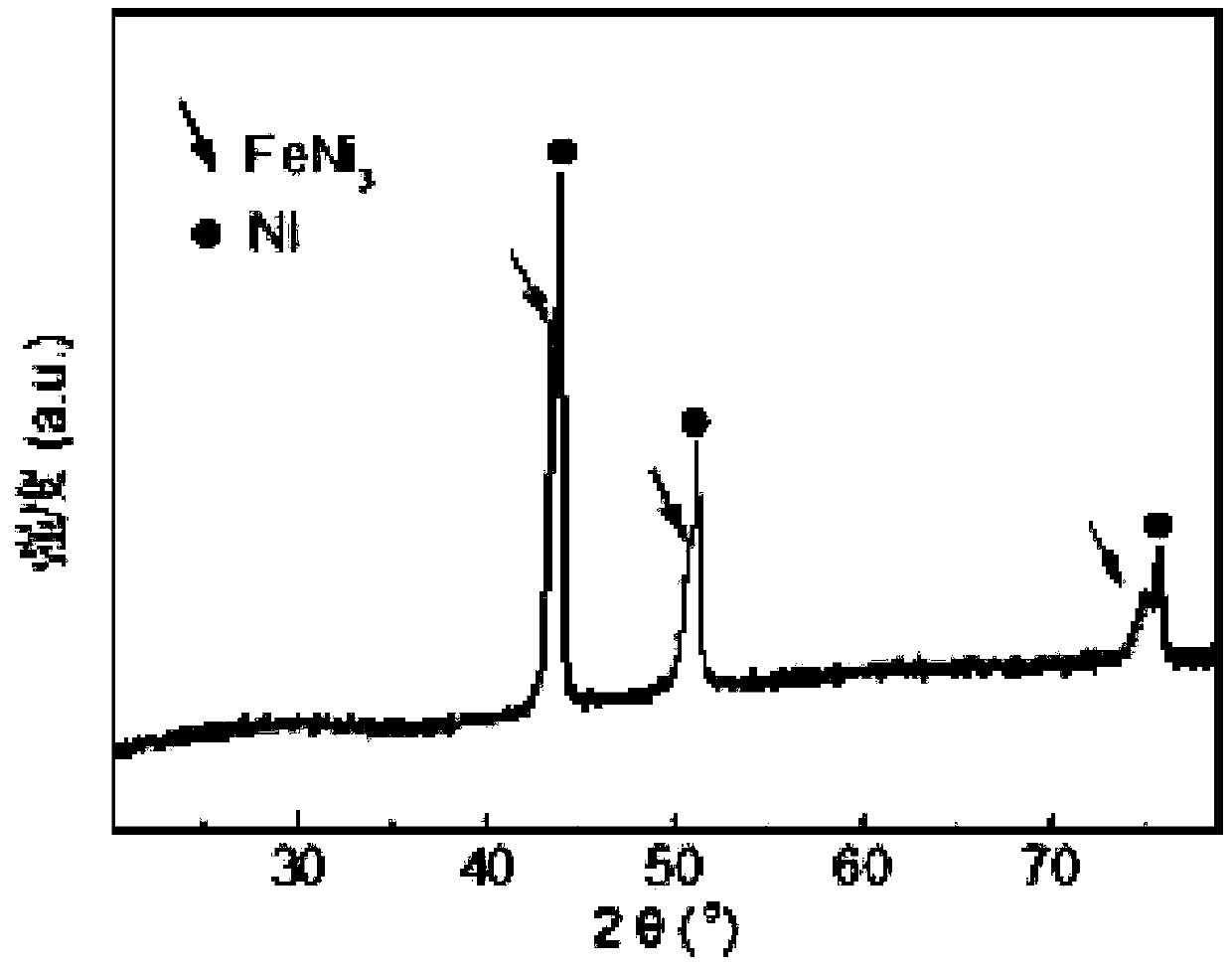

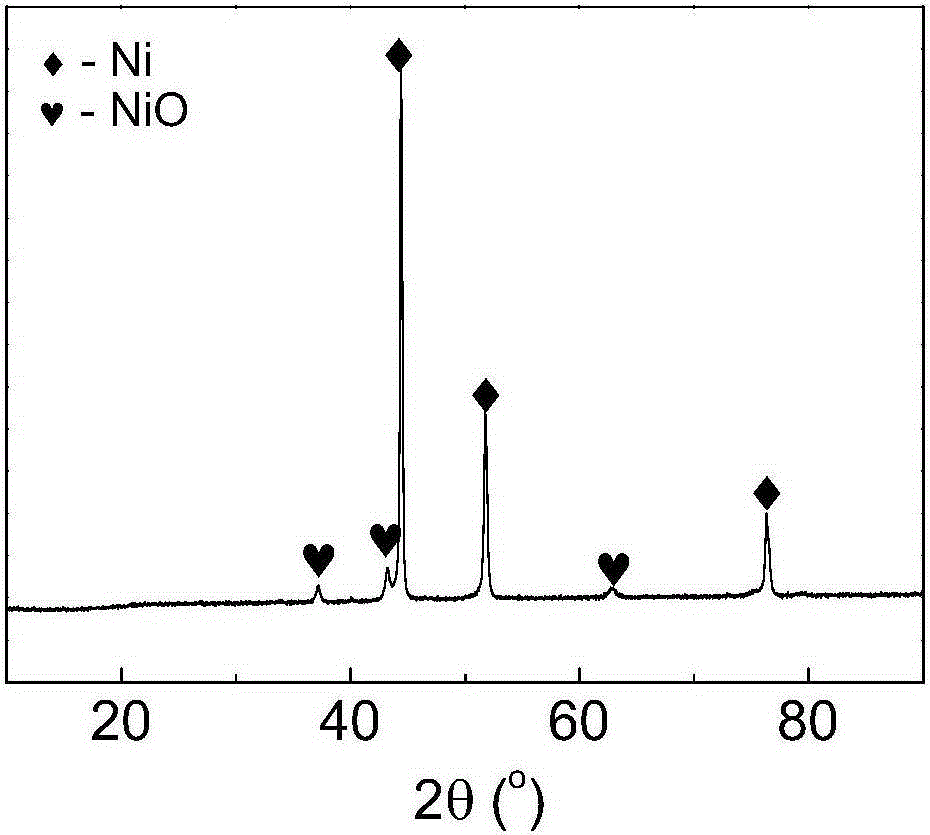

Supported nickel-based alloy catalyst as well as preparation method and application thereof

PendingCN109675569AStable structureThe structure is economical and practicalOrganic compound preparationCarboxylic acid esters preparationIndiumHigh activity

The invention discloses a supported nickel-based alloy catalyst as well as a preparation method and application thereof. The supported nickel-based alloy catalyst comprises a carrier and a nickel-based alloy supported by the carrier. The nickel-based alloy is a NixMyCz alloy, wherein x is greater than or equal to 1 and less than or equal to 10, y is greater than or equal to 1 and less than or equal to 10, and z is greater than or equal to 0 and less than or equal to 5; M is selected from at least one of iron, copper, cobalt, zinc, molybdenum, palladium, silver, gallium, indium, tin, germanium,bismuth and lead; in addition, when z is greater than 0, M is not indium, the total mass of the nickel-based alloy is 1 to 50 percent, and the balance is a carrier. The catalyst provided by the invention has the advantages of stable structure, good thermal conductivity, high permeability, high conversion rate, high selectivity, high activity, high mechanical strength, easiness in forming and filling, high throughput, low pressure drop and the like. The supported nickel-based alloy catalyst is a good catalyst for reactions for preparing methyl glycollate, ethylene glycol and ethanol by hydrogenation of dimethyl oxalate.

Owner:EAST CHINA NORMAL UNIV

Preparation method of gold-based catalyst for preparing vinyl chloride by acetylene hydrochlorination method

ActiveCN109622036AImprove performanceHigh activityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsFixed bedSolvent

The invention provides a preparation method of a gold-based catalyst for preparing vinyl chloride by an acetylene hydrochlorination method and the catalyst prepared by the method. According to the catalyst, an activated carbon is used as a carrier, a complex formed by gold and a nitrogen-containing ligand is a main active component, compared with other gold-based catalysts, green solvents such aswater, ethanol and the like are utilized to replace acidic solvents such as hydrochloric acid, aqua regia and the like in the catalyst preparation process, and the gold in a high valence state is stabilized by the complexation of the nitrogen-containing ligand with the gold, thereby improving the effectiveness of the catalyst. The catalyst has high activity and vinyl chloride selectivity in the reaction of fixed bed acetylene hydrochlorination to prepare the vinyl chloride, the preparation method is green and environmentally friendly, and the method has a great industrial application value.

Owner:NANKAI UNIV

Method for preparing levodopa by virtue of enzymic method

ActiveCN104726513ARich sourcesReduce manufacturing costMicroorganism based processesFermentationBiotechnologyStenotrophomonas maltophilia

The invention discloses a method for preparing levodopa by virtue of an enzymic method. The method comprises the following steps: picking up an annular stenotrophomonas maltophilia strain slant for inoculation into a seed culture medium for culturing, thereby obtaining a primary seed liquid; inoculating a fermentation culture medium with the primary seed liquid at the inoculum size of 3-10% for fermentation culturing, centrifuging after the fermentation is ended and collecting bacterial cells; and adding tyrosine and the bacterial cells to a buffer solution to have an enzymatic reaction under the conditions of 18-30 DEG C and the pH of 5.0-6.0, thereby converting the tyrosine into the levodopa. According to the method, due to the resting cell transformation technology, and the preferred intermittent weak ventilation technology, adopted in the transformation process, the catalytic efficiency of the enzyme is improved; the concentration of the levodopa is 27g / L and the molar transformation rate of the tyrosine is above 99%; and besides, the method is mild in conditions, high in enantio-selectivity and free from racemization effect, is more suitable for industrial production, and has remarkable economic benefit and industrial application value.

Owner:SHANDONG YANGCHENG BIOLOGY TECH CO LTD

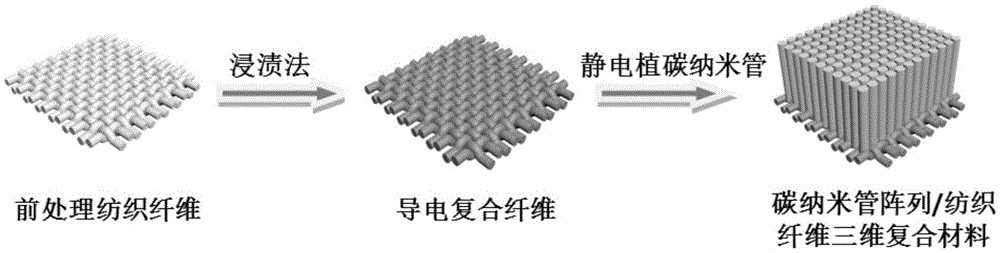

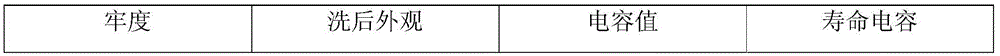

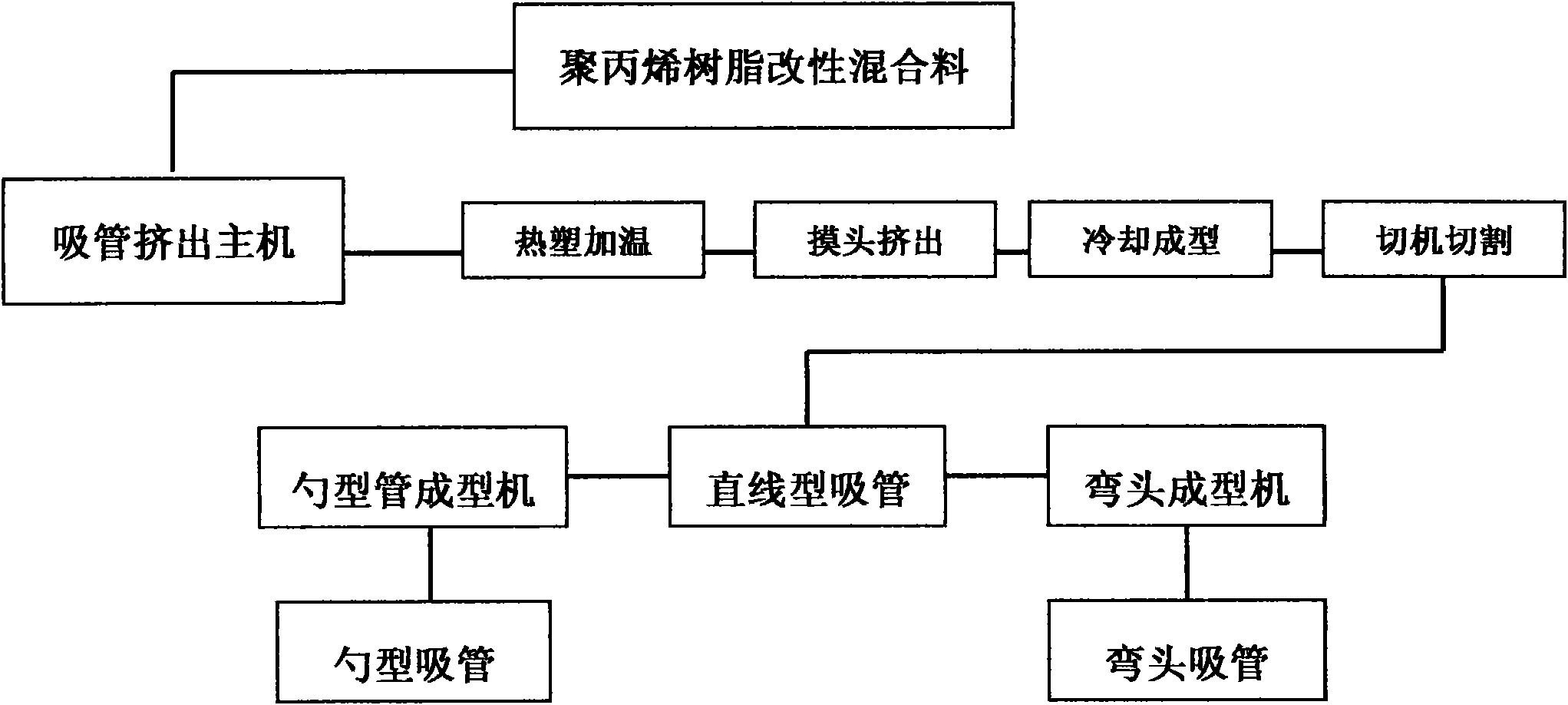

Preparation method for three-dimensional aminated carbon nanotube array/stretchable textile fiber electrode material

ActiveCN105679555AGood stretchabilityImprove mechanical propertiesHybrid capacitor electrodesHybrid/EDL manufactureTextile fiberCooking & baking

The invention relates to a preparation method for a three-dimensional aminated carbon nonotube array / stretchable textile fiber electrode material. The preparation method comprises the following steps of placing textile fiber subjected to pre-treatment in a composite agent containing a dispersing agent and an aminated carbon nanotube in a room temperature, carrying out immersion and drying to obtain a conductive and stretchable textile substrate; placing the aminated carbon nanotube in an electricity processing liquid to obtain aminated carbon nanotube subjected to electricity processing; and uniformly coating the conductive and stretchable textile substrate with a graphene conductive adhesive, implanting the aminated carbon nanotube subjected to electricity processing into the surface of the substrate through single-surface static electricity to obtain the three-dimensional conductive electrode material, carrying out pre-baking and baking, and absorbing the aminated carbon nanotube floated on the surface to obtain the three-dimensional aminated carbon nanotube array / stretchable textile fiber electrode material. The method disclosed by the invention is simple in process, the cost can be substantially reduced, and meanwhile, mass production of a high-capacitance electrode is achieved.

Owner:DONGHUA UNIV

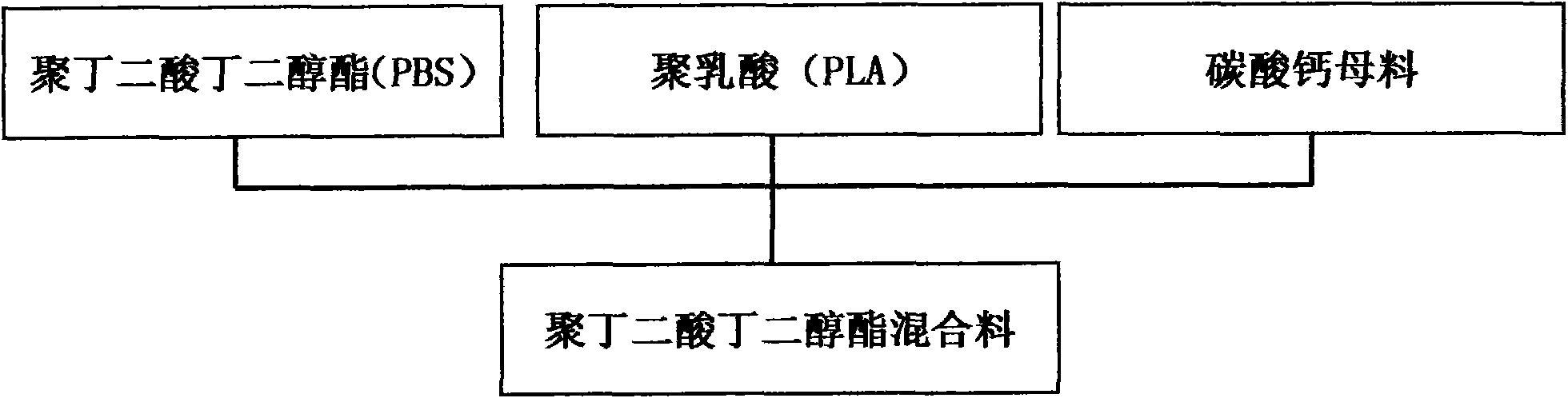

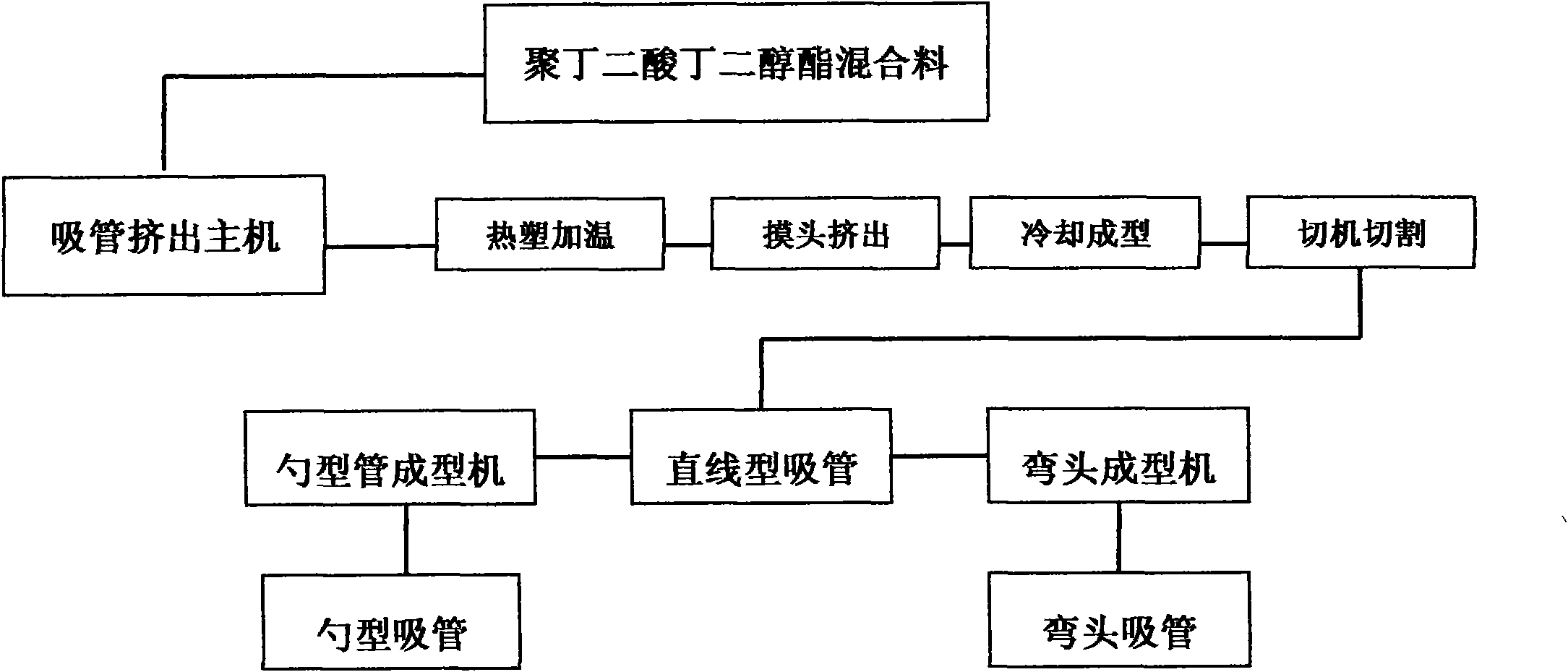

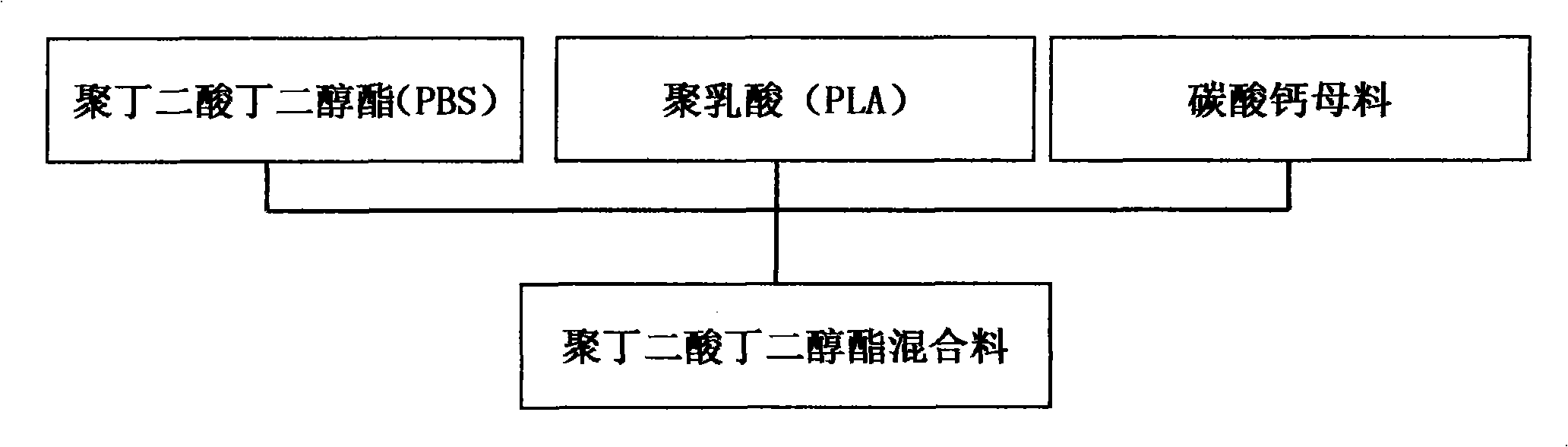

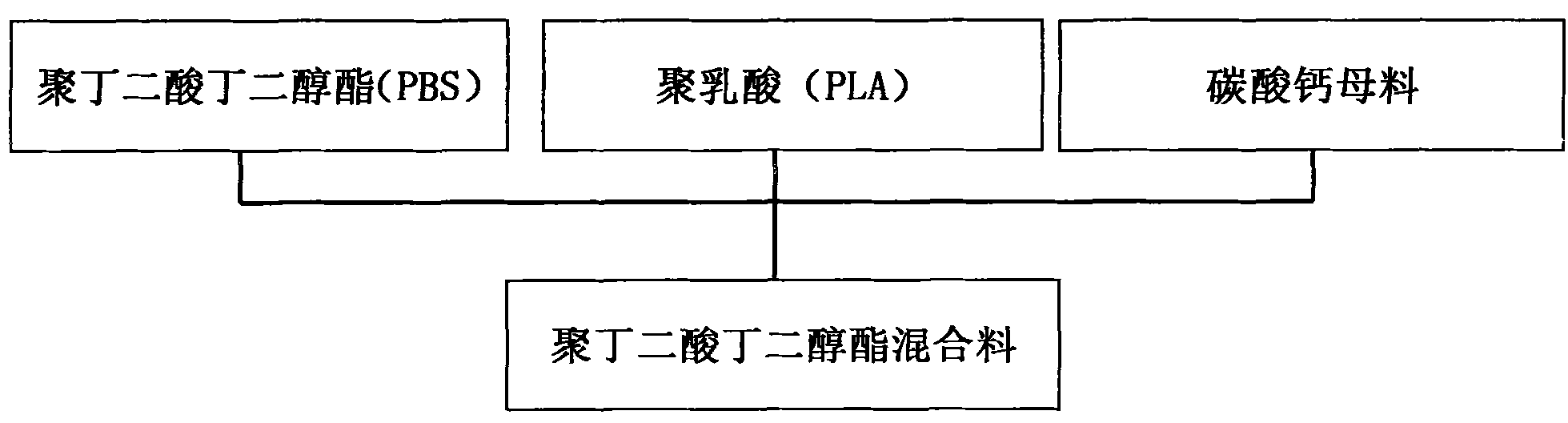

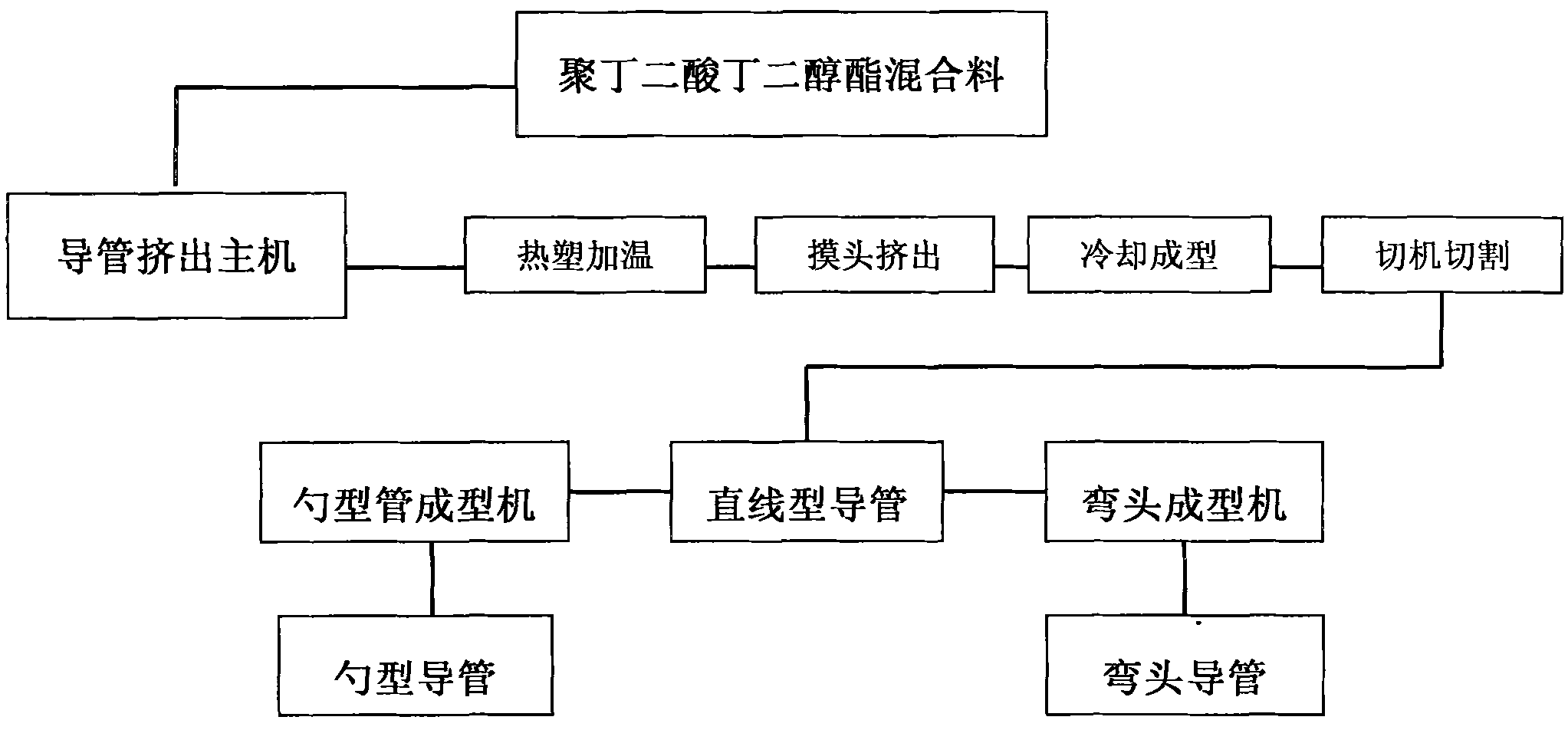

Biomass degradable material preparation method and straw

InactiveCN102079849AReduce investmentImprove the decomposition cycleTubular articlesTablewaresMaterials preparationMixed materials

The invention provides a biomass degradable material preparation method. The method is characterized by comprising the following steps of: 1) preparing raw materials, namely weighing the following raw material components in percentage by weight: 40 to 60 percent of poly(butylene succinate) serving as a main material, 40 to 60 percent of polylactic acid serving as a modified material and 0.1 to 20 percent of calcium carbonate master batch serving as a filler; 2) mixing the components to form a modified poly(butylene succinate) mixed material; and 3) standing the modified mixed material at a low temperature for later use. The invention also discloses a method for preparing a straw by using the material, which comprises the following steps of: 4) preparing a straw extruding main machine and a circular die head which is matched with the main machine for use; 5) feeding the modified poly(butylene succinate) mixed material into the extruding main machine to obtain a continuous circular hollow straw; and 7) cutting into straw sections. The invention also provides the straw which is prepared by the method. The material provided by the invention can be completely degraded; the method is scientific and rational and has high production efficiency; and a product has high performance and is low in cost.

Owner:楼仲平

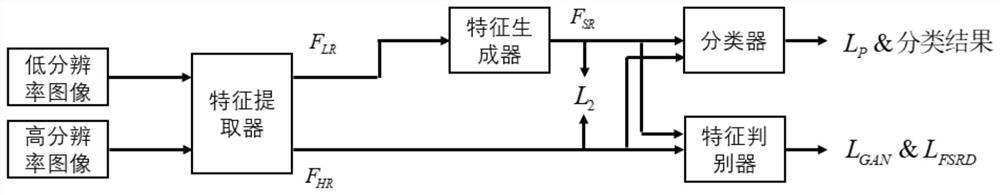

Low-resolution image facial expression recognition method based on feature reconstruction model

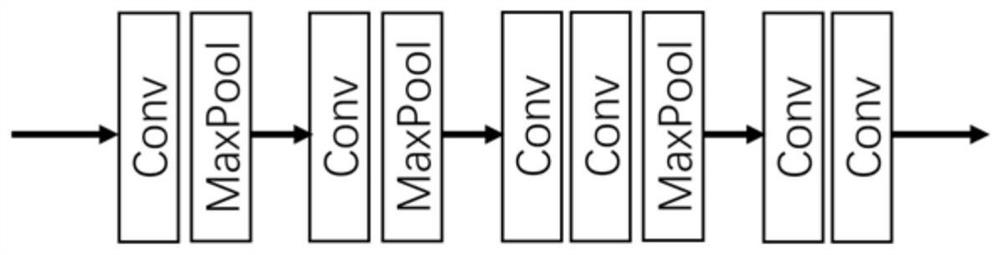

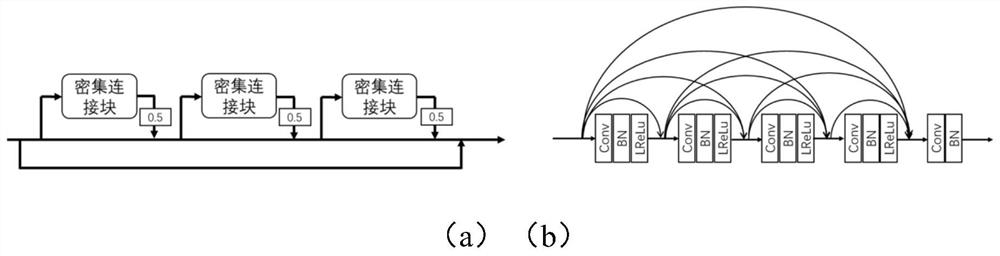

ActiveCN112818764AFast convergenceAvoid increased computationGeometric image transformationNeural architecturesData setImage resolution

The invention discloses a low-resolution image facial expression recognition method based on a feature reconstruction model, and belongs to the field of facial image expression recognition. The method comprises the following steps: constructing training and testing data sets; training a facial expression recognition model of the feature reconstruction model, extracting image expression features by using a feature extraction network with fixed parameters, training the model by using a generative adversarial network mode to obtain an expression feature generator and a feature discriminator, and reconstructing features by using FSRG as an input image to obtain FSR; classifying the feature FSR by a classifier consisting of a full-connection network and a softmax function layer, and re-weighting sample loss by using a probability value of a correct category corresponding to a sample output by the softmax layer; the invention is not sensitive to the resolution of the input image, the recognition accuracy under the low resolution is improved, and the recognition effect on each resolution is more stable.

Owner:XI AN JIAOTONG UNIV

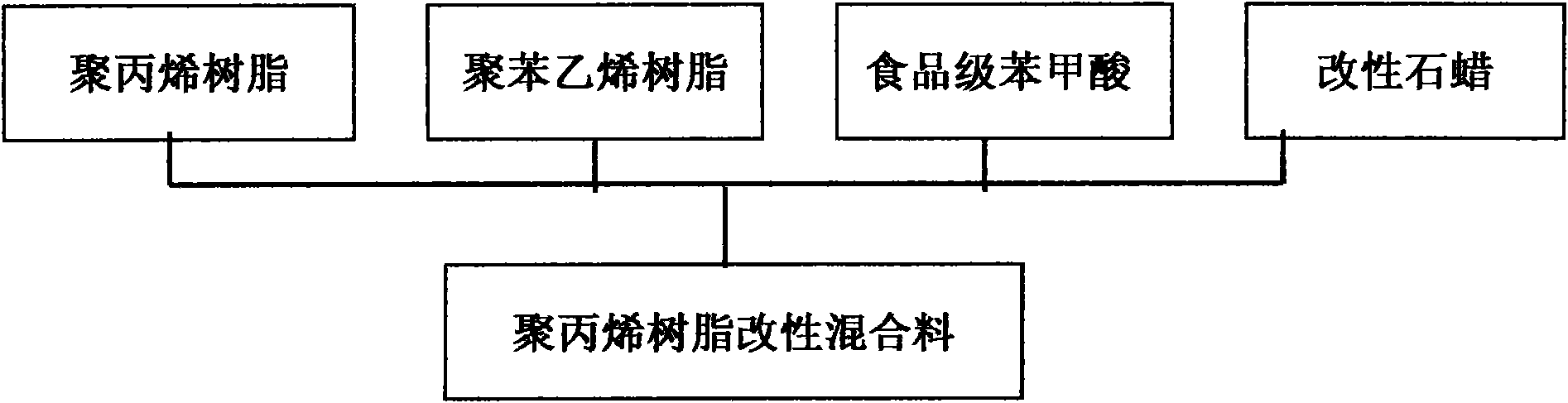

Preparation method of high transparent degradable material and suction tube

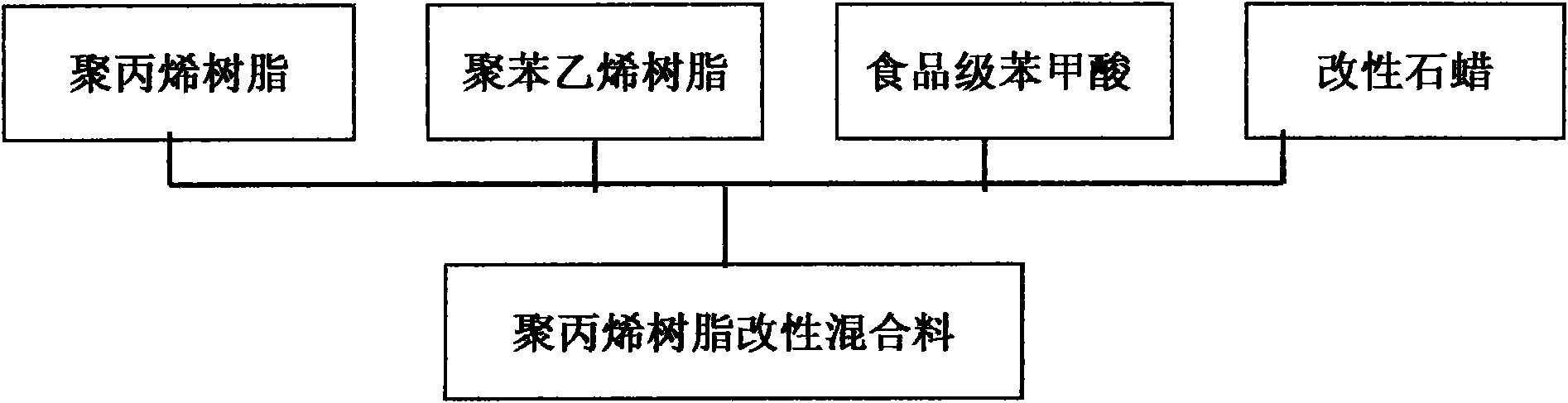

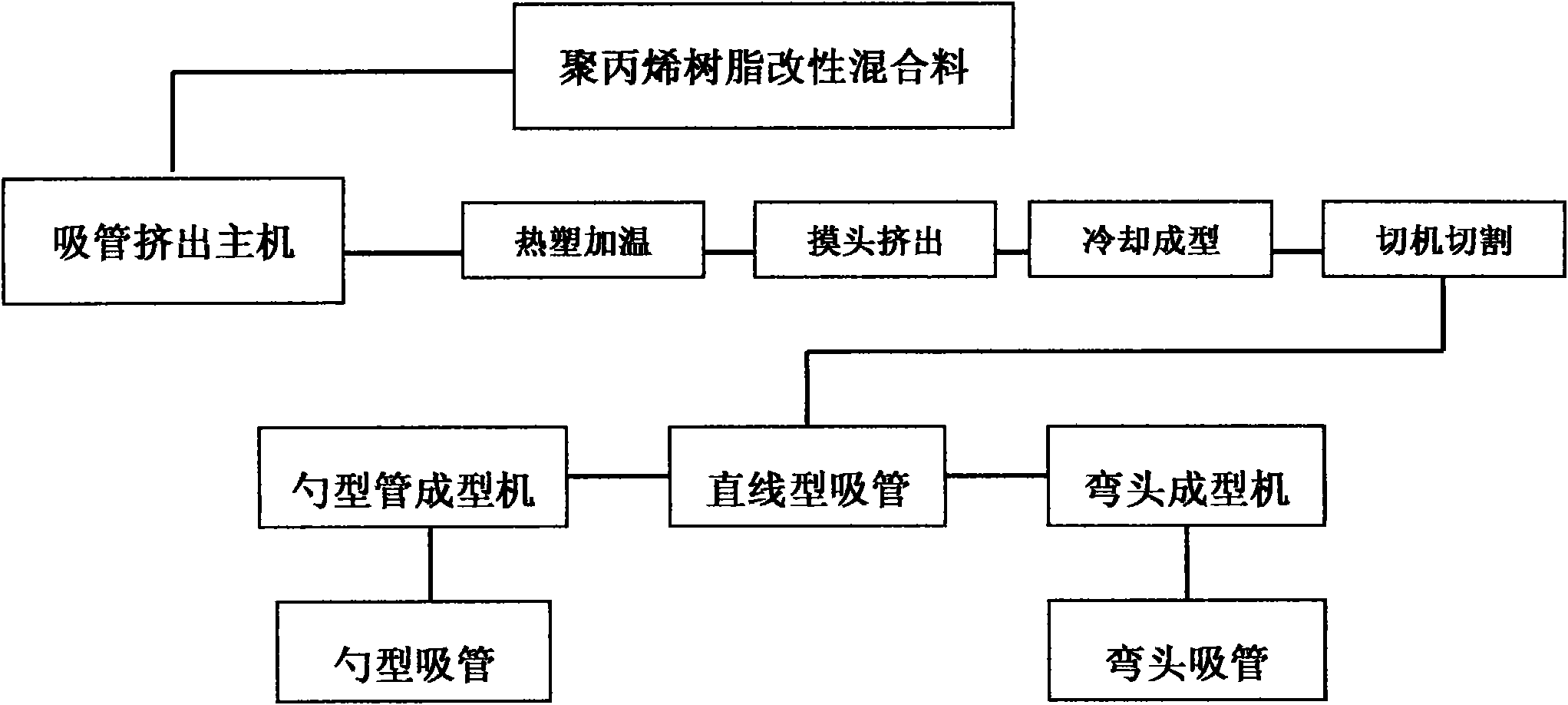

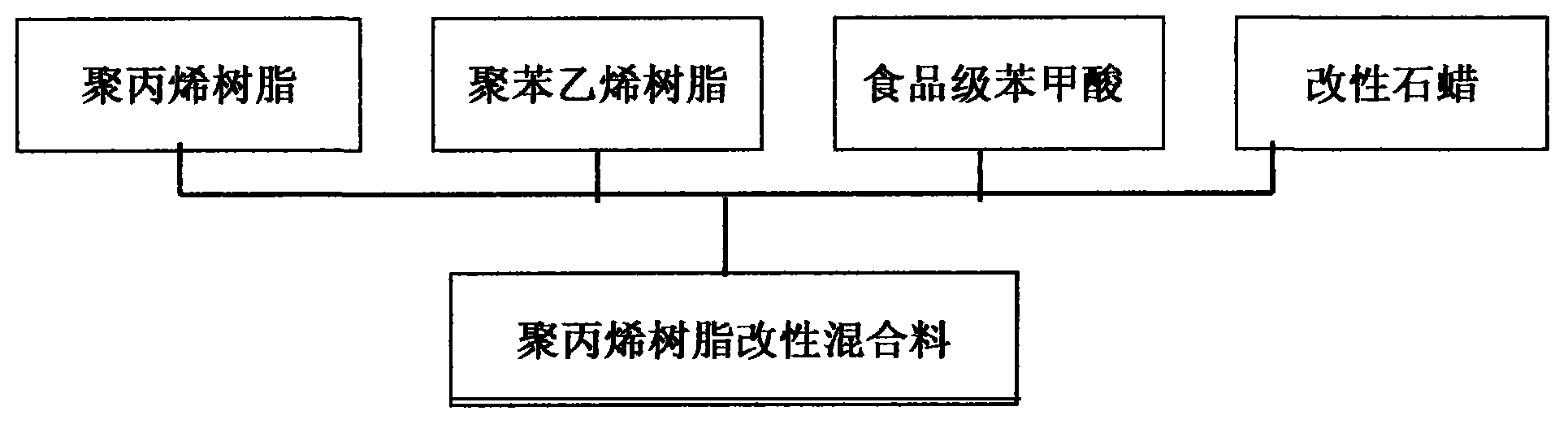

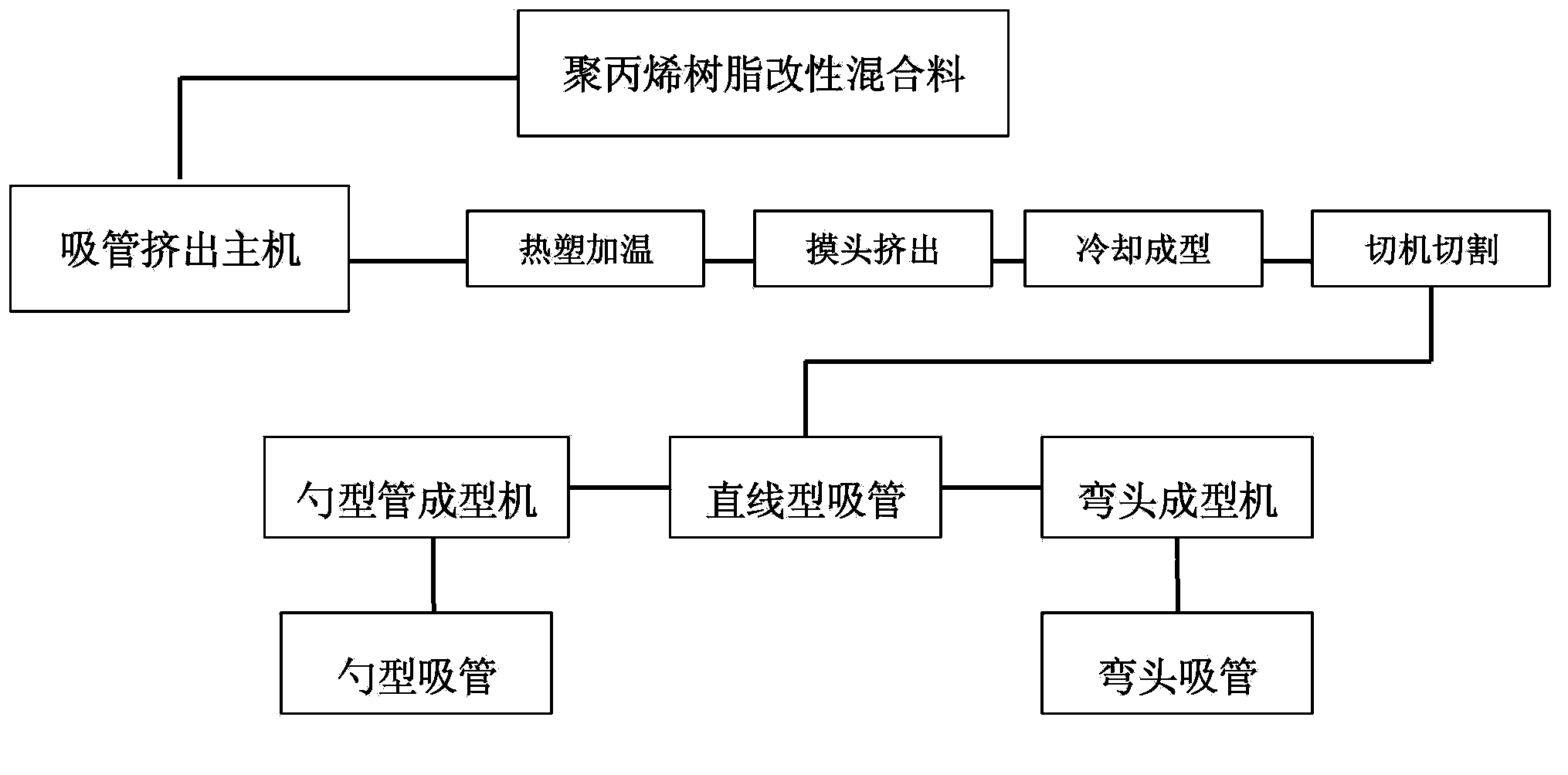

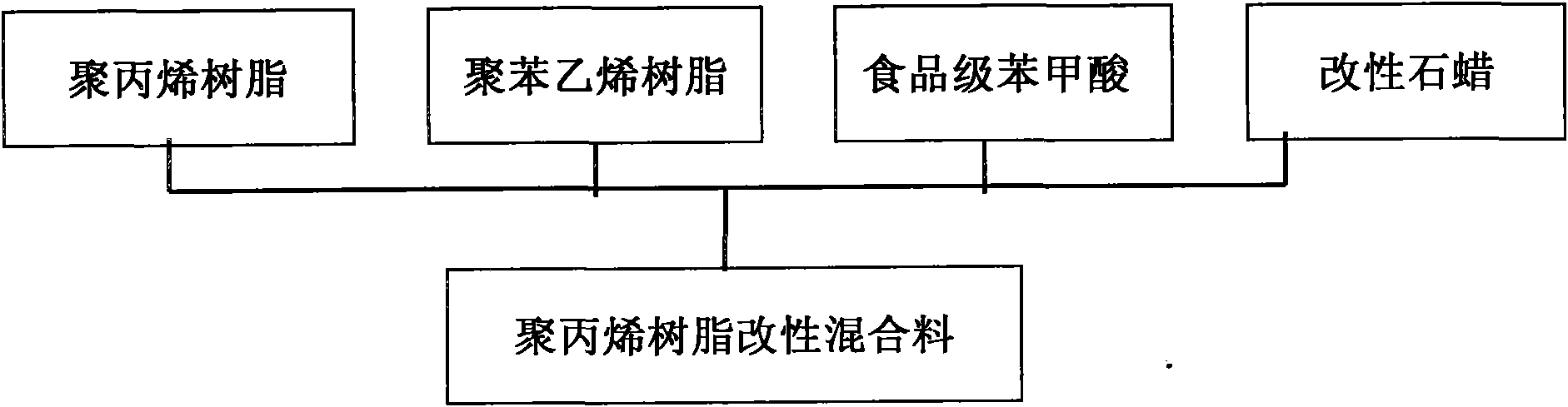

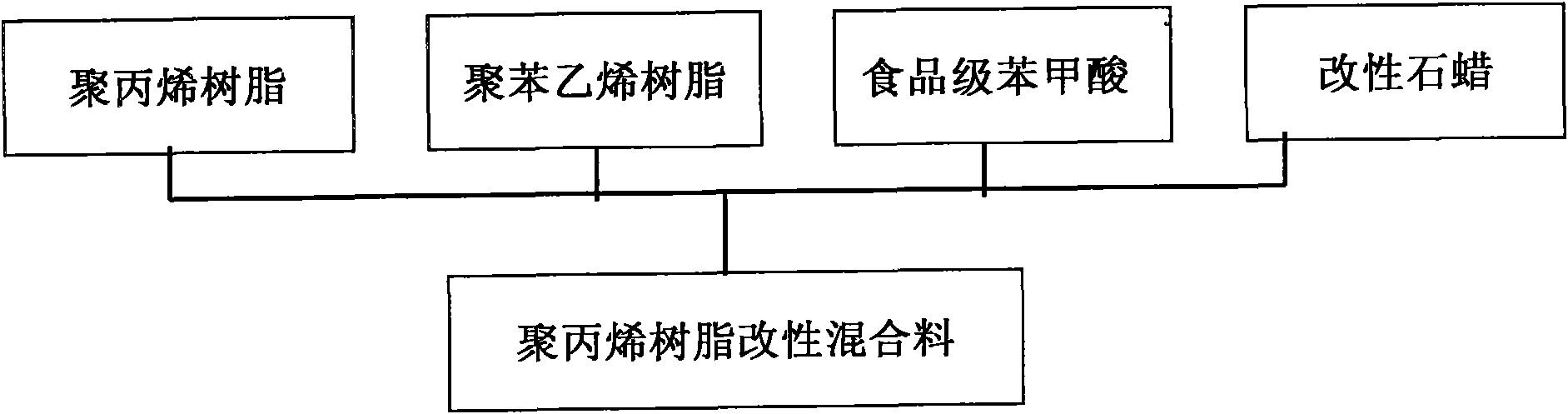

ActiveCN102070828AImprove and increase transparencyImprove and enhance the finishTubular articlesTablewaresBenzoic acidPolymer science

The invention provides a preparation method of a high transparent degradable material. The preparation method is characterized by comprising the following steps of: 1) preparing raw materials: based on weight percent, weighing the following raw material components: 95-98 of polypropylene resin, 1-5 of polystyrene resin, 0.01-0.05 of food-grade benzoic acid and 0.1-0.5 of modified paraffin; 2) mixing the components to form a modified polypropylene resin mixing material; and 3) carrying out low-temperature standing on the modified mixing material for later use. The invention also discloses a method for preparing a suction tube by using the above materials. The method for preparing the suction tube comprises the following steps of: 4) preparing a suction tube extruding main machine and a round die head matched with the main machine; 5) feeding the modified mixing material in the extruding main machine to obtain a continuous round hollow suction tube; and 6) cutting the prepared continuous linear type suction tube to suction tube sections. The invention further provides the suction tube prepared by the method. The material provided by the invention is highly transparent and degradable, the method is scientific and reasonable, the production efficiency is high, the product property is good, and the cost is low.

Owner:义乌市双童日用品有限公司

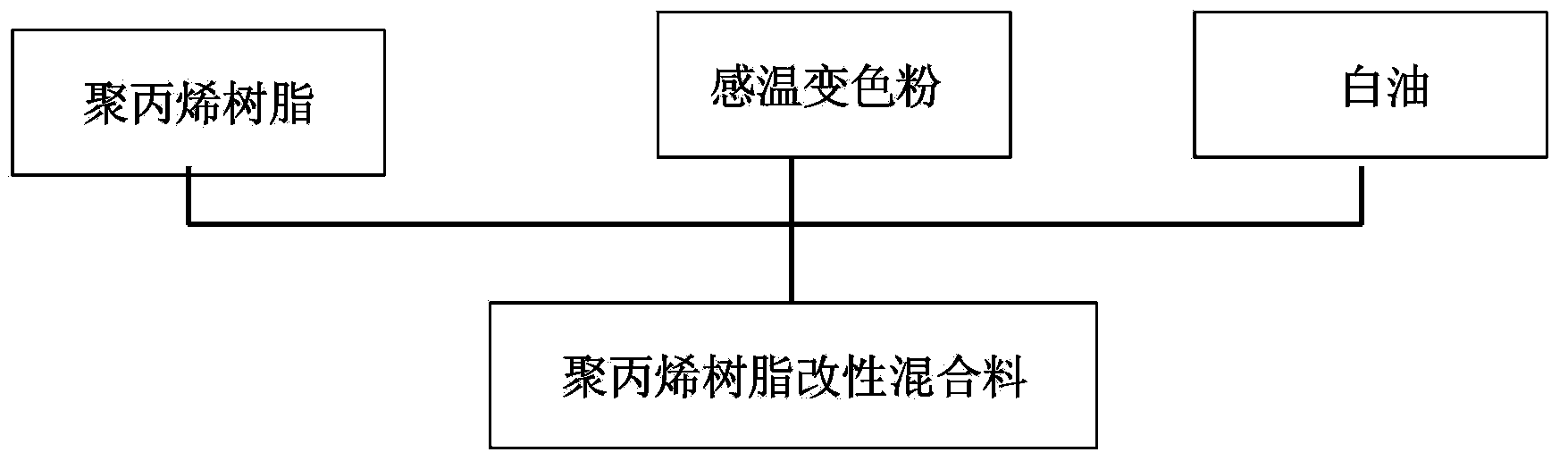

Preparation method of high-performance thermochromic material and suckers

InactiveCN103408833AImprove competitivenessSignificant industrial application valueTenebresent compositionsTablewaresPolypropyleneWhite oil

Owner:楼仲平

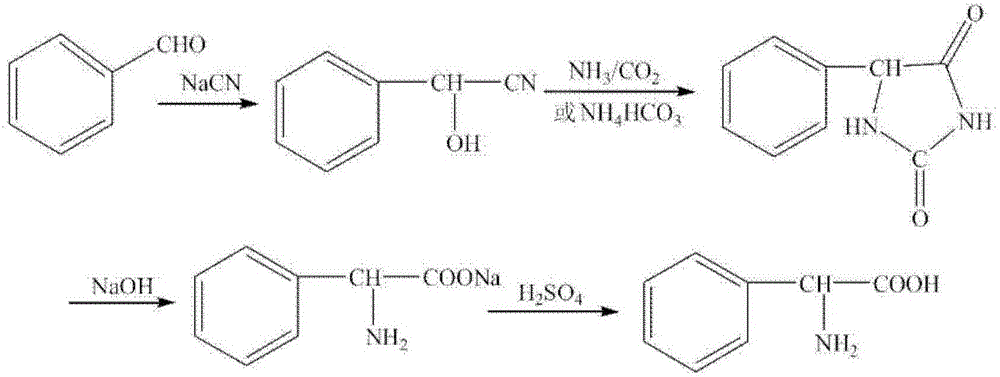

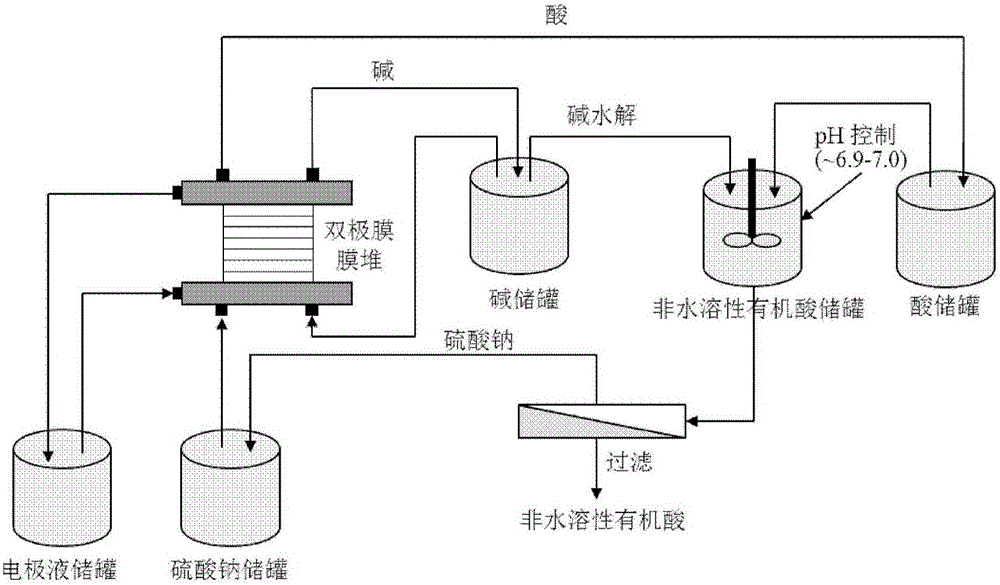

Method for producing water-insoluble organic acid by bipolar membrane electrodialysis

ActiveCN105964145ASimple production processRealize cleaner productionOrganic compound preparationAmino-carboxyl compound preparationOrganic acidWater insoluble

The invention relates to a method for producing water-insoluble organic acid by bipolar membrane electrodialysis. The method comprises the steps that a sodium sulfate aqueous solution is pumped into a bipolar membrane electrodialysis device to produce sulfuric acid and sodium hydroxide, the produced sulfuric acid is used for acidifying water-insoluble organic acid sodium salt to produce the water-insoluble organic acid and sodium sulfate, the produced water-insoluble organic acid solid is filtered and collected to obtain the required product, and the sodium sulfate aqueous solution used as a filtrate is used as a feed liquid to form a closed production loop. By the adoption of the method for producing the water-insoluble organic acid by the bipolar membrane electrodialysis, the full-closed and cycled clean production of the water-insoluble organic acid such as phenylglycine can be realized, so that chemical materials can be saved and a large number of high salinity wastewater can be avoided, the environmental pollution is reduced, and industrial application values and environmental benefits are obvious.

Owner:UNIV OF SCI & TECH OF CHINA

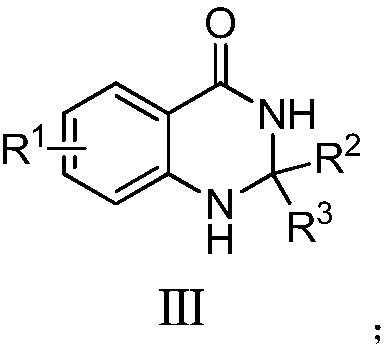

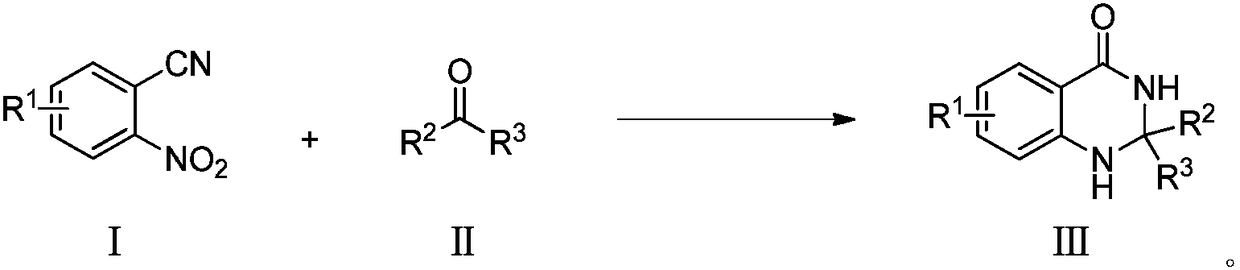

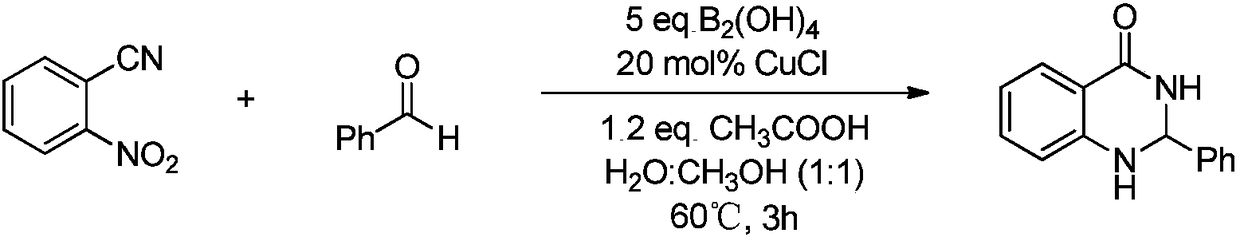

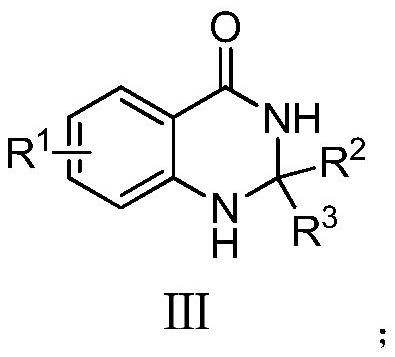

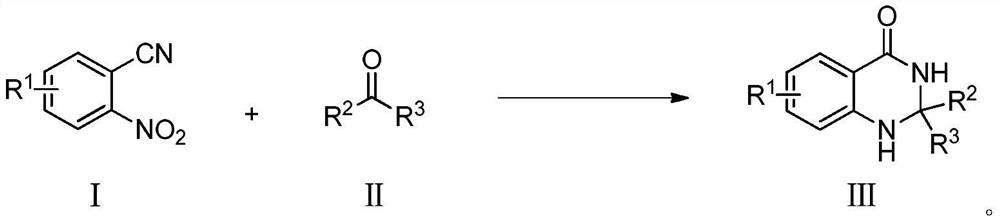

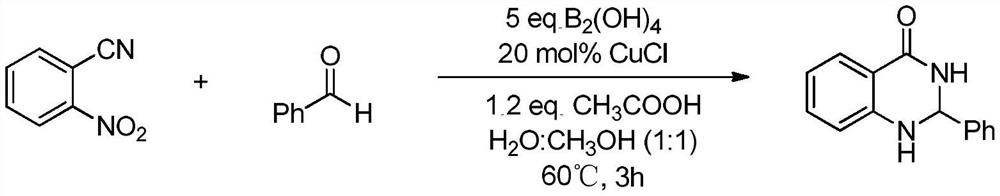

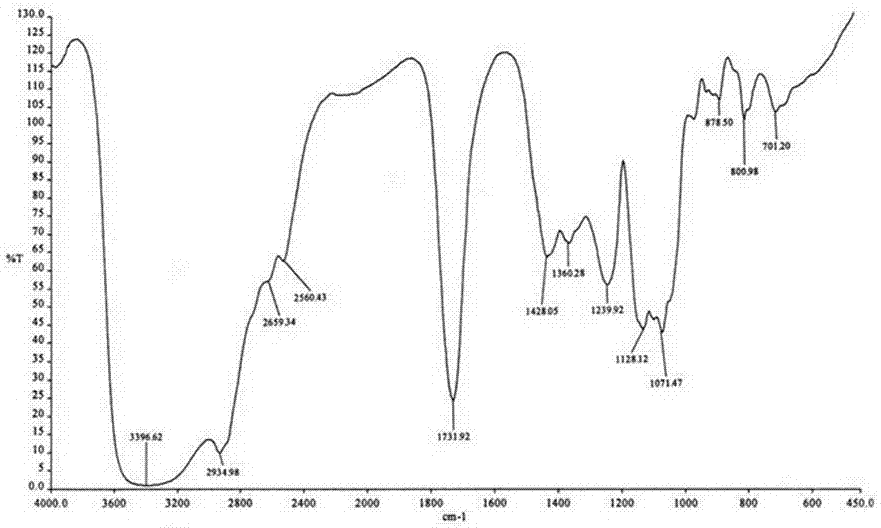

Dihydroquinoxalinone compound and preparation method thereof

ActiveCN108558778ARaw materials are easy to getSimple and fast operationOrganic chemistryKetoneSolvent

The invention relates to a dihydroquinoxalinone compound and a preparation method, and the specific structure is shown in III. The method uses cheap and readily available o-nitrobenzonitrile (I) and aldehyde or ketone (II) as raw materials, and alcohol and water as solvent. The target product (III) is obtained by a nitro reduction, a cyano hydrolysis, and a condensation reaction in a one-pot reaction system under the action of tetrahydroxydiboron, glacial acetic acid and catalytic amount of cuprous chloride. The preparation method uses 2-nitrobenzonitrile (I) as a raw material for the first time, which is easy to operate, easy to obtain raw materials, high in yield, and has the advantages of green synthesis such as step economy, atomic economy, mild reaction conditions and the like. The specific formula is shown in the description.

Owner:CHINA THREE GORGES UNIV

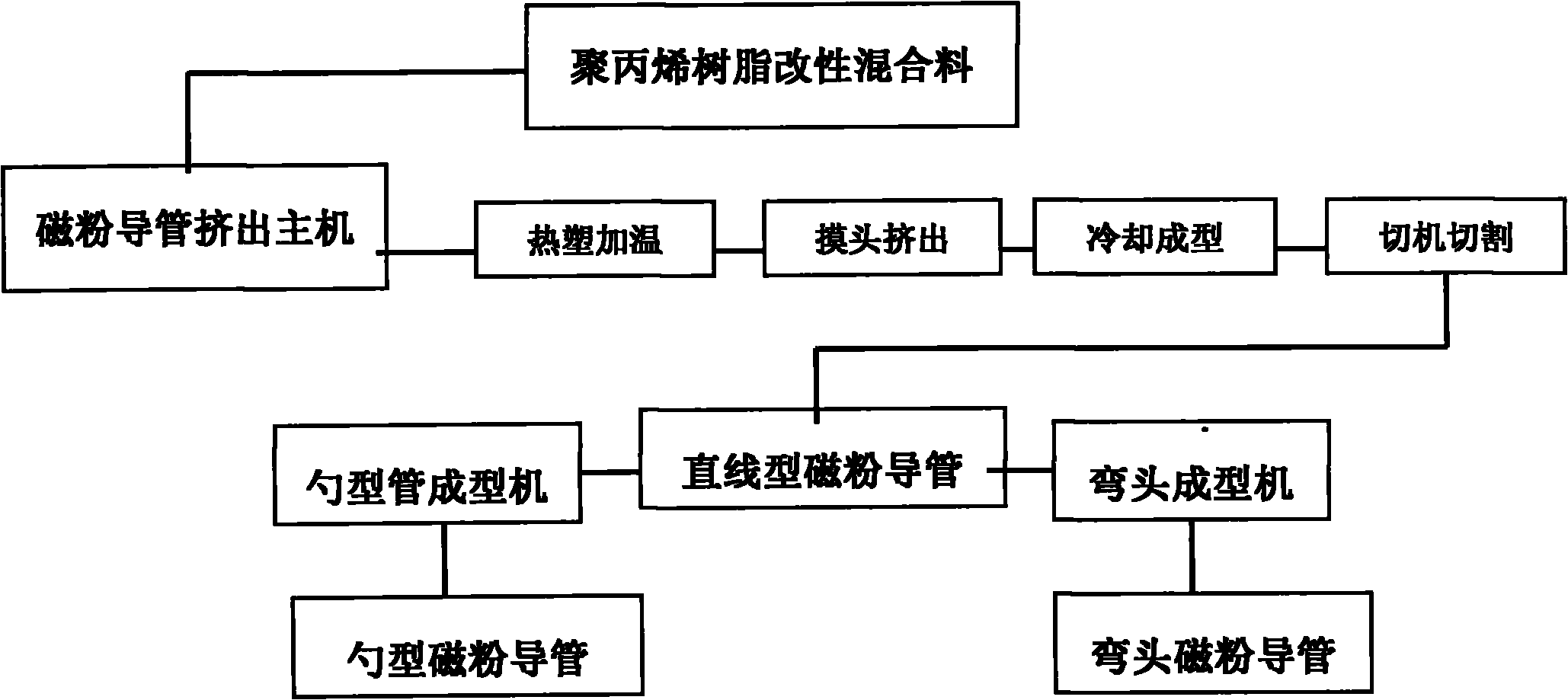

Preparation method for biomass degradation material and magnetic powder catheter

InactiveCN102140234AImprove impact resistanceGood flexibilityRigid pipesBiomass degradationFiller Excipient

The invention provides a preparation method for biomass degradation material, which comprises the following steps: (1) preparing raw materials: weighing the following compositions of raw materials by weight percentage: 40 to 60 of major ingredient poly( butylene succinate), 40 to 60 of modified material polylactic acid and 0.1 to 20 of filler calcium carbonate master batch; (2) mixing the compositions to form modified poly( butylene succinate) mixture; and (3) statically placing the modified mixture at low temperature for standby application. The invention also discloses a method for manufacturing a magnetic powder catheter by adopting the raw materials, which comprises the following steps: (4) preparing a magnetic powder catheter extrusion main machine and a round die head matched with the main machine for use; (5) feeding the modified poly( butylene succinate) mixture into the extrusion main machine so as to manufacture a continuous round hollow magnetic powder catheter; and (7) cutting the continuous round hollow magnetic powder catheter into magnetic powder catheter sections. The invention also provides the magnetic powder catheter prepared by the method. The materials provided by the invention can completely degrade. The method is scientific and reasonable; the production efficiency is high; the product performance is good; and the cost is low.

Owner:广州高馨能生物科技有限公司

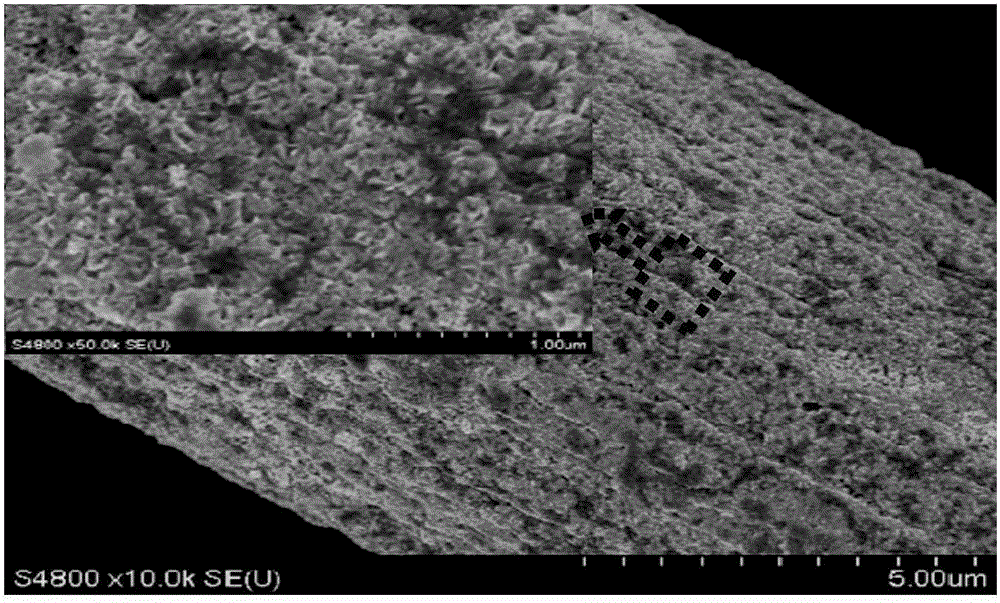

Preparation method of high-transparency degradable material and magnetic powder conduit

InactiveCN102101925AImprove and increase transparencyImprove and enhance the finishMaterial magnetic variablesBenzoic acidPolystyrene

The invention provides a preparation method of a high-transparency degradable material. The method is characterized by comprising the following steps of: (1) preparing raw materials, namely weighing the following raw material components in percentage by weight: 95-98 percent of polypropylene resin, 1-5 percent of polystyrene resin, 0.01-0.05 percent of food-grade benzoic acid and 0.1-0.5 percent of modified paraffin; (2) mixing the components to obtain a polypropylene resin modified mixture; and (3) standing the modified mixture at low temperature for later use. The invention also discloses a method for manufacturing a magnetic powder conduit by using the material. The method comprises the following steps of: (4) preparing a magnetic powder conduit main extruder and a circular die head used together with the main extruder; (5) feeding the modified mixture into the main extruder to obtain a continuous circular hollow magnetic powder conduit; and (7) cutting the obtained continuous linear magnetic powder conduit into magnetic powder conduit sections. The invention also provides the magnetic powder conduit manufactured by the method. The material provided by the invention is highly transparent and degradable. The method is scientific and reasonable, and has high production efficiency, high product performance and low cost.

Owner:广州高馨能生物科技有限公司

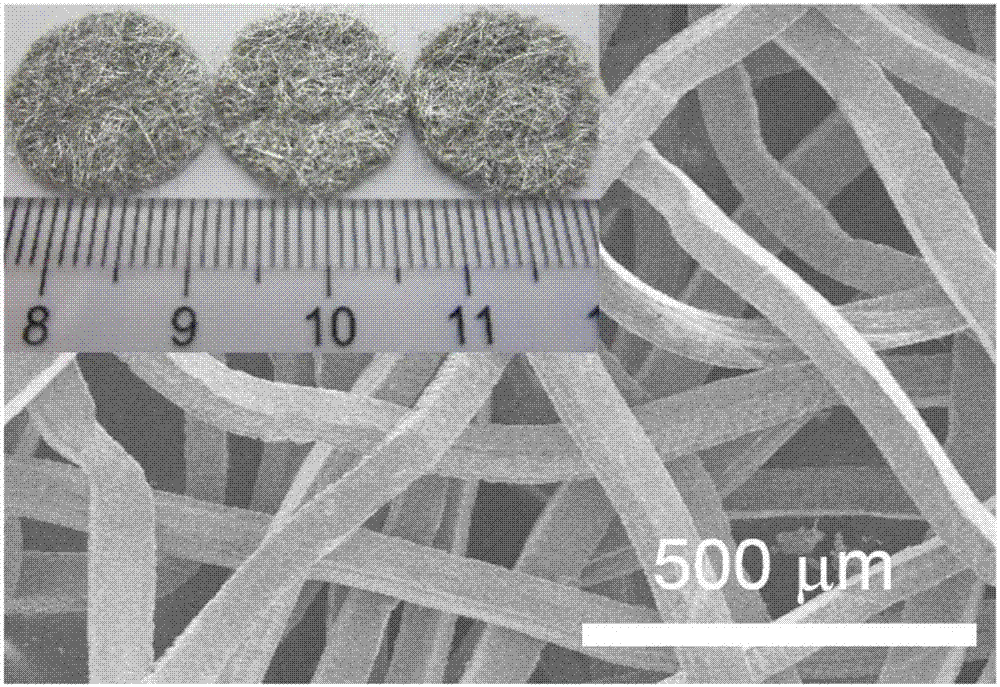

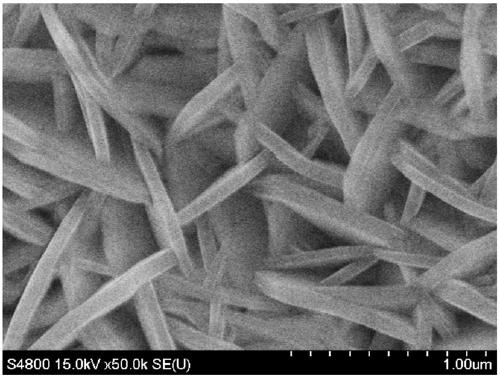

A kind of monolithic catalyst and its preparation method and application

ActiveCN104069869BStable structureOptimal Control StructureCatalyst carriersIncinerator apparatusHigh activityCatalytic combustion

Owner:EAST CHINA NORMAL UNIV

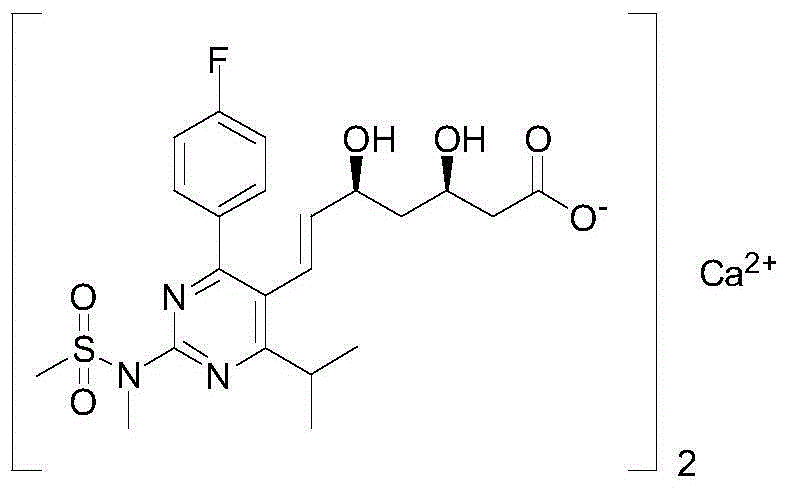

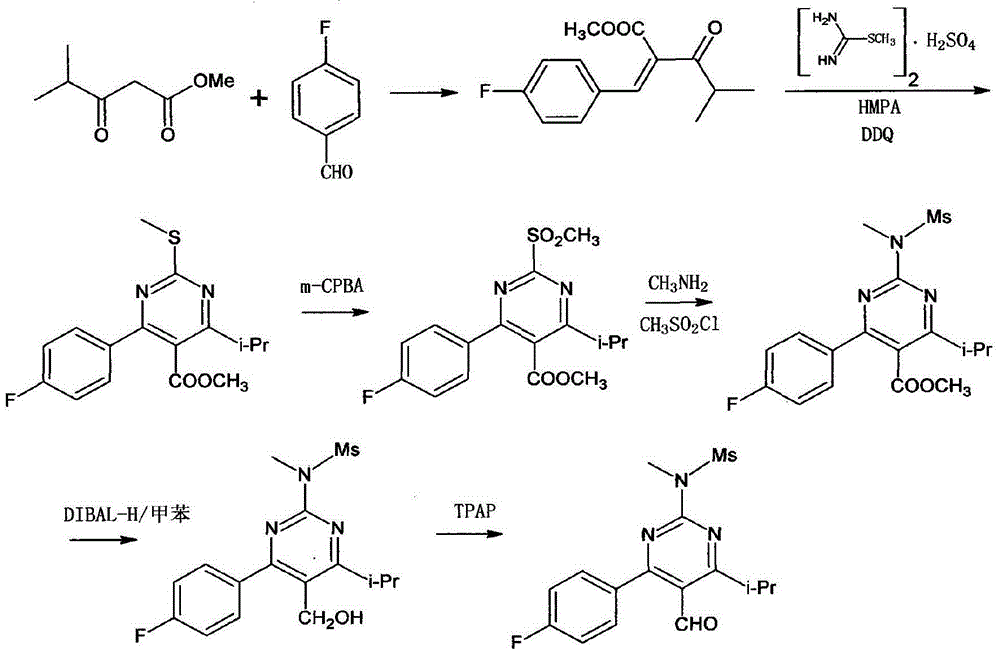

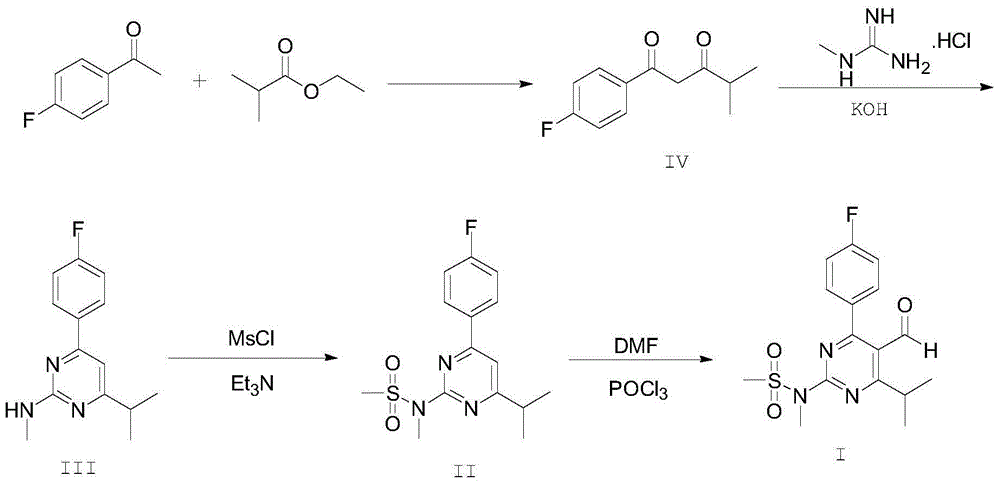

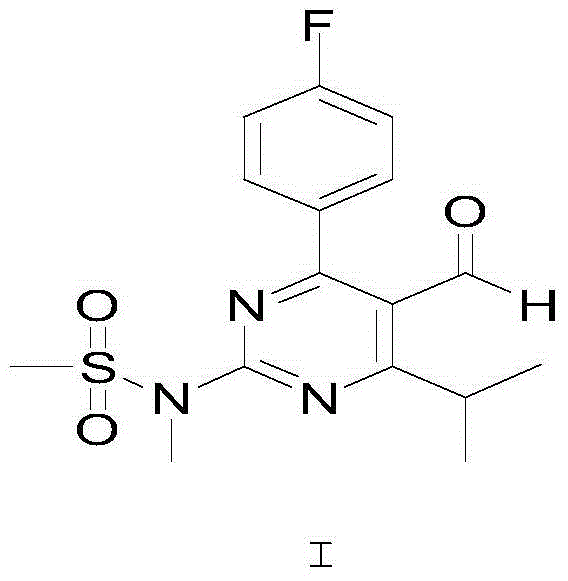

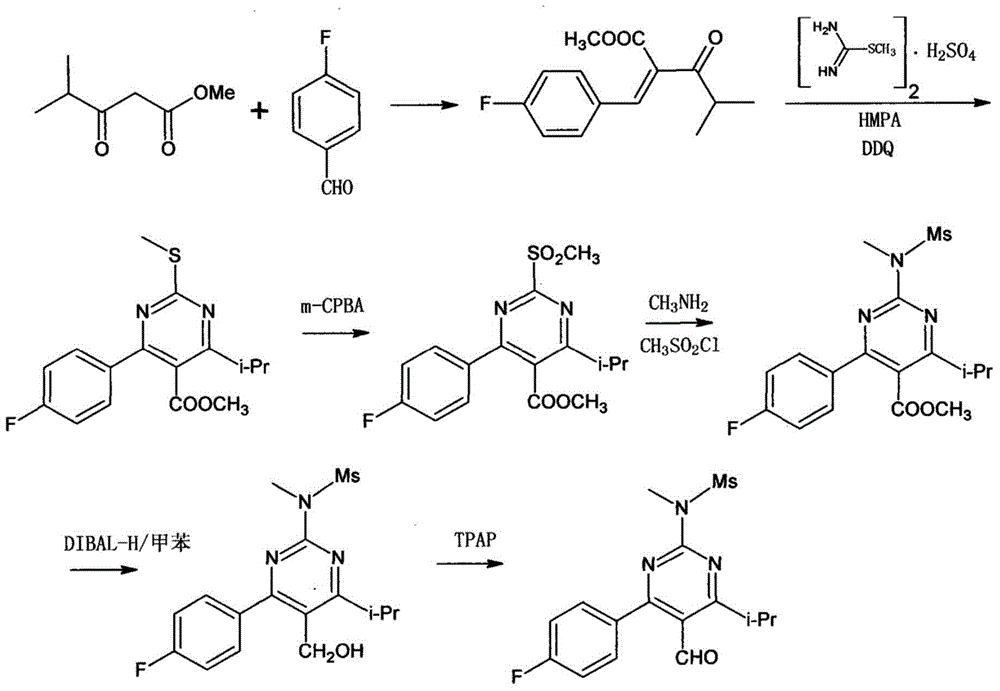

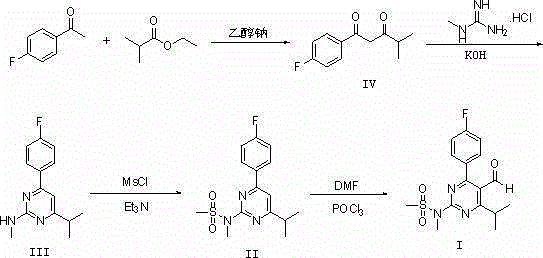

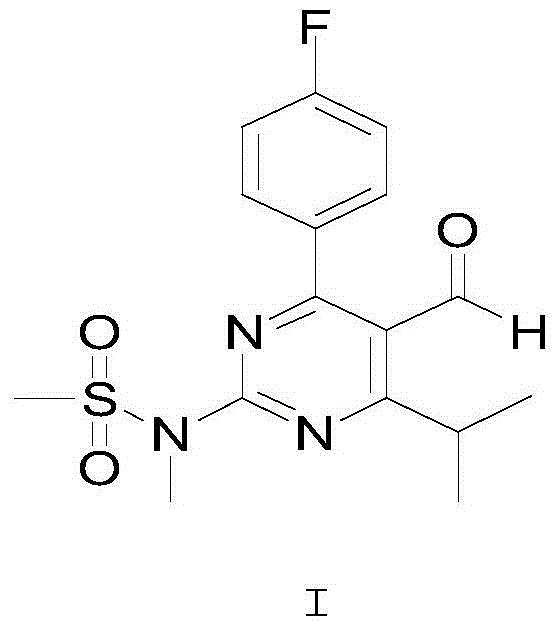

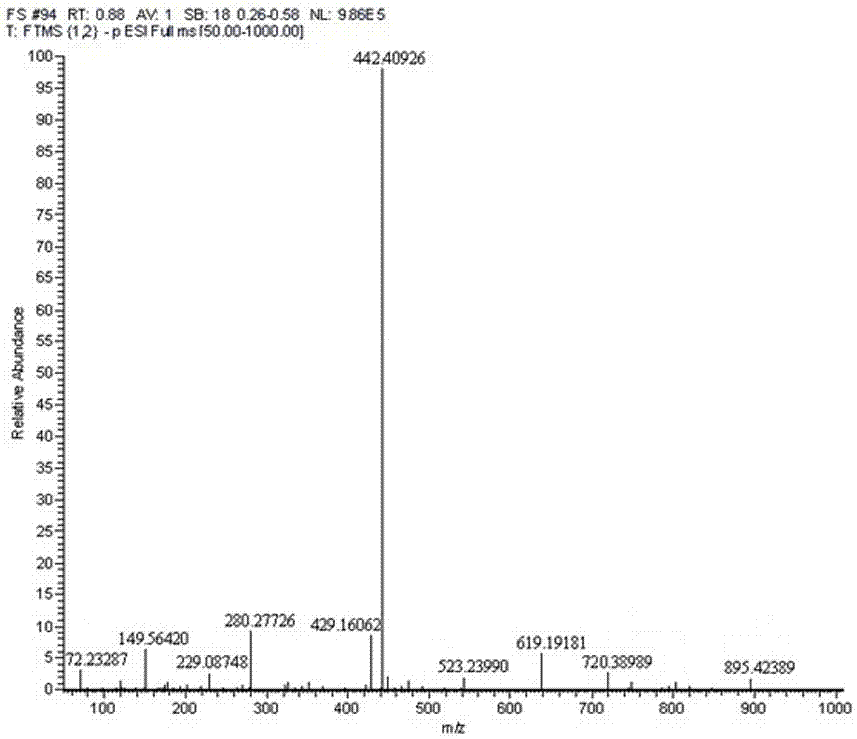

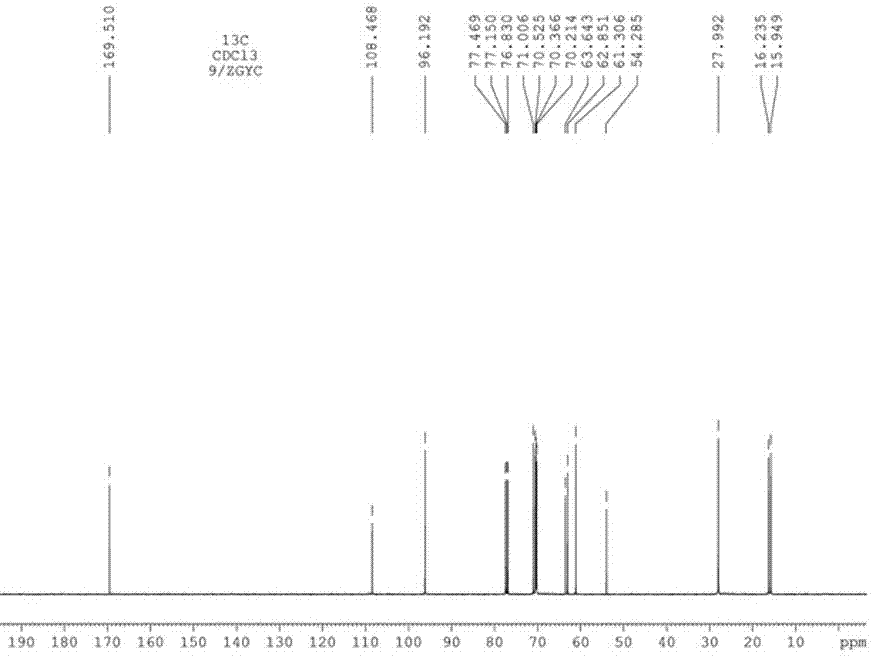

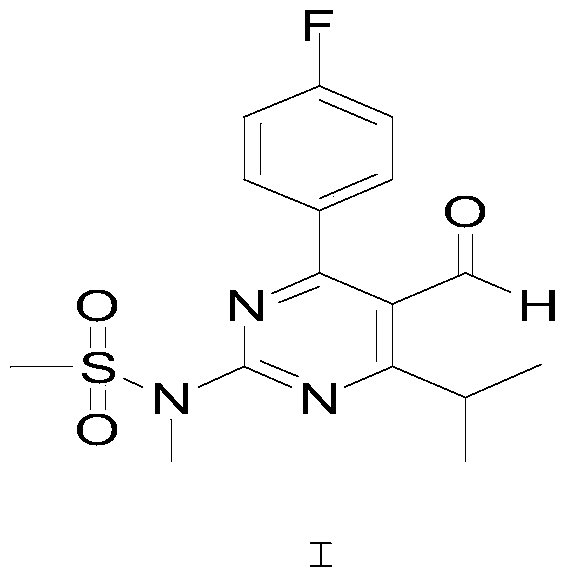

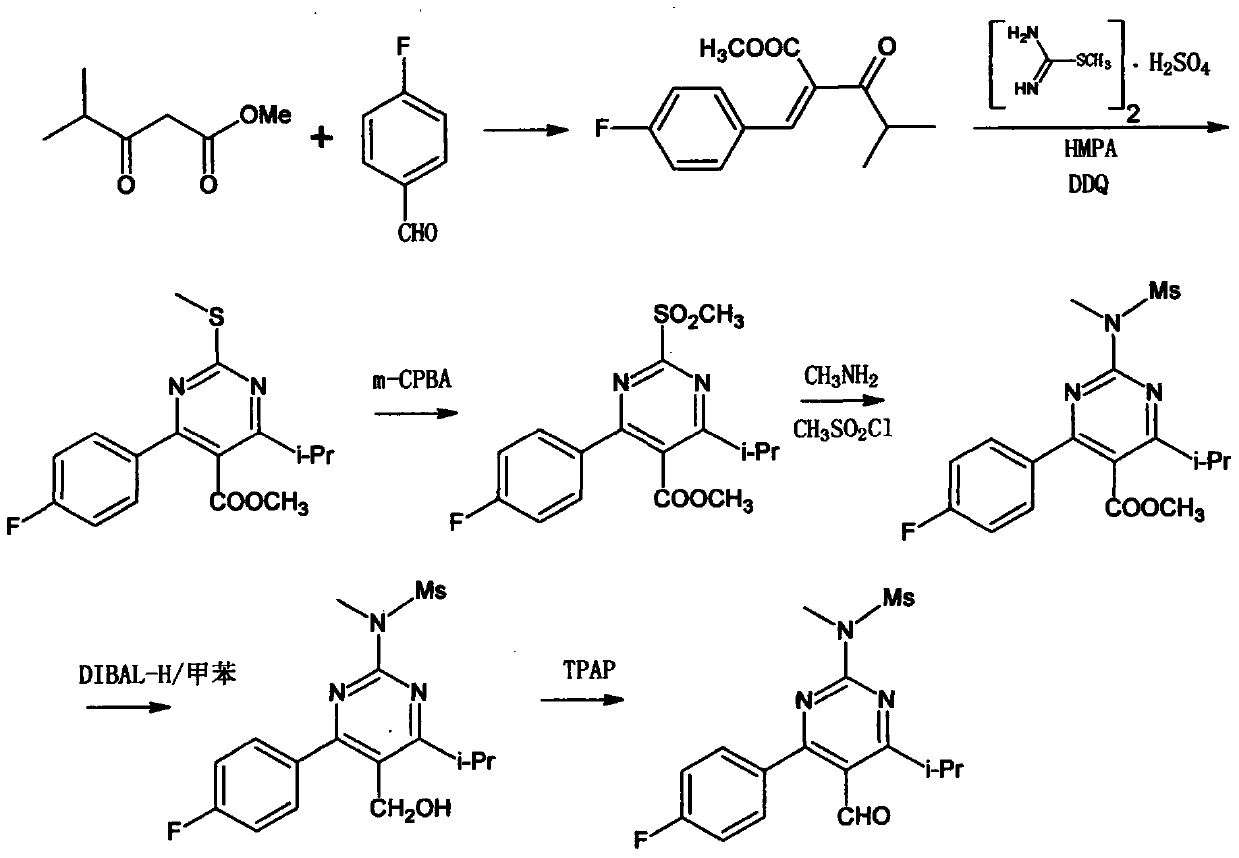

Preparation method of rosuvastatin calcium key intermediate

ActiveCN105622521AWide variety of sourcesEnsure safetyOrganic chemistryN dimethylformamidePotassium hydroxide

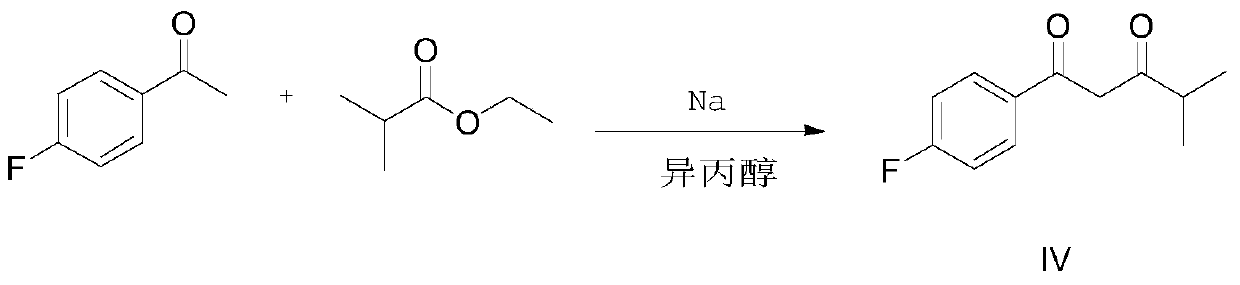

The invention discloses a preparation method of a rosuvastatin calcium key intermediate, i.e. a compound as shown in a formula I. The preparation method comprises the following steps: a, carrying out a reaction between fluoroacetophenone and ethyl isobutyrate to prepare a compound as shown in a formula IV; b, carrying out a reaction between the obtained compound IV and methylguanidine hydrochloride as well as potassium hydroxide to obtain a compound as shown in a formula III; c, carrying out a reaction between the compound III and triethylamine as well as methanesulfonyl chloride to prepare a compound as shown in a formula II; d, carrying out a reaction between the compound as shown in the formula II and N,N-dimethylformamide as well as phosphorus oxychloride to obtain the compound as shown in the formula I. A reaction route of the preparation method is as shown in the following: (referring to the specification). The method disclosed by the invention has the advantages of being simple to operate, low in raw material price, high in availability of used raw materials, mild in reaction conditions, low in equipment requirements and production cost, easy for scale production and the like, and has significance industrial application value.

Owner:重庆瑞泊莱医药科技有限公司

A method for synthesizing the key intermediate of rosuvastatin calcium

ActiveCN105712939BWide variety of sourcesReduce manufacturing costOrganic chemistry4-methylmorpholine N-oxideSolvent

Owner:重庆瑞泊莱医药科技有限公司

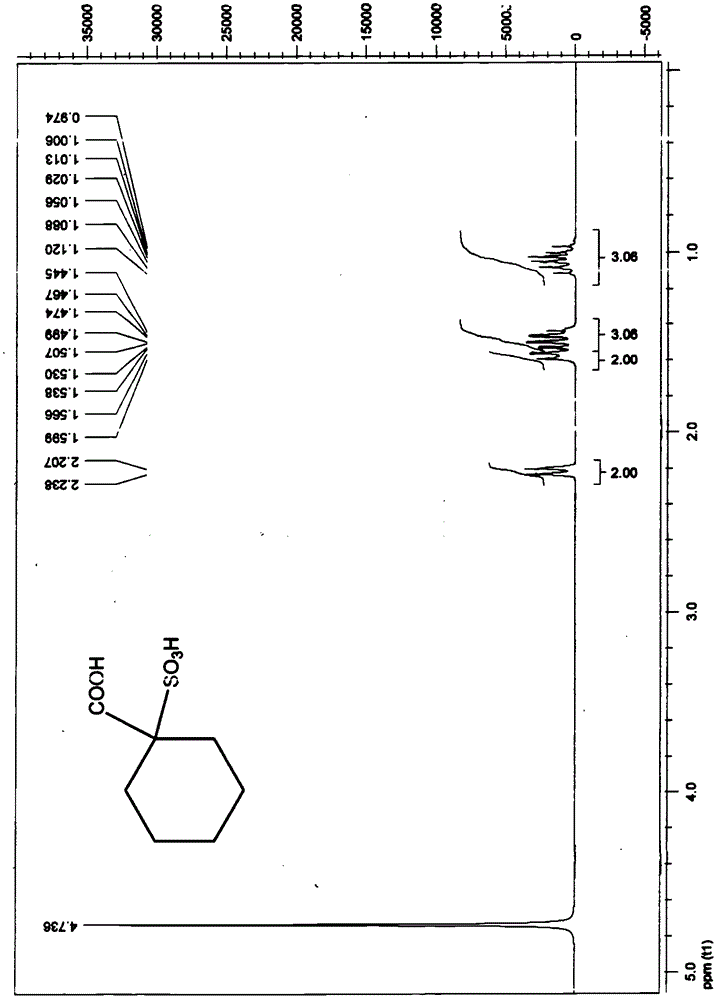

Method for preparing cyclohexyl formic acid sulfonic acid by using bipolar membrane method

InactiveCN106278959AImprove qualityHigh puritySemi-permeable membranesOrganic compound preparationCaprolactamImpurity

The invention provides a method for preparing cyclohexyl formic acid sulfonic acid from cyclohexyl formic acid sulfonate in process wastewater generated when caprolactam is produced by using a toluene method, by using a bipolar membrane electrodialysis technique. The method comprises the following step: converting cyclohexyl formic acid sulfonate in a cyclohexyl formic acid sulfonate solution into cyclohexyl formic acid sulfonic acid through bipolar membrane electrodialysis, wherein the bipolar membrane electrodialysis is achieved through three compartments, bipolar membranes, anode membranes and cathode membranes which are arranged alternatively; specific conditions are that the concentration of the cyclohexyl formic acid sulfonate solution is 5-30% (W / W), the voltage is 25V, the current density is 4-8A / dm<2>, and the reaction time is 3-4 hours. By adopting the method, a conventional concentrated sulfuric acid acidification method for preparing cyclohexyl formic acid sulfonic acid can be completely replaced, high-quality cyclohexyl formic acid sulfonic acid can be prepared, process steps are simple, meanwhile, pollution caused by a great deal of impurity sulfuric acid can be effectively avoided as parameter conditions are optimized, and remarkable industrial application values and environmental benefits can be obtained.

Owner:TIANJIN FUTESI TECH DEV

Preparation method of a three-dimensional carbon nanotube/textile fiber stretchable electrode material

ActiveCN105470003BImprove storage effectLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureWater bathsTextile fiber

The invention relates to a preparation method of a three-dimensional carbon nanotube / textile fiber stretchable electrode material, comprising: coating the pretreated textile fiber with graphene conductive adhesive on both sides, electrostatically flocking on both sides, and then placing it in a Add a biological cationic modifier to the water bath of the chemical agent; add soda ash to adjust the pH of the dye bath, wash and dry at 65-80°C; place the carbon nanotubes in the acid solution and reflux at 110°C for 4-5h to obtain Acidified carbon nanotubes: at room temperature, the dried textile fibers are placed in a compound preparation solution of a dispersant and acidified carbon nanotubes, ultrasonicated, impregnated, and dried to obtain the product. The process of the invention is simple and easy for industrialization, and the prepared three-dimensional carbon nanotube / textile fiber stretchable electrode material is easy to realize large-scale production, and is energy-saving and environmentally friendly, and has great industrial application value.

Owner:DONGHUA UNIV

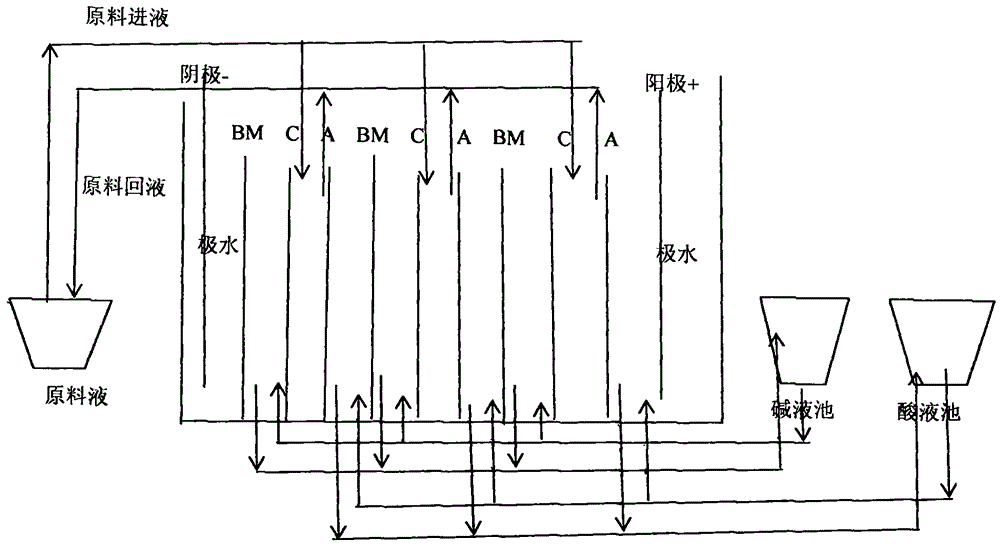

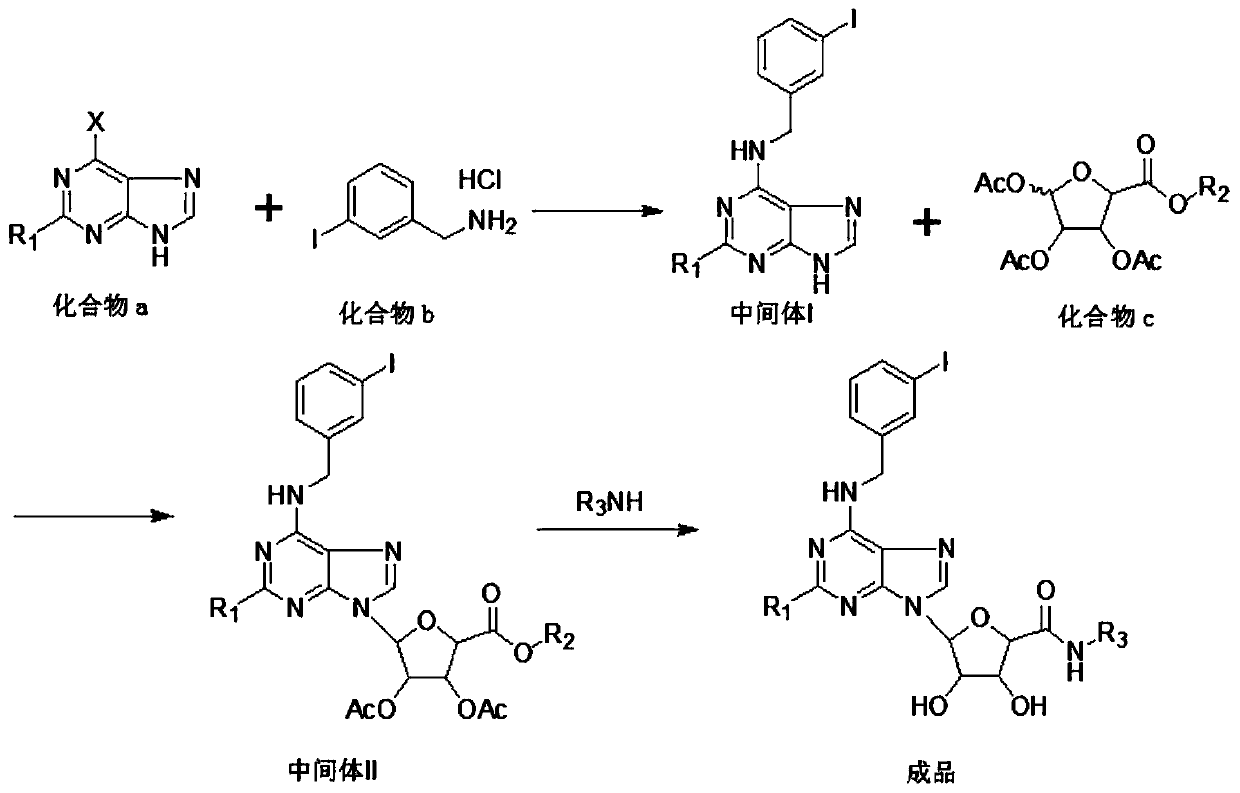

New synthetic process of anticancer drug CF-102

InactiveCN110003211AReduce pollutionMild reaction conditionsOrganic chemistryAmino estersPharmaceutical drug

The invention discloses a new synthetic process of an anticancer drug CF-102, and relates to the technical field of pharmaceutical production methods. The new synthetic process aims to solve problemsthat the synthetic method of CF-102 on the market has the characteristics of many steps, complicated operation and high production cost, and many steps are also needed to obtain a final product aftercondensation and the reaction route is not economical. The new synthetic process comprises the following steps: step 1: a compound a is used as a starting material, and a substitution reaction of thecompound a and m-iodobenzylamine hydrochloride is carried out to obtain an intermediate I; step 2: the intermediate I is condensed with a compound c to form a nucleoside bond to obtain an intermediateII; and step 3: amino-ester exchange and acetyl hydrolysis reaction of the intermediate II are synergistically carried out to obtain a final finished product.

Owner:江苏艾利瑞化学有限公司

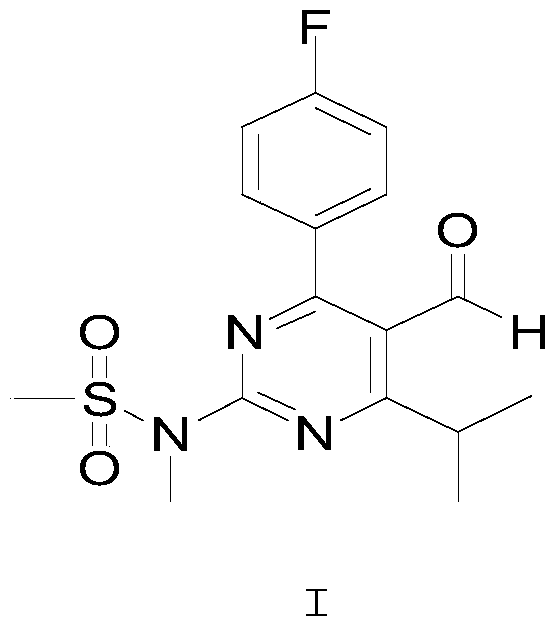

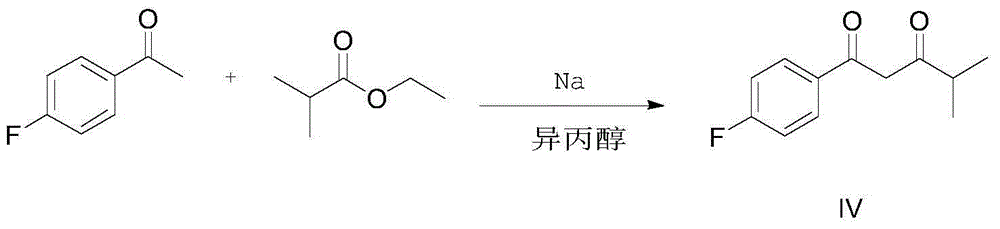

Synthetic method of rosuvastatin calcium key intermediate

ActiveCN105622522AWide variety of sourcesEnsure safetyOrganic chemistryMethanesulfonyl chlorideRosuvastatin Calcium

The invention discloses a synthetic method of a rosuvastatin calcium key intermediate. The synthetic method particularly comprises the following steps: carrying out a condensation reaction between fluoroacetophenone and ethyl isobutyrate under the condition of using sodium as alkali by using isopropyl alcohol as a solvent to prepare 1-(4-fluorophenyl)-4-methyl amyl-1,3-diketone; then carrying out a ring closing reaction between the 1-(4-fluorophenyl)-4-methyl amyl-1,3-diketone and methylguanidine hydrochloride by using isopropanol as a solvent to obtain 4-(4-fluorophenyl)-6-isopropyl-N-methyl pyrimidine-2-amine; carrying out a substitution reaction between the 4-(4-fluorophenyl)-6-isopropyl-N-methyl pyrimidine-2-amine and methanesulfonyl chloride by using dichloromethane as a solvent to obtain 4-(4-fluorophenyl)-6-isopropyl-2-[(N-methyl-N-methanesulfonyl) amino] pyrimidine; finally, carrying out a Vilsmeier reaction between the 4-(4-fluorophenyl)-6-isopropyl-2-[(N-methyl-N-methanesulfonyl) amidogen] pyrimidine and DMF (Dimethyl Formamide) as well as phosphoryl chloride to obtain a target compound. The method disclosed by the invention has the advantages of being simple to operate, low in raw material price, high in availability of used raw materials, mild in reaction conditions, low in equipment requirements and production cost, easy for scale production and the like, and has significance industrial application value.

Owner:重庆瑞泊莱医药科技有限公司

Preparation method of high transparent degradable material and suction tube

ActiveCN102070828BEnsure safetyHigh transparencyTablewaresTubular articlesBenzoic acidPolymer science

The invention provides a preparation method of a high transparent degradable material. The preparation method is characterized by comprising the following steps of: 1) preparing raw materials: based on weight percent, weighing the following raw material components: 95-98 of polypropylene resin, 1-5 of polystyrene resin, 0.01-0.05 of food-grade benzoic acid and 0.1-0.5 of modified paraffin; 2) mixing the components to form a modified polypropylene resin mixing material; and 3) carrying out low-temperature standing on the modified mixing material for later use. The invention also discloses a method for preparing a suction tube by using the above materials. The method for preparing the suction tube comprises the following steps of: 4) preparing a suction tube extruding main machine and a round die head matched with the main machine; 5) feeding the modified mixing material in the extruding main machine to obtain a continuous round hollow suction tube; and 6) cutting the prepared continuous linear type suction tube to suction tube sections. The invention further provides the suction tube prepared by the method. The material provided by the invention is highly transparent and degradable, the method is scientific and reasonable, the production efficiency is high, the product property is good, and the cost is low.

Owner:义乌市双童日用品有限公司

Preparation method of a three-dimensional aminated carbon nanotube array/stretchable textile fiber electrode material

ActiveCN105679555BGood stretchabilityImprove mechanical propertiesHybrid capacitor electrodesHybrid/EDL manufactureTextile fiberAdhesive

The invention relates to a preparation method of a three-dimensional aminated carbon nanotube array / stretchable textile fiber electrode material, comprising: placing pretreated textile fibers in a composite preparation containing a dispersant and aminated carbon nanotubes at room temperature immersion, drying, to obtain a conductive stretchable fiber substrate; the aminated carbon nanotubes are placed in the electrodeposition treatment solution to obtain the electrodeposited aminated carbon nanotubes; the conductive stretchable fiber substrate is evenly coated Cover with graphene conductive adhesive, electrostatically implant electrodeposited aminated nanotubes onto the surface of the substrate on one side to obtain a three-dimensional conductive electrode material, pre-bake, bake, and absorb the aminated carbon nanotubes floating on the surface. The method of the invention has simple procedures and can greatly reduce the cost while realizing large-scale production of high-capacitance electrodes.

Owner:DONGHUA UNIV

Sm2Co17 type rare earth permanent magnet material and preparation method thereof

ActiveCN113539596AExpanding the Scope of Ingredient DesignIncrease Fe contentInductances/transformers/magnets manufactureMagnetic materialsMetallurgySamarium cobalt

The invention relates to a Sm2Co17 type rare earth permanent magnet material and a preparation method thereof. The Sm2Co17 type rare earth permanent magnet material consists of the following components in percentage by mass: Sm, heavy rare earth, Co, Fe, Cu and Zr. The preparation method comprises the following steps: preparing a samarium cobalt-based rare earth permanent magnet material sintered blank, heating the sintered blank to 1150-1200 DEG C by adopting microwaves at a heating speed of 15-90 DEG C / min in a protective atmosphere, carrying out solid solution and heat preservation, rapidly cooling by circulating gas to obtain a microwave solid solution blank, heating the solid solution blank to 820-880 DEG C by adopting microwaves at a heating speed of 15-90 DEG C / min, carrying out aging and heat preservation for 20-170min, and cooling. The method is reasonable in process design and convenient to operate, the preparation period of the Sm2Co17 type rare earth permanent magnet material can be greatly shortened, the prepared Sm2Co17 type rare earth permanent magnet material is better in magnetic performance, and remarkable industrial application value and economic benefits are achieved.

Owner:CENT SOUTH UNIV

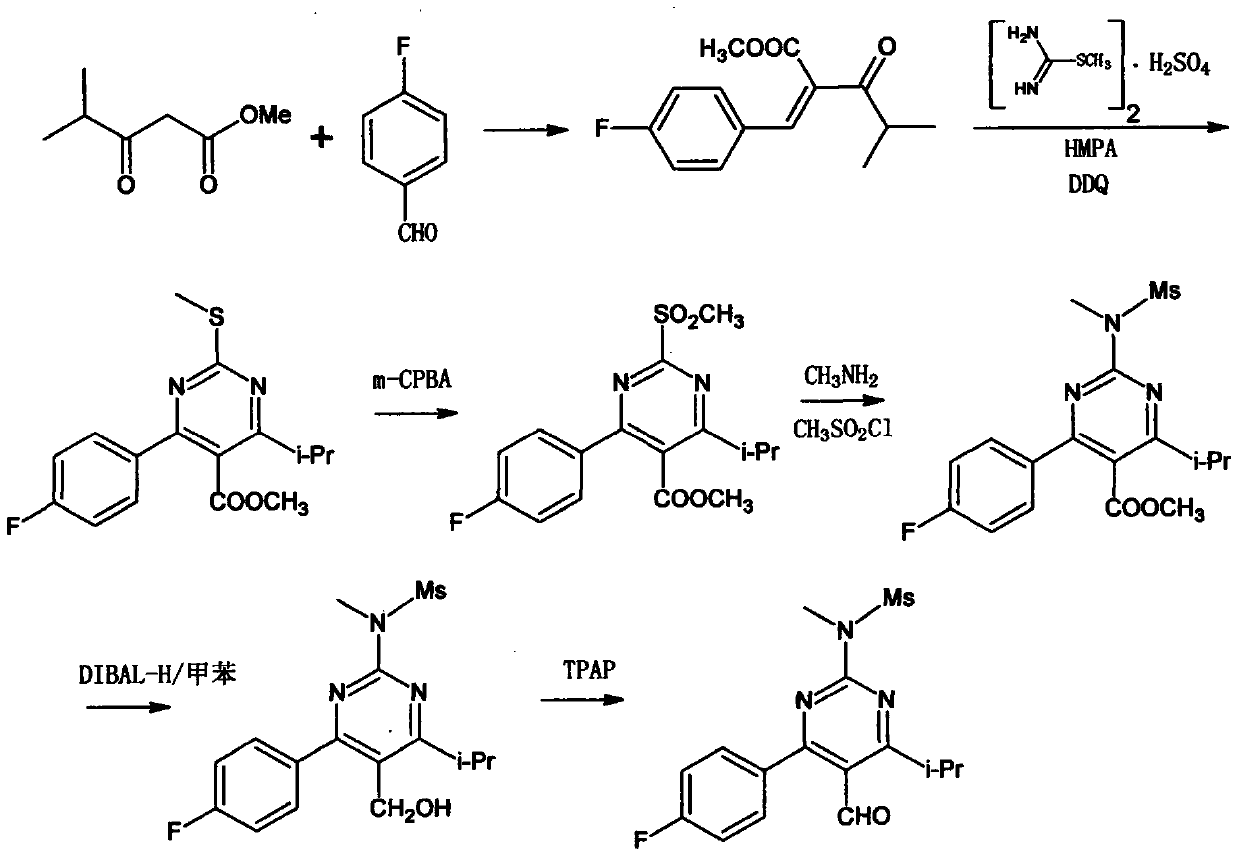

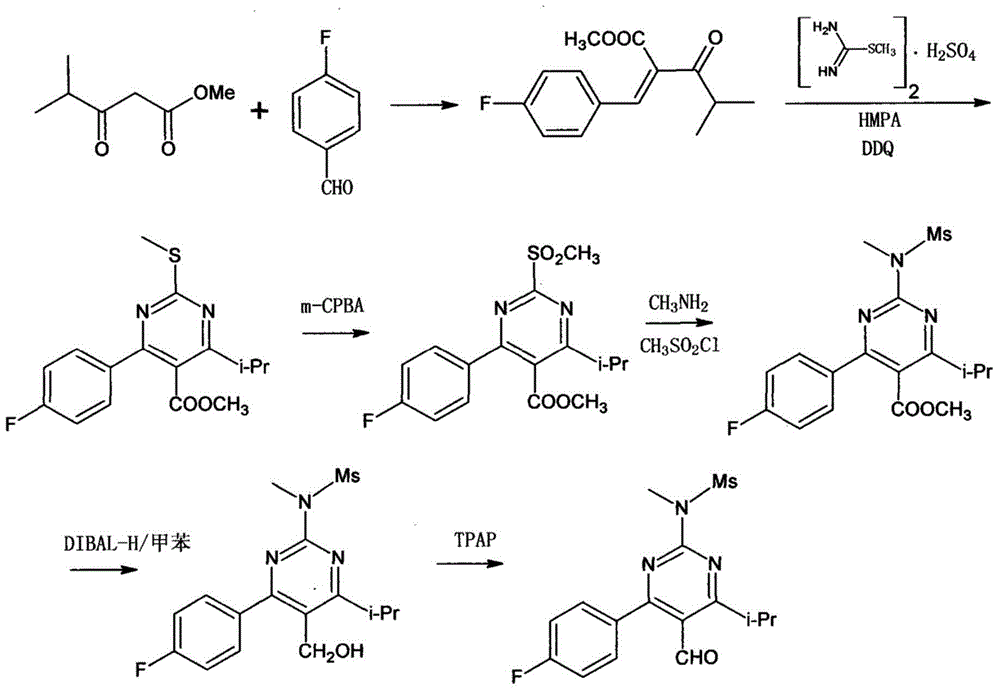

Method used for synthesizing rosuvastatin calcium key intermediate

ActiveCN105712939AWide variety of sourcesReduce manufacturing costOrganic chemistry4-methylmorpholine N-oxideRosuvastatin Calcium

The invention discloses a method used for synthesizing a rosuvastatin calcium intermediate represented by formula I. The reaction route is disclosed in the invention. Raw materials used in the method are low in toxicity; synchronous recycling of used solvents can be realized; expensive materials such as 4-methylmorpholine-N-oxide, TPAP (tetrapropylammonium perruthenate), and DIBAL-H are not used, so that production cost is reduced effectively; reaction conditions are mild; energy consumption is low; no special reaction equipment is needed; operation is simple; one-pot preparation can be realized; and the method is convenient for large-scale production.

Owner:重庆瑞泊莱医药科技有限公司

Dihydroquinazolone compounds and preparation methods thereof

ActiveCN108558778BRaw materials are easy to getSimple and fast operationOrganic chemistryNitrobenzeneKetone

The present invention relates to dihydroquinazolone compounds and a preparation method thereof, the specific structure of which is shown in III. The method uses cheap and easy-to-obtain o-nitrobenzonitrile (I) and aldehydes or ketones (II) as raw materials, alcohol and water as solvents, under the action of tetrahydroxydiboron, glacial acetic acid and a catalytic amount of cuprous chloride , the target product (III) was obtained through nitro reduction, cyano hydrolysis and condensation in a one-pot reaction system. The method uses 2-nitrobenzonitrile (I) as a raw material for the first time, and has the advantages of simple operation, easy-to-obtain raw material and high yield, and has the advantages of green synthesis such as step economy, atom economy, and mild reaction conditions.

Owner:CHINA THREE GORGES UNIV

Monomer flavor mal-val for tobacco, preparation method and application thereof

ActiveCN104341466BSimple processRaw materials are easy to getSugar derivativesTobacco treatmentFlavorIrritation

The invention relates to a novel monomer spice Mal-Val for cigarettes, a preparation method and an application thereof. The Mal-Val structure is as follows:. The present invention conducts the physical moisturizing performance test and internal sensory quality evaluation of the monomer fragrance, and finds that it can significantly improve the physical moisturizing performance of shredded tobacco, and at the same time significantly improve the sensory quality of cigarettes, reduce irritation and miscellaneous gas, and improve It enhances the mellowness of cigarette smoke.

Owner:CHINA TOBACCO HENAN IND

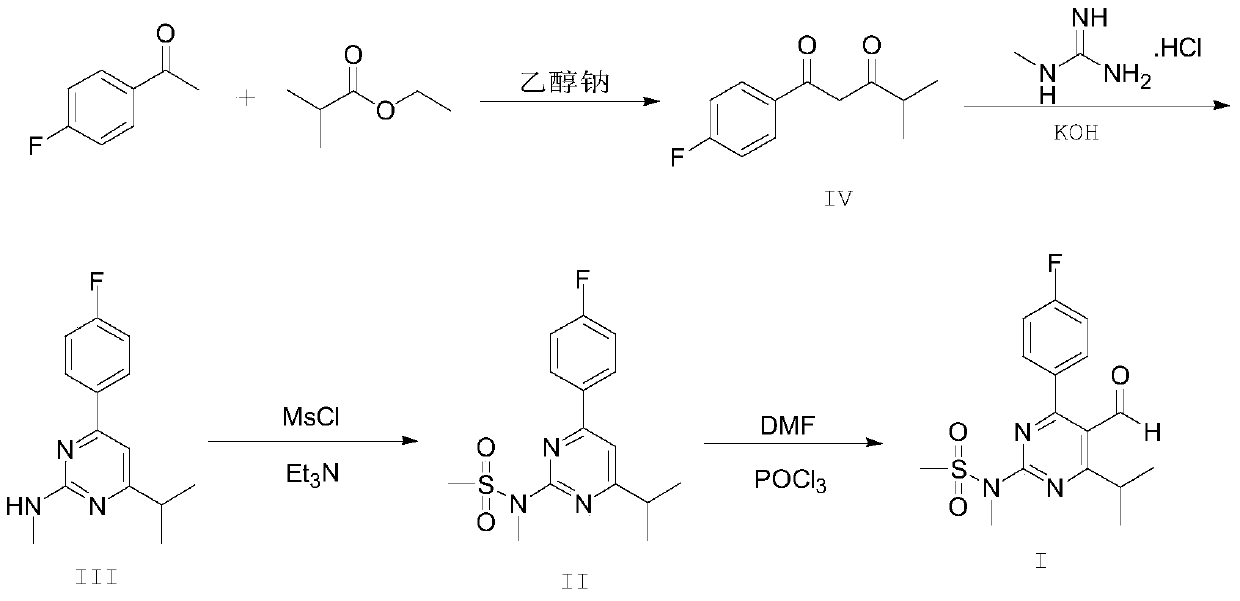

A kind of synthetic method of rosuvastatin calcium key intermediate

ActiveCN105622522BWide variety of sourcesEnsure safetyOrganic chemistryRosuvastatin CalciumMethanesulfonyl chloride

The invention discloses a synthesis method of rosuvastatin calcium intermediate formula I; the details are as follows: under the condition of using p-fluoroacetophenone and ethyl isobutyrate under the condition of sodium as base and isopropanol as solvent, after condensation The reaction produces 1-(4-fluorophenyl)-4-methylpentane-1,3-diketone; then with methylguanidine hydrochloride using isopropanol as a solvent, ring-closing reaction occurs to obtain 4-(4 ‑Fluorophenyl)‑6‑isopropyl‑N‑methylpyrimidine‑2‑amine; then with methanesulfonyl chloride using dichloromethane as a solvent, a substitution reaction occurs to obtain 4‑(4‑fluorophenyl)‑6‑ Isopropyl-2-[(N-methyl-N-methylsulfonyl)amino]pyrimidine; finally Vilsmeier reaction with DMF and phosphorus oxychloride to obtain the target compound. The method of the invention has the advantages of simple operation, cheap and readily available raw materials, mild reaction conditions, low equipment requirements, low production cost, easy large-scale production, etc., and has significant industrial application value.

Owner:重庆瑞泊莱医药科技有限公司

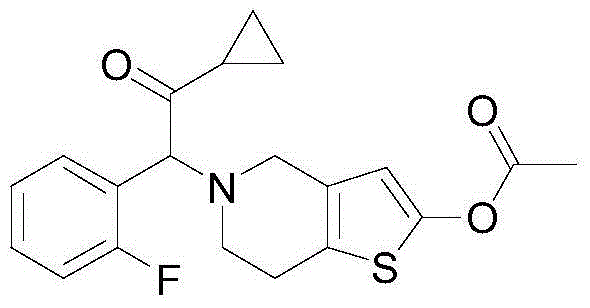

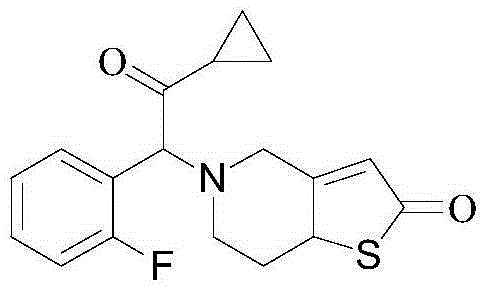

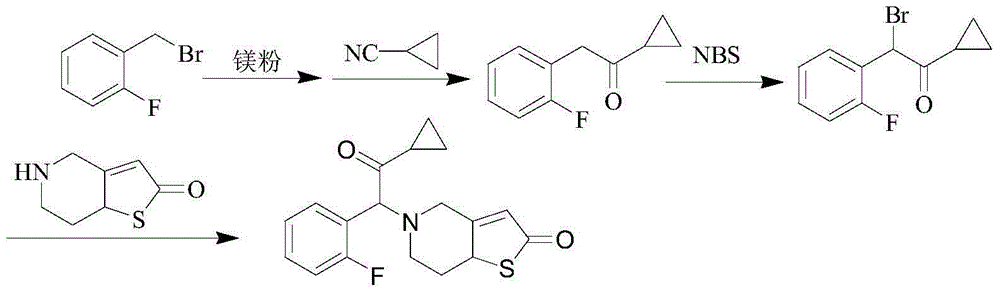

Method for preparing prasugrel intermediate

The invention discloses a method for preparing a prasugrel intermediate 5-(alpha-cyclopropylcarbonyl-2-fluorobenzyl)-2-oxo-1,4,5,6,7,7a-hexahydrothieno[3,2-c]pyridine. The method comprises a following reaction route. As a result of experiments, the method provided by the invention has the advantages of simple operation, mild reaction conditions, low requirement on equipment, inexpensive and easy-to-obtain raw materials, high yield, and low production cost. An adopted solvent can synchronously recovered. The method can be easily applied in large-scale productions. The method meets the requirements of prasugrel industrialized production, and has industrial application value.

Owner:重庆瑞泊莱制药有限公司

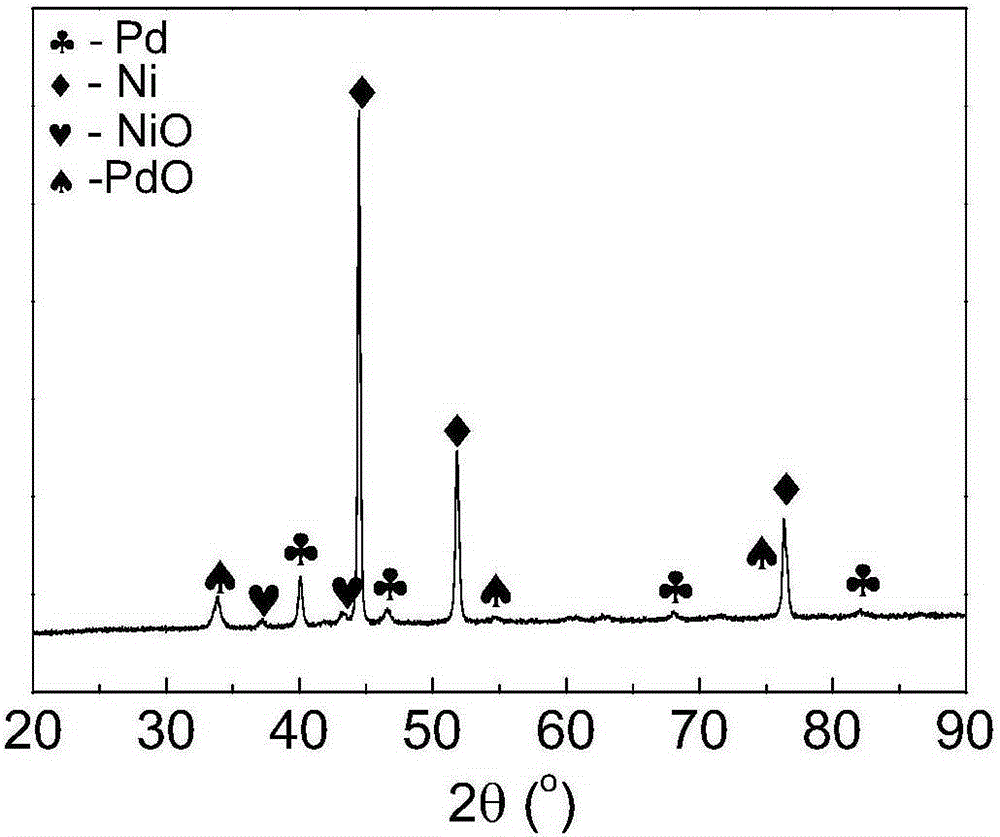

A kind of monolithic palladium catalyst and its preparation method and application

ActiveCN103977813BStable structureOptimal Control StructureCatalyst carriersOrganic compound preparationOrganic acidNitrous acid ester

The invention discloses an integrally-used palladium catalyst, a preparation method and an application. The integrally-used palladium catalyst is a catalyst loading a palladium metal or a palladium metal and auxiliary agent metal oxide on a metal phase carrier of a porous anchors oxide. The preparation method of the catalyst comprises the following steps: performing porous treatment on a metal phase frame or the metal phase frame through alloyage treatment by acid or alkali for roasting, preparing the metal phase carrier of the porous anchors oxide, then performing isopyknic dipping treatment and roasting the prepared metal phase carrier by a palladium-containing ionic solution, or a palladium ion-containing solution and a M1 ion-containing solution, and a mixture of palladium ion-containing solution and M1 ion-containing solution, and then prepared the integrally-used palladium catalyst. The integrally-used palladium catalyst can be used for reacting carbon monoxide and nitrous acid ester for synthesis of oxalic acid diester, reacting of nitrous acid ester through catalytic decomposition for synthesis of organic acid ester and reacting of carbon monoxide and nitrous acid ester for synthesis of carbonic acid diester.

Owner:易高卓新节能技术(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com