Preparation method of high-performance thermochromic material and suckers

A technology of thermochromic and thermochromic powder, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, table utensils, etc., can solve the problems of scalding children, unsanitary, etc. The effect of industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example 1:

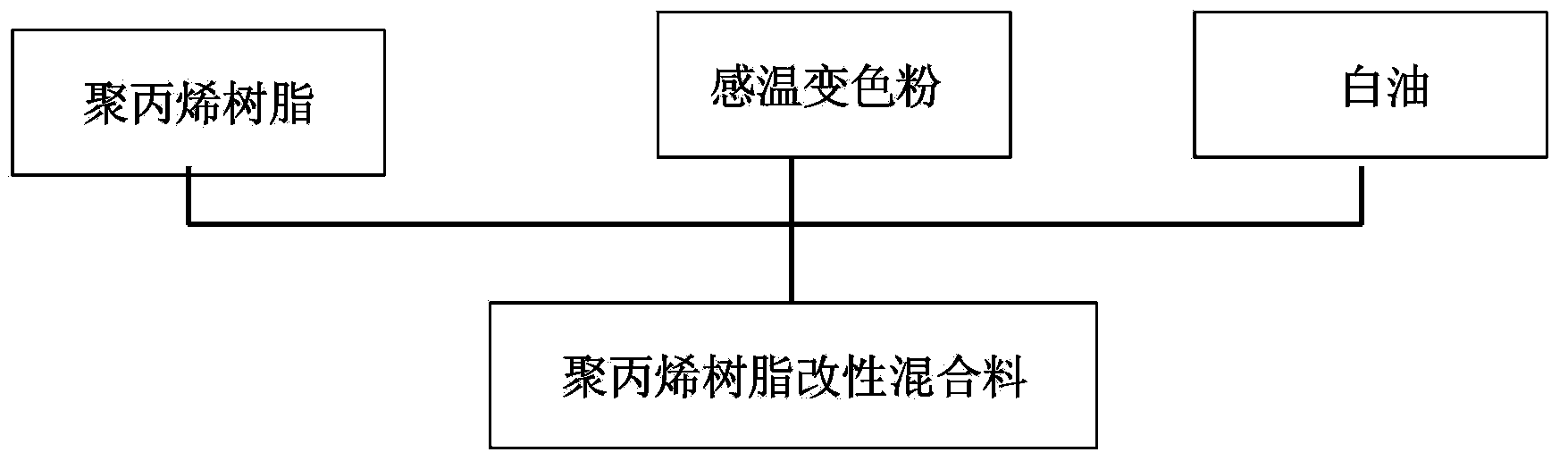

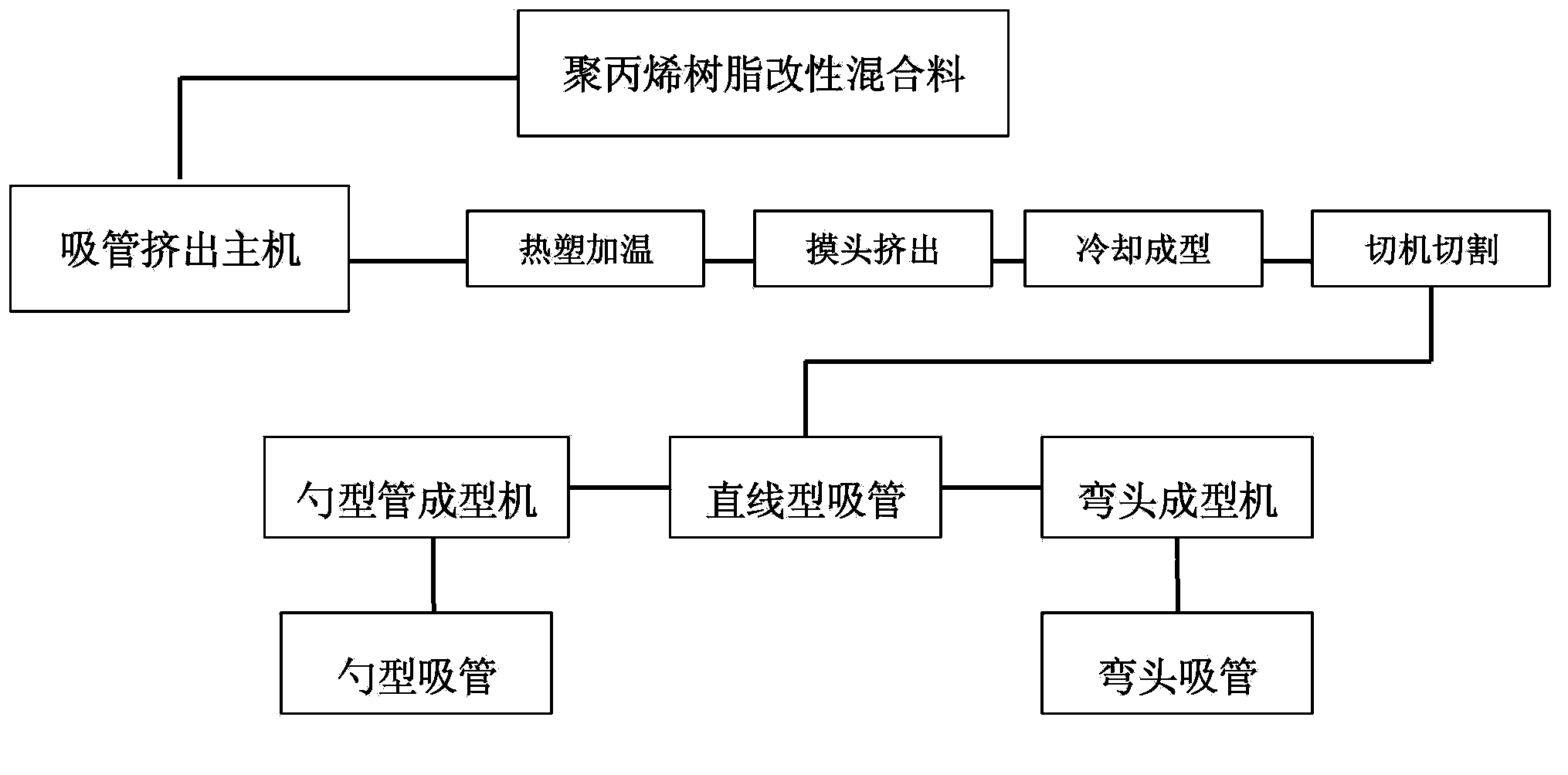

[0029] See figure 1 , The method for preparing the high-performance thermochromic material provided by the embodiment of the present invention includes the following steps:

[0030] 1) Preparation of raw materials: According to weight percentage, weigh the following raw material components:

[0031] Polypropylene resin 95-99.8, thermochromic powder 0.1-4.9, white oil 0.1-0.5. Adjust the weight percentage of the thermochromic powder according to the color depth; the thermochromic powder is a powdered reversible organic thermochromic material purchased from the market or prepared according to conventional methods, such as fluorane compounds as the color-developing agent The thermochromic materials, etc. According to the application temperature of the general straw (that is, the temperature at which liquid may be absorbed in daily life), the color change temperature of the thermochromic powder is set to: 31℃, 38℃, 43℃, 45℃, and the thermochromic powder can be adjus...

Example Embodiment

[0046] Example 2:

[0047] The method for preparing the high-performance thermochromic material provided by the present invention includes the following steps:

[0048] 1) Preparation of raw materials: According to weight percentage, weigh the following raw material components:

[0049] Polypropylene resin 95, thermochromic powder 4.9, white oil 0.1.

[0050] 2) Mixing of components:

[0051] 2.1) Firstly, the above components are prepared into 100-300 mesh powder, and dried;

[0052] 2.2) Weigh 1 / 3 of the total polypropylene resin, add all the thermochromic powder, stir and mix; the thermochromic powder and polypropylene resin particles should be fully mixed evenly;

[0053] 2.3) Then gradually add the remaining polypropylene resin and white oil and stir and mix until the addition is complete, so that the powder components are uniformly mixed to form a polypropylene resin modified mixture;

[0054] 3) Put the polypropylene resin modified mixture under low temperature conditions, vacuum, a...

Example Embodiment

[0064] Example 3:

[0065] The preparation method of the high-performance thermochromic material, the preparation method of the straw, and the straw provided in this implementation are basically the same as those in Examples 1 and 2, except that the method of preparing the high-performance thermochromic material in:

[0066] The weight percentage of each component in the step 1) is: the main material polypropylene resin 99.8, the temperature sensitive color powder 0.1, and the white oil 0.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com