Supported nickel-based alloy catalyst as well as preparation method and application thereof

A nickel-based catalyst and nickel-based alloy technology, applied in the field of catalysis, can solve the problems of complex preparation process, difficulty in activating ester group, high ratio of reaction hydrogen to ester, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

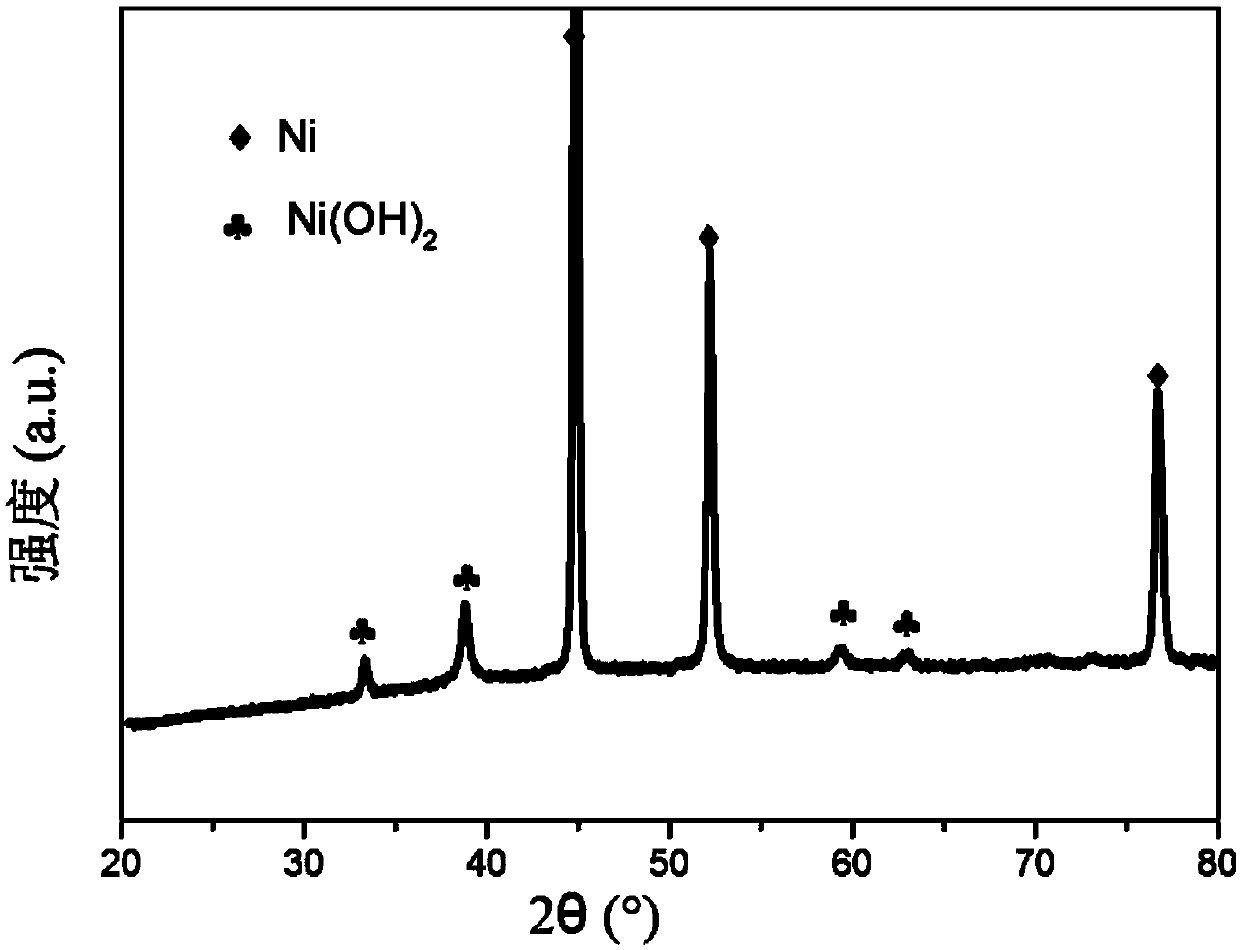

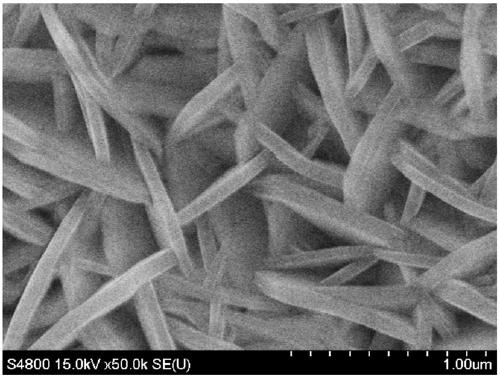

[0080] 1) Weigh 1 gram of foamed nickel (110PPI), put it in a 1% aqueous solution of sodium carbonate and ultrasonically treat it for 30 minutes, remove surface oil stains, wash it with distilled water, and then place the foamed nickel in 1 mol / liter of dilute hydrochloric acid Ultrasonic treatment in the solution for 30 minutes to remove surface oxides, wash with distilled water until the solution is neutral; then transfer the foamed nickel to an autoclave, add 20 mmol of nickel nitrate, 80 mmol of ammonium chloride, and 80 ml of water, At 100°C, hydrothermal reaction for 6 hours, the reaction was completed, the temperature was naturally lowered to room temperature, the distilled water was taken out for ultrasonic cleaning, and dried at 100°C to obtain a supported nickel-based catalyst with a nickel hydroxide crystal layer grown in situ on the carrier precursor;

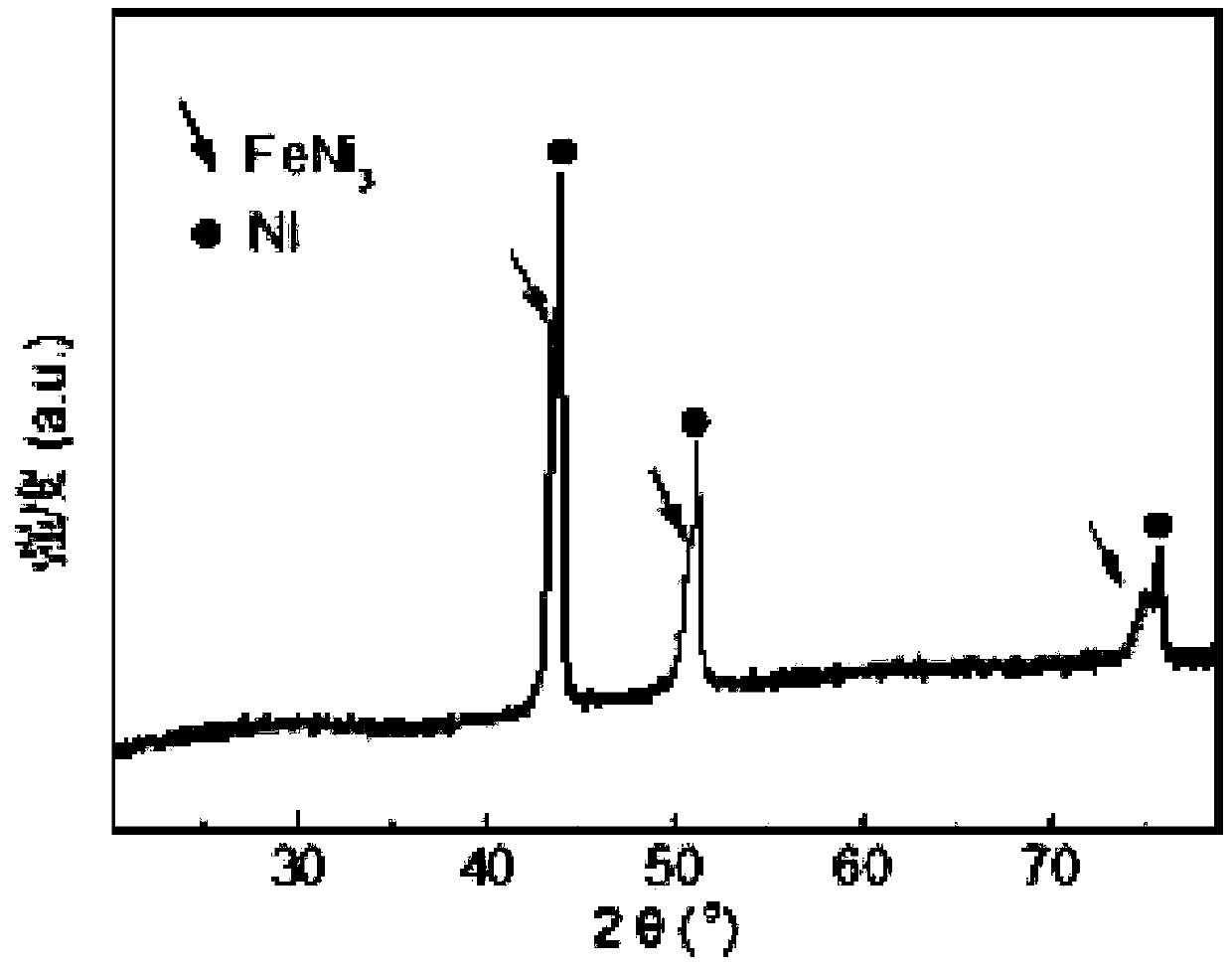

[0081] 2) Take by weighing 1.73 grams of ferric nitrate nonahydrate and dissolve in 0.7 gram of water to obtain a...

Embodiment 2

[0102] 1) Weigh 1 gram of foamed nickel (110PPI), put it in a 1% aqueous solution of sodium carbonate and ultrasonically treat it for 30 minutes, remove surface oil stains, wash it with distilled water, and then place the foamed nickel in 1 mol / liter of dilute hydrochloric acid The solution was ultrasonically treated for 30 minutes to remove surface oxides, and washed with distilled water until the solution was neutral; then the nickel foam was transferred to an autoclave, and 180 mmol of oxalic acid, 15 mmol of ammonium chloride, and 80 ml of water were added. Under 180°C, hydrothermal reaction for 24 hours, finish the reaction, naturally cool down to room temperature, take out distilled water, ultrasonically clean, and dry at 100°C to obtain a supported nickel-based catalyst precursor with a nickel oxalate crystal layer grown in situ on the carrier ;

[0103] 2) Weigh 0.55 grams of zinc nitrate and dissolve in 0.7 grams of water to obtain an aqueous solution containing zinc ...

Embodiment 3

[0118] 1) Weigh 1 gram of foamed nickel (110PPI), put it in a 1% aqueous solution of sodium carbonate and ultrasonically treat it for 30 minutes, remove surface oil stains, wash it with distilled water, and then place the foamed nickel in 1 mol / liter of dilute hydrochloric acid Ultrasonic treatment in the solution for 30 minutes to remove surface oxides, washing with distilled water until the solution is neutral; then transfer the foamed nickel to an autoclave, add 80 mmoles of terephthalic acid, 80 mmoles of nickel nitrate, 80 ml of di Methylformamide, at 140 ° C, solvothermal reaction time of 24 hours, the reaction is completed, the temperature is naturally cooled to room temperature, the distilled water is taken out and ultrasonically cleaned, and dried at 100 ° C, that is, the in-situ growth of nickel terephthalate on the carrier Supported nickel-based catalyst precursors for crystalline layers;

[0119] 2) Take by weighing 0.52 gram of tin protochloride and be dissolved i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com