A self-supporting catalyst having a core-shell structure, a preparing method thereof and applications of the catalyst

A catalyst and self-supporting technology, applied in the field of catalysis, can solve problems such as low pressure drop, and achieve the effects of easy molding, controllable overall structure, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1. Take 5 grams of foamed nickel, treat it with 1wt% dilute nitric acid for 10 minutes, wash it with distilled water and put it into a stainless steel hydrothermal kettle, add 0.714 grams of sodium metaaluminate (NaAlO 2 ) and 2.016 grams of urea (NH 2 CONH 2 ) mixed solution 70 milliliters, hydrothermal treatment at 120 ℃ for 12 hours. After cooling down to room temperature, wash with distilled water for several times and dry to obtain a self-supporting AlOOH / Ni-foam composite carrier containing abundant surface hydroxyl groups and anchoring flaky pseudo-boehmite;

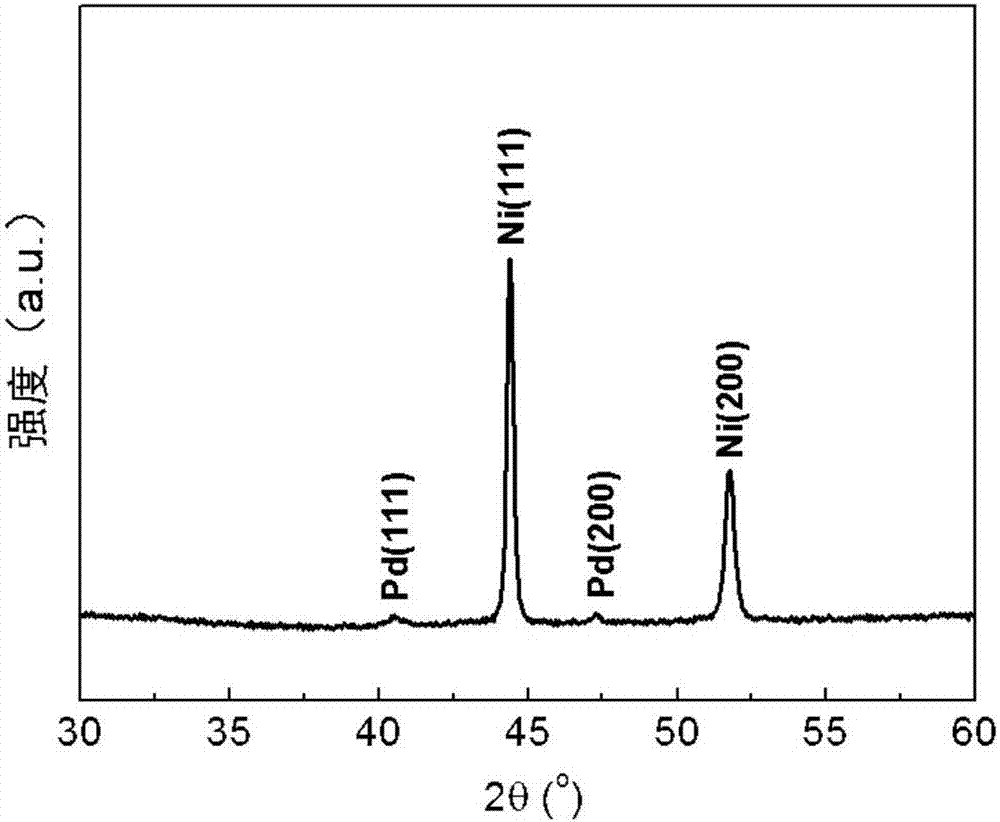

[0056] 2, take by weighing 5 grams of the self-supporting AlOOH / Ni-foam composite carrier that step 1 makes, use Pd(NO 3 ) 2and 0.352 grams of γ-(methacryloyloxy)propyltrimethoxysilane (KH570) in acetone solution, at room temperature for 4 hours equal-volume impregnation, after drying, in nitrogen at 550 ° C roasting for 2 hours, that is γ-Al 2 o 3 Pd@SiO loaded on the nickel foam support 2 Core-shel...

Embodiment 2

[0068] 1, with the step 1 of embodiment 1;

[0069] 2, take by weighing 5 grams of the self-supporting AlOOH / Ni-foam composite carrier that step 1 makes, use Pd(NO 3 ) 2 , 0.125 g CeO 2 Ce(NO 3 ) 2 and 0.717 g of KH570 in acetone solution, at room temperature for 4 hours of equal volume impregnation, after drying, in nitrogen at 550 ° C for 2 hours to obtain anchored γ-Al 2 o 3 Pd-CeO supported on the nickel foam support 2 @SiO 2 Core-shell catalysts.

[0070] Through the measurement of inductively coupled plasma atomic emission spectrometry, it is known that in the prepared catalyst, the mass content of Pd is 0.45%, CeO 2 The mass content is 2.54%, SiO 2 The mass content is 3.23%, Al 2 o 3 The mass content of is 5.91%; Therefore, the catalyst prepared in this embodiment is abbreviated as: 0.5Pd-2.5CeO 2 @3.2SiO 2 / 6Al 2 o 3 / Ni-foam.

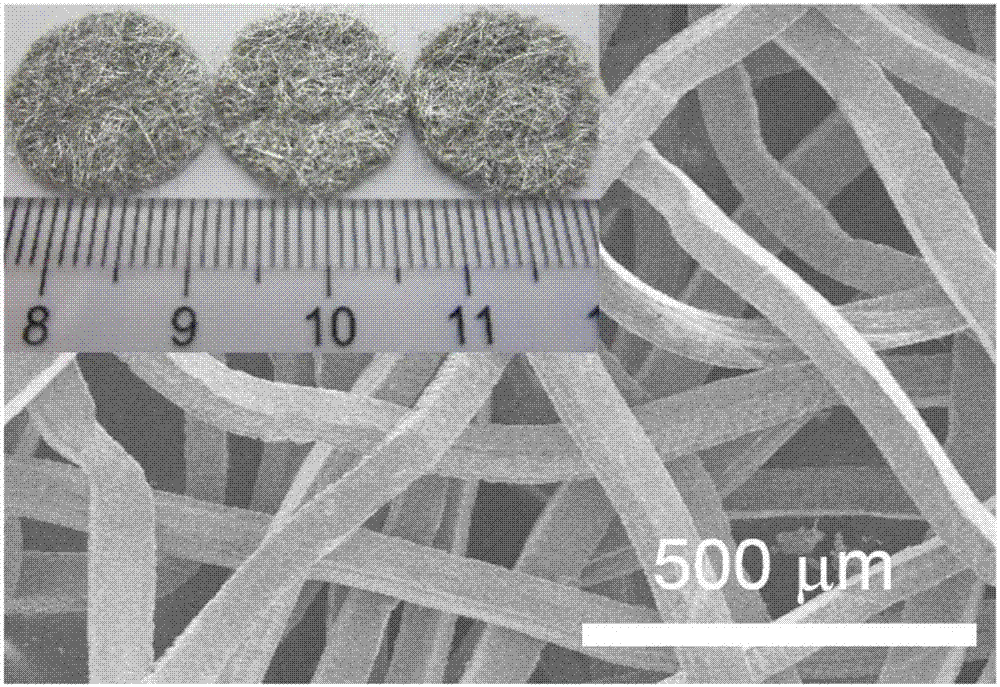

[0071] According to the macroscopic measurement, the self-supporting core-shell structure catalyst prepared in this implementa...

Embodiment 3

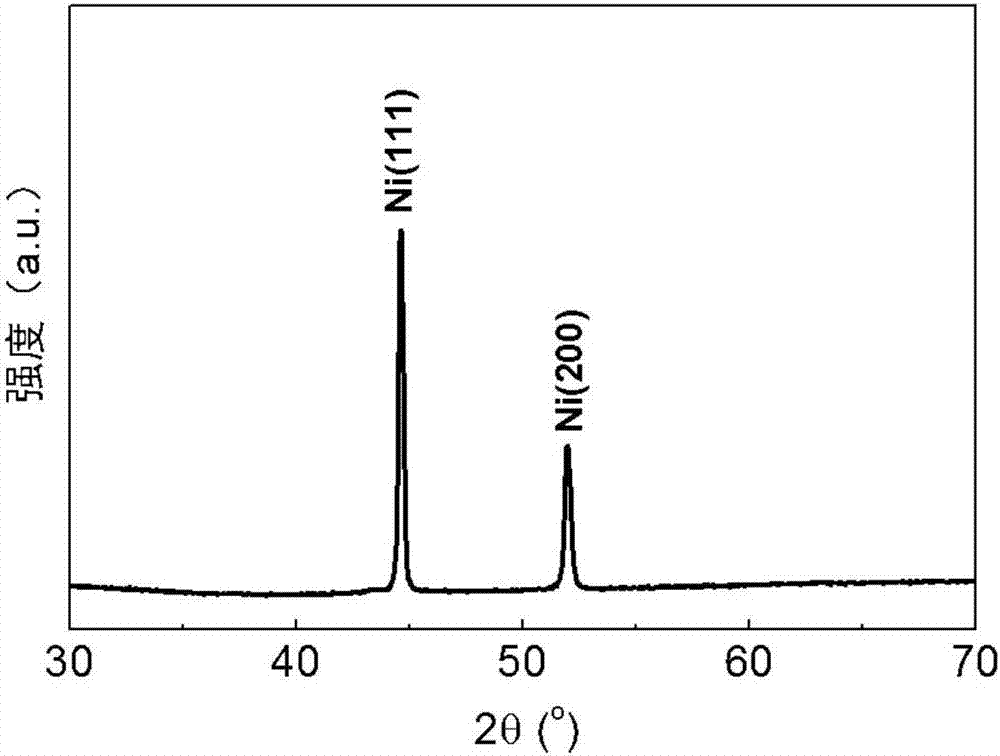

[0074] 1. Take 5 grams of sintered aluminum fiber (fiber diameter 50 microns) sheet, treat it with 1 wt% sodium hydroxide aqueous solution for 10 minutes, wash it with distilled water, put it into a stainless steel hydrothermal kettle, add 70 milliliters of distilled water, and Hydrothermal treatment at 120°C for 12 hours. After cooling down to room temperature, wash with distilled water several times and dry to obtain a self-supporting AlOOH / Al50-SMF composite carrier containing abundant surface hydroxyl groups and anchoring flaky pseudo-boehmite;

[0075] 2. Take 5 grams of the self-supporting AlOOH / Al50-SMF composite carrier prepared in step 1, and use Pd(NO 3 ) 2 and 0.208 g of silane coupling agent KH550 in acetone solution, at room temperature for equal volume impregnation for 4 hours, after drying, in nitrogen at 550 ° C for 2 hours to obtain anchored γ-Al 2 o 3 Pd@SiO supported on aluminum fiber support 2 Core-shell catalysts.

[0076] Through inductively coupled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com