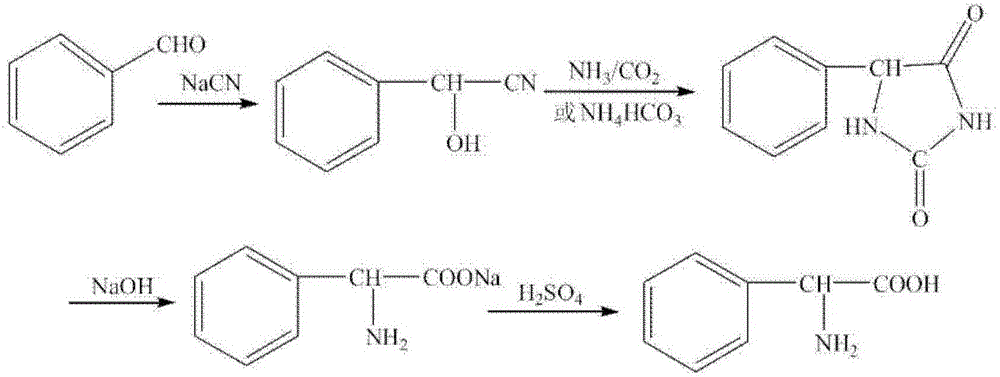

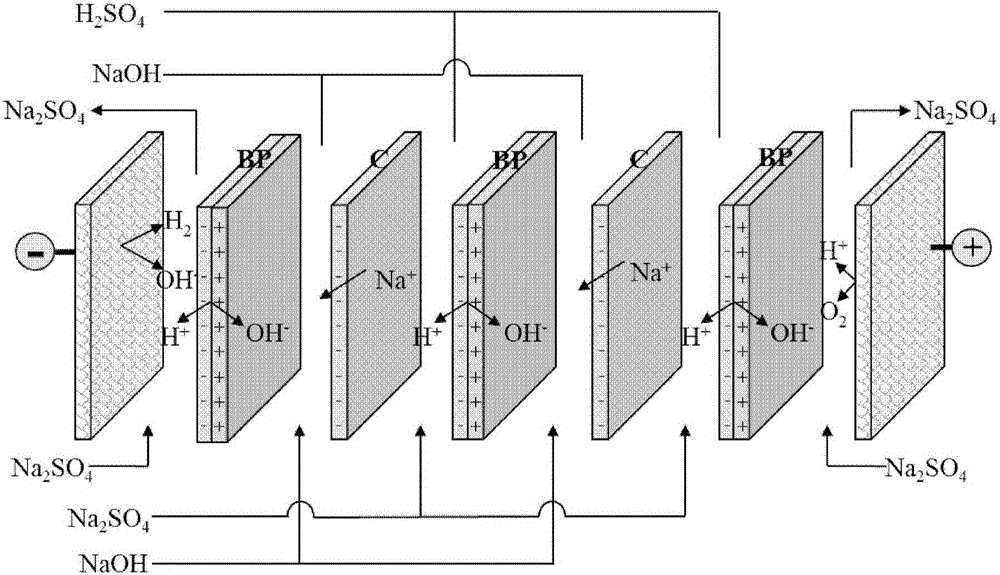

Method for producing water-insoluble organic acid by bipolar membrane electrodialysis

A bipolar membrane electrodialysis, water-insoluble technology, applied in electrodialysis, preparation of organic compounds, organic chemistry, etc., can solve the problems of high membrane stack resistance, poor conductivity of organic solvents, high energy consumption, and achieve clean production. , the effect of saving chemical raw materials, significant industrial application value and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

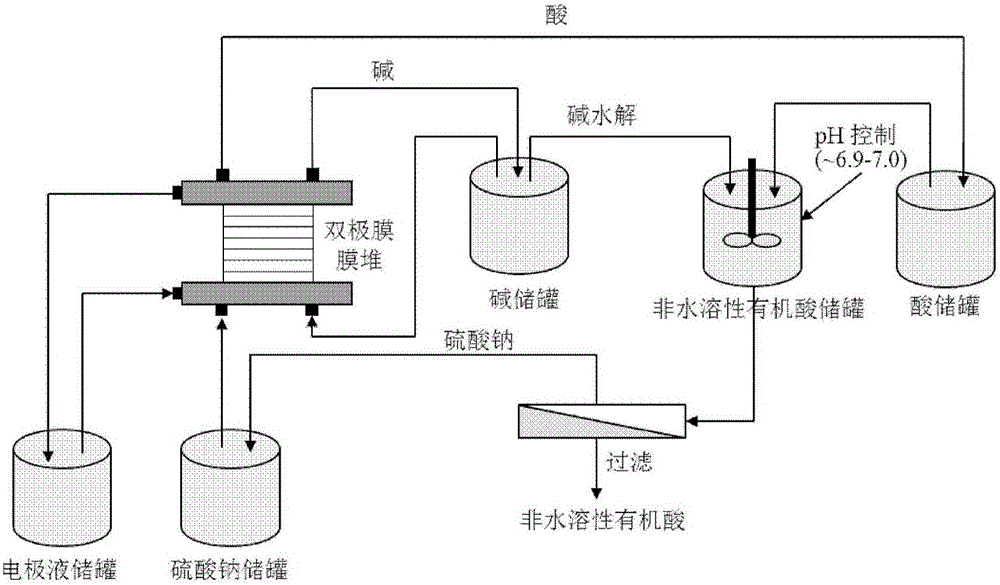

Embodiment 1

[0039] First, put 400mL of 0.3mol / L sodium sulfate solution in the electrode solution storage tank to serve as the electrode solution. The alkali storage tank is initially put into 400mL of 0.05mol / L sodium hydroxide to reduce the initial resistance. Keep a sufficient amount of 0.3mol / L sodium sulfate solution in the sodium sulfate storage tank of the feed liquid, pass it through the peristaltic pump into the two-compartment bipolar membrane electrodialysis membrane stack and then directly flow out into the acid storage tank. At the same time, the acid in the acid storage tank is passed through a peristaltic pump at the same flow rate as the acid chamber into the 100 mL 2mol / L sodium phenylglycinate solution to be processed. Before turning on the power, turn on the peristaltic pump and circulate the entire device for half an hour to eliminate the damage to the membrane caused by bubbles. After the power is turned on, use a stopwatch to count the time. During the operation of t...

Embodiment 2

[0041] First, put 400mL of 0.3mol / L sodium sulfate solution in the electrode solution storage tank to serve as the electrode solution. The alkali storage tank is initially put into 400mL of 0.05mol / L sodium hydroxide to reduce the initial resistance. Keep a sufficient amount of 0.3mol / L sodium sulfate solution in the sodium sulfate storage tank of the feed liquid, pass it through the peristaltic pump into the two-compartment bipolar membrane electrodialysis membrane stack and then directly flow out into the acid storage tank. At the same time, the acid in the acid storage tank is fed into the 100mL 2mol / L sodium phenylglycinate solution to be processed through the peristaltic pump at the same flow rate as the acid chamber. Before turning on the power, turn on the peristaltic pump and circulate the whole device for half an hour to eliminate the damage to the membrane caused by bubbles. After the power is turned on, use a stopwatch to count the time. During the operation of the ...

Embodiment 3

[0043] First, put 400mL of 0.3mol / L sodium sulfate solution in the electrode solution storage tank to serve as the electrode solution. The alkali storage tank is initially put into 400mL of 0.05mol / L sodium hydroxide to reduce the initial resistance. Keep a sufficient amount of 0.3mol / L sodium sulfate solution in the sodium sulfate storage tank of the feed liquid, pass it through the peristaltic pump into the two-compartment bipolar membrane electrodialysis membrane stack and then directly flow out into the acid storage tank. At the same time, the acid in the acid storage tank is passed through the peristaltic pump at the same flow rate as the acid chamber into the 100 mL 2mol / L sodium phenylglycinate solution to be processed. Before turning on the power, turn on the peristaltic pump and circulate the whole device for half an hour to eliminate the damage to the membrane caused by bubbles. After the power is turned on, use a stopwatch to count the time. During the operation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com