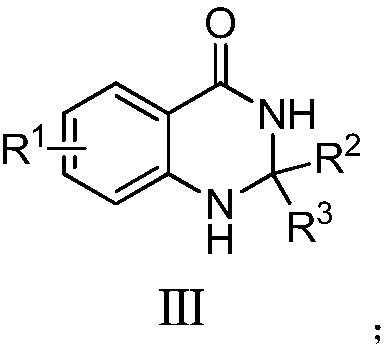

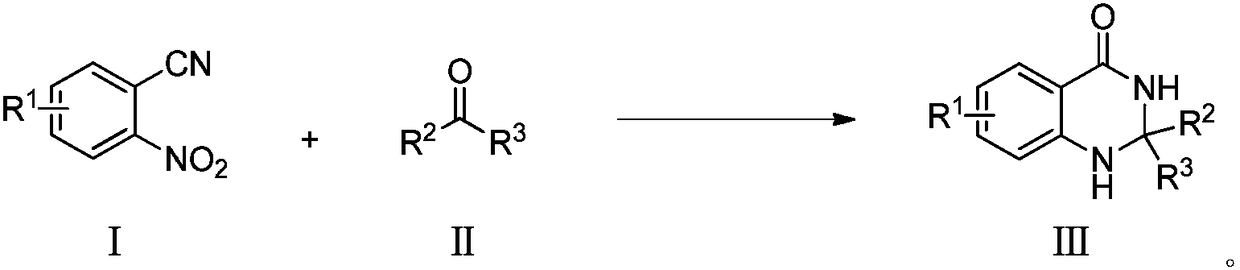

Dihydroquinoxalinone compound and preparation method thereof

A technology for dihydroquinazolinones and compounds is applied in the field of dihydroquinazolinones and their preparation, and can solve the problems of complex post-treatment process, harsh reaction conditions, single reaction raw materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

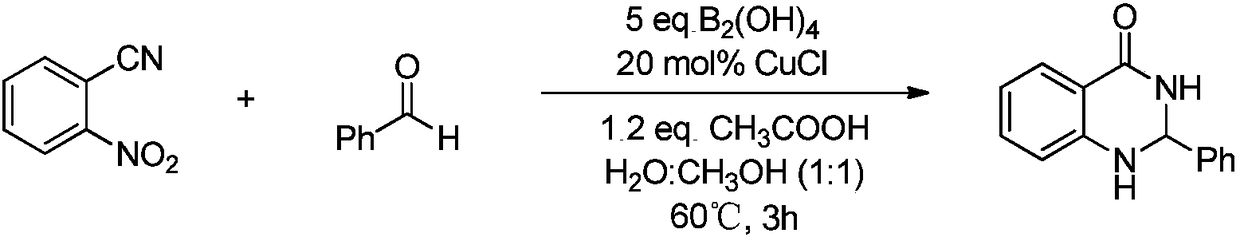

Embodiment 1

[0023]

[0024] 2-Nitrobenzonitrile (0.2mmol, 29.6mg), tetrahydroxydiboron (1mmol, 89.6mg), glacial acetic acid (0.24mmol, 14.5mg), cuprous chloride (0.04mmol, 4.0mg), benzene Formaldehyde (0.24mmol, 25.4mg), methanol (1ml), and water (1ml) were sequentially added to the test tube, and reacted at 60°C for 3h. Analysis (petroleum ether: ethyl acetate = 4:1) separation, yield: (40.8mg, 91%). m.p.225-226℃. 1 HNMR (400MHz, CDCl 3 )δ=7.99(dd,J 1 =8.0Hz,J 2 =1.6Hz,1H),7.65(m,2H),7.50(m,2H),7.39(dt,J 1 =7.6Hz,J 2 =1.6Hz,1H),6.95(dd,J 1 =7.6Hz,J 2 =0.8Hz,1H),6.72(d,J=8.0Hz,1H),5.95(s,1H),5.80(s,1H),4.44(s,1H). 13 C NMR (100MHz, CDCl 3 )δ=164.7, 147.2, 138.6, 134.0, 130.2, 129.2, 128.8, 127.4, 119.7, 115.7, 114.6, 69.2.

Embodiment 2

[0026]

[0027] Add 2-nitrobenzonitrile (0.2mmol, 29.6mg), tetrahydroxydiboron (1mmol, 89.6mg), benzaldehyde (0.24mmol, 25.4mg), methanol (1ml), water (1ml) into the test tube in turn , reacted at 60°C for 12h, after the end, the reaction solution was extracted 3 times with ethyl acetate, the combined organic phase was concentrated to dryness, and separated by column chromatography (petroleum ether: ethyl acetate = 4:1), the yield: (6.7mg, 15%).

Embodiment 3

[0029]

[0030] 2-Nitrobenzonitrile (0.2mmol, 29.6mg), tetrahydroxydiboron (1mmol, 89.6mg), glacial acetic acid (0.24mmol, 14.5mg), cuprous chloride (0.04mmol, 4.0mg), benzene Add formaldehyde (0.24mmol, 25.4mg) and water (2ml) into the test tube in turn, and react at 60°C for 3h. Ethyl acetate=4:1) isolated, yield: (13.2 mg, 30%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com