Method for preparing cyclohexyl formic acid sulfonic acid by using bipolar membrane method

A technology of cyclohexyl formic acid sulfonic acid and cyclohexyl formic acid sulfonate, applied in the direction of sulfonate preparation, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of unsatisfactory industrial application, low purity and yield, and environmental problems. Pollution and other issues, to achieve significant industrial application value and environmental benefits, high purity, reduce pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

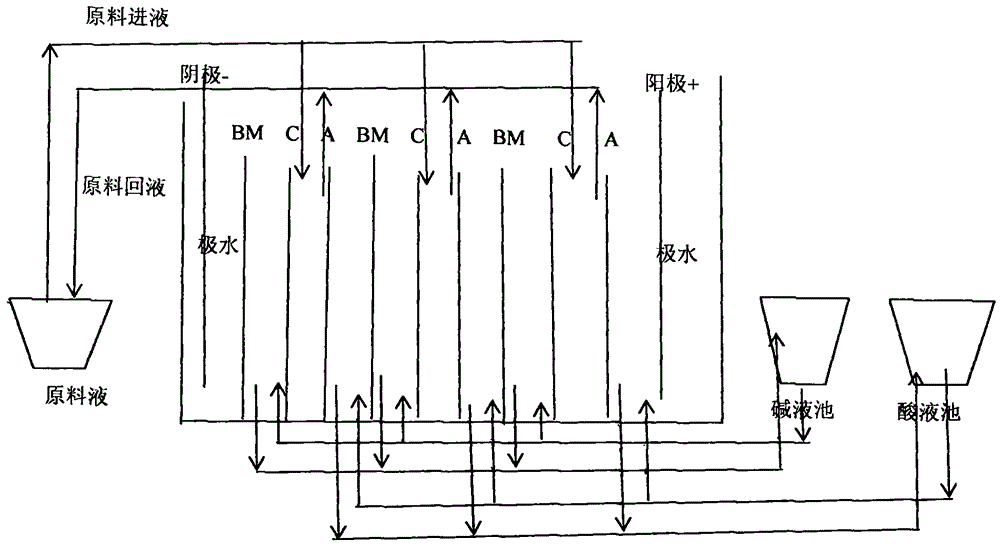

[0021] Embodiment 1: Determine the relationship between the concentration of cyclohexyl formic acid sulfonate and the current density and the content of impurity sulfuric acid in the final product

[0022] Preparation of cyclohexyl formic acid sulfonate solutions with different mass percentage concentrations, the salt solution is respectively treated by bipolar membrane electrodialysis according to the present invention, the specific conditions are voltage 25V, current density 8A / dm 2 , circulation volume 40L / h, experiment time 3h, experiment results are shown in Table 1 and image 3 shown. The results show that with the increase of the concentration of cyclohexyl formate sulfonate, the content of impurity sulfuric acid in the final product will increase accordingly, and when the concentration of cyclohexyl formate sulfonate aqueous solution is greater than 20%, the content of impurity sulfuric acid will increase significantly.

[0023] Table 1: The relationship between the c...

Embodiment 2

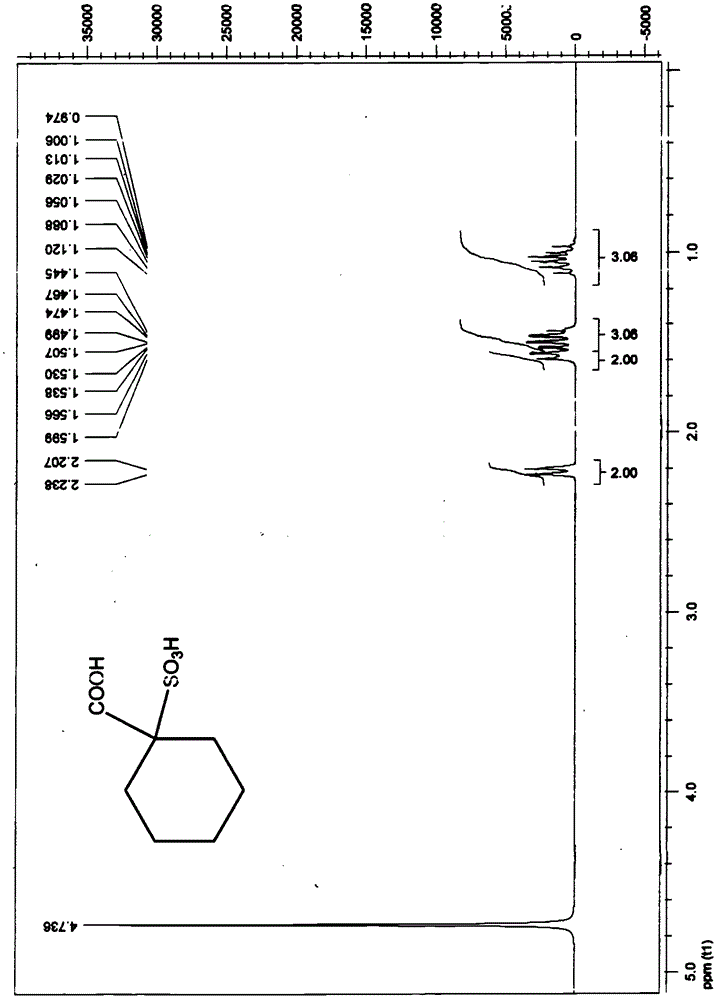

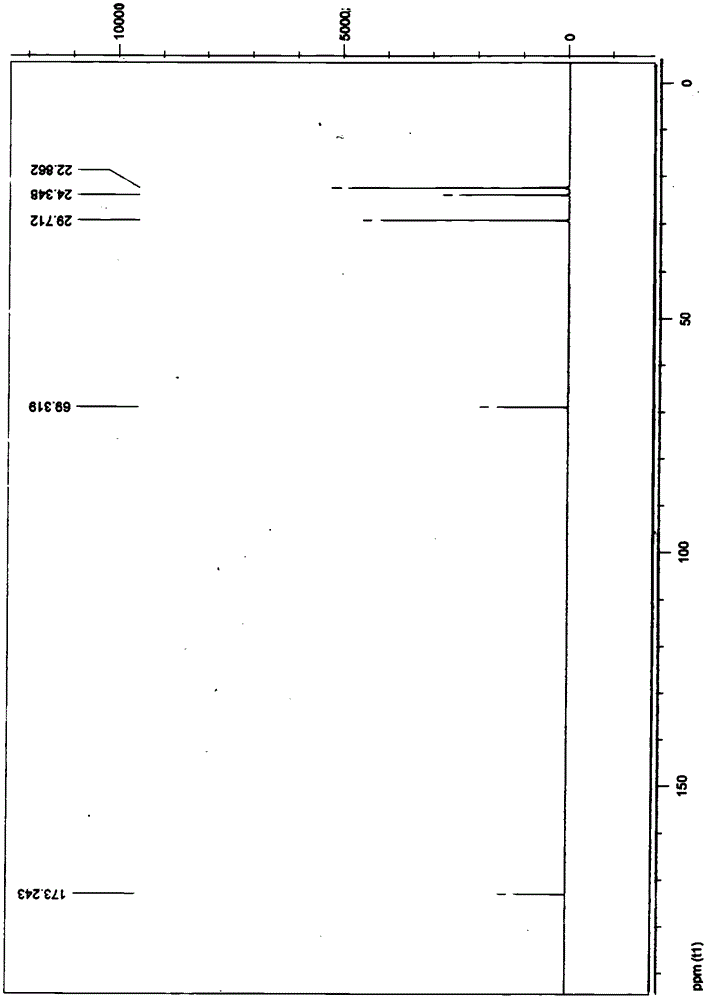

[0030] Embodiment 2: Determination of the structure of cyclohexyl formic acid sulfonic acid

[0031] The cyclohexyl formic acid sulfonic acid obtained by the above-mentioned electrochemical bipolar membrane method was concentrated and recrystallized to finally obtain white needle-like crystals. 1 H-NMR, 13 C-NMR identification (the described equipment is Bruker AVANCE III HD 400M), the resulting product is cyclohexyl formic acid sulfonic acid, and the collection of illustrative plates is respectively shown in the attached Figure 5-6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com