Patents

Literature

74results about How to "Strong magnetic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

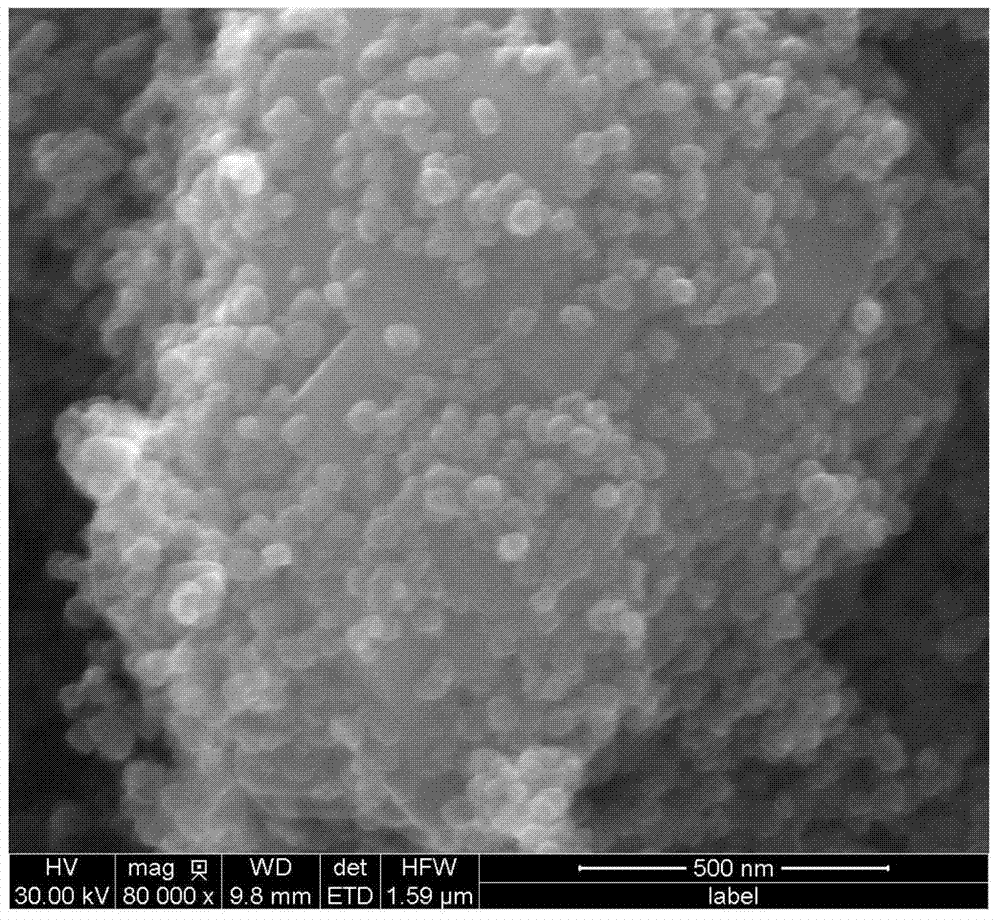

Composite nano silica/ferroferric oxide grain material and its prepn process

The present invention is composite nano silica / ferroferric oxide grain material and its preparation process. By means of chemical deposition process, nano ferroferric oxide crystal produced in the reaction is compounded and assembled onto the surface of spherical nano silica particle to form the composite grain material in spherical shell shape. The present invention features that through coating silica with nano ferroferric oxide, the features of both the silica and the nano ferroferric oxide are combined together to make the composite material possess light weight, magnetism and low radiance. The composite material may be used in making transparent pigment, stealth material, etc.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

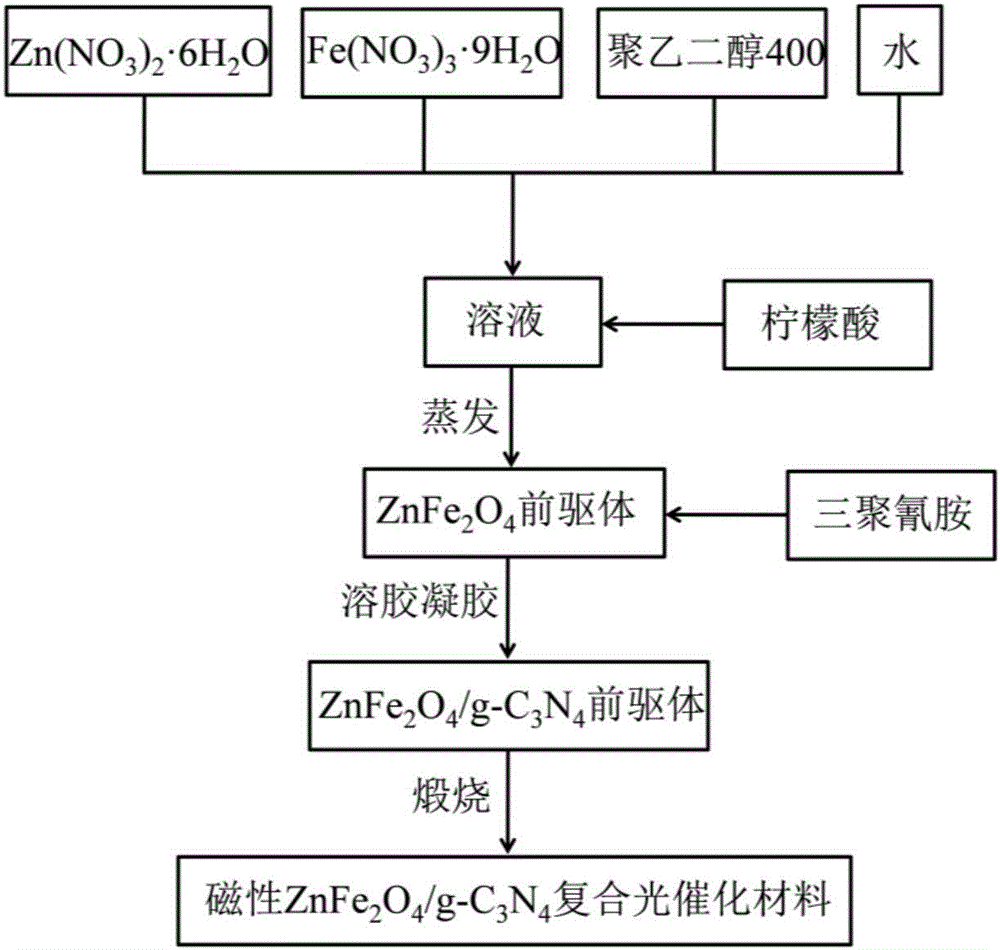

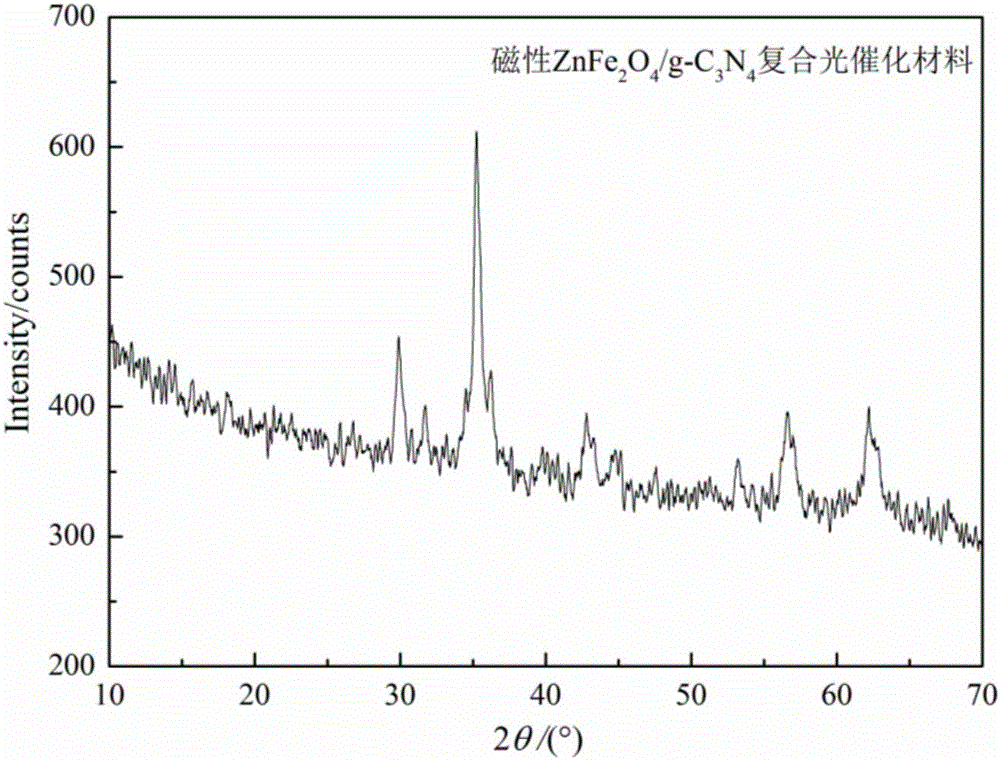

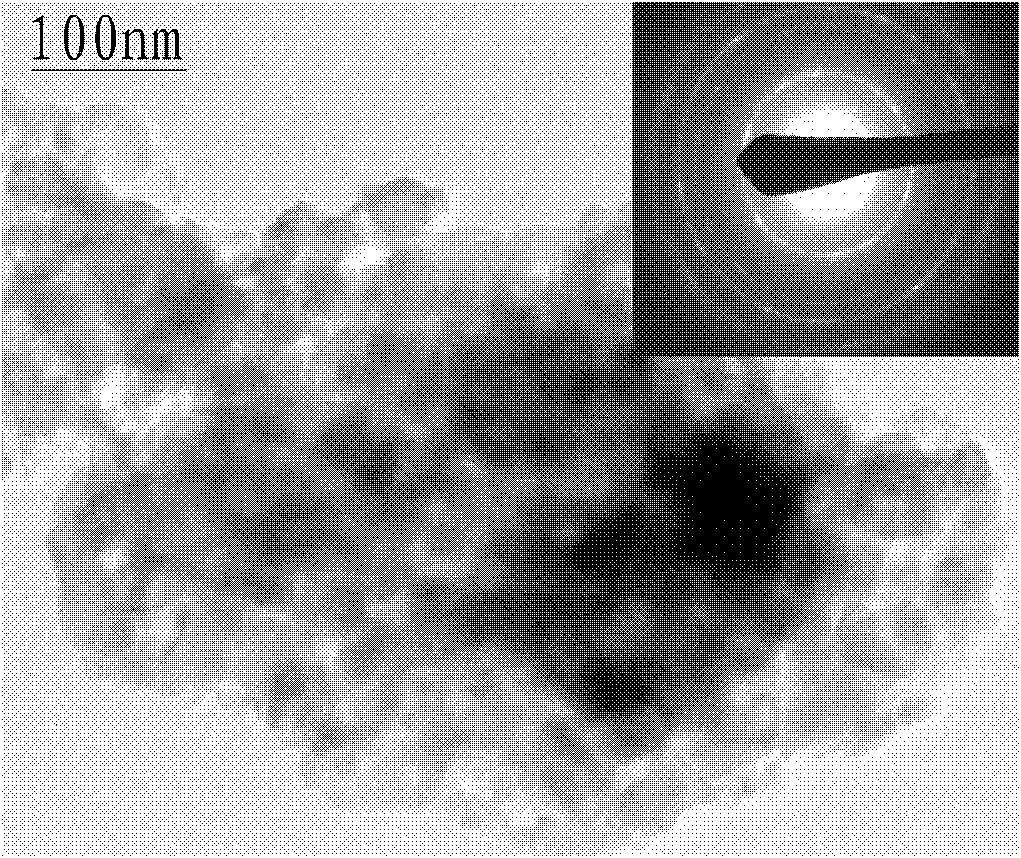

A method of preparing a magnetic ZnFe<2>O4/g-C3N4 composite photocatalytic material

ActiveCN106378171AAvoid it happening againStrong magneticPhysical/chemical process catalystsWater bathsSemiconductor materials

A method of preparing a magnetic ZnFe<2>O4 / g-C3N4 composite photocatalytic material is disclosed. The method prepares the composite photocatalytic material through a process combining sol gel and calcination. The method includes dissolving Zn(NO3)<2>.6H2O and Fe(NO3)<3>.9H2O into a proper amount of a mixed solution of polyethylene glycol 400 and water, putting into a water bath, stirring for a certain period of time, adding citric acid, putting into a water bath, reacting, adding melamine into the prepared precursor, continuously stirring to form gel, and performing calcination in a muffle furnace to obtain the composite photocatalytic material having high catalytic activity. The method overcomes disadvantages that the photocatalytic efficiency is low and recoverability is poor of a novel semiconductor material g-C3N4. A process of preparing the composite photocatalytic material has advantages of simple and convenient procedures, a high efficiency and easy operation, and avoids generation of waste water and waste residues. The composite photocatalytic material can replace TiO2, ZnO, and other traditional photocatalysts and be applied to photocatalytic purification of organic waste water pollution and air pollution.

Owner:ZHEJIANG UNIV OF TECH

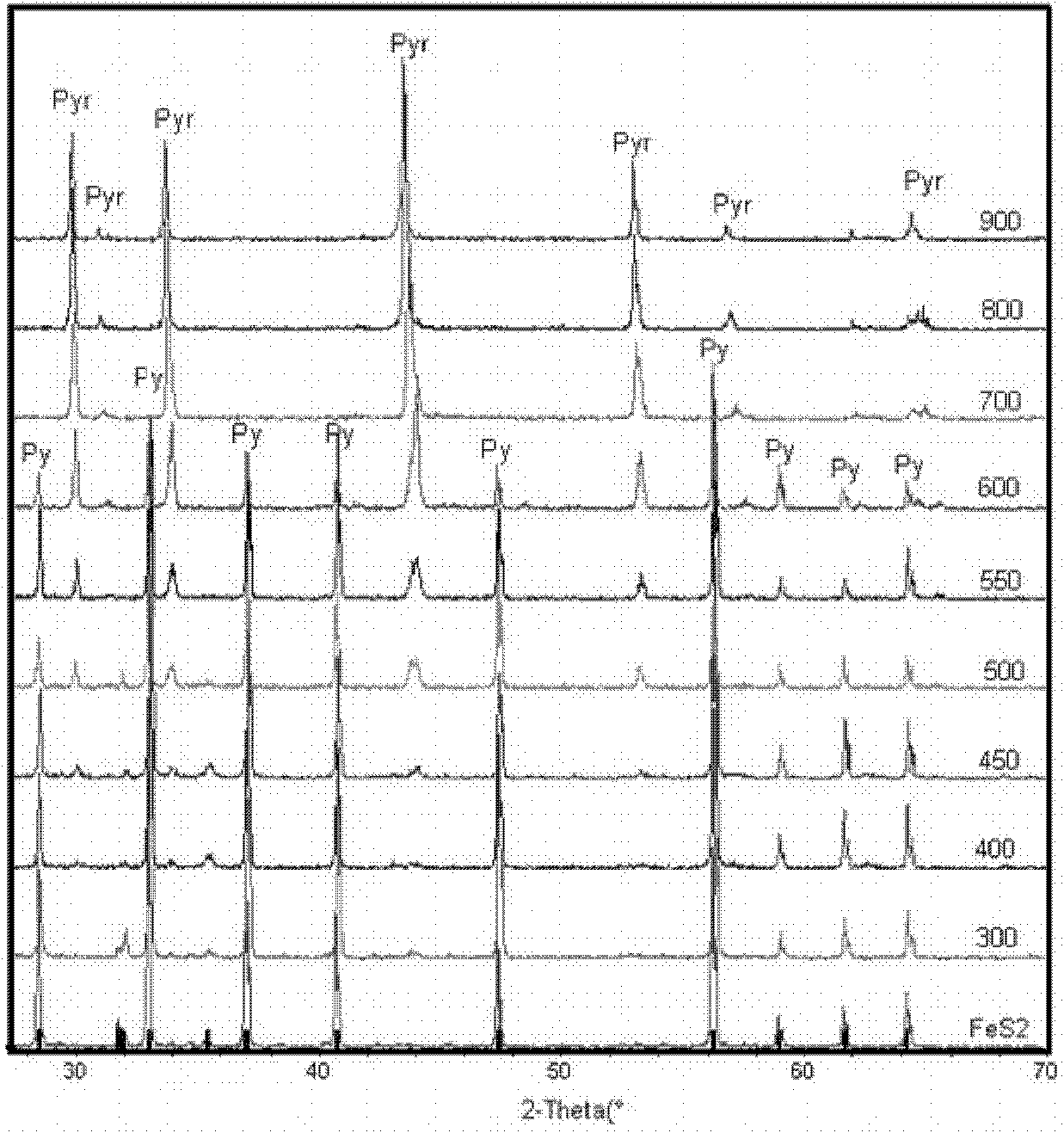

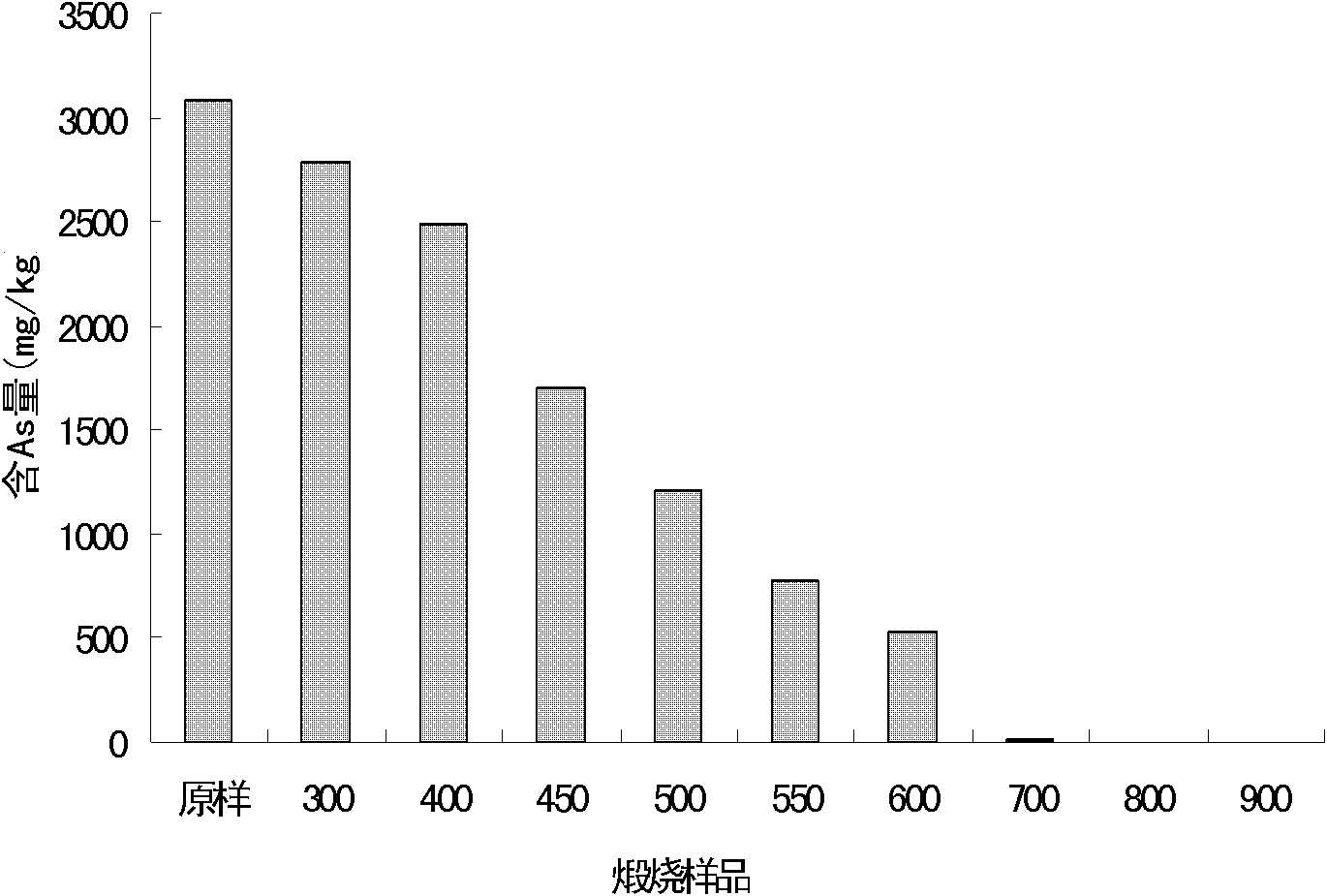

Pyrite nano mineral material and preparation method thereof

ActiveCN102320668ARegulatory structure stateRegulate physicochemical propertiesSulfur preparation/purificationNanotechnologyChemical reactionRoom temperature

The invention discloses a pyrite nano mineral material and a preparation method thereof. The pyrite nano mineral material uses pyritic sulfur and sulphide concentrate as raw materials, the mass percent of pyrite in the pyritic sulfur is not smaller than 50%, and the mass percent of the pyrite in the sulphide concentrate is not smaller than 90%. The preparation method comprises the following stepsof: crushing pyritic sulfur ores, sieving with a sieve of 100 meshes to obtain powder or directly selecting the sulphide concentrate with the particle diameter which is smaller than 0.165mm as powder, adding a bonder to the powder, pelletizing and molding to obtain particles with the particle diameter of 1-3mm, calcinating the particles at a temperature of 500-1000DEG C for 0.5-30min under anaerobic conditions, separating gas from solids, condensating the gas, recovering sulfur, and cooling the solids under oxygen isolation conditions to a room temperature to obtain a finished product. The material has the advantages of large specific area, strong magnesium, high chemical reaction activity, simple preparation technology, low cost and wide raw material resources.

Owner:HEFEI UNIV OF TECH

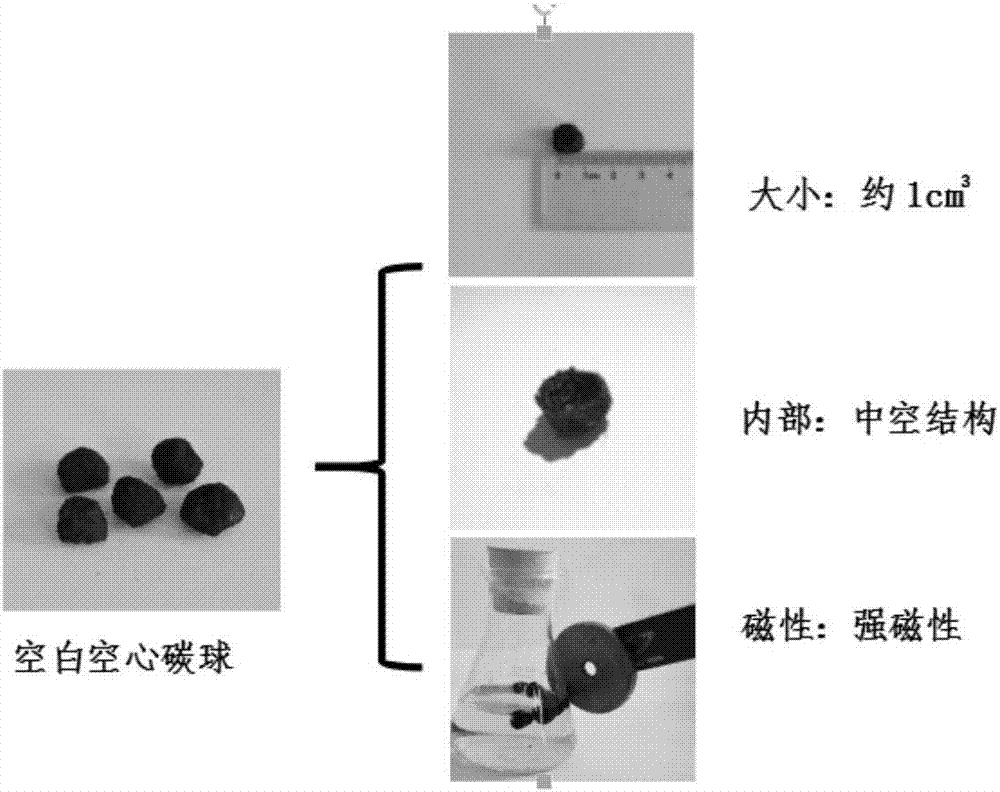

Preparation and application of floatable magnetic hollow material for removing heavy metal in water and soil

ActiveCN107398251ADevelop resource utilizationEfficient adsorption capacity of heavy metalsOther chemical processesWater contaminantsResource utilizationHusk

The invention discloses preparation and application of a floatable magnetic hollow material for removing heavy metal in water and soil. Agricultural wastes of musaceae, such as banana, dried-up leaves, corn dried-up leaves and rice husks are combined with alginate to prepare the floatable magnetic hollow material containing nanometer ferroferric oxide and nanometer ferrous chloride, and the floatable magnetic hollow material is applied to remove the heavy metal in the water and the soil, so that not only is the resource utilization of the agricultural wastes developed, and a new way is opened for farmer income increase, but also the prepared nanometer ferrous chloride and nanometer ferroferric oxide and a high-quality porous biological carbon material have a high-efficient heavy metal adsorption capability, the hollow material with magnetism and floated on a water surface can be conveniently recovered, and the heavy metal in the water and the soil is removed. The floatable magnetic hollow material provided by the invention is wide in application range, can be used for renovating the water with heavy metal pollution such as urban or industrial sewage, rivers, pools and lakes, and can be also used for renovating the soil with heavy metal pollution such as rice fields, water vegetable fields and green plant fields.

Owner:SOUTH CHINA AGRI UNIV

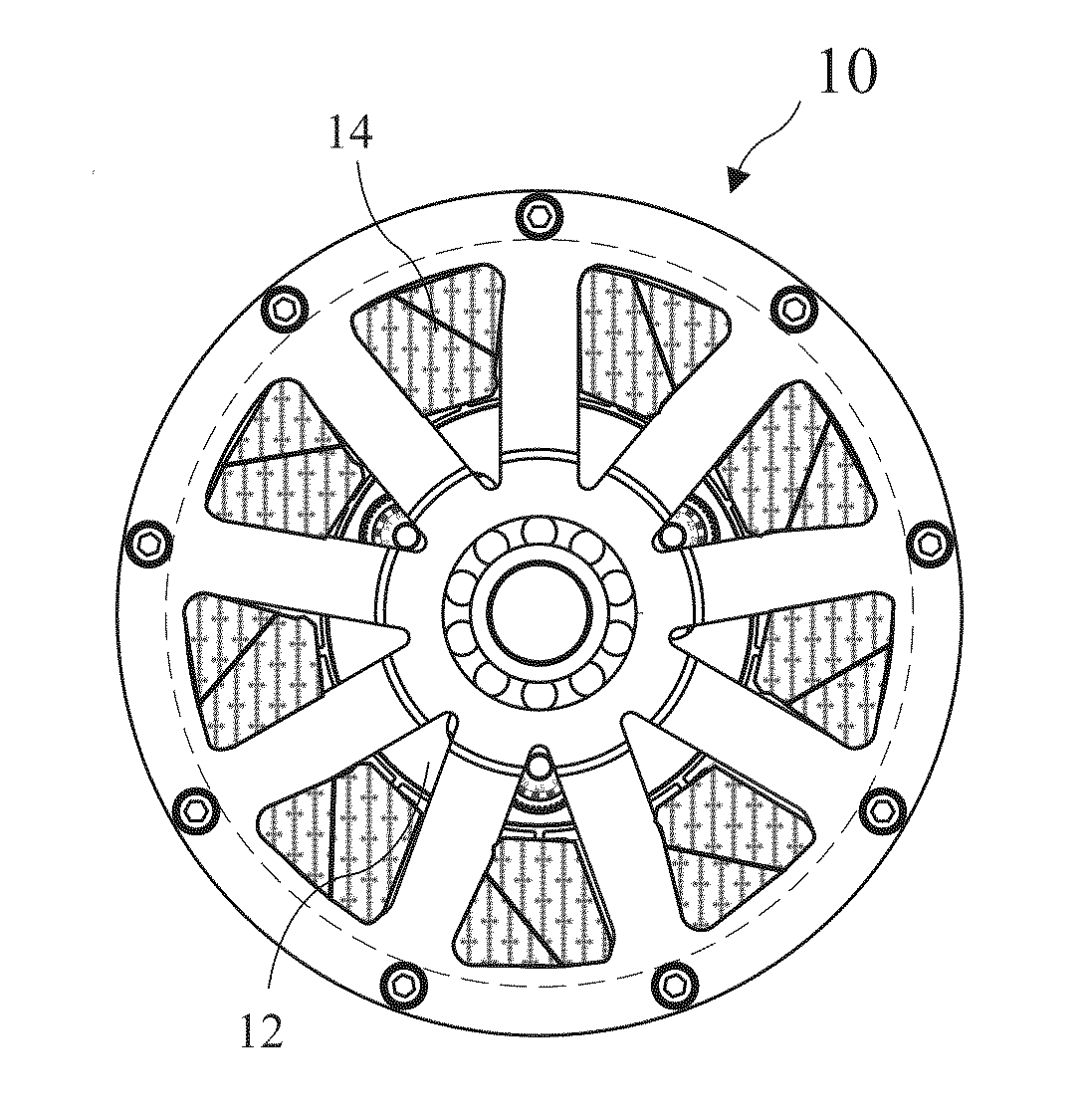

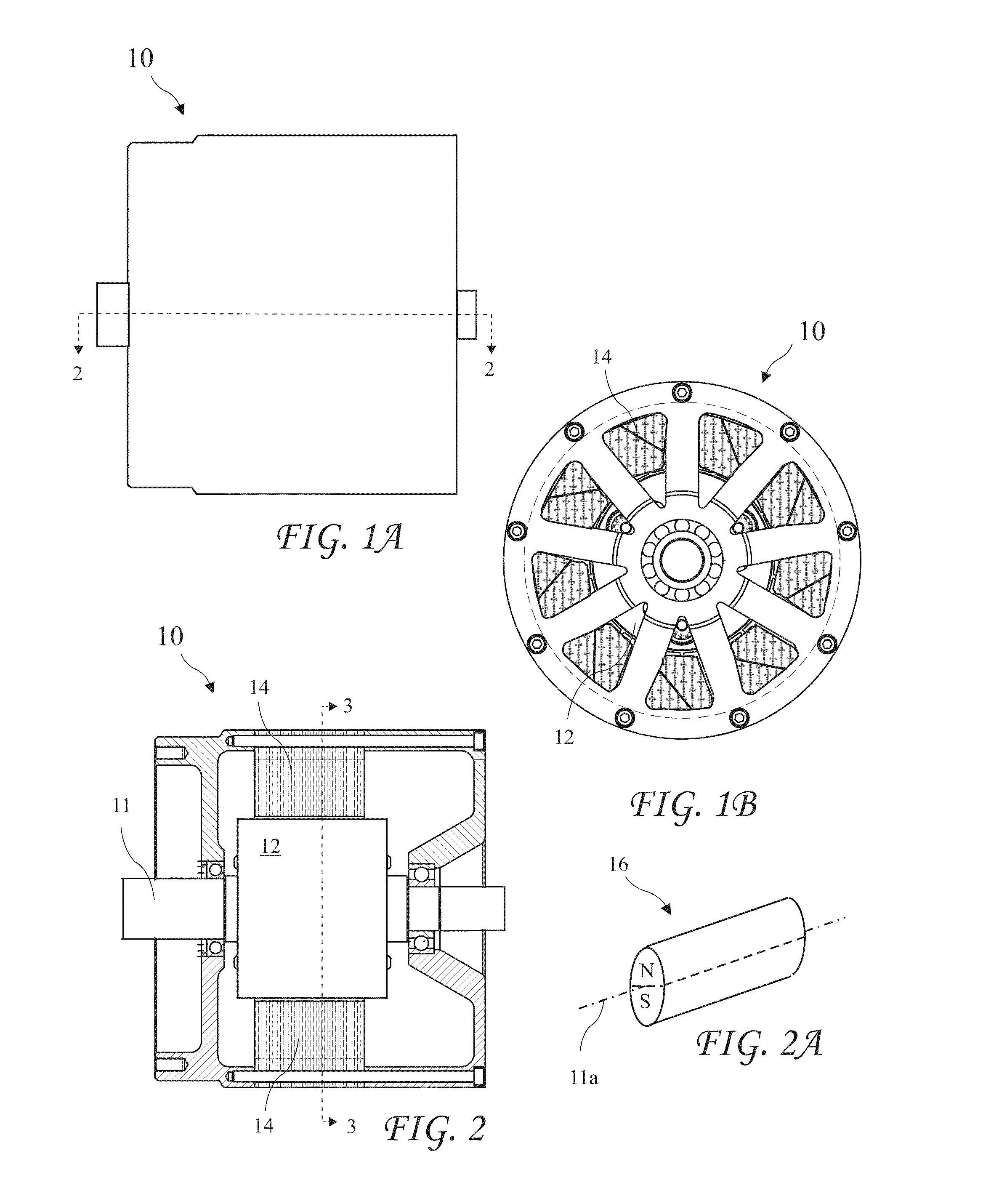

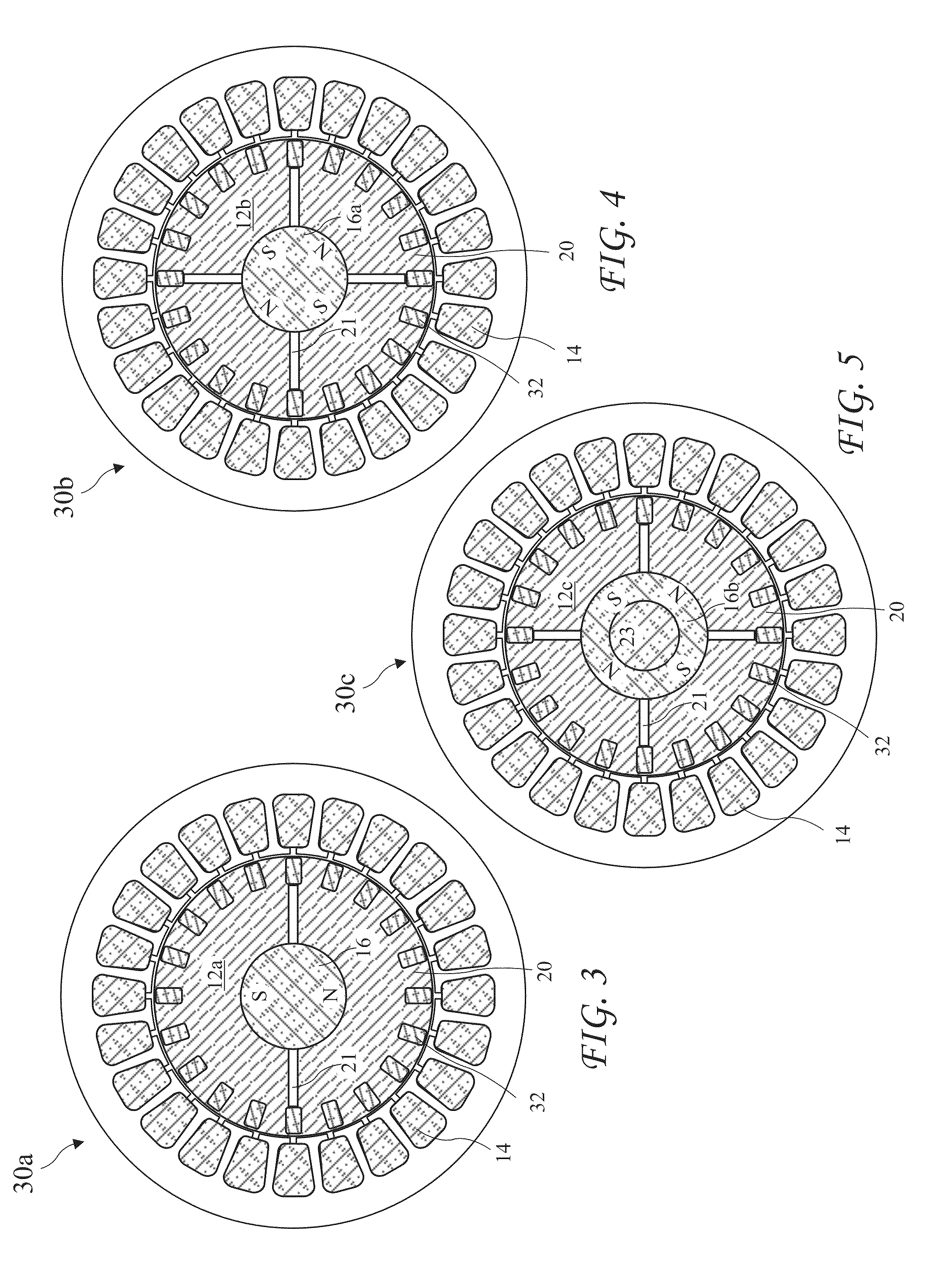

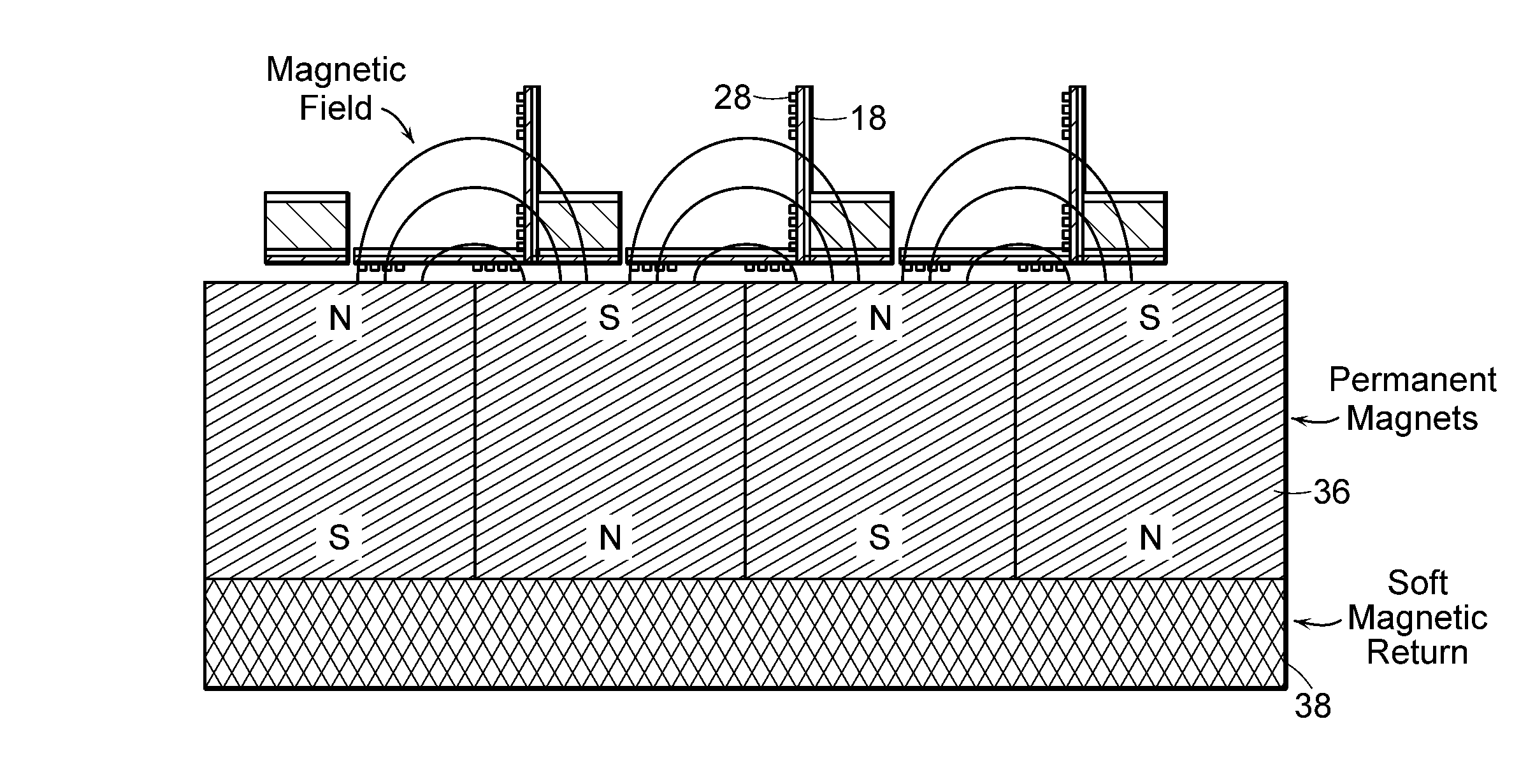

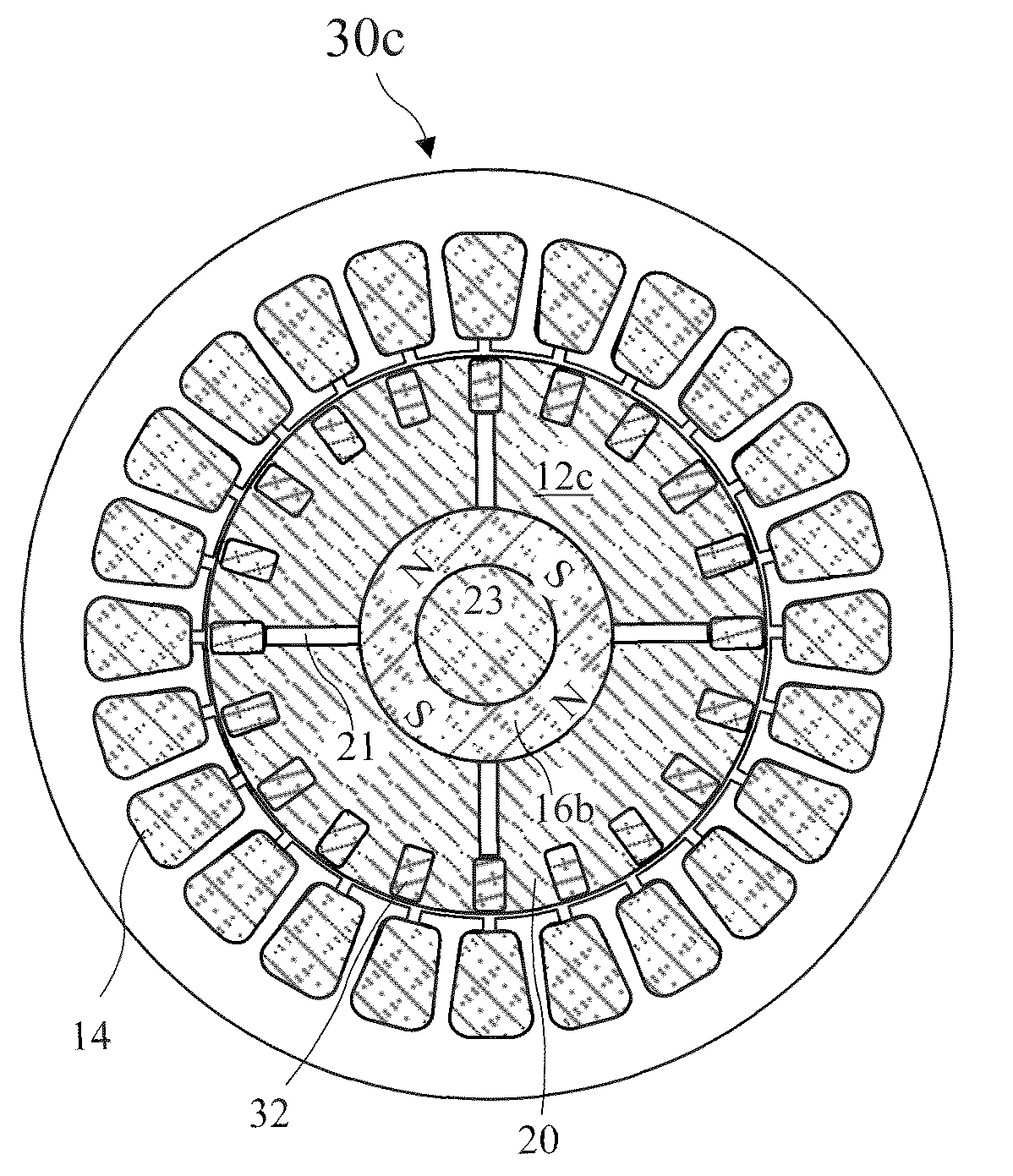

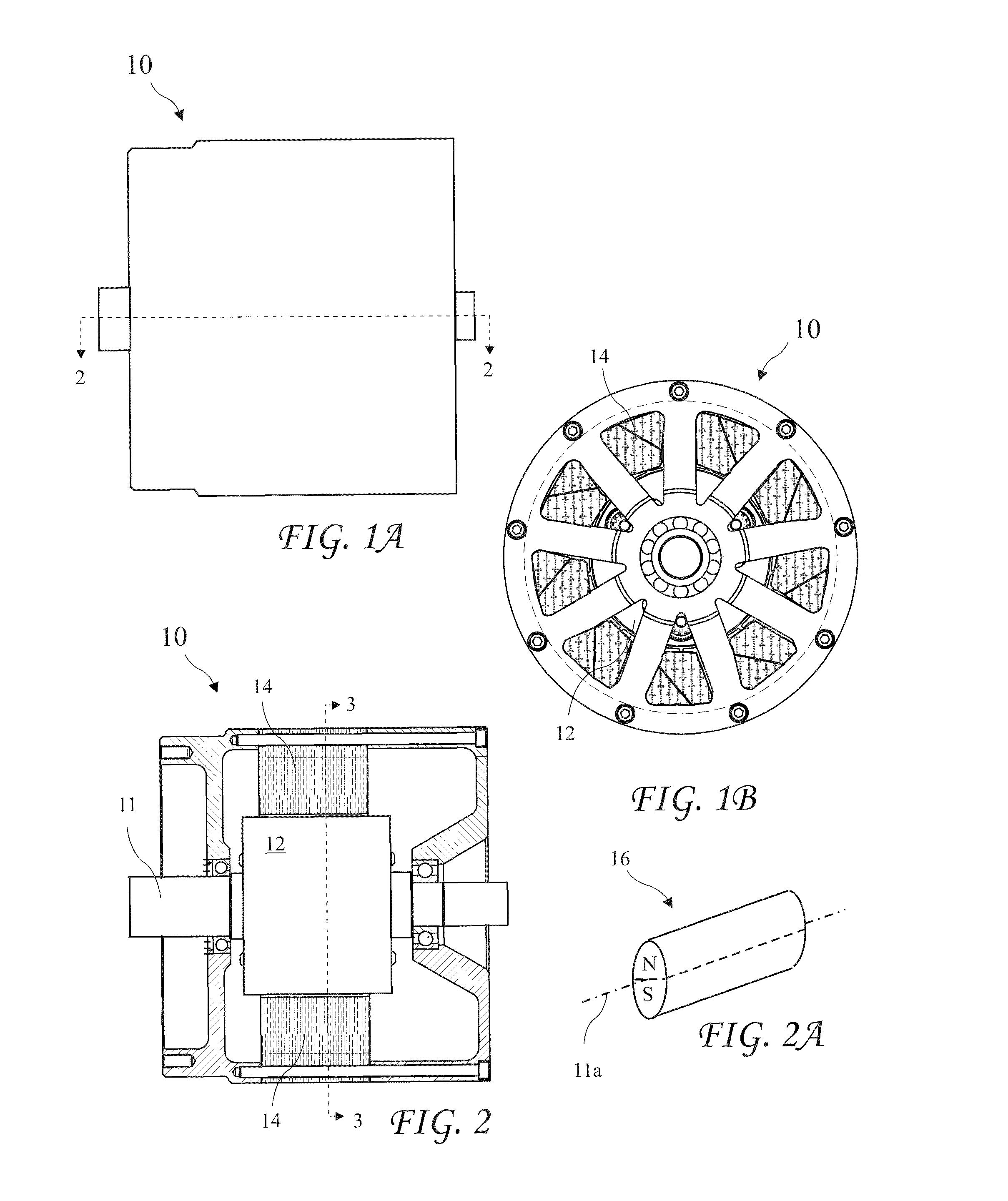

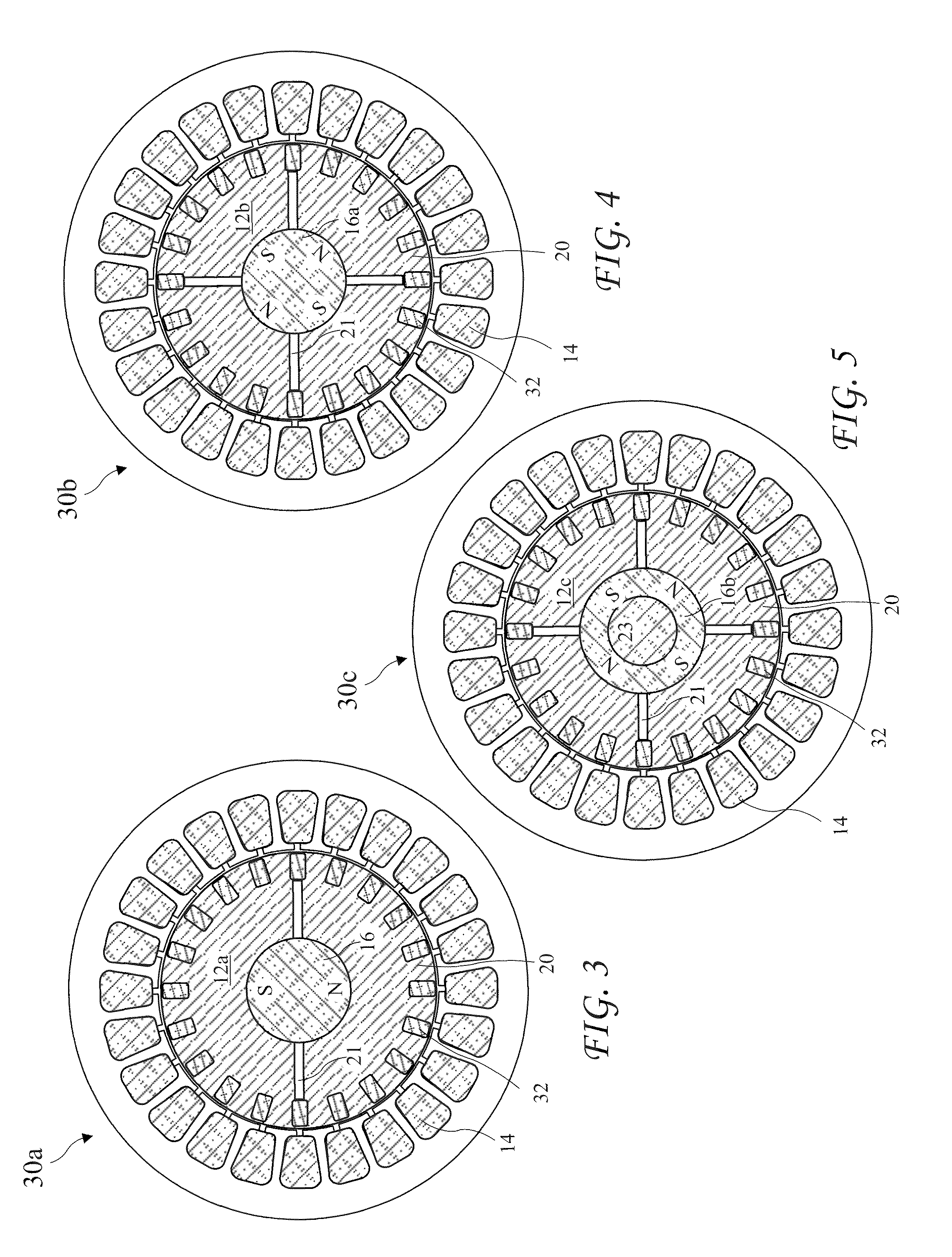

Reconfigurable Inductive to Synchronous Motor

ActiveUS20110101814A1High efficiency synchronous operationEfficient synchronous operationSynchronous generatorsWindingsSynchronous motorInduction motor

A reconfigurable electric motor includes a rotor containing rotatable permanent magnets or non-magnetically conducting shunting pieces. The magnets and / or shunting pieces have a first position producing a weak magnetic field for asynchronous induction motor operation at startup and a second position producing a strong magnetic field for efficient synchronous operation. The motor includes a squirrel cage for induction motor operation at startup with the permanent magnets and / or shunting pieces positioned to product the weak magnetic field to not interfere with the startup. When the motor approaches or reaches synchronous RPM, the permanent magnets and / or shunting pieces rotate to produce a strong magnetic field for high efficiency synchronous operation. The position of the magnets and / or shunting pieces may be controlled by a centrifugal mechanism, or viscous damping may delay rotation of the magnets and / or shunting pieces, or electrically controlled apparatus may control positions of the magnets and / or shunting piece.

Owner:MOTOR GENERATOR TECH INC

Preparation method and application of core-shell P-CoFe2O4(at)GCN photocatalyst

InactiveCN110142061AUniform particlesHigh crystallinityPhysical/chemical process catalystsWater/sewage treatment by irradiationPhotocatalytic degradationAir atmosphere

The invention belongs to the technical field of composite materials and relates to a preparation method and application of a core-shell P-CoFe2O4(at)GCN photocatalyst. The preparation method comprisesthe following steps: firstly mixing cobalt salt and ferric salt, dropwise adding alkali lye and precipitating to prepare strongly magnetic nanoparticles CoFe2O4; fully dispersing a graphite-type carbonitride precursor and a phosphorus source in distilled water, carrying out solid-liquid separation, drying a solid at 80-100 DEG C for 12-24 h, and grinding to obtain a powder; and finally placing the powder into a muffle furnace, and heating in the air atmosphere at 500-600 DEG C for 2-5 h so as to obtain the photocatalyst. In the invention, the prepared material is also applied to wastewater soas to remove antibiotics. By compound modification of the graphite-type carbonitride, the photocatalytic performance is greatly improved, and the solid-liquid separation problems are solved. The preparation method is simple to operate, and the sources of the raw materials are wide. The surface of the prepared material has a pore structure, and the specific surface area is increased, thus providing more active sites for a photo-catalytic reaction. The result shows that the tetracycline photocatalytic degradation rate of the product is 3.66 times higher than the tetracycline photocatalytic degradation rate of pure graphite-type carbonitride before modification.

Owner:EAST CHINA JIAOTONG UNIVERSITY

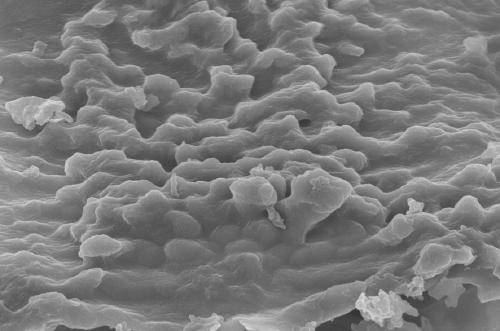

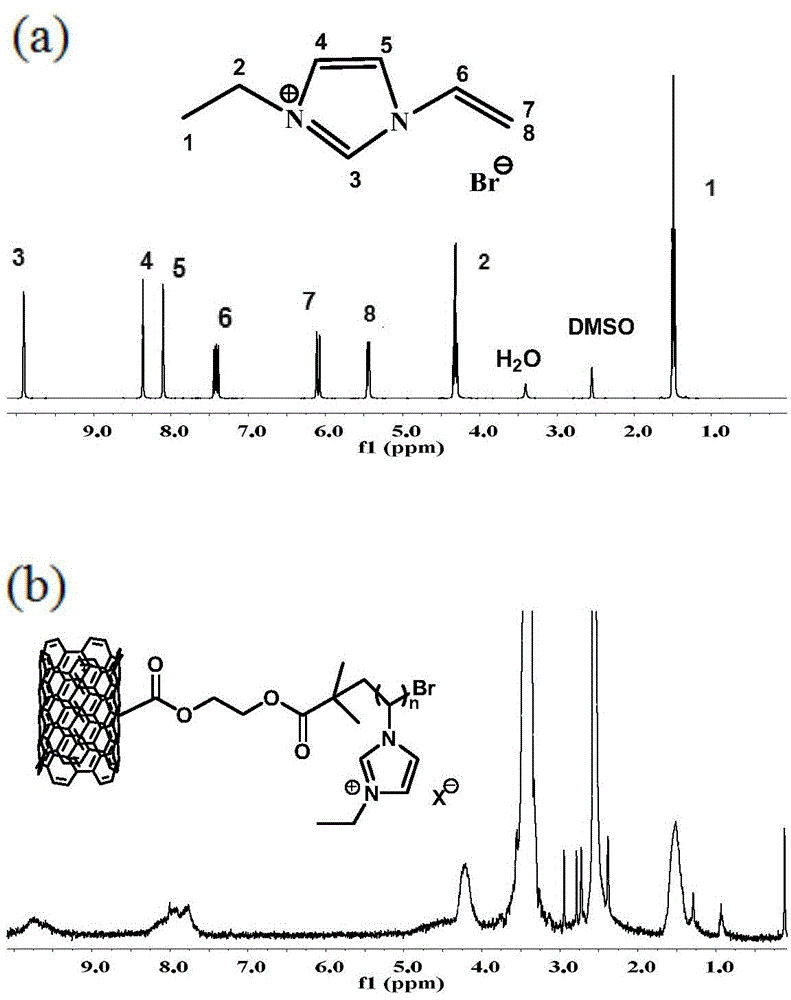

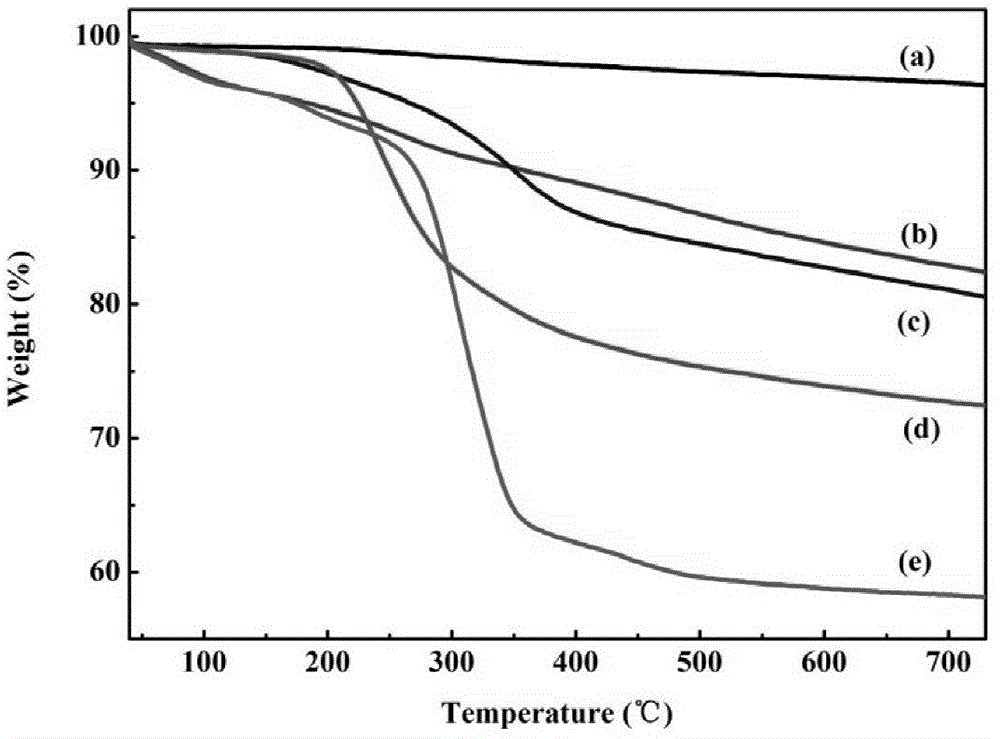

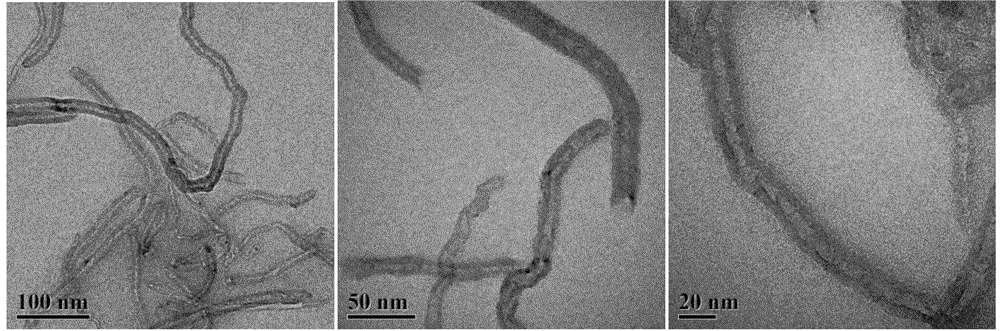

Ionic liquid polymer grafted magnetic carbon nanotube and preparation method thereof

The invention discloses a preparation method of an ionic liquid polymer grafted magnetic carbon nanotube. The method comprises the following steps: reacting halogenated hydrocarbon with 1-vinyl imidazole to synthesize an ionic liquid for later use, carrying out acidifying oxidation treatment on an original carbon nanotube by using concentrated sulfuric acid and concentrated nitric acid, and reacting the obtained carbon nanotube with thionyl chloride and ethylene glycol to obtain a hydroxylated carbon nanotube; loading an initiator bromoisobutyryl bromide to the surface of the hydroxylated carbon nanotube, and initiating polymerization of the ionic liquid on the surface of the carbon nanotube; and carrying out one-step simple ion exchange to introduce magnetic anions in order to synthesize the novel magnetic carbon nanotube. The magnetic carbon nanotube prepared in the invention has nanometer dimension and strong magnetism, and can be rapidly separated and enriched through simple magnetic field action.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

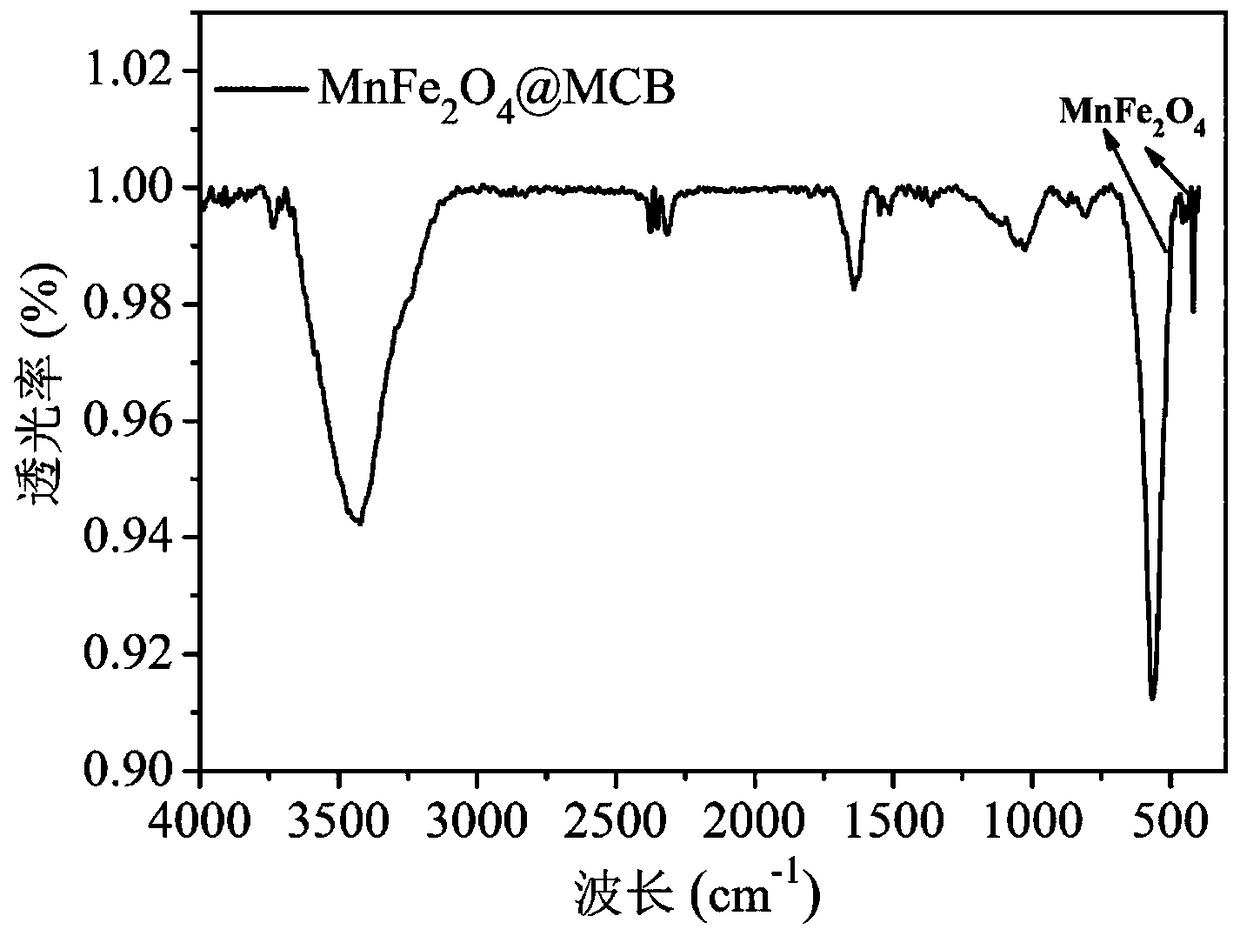

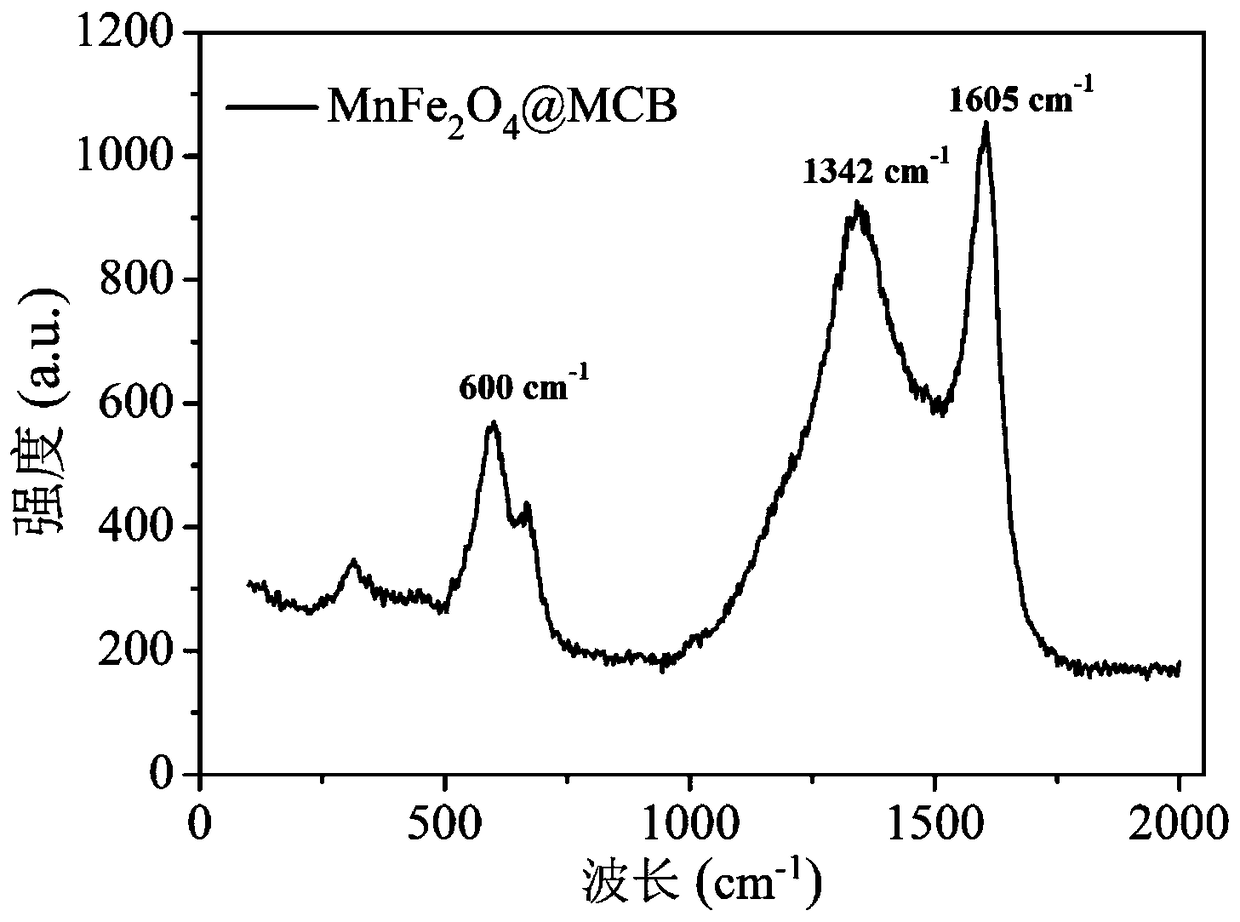

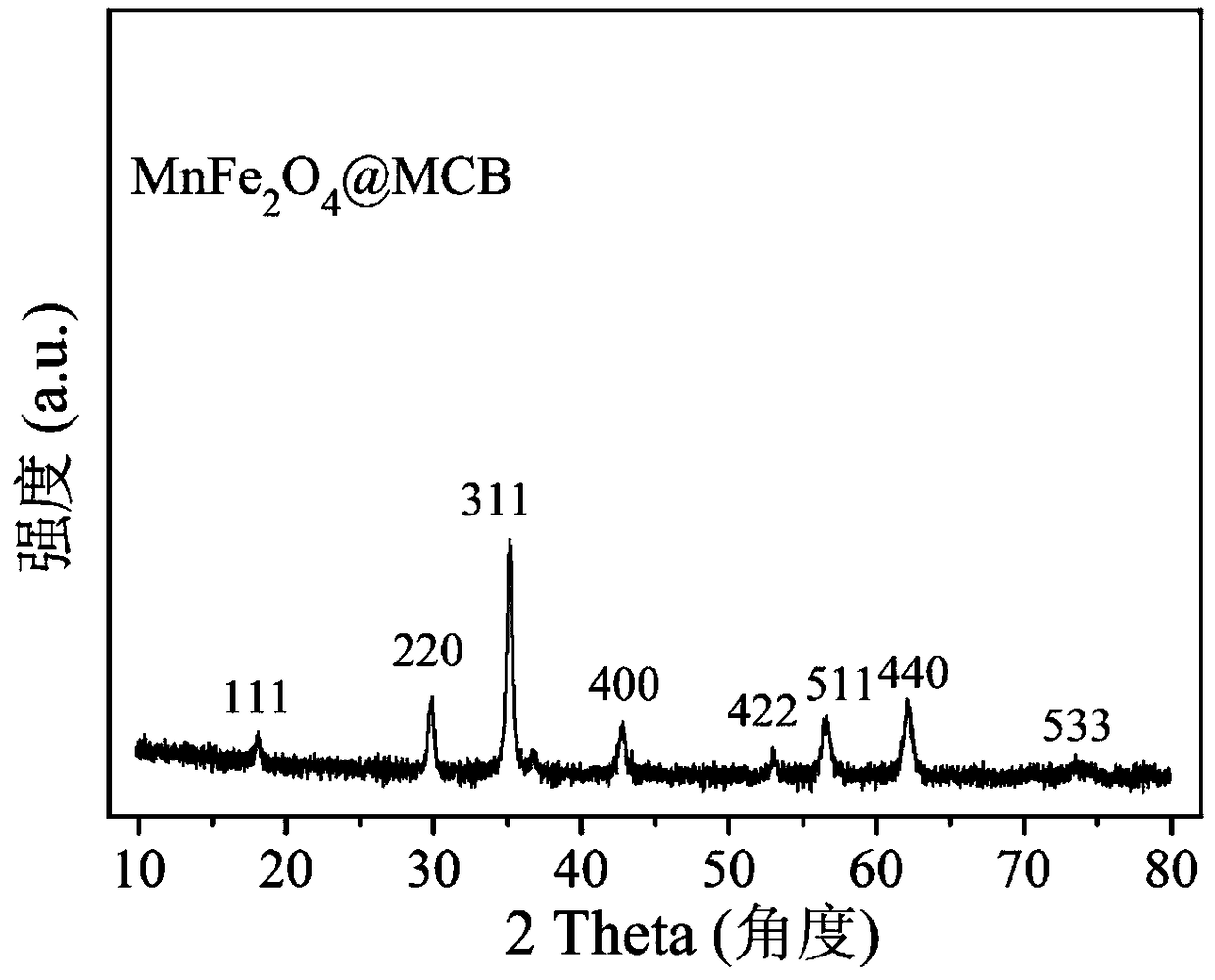

Magnetic ferromanganese oxide-loaded mesoporous cellulose biochar composite, and preparation method and application thereof

ActiveCN108704611AAchieve reuseNo pollution in the processOther chemical processesWater contaminantsDispersion stabilityCellulose

The invention belongs to the technical field of biomass resource recycling and new environmental functional materials, discloses a magnetic ferromanganese oxide-loaded mesoporous cellulose biochar composite, a preparation method thereof and application of the mesoporous cellulose biochar composite in environmental governance and remediation, and is particularly applicable to the field of adsorption of anionic pollutants. The preparation method comprises preparing mesoporous cellulose biochar, compositing MnFe2O4 in one step according to a solvothermal method, and loading the MnFe2O4 onto the mesoporous cellulose biochar to obtain the magnetic ferromanganese oxide-loaded mesoporous cellulose biochar composite. The mesoporous cellulose biochar composite prepared according to the method has the characteristics of strong magnetism, capability of being charged positively under acidic conditions, high dispersion stability, high adsorptive property and the like, can be widely applied to the field of environmental governance and remediation, is particularly applicable to pollution remediation of the anionic pollutants, such as adsorption of heavy metal and organophosphorus pesticides, andhas the glyphosate adsorption capacity as high as 167.2mg / g.

Owner:SOUTH CHINA UNIV OF TECH

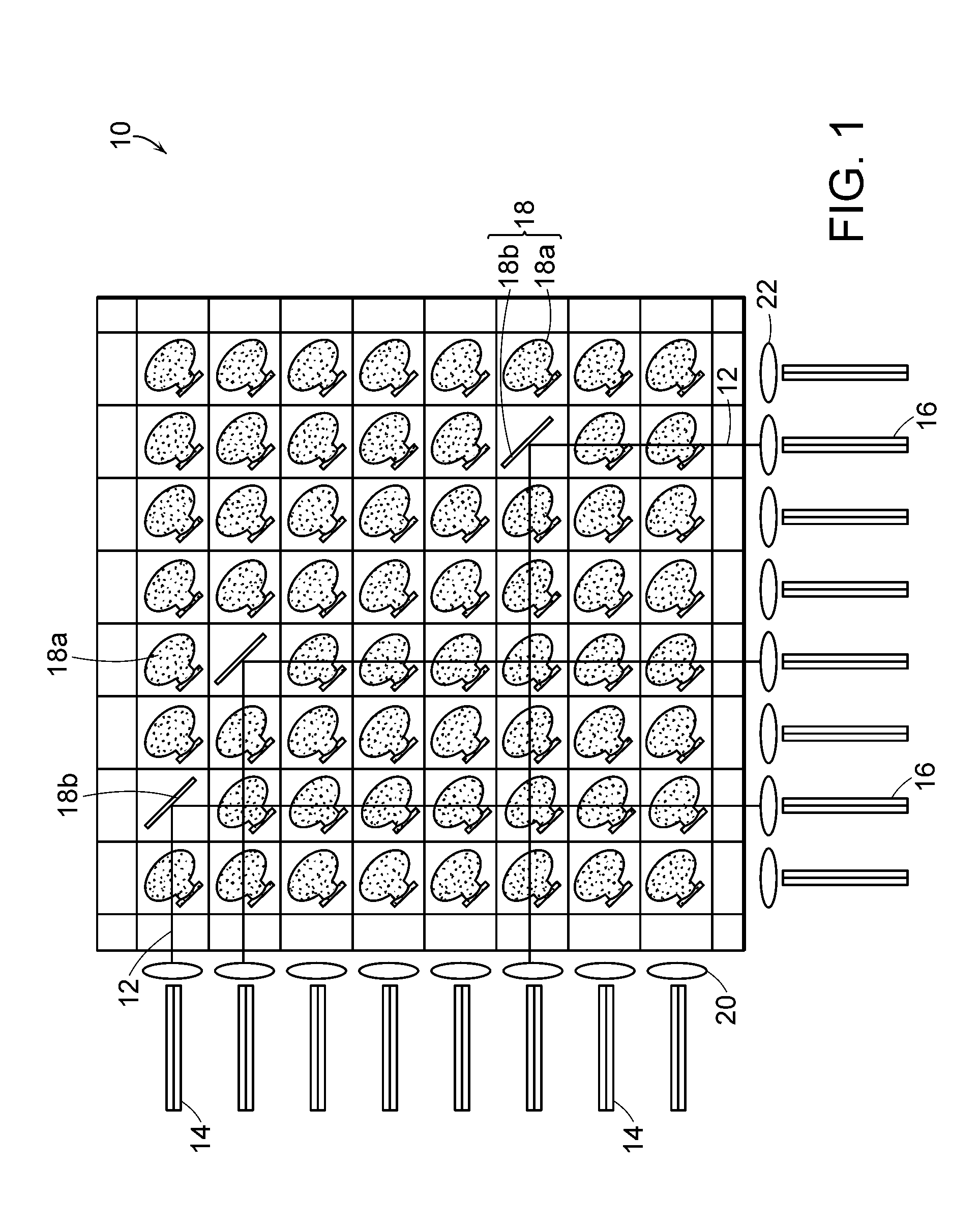

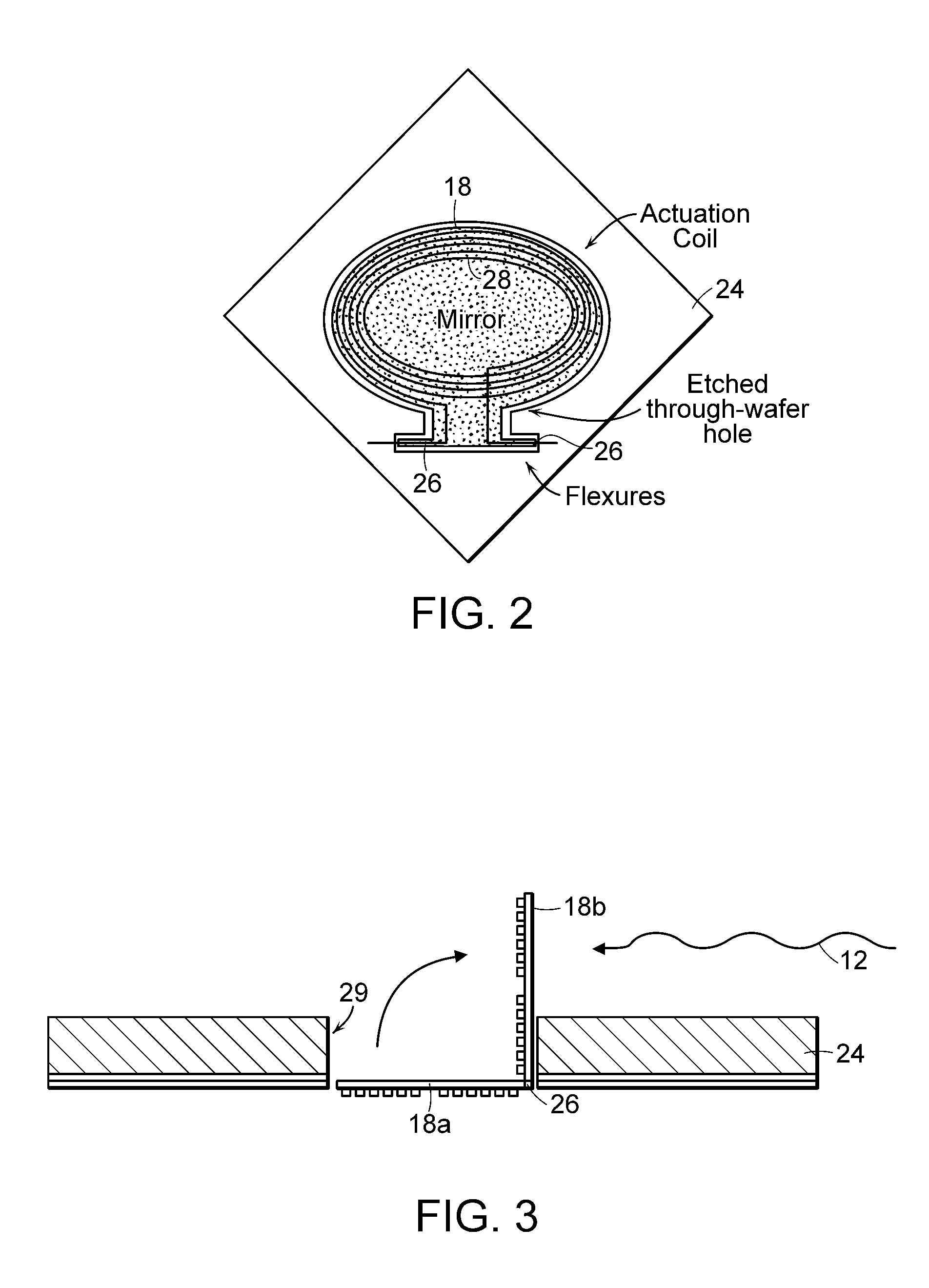

Latching mechanism for magnetically actuated micro-electro-mechanical devices

InactiveUS7142743B2Enhance magnetic fieldReduce voltageCoupling light guidesOptical switchMechanical devices

A latching mechanism is provided for selectively latching mirrors in an optical switch. The mirrors are selectively movable between rest and actuated positions. The latching mechanism provides stable latching of mirrors in an actuated position, i.e., without power being applied to maintain the actuated state.

Owner:CORNING INC

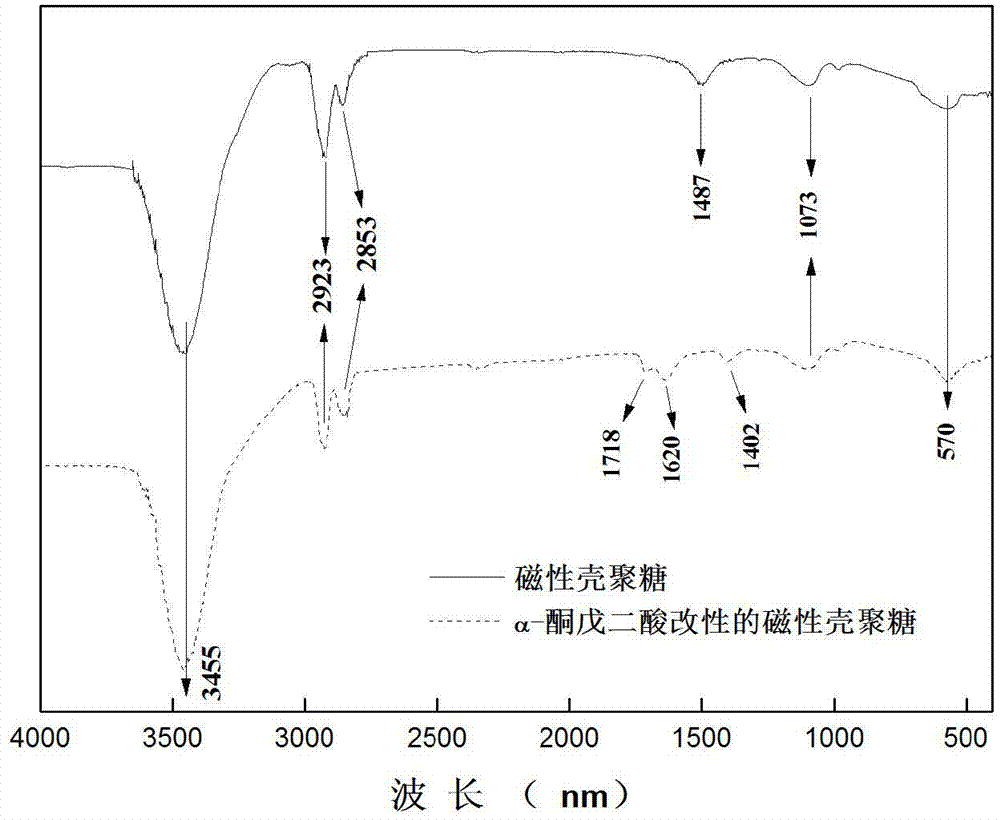

Alpha-ketoglutaric acid modified magnetic chitosan and preparation method and application thereof in field of cadmium-containing wastewater treatment

InactiveCN103611503AStable physical and chemical propertiesStrong magnetismOther chemical processesAlkali metal oxides/hydroxidesCadmium CationKetoglutaric Acid

The invention provides alpha-ketoglutaric acid modified magnetic chitosan. The alpha-ketoglutaric acid modified magnetic chitosan contains ferroferric oxide, chitosan and alpha-ketoglutaric acid and has the saturated magnetization value of 20-25emu / g, wherein magnetic chitosan is prepared from ferroferric oxide and chitosan, modified magnetic chitosan is of a reticular structure, peak values of functional groups, such as Fe-O bonds and the like, appear in an infrared spectrogram, and an agglomeration phenomenon is expressed. A preparation method of the alpha-ketoglutaric acid modified magnetic chitosan comprises the steps of adding an acetic acid solution containing chitosan into a ferroferric oxide suspension, adding a sodium tripolyphosphate solution, reacting and separating, so as to obtain the magnetic chitosan; then, adding alpha-ketoglutaric acid into an acetic acid buffer solution containing the magnetic chitosan, adding a sodium borohydride solution, and separating, thereby obtaining the alpha-ketoglutaric acid modified magnetic chitosan. The alpha-ketoglutaric acid modified magnetic chitosan has stable physical and chemical properties and strong magnetism; during the treatment of wastewater containing cadmium ions, the treatment efficiency is high, and the alpha-ketoglutaric acid modified magnetic chitosan can be repeatedly used and is convenient to recover.

Owner:HUNAN UNIV

Reconfigurable inductive to synchronous motor

ActiveUS8288908B2Guaranteed uptimeStrong magneticSynchronous generatorsWindingsViscous dampingSynchronous motor

A reconfigurable electric motor includes a rotor containing rotatable permanent magnets or non-magnetically conducting shunting pieces. The magnets and / or shunting pieces have a first position producing a weak magnetic field for asynchronous induction motor operation at startup and a second position producing a strong magnetic field for efficient synchronous operation. The motor includes a squirrel cage for induction motor operation at startup with the permanent magnets and / or shunting pieces positioned to product the weak magnetic field to not interfere with the startup. When the motor approaches or reaches synchronous RPM, the permanent magnets and / or shunting pieces rotate to produce a strong magnetic field for high efficiency synchronous operation. The position of the magnets and / or shunting pieces may be controlled by a centrifugal mechanism, or viscous damping may delay rotation of the magnets and / or shunting pieces, or electrically controlled apparatus may control positions of the magnets and / or shunting piece.

Owner:MOTOR GENERATOR TECH INC

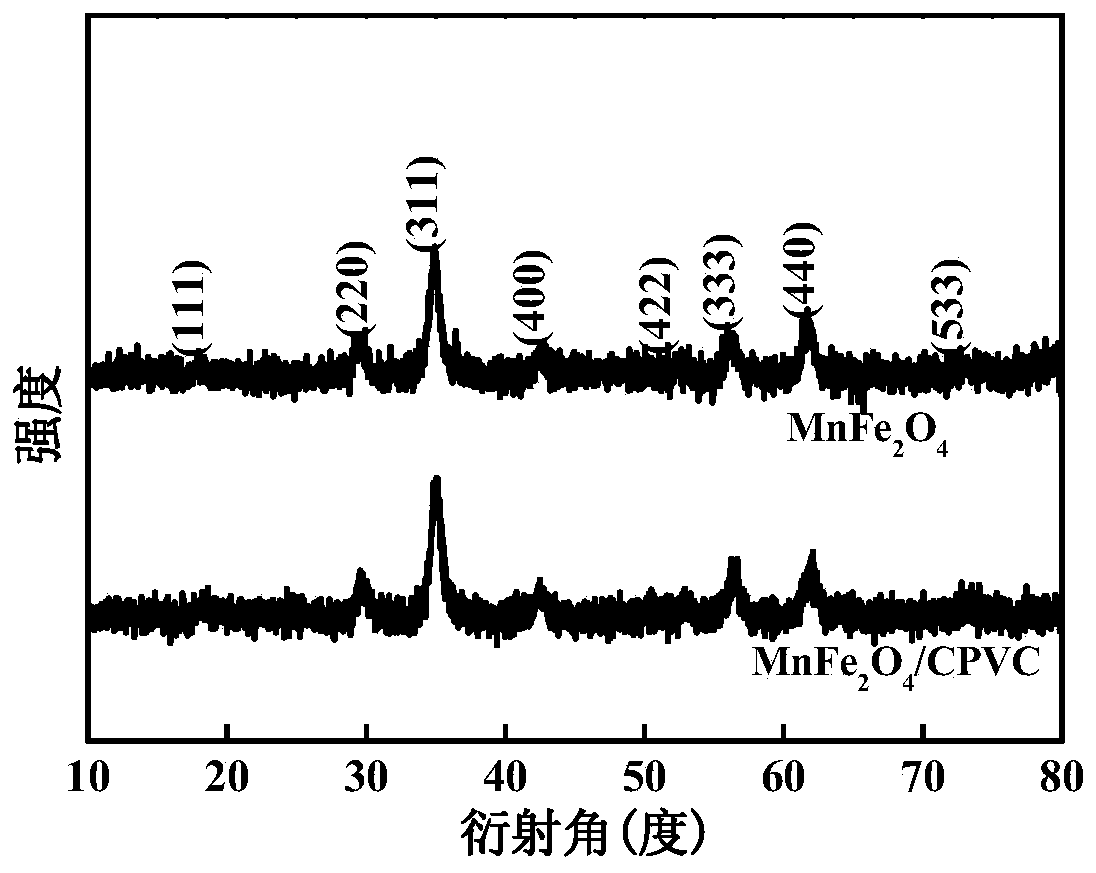

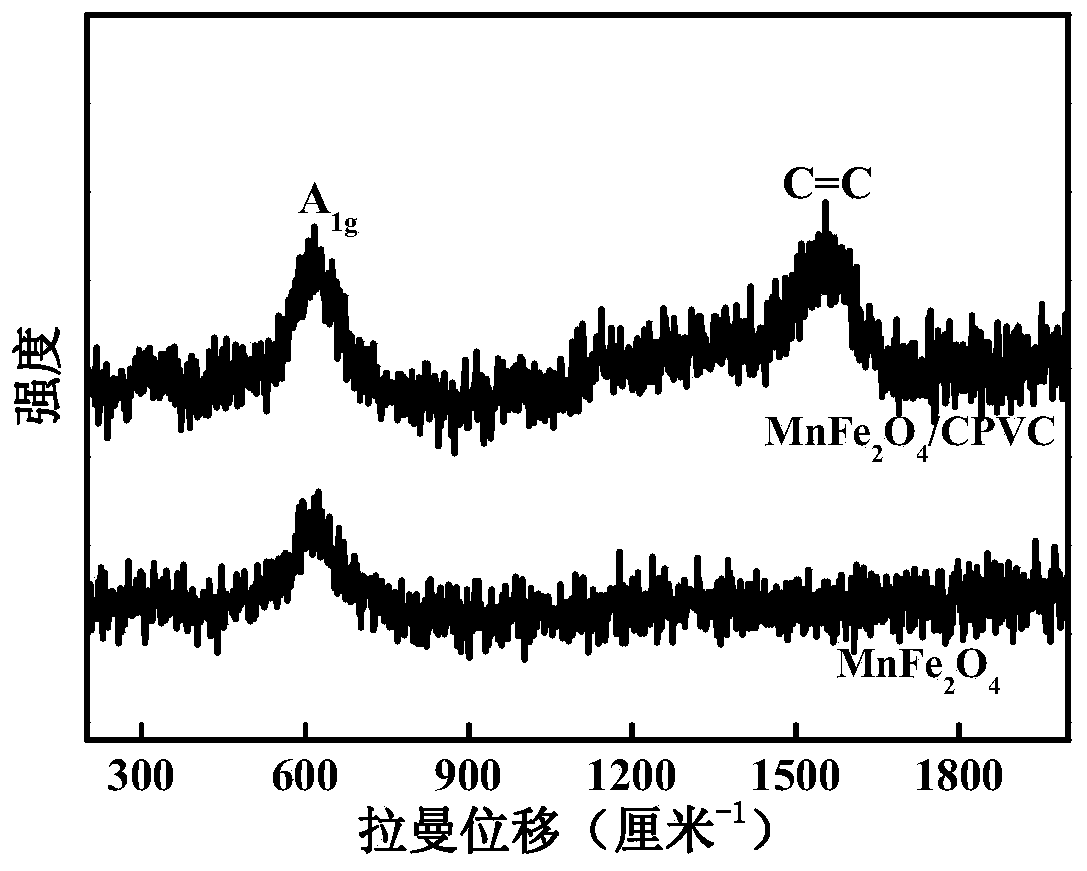

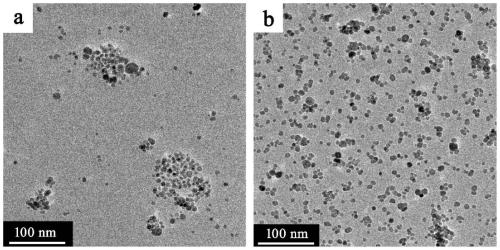

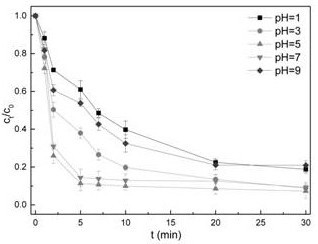

Magnetic visible-light-driven photocatalyst for treating hexavalent chromium wastewater and preparation method of magnetic visible-light-driven photocatalyst

ActiveCN109908915AEasy to handleStrong magneticWater/sewage treatment by irradiationWater contaminantsNanoparticlePolyvinyl chloride

The invention discloses a magnetic visible-light-driven photocatalyst for treating hexavalent chromium wastewater and a preparation method of the magnetic visible-light-driven photocatalyst. The preparation method comprises the following steps: preparing MnFe2O4 nanoparticles by using a solvothermal method at first; and then uniformly dispersing the MnFe2O4 nanoparticles in a tetrahydrofuran solution containing polyvinyl chloride (PVC) with different masses, and then carrying out processes of evaporating the tetrahydrofuran solvent to dryness, pyrolyzing PVC in the tetrahydrofuran solvent to convert PVC into a conjugated derivative CPVC and the like to obtain a series of MnFe2O4 / CPVC nanocomposites. The method is simple and feasible, raw materials are easy to obtain, the cost is low, the obtained nano composite material not only has high visible light catalytic activity for reducing hexavalent chromium in water, but also has strong magnetism, is easy to magnetically separate and recycle, and can be used as a new magnetic visible-light-driven photocatalyst for treating the hexavalent chromium wastewater.

Owner:YANGZHOU UNIV

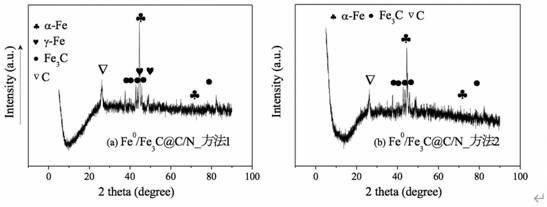

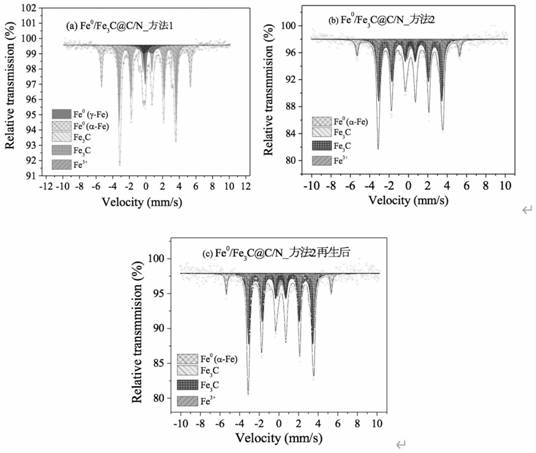

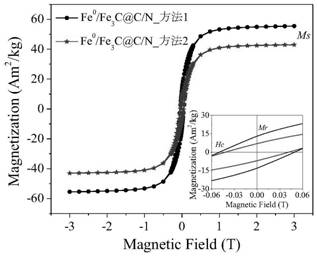

MOF-derived Fe0/Fe3C@ C/N magnetic mesoporous composite material and preparation method and application thereof

PendingCN113019420ASolve the technical problems of secondary pollutionStrong magneticWater treatment parameter controlPhysical/chemical process catalystsDimerCarbon nanocomposite

The invention discloses an MOF-derived Fe0 / Fe3C@ C / N magnetic mesoporous composite material and a preparation method and application thereof. Firstly, dicarbonyl cyclopentadienyl iron dimer is used as a metal source, benzimidazole-5, 6-dicarboxylic acid is used as an organic ligand, MOF: Fe (Hbidc) is prepared through a hydrothermal method, and then the carbonized derivative Fe<0> / Fe3C@C / N is obtained through high-temperature calcination. The preparation process is simple and controllable, and the preparation period is short. The Fe<0> / Fe3@ C / N nitrogen-doped iron-carbon nano composite material prepared by the method has high PS catalytic activity and strong ferromagnetism, is easy to separate and recover, can be recycled and regenerated, and has a good application prospect in the aspect of persulfate environment catalytic materials.

Owner:DONGGUAN UNIV OF TECH

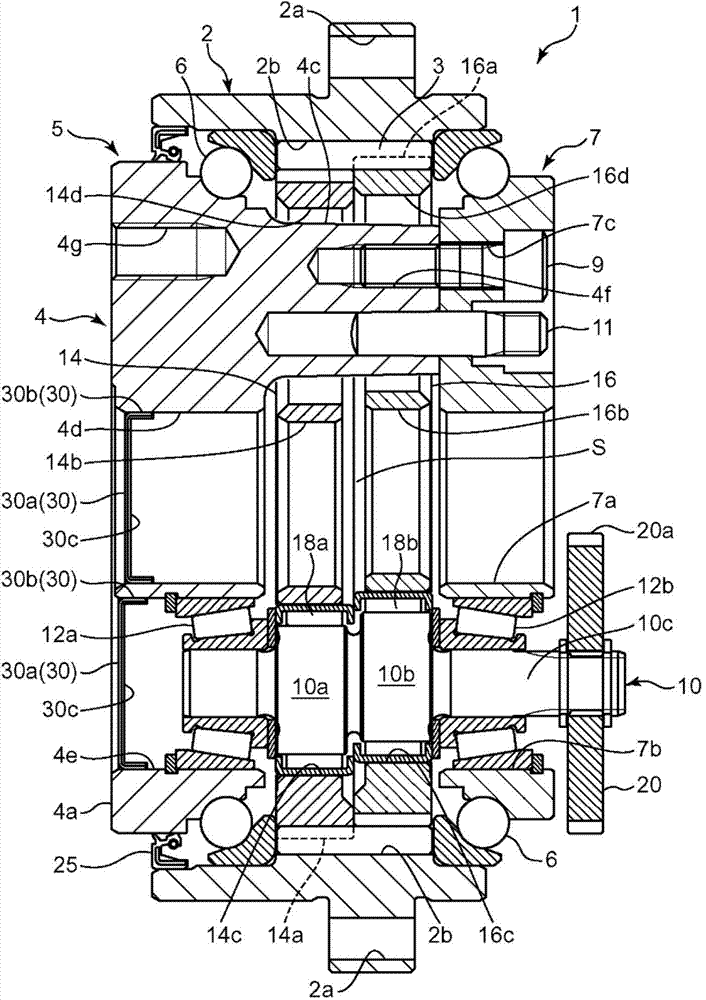

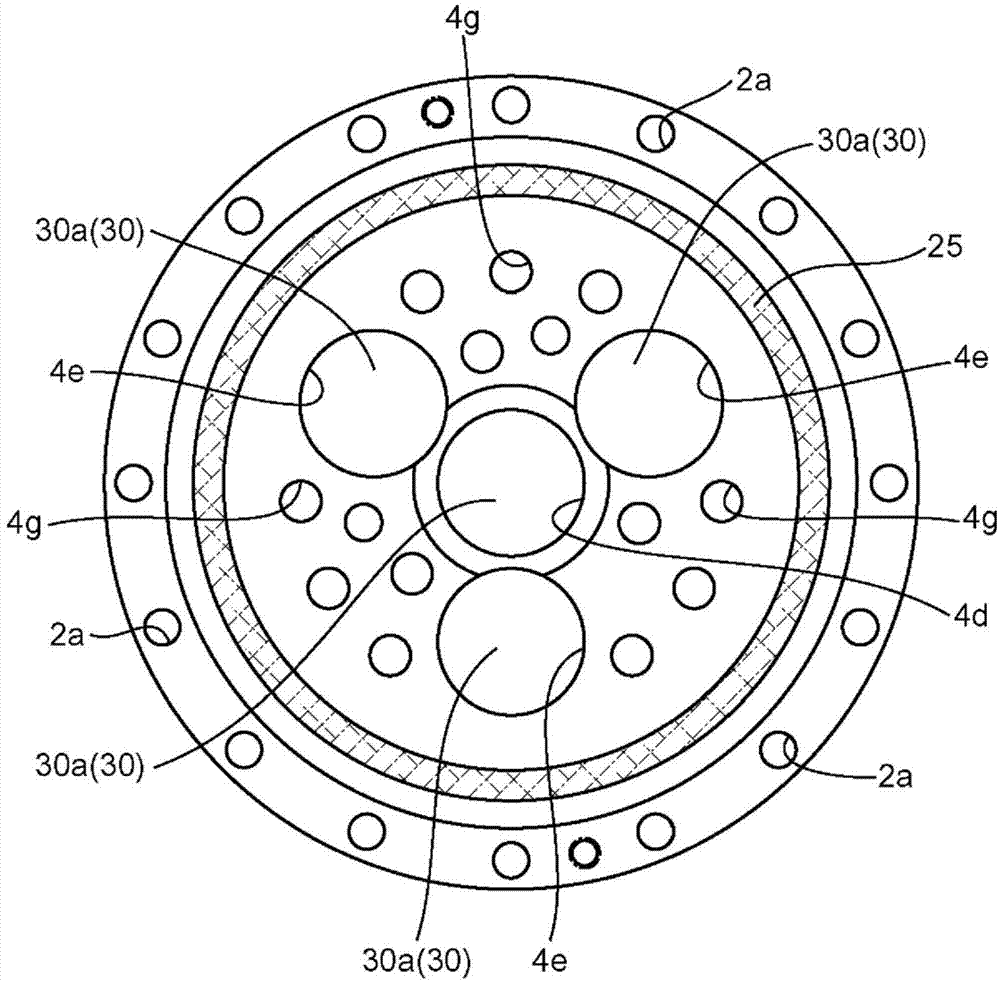

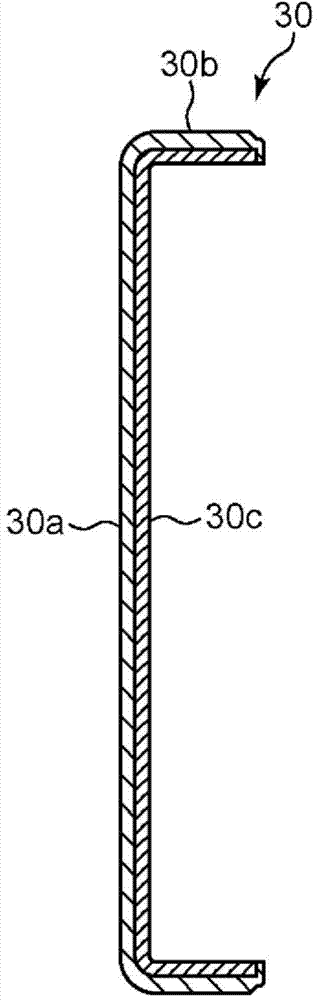

Eccentric oscillation-type gear device

An eccentric oscillation-type gear device (1) comprising: eccentric sections (10a, 10b); oscillating gears (14, 16); an outer tube (2) having an internal gear pin (3) that engages with the outer teeth (14a, 16a) of the oscillating gears (14, 16); a carrier (4); and an oil seal cap (30). A closed space (S) housing the oscillating gears (14, 16) is formed by the carrier (4) and the outer tube (2). A penetration hole (4d) and a crank shaft attachment hole (4e) that connect to the closed space (S) are formed in the carrier (4). The oil seal cap (30) is arranged on the penetration hole (4d) and the crank shaft attachment hole (4e), and has strong magnetism so as to be capable of attaching metal powder.

Owner:NABLESCO CORP

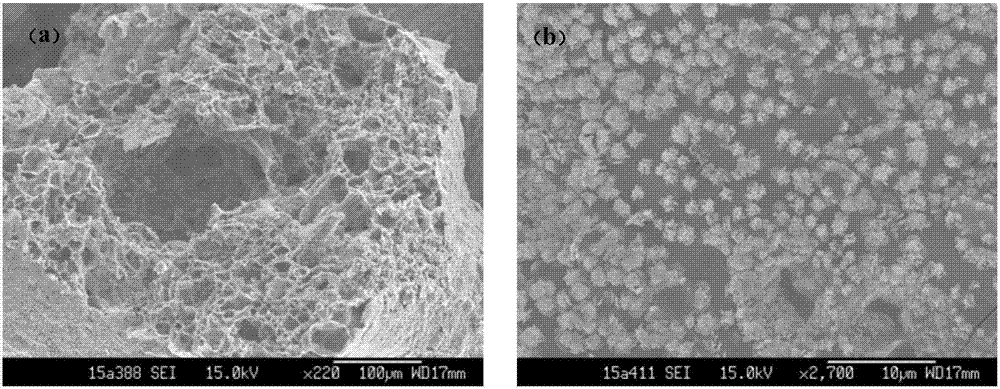

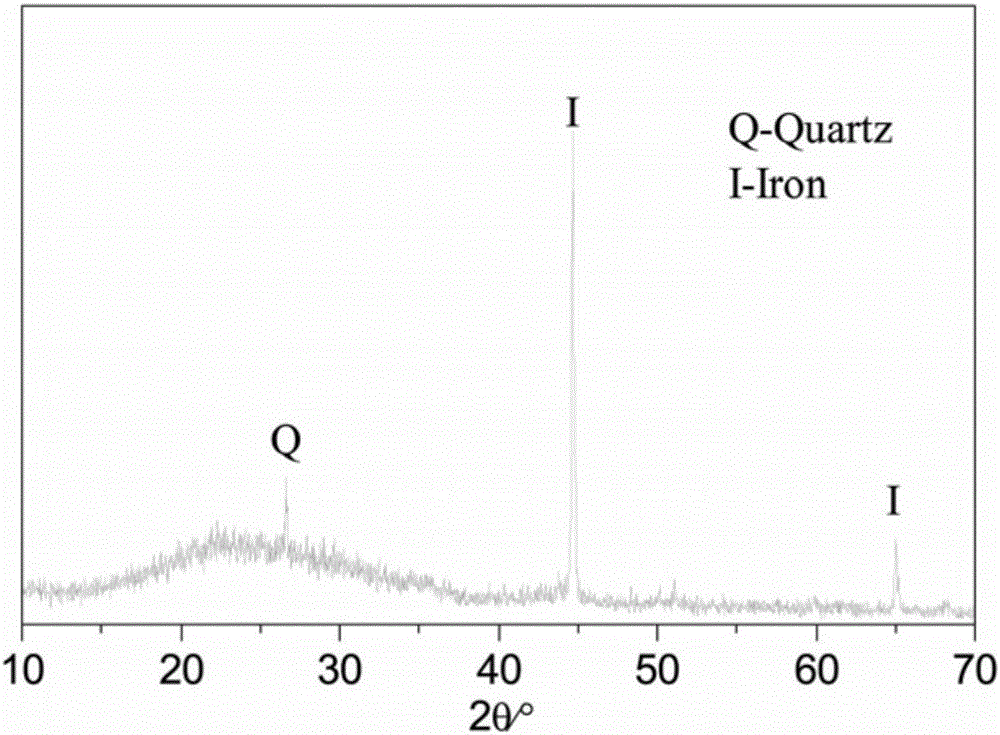

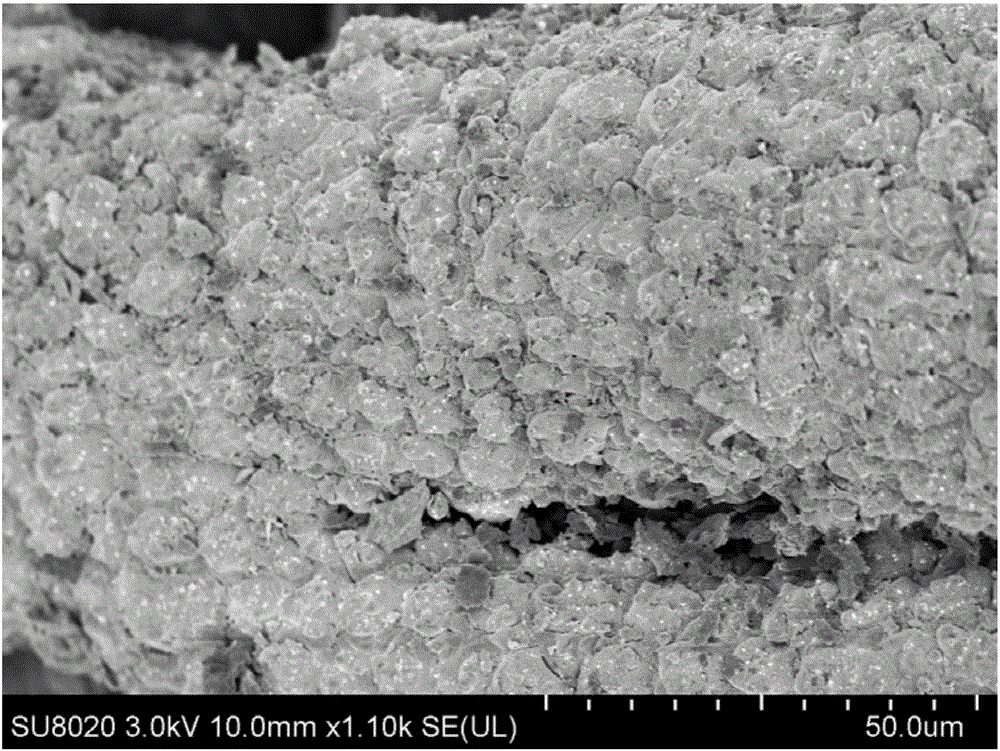

Method for preparing Fe/C composite material of porous structure by using sedimentary siderite

ActiveCN105817212AHigh particle strengthHas a bonding effectOther chemical processesWater contaminantsPorosityMagnetic susceptibility

The invention discloses a method for preparing a Fe / C composite material of a porous structure by using sedimentary siderite .The method is characterized in that the Fe / C composite material is obtained by using the low-grade sedimentary siderite and biomass powder as raw materials, performing mixing and forming and then performing pyrolysis and reduction reaction at the temperature of 650-900 DEG C under a reducing atmosphere, and the main phase of the material is biomass charcoal and zero-valent iron .The Fe / C composite material of the porous structure has high open porosity, high magnetic susceptibility, high adsorption and high biochemical activity, is a cheap biological carrier material having biological activity and adsorption performance, has a great application prospect in slightly polluted water purification and is especially suitable for simultaneous denitrification treatment of an eutrophic water body.

Owner:HEFEI UNIV OF TECH

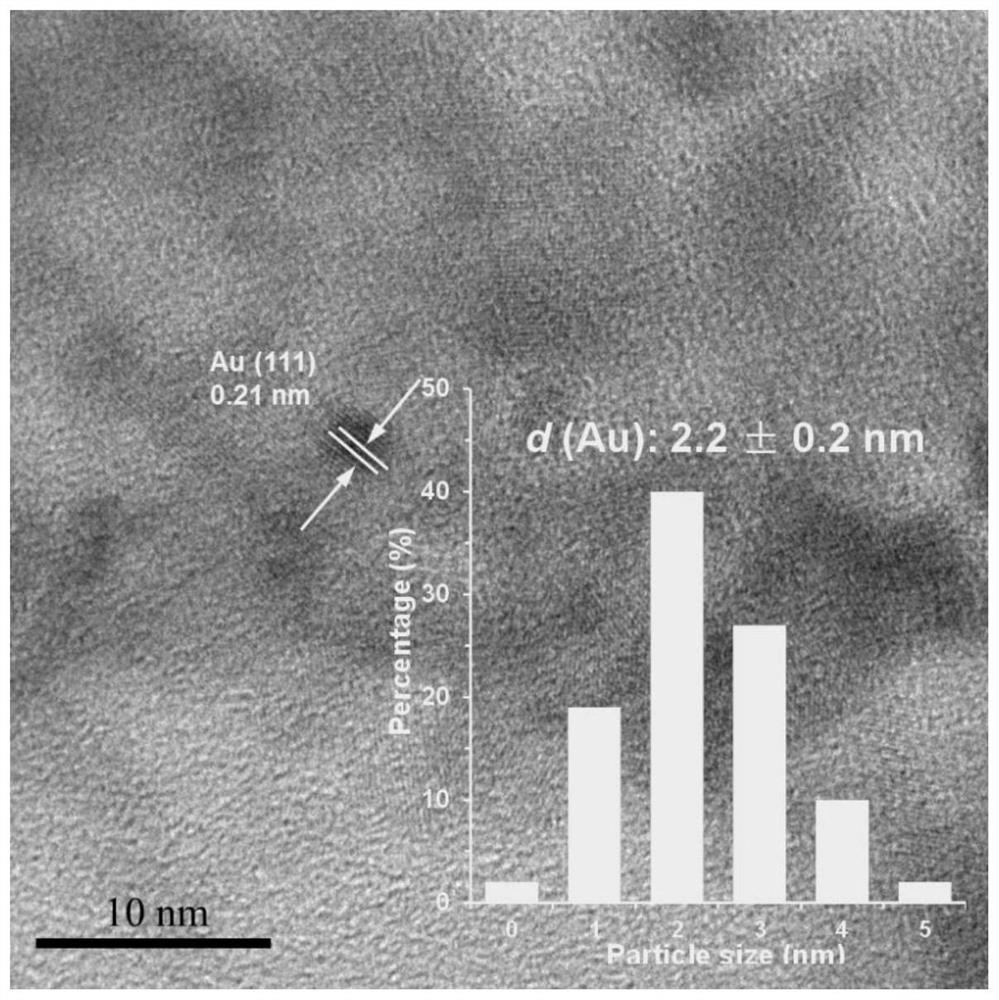

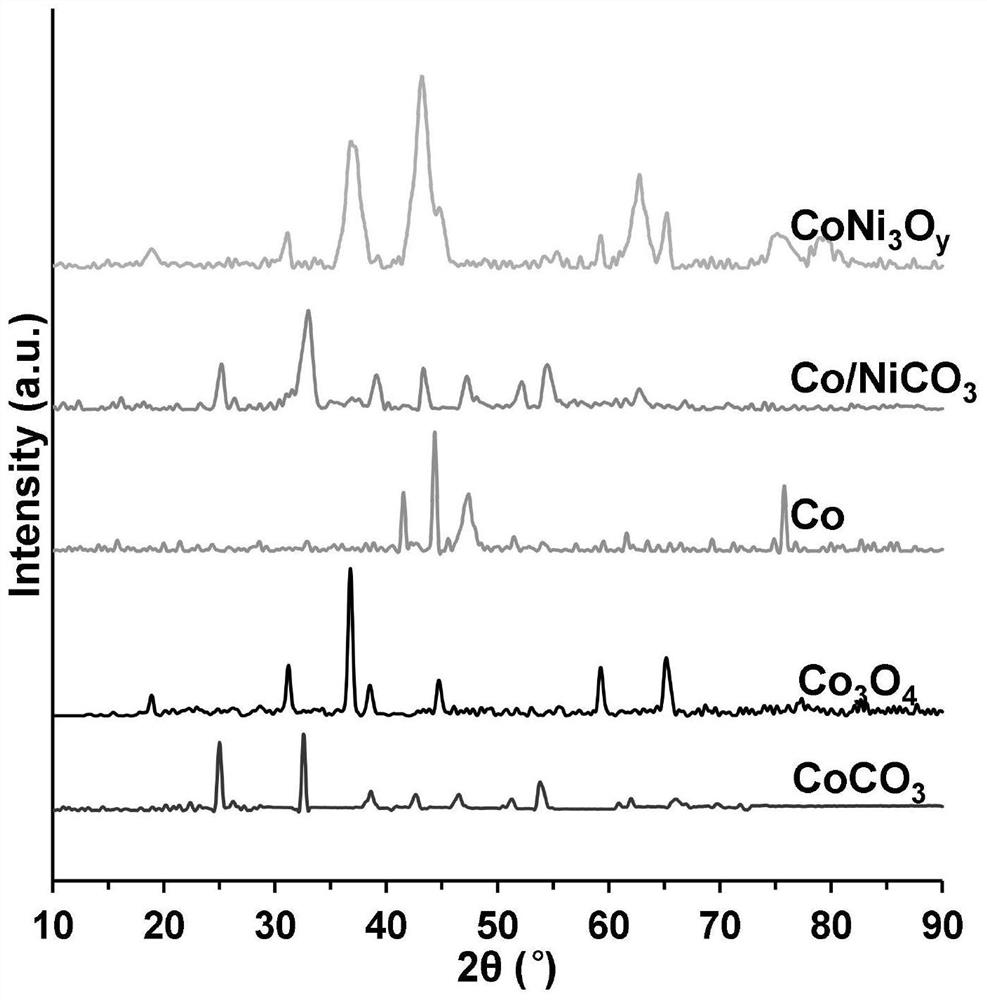

Magnetic nickel-cobalt oxide supported gold catalyst, preparation method and application thereof, and preparation method of 2, 5-furandicarboxylic acid

ActiveCN113275019AStrong magneticEfficient recyclingOrganic chemistryCatalyst activation/preparationPtru catalystChemical composition

The invention provides a magnetic nickel-cobalt oxide supported gold catalyst, a preparation method and application thereof, and a preparation method of 2, 5-furandicarboxylic acid, and belongs to the technical field of catalysts. The magnetic nickel-cobalt oxide supported gold catalyst provided by the invention comprises a magnetic nickel-cobalt oxide carrier and gold nanoparticles supported on the magnetic nickel-cobalt oxide carrier, wherein the chemical composition of the magnetic nickel-cobalt oxide carrier is CoNixOy, x ranges from 1 to 5, and y is the number of oxygen atoms meeting the requirement that the valence state of CoNixOy is zero. The magnetic nickel-cobalt oxide supported gold catalyst provided by the invention has high catalytic activity on preparation of 2, 5-furandicarboxylic acid by oxidation of 5-hydroxymethylfurfural, has high selectivity on a target product 2, 5-furandicarboxylic acid, has good stability, can realize separation of the catalyst and the product through a simple and convenient physical magnetic separation mode, and the catalyst is high in repeated utilization rate and is an efficient, specific, green and environment-friendly catalyst.

Owner:YUNNAN UNIV

Magnetic flocculant with aluminum salt loaded with ferroferric oxide and preparation method of magnetic flocculant

InactiveCN106966473AReduce dosageShort flocculation timeWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by flocculation/precipitationFlocculationIron(II,III) oxide

The invention discloses a magnetic flocculant with aluminum salt loaded with ferroferric oxide. The magnetic flocculant is prepared by loading ferroferric oxide nanoparticles on aluminum salt. The invention further discloses a preparation method of the magnetic flocculant. The preparation method comprises the following steps: S1, adding aluminum salt and water into a reactor, and stirring till the aluminum salt is dissolved and sufficiently mixed; S2, adding NaOH, performing high-temperature polymerization reaction, and transferring a reaction solution into an ultrasonic cleaning machine; S3, adding ferroferric oxide nanoparticles into hydrochloric acid for acidizing treatment, filtering, adding into the ultrasonic cleaning machine of the step S2, performing ultrasonic treatment, and performing standing to age, thereby obtaining the magnetic flocculant. The magnetic flocculant disclosed by the invention has the advantages of being small in addition amount, short in flocculation time, good in flocculation property, small in pH value and temperature influence and the like as compared with a conventional flocculant, not only is a relatively large specific surface area maintained, but also a relatively good adsorption property is achieved, and the magnetic flocculant can be effectively separated and recycled after being used.

Owner:SCIMEE TECH & SCI CO LTD

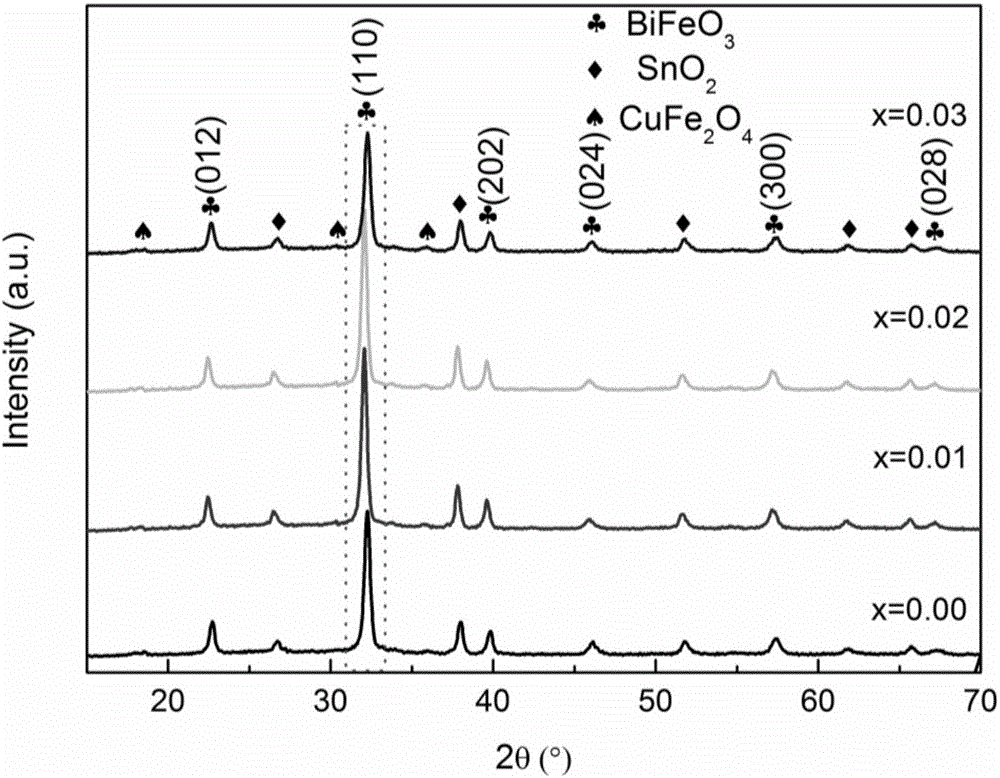

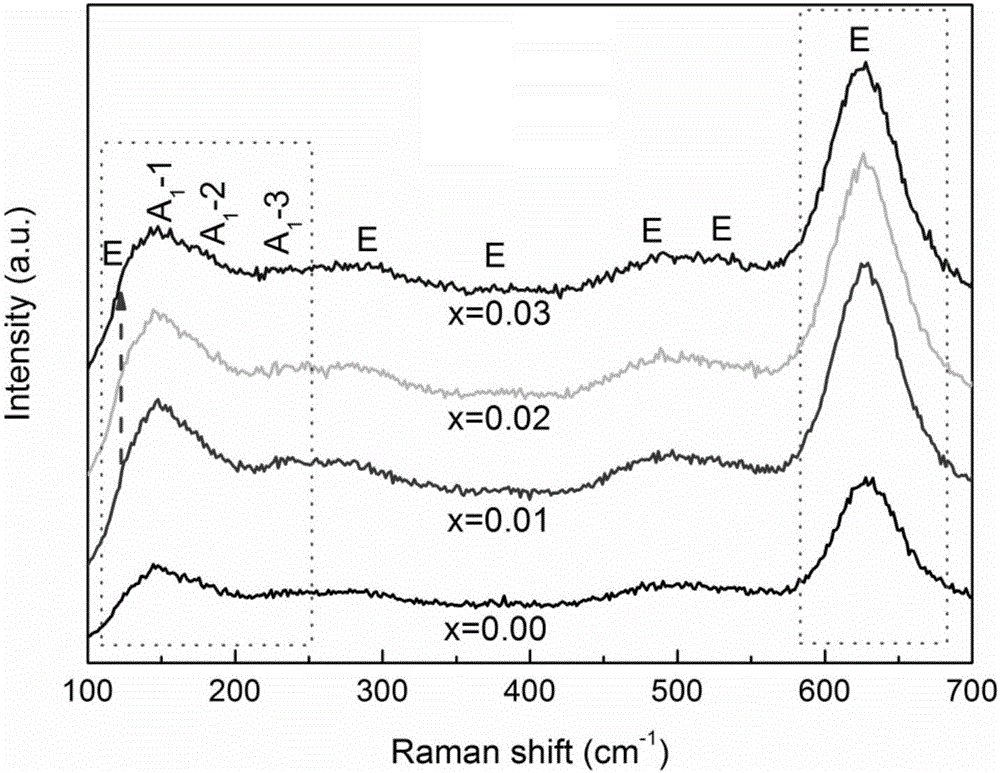

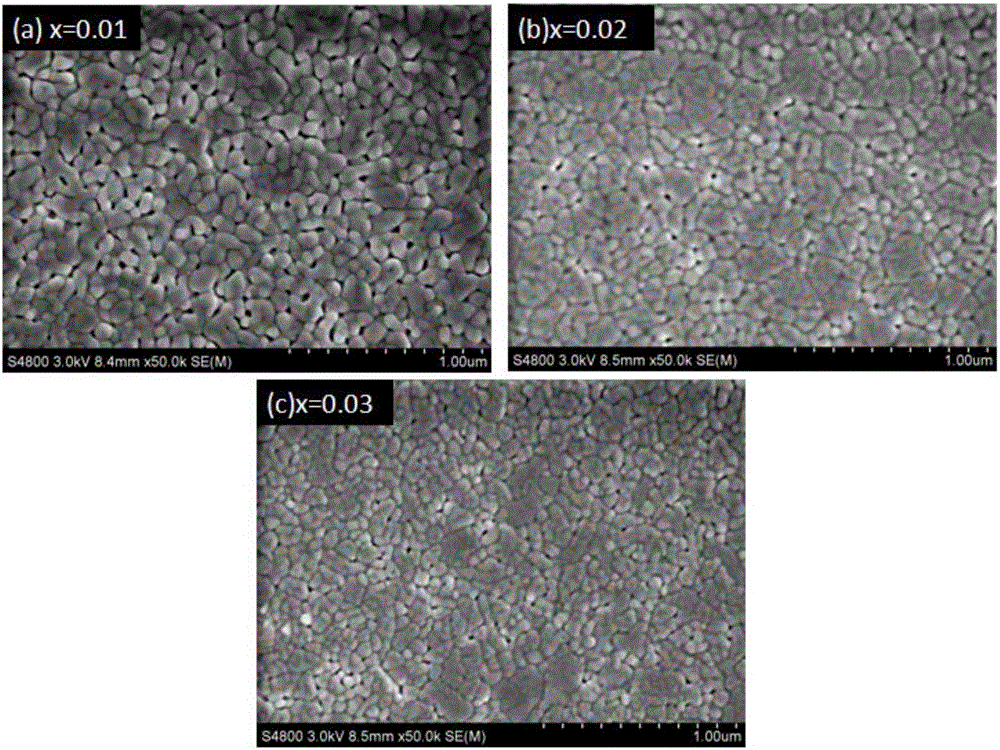

Multiferroic Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3-CuFe2O4 composite film and preparation method thereof

ActiveCN105906221APrevent volatilizationInhibition transitionCoatingsLeakage current densityComposite film

The invention discloses a multiferroic Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3-CuFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3 (x=0.01-0.05) crystalline film in the upper layer and a CuFe2O4 crystalline film in the lower layer. The preparation method comprises respectively preparing a Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3 precursor solution and a CuFe2O4 precursor solution, carrying out spin-coating on a substrate with multiple CuFe2O4 films and carrying out spin-coating on the CuFe2O4 film with multiple Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3 films to obtain the multiferroic Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3-CuFe2O4 composite film. The preparation method has simple equipment requirements, can prepare the film with good uniformity, easily controls a doping amount, improves ferroelectric and ferromagnetic properties of the film and effectively reduces film leakage current density.

Owner:SHAANXI UNIV OF SCI & TECH

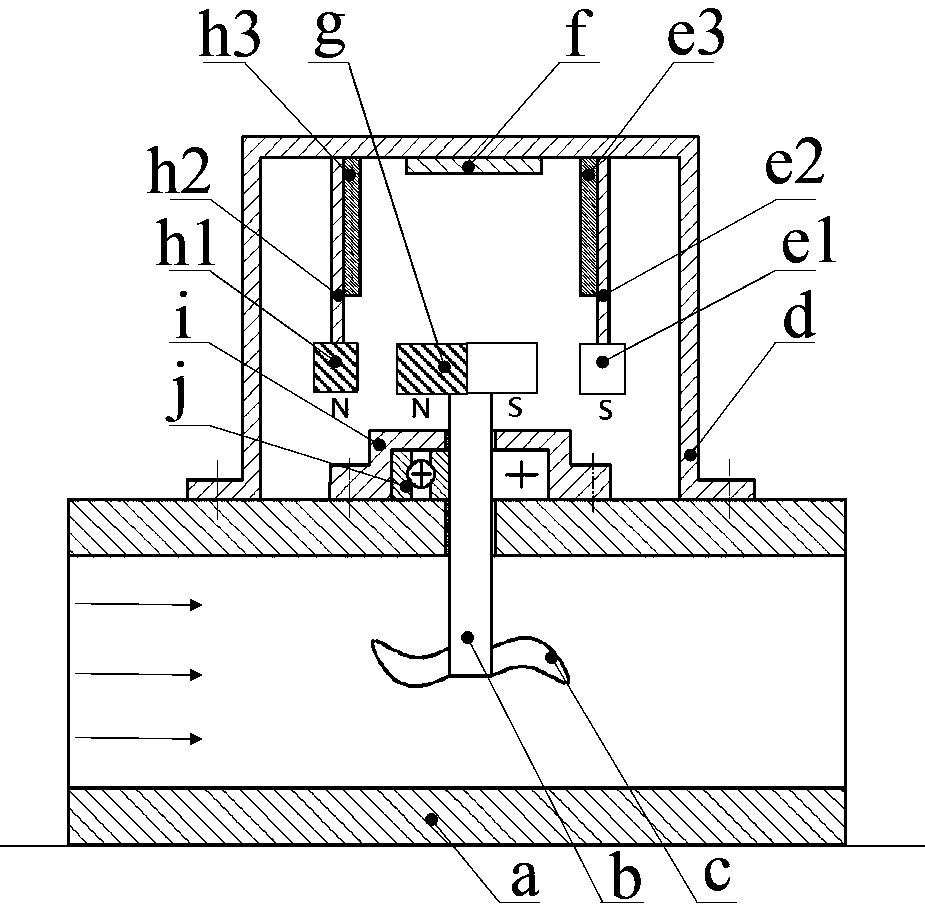

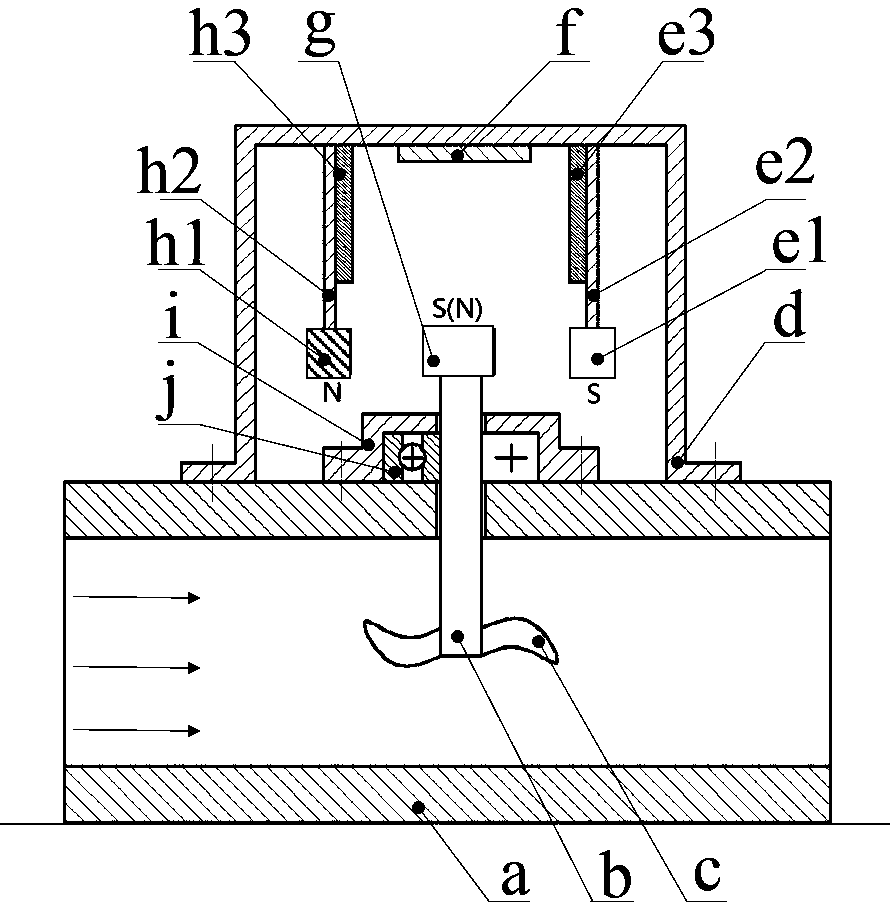

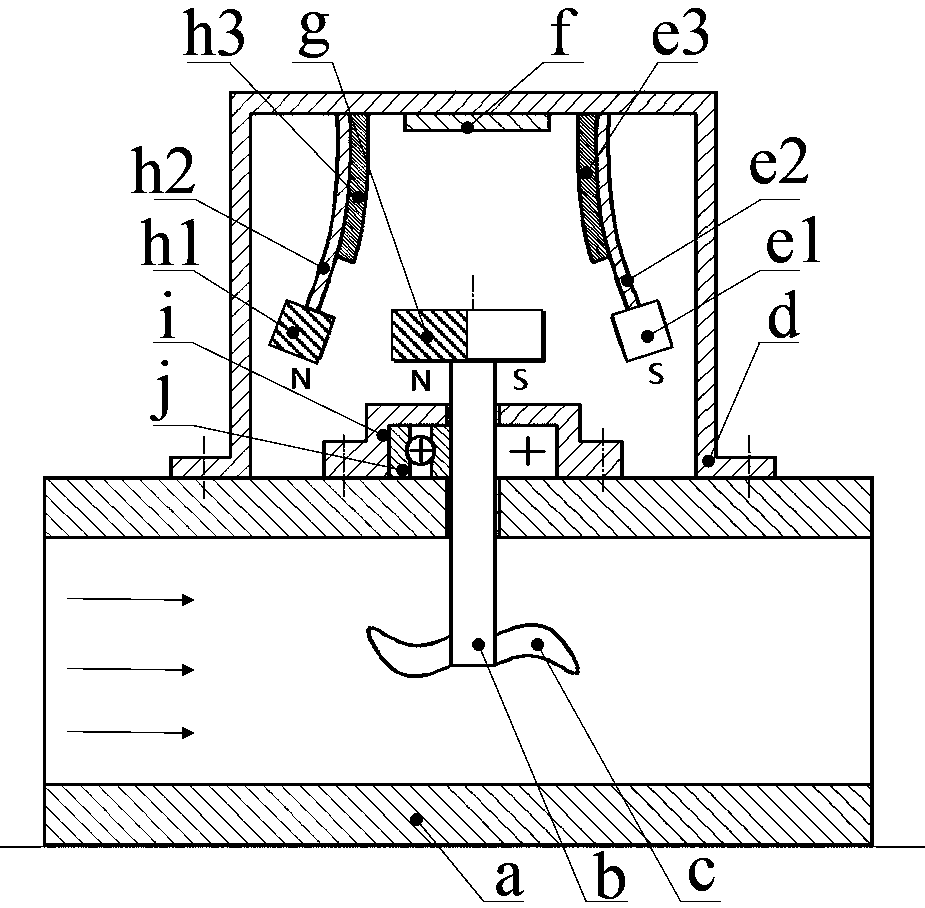

Piezoelectric energy harvester applied to pipeline fluid monitoring

ActiveCN107707151ASimple structure and processSimple preparation processPiezoelectric/electrostriction/magnetostriction machinesElectricityImpeller

The invention relates to a piezoelectric energy harvester applied to pipeline fluid monitoring, and belongs to the fields of new energy and piezoelectric power generation. Impellers are positioned onthe inner wall, which passes through one end of a shaft, of a pipeline, and are positioned in the center of the pipeline; strip-shaped permanent magnets are arranged at the other end of the shaft, andare positioned on the outer wall of the pipeline; the shaft is supported by a bearing and a bearing pedestal and vertically mounted above the pipeline; each piezoelectric vibrator consists of a metalsubstrate, a piezoelectric sheet and the strip-shaped permanent magnets in a gluing manner; one end of the metal substrate is connected with the interior of the metal shell, the free end is connectedwith the permanent magnets, and the surface is glued with the piezoelectric sheet; and a circuit board is just mounted in the center of the interior of the shell, and the shell is mounted on the upper part of the pipeline. The piezoelectric energy harvester has the characteristics and advantages as follows: the stable piezoelectric energy harvester is formed by interaction force between the permanent magnets; and the piezoelectric energy harvester is simple in structure and process, low in cost, free of accelerated speed sudden change, high in vibration stability, high in power generation capability and high in reliability, and capable of improving electric energy production by increasing the number and prolonging the piezoelectric vibrators.

Owner:XIANGTAN UNIV

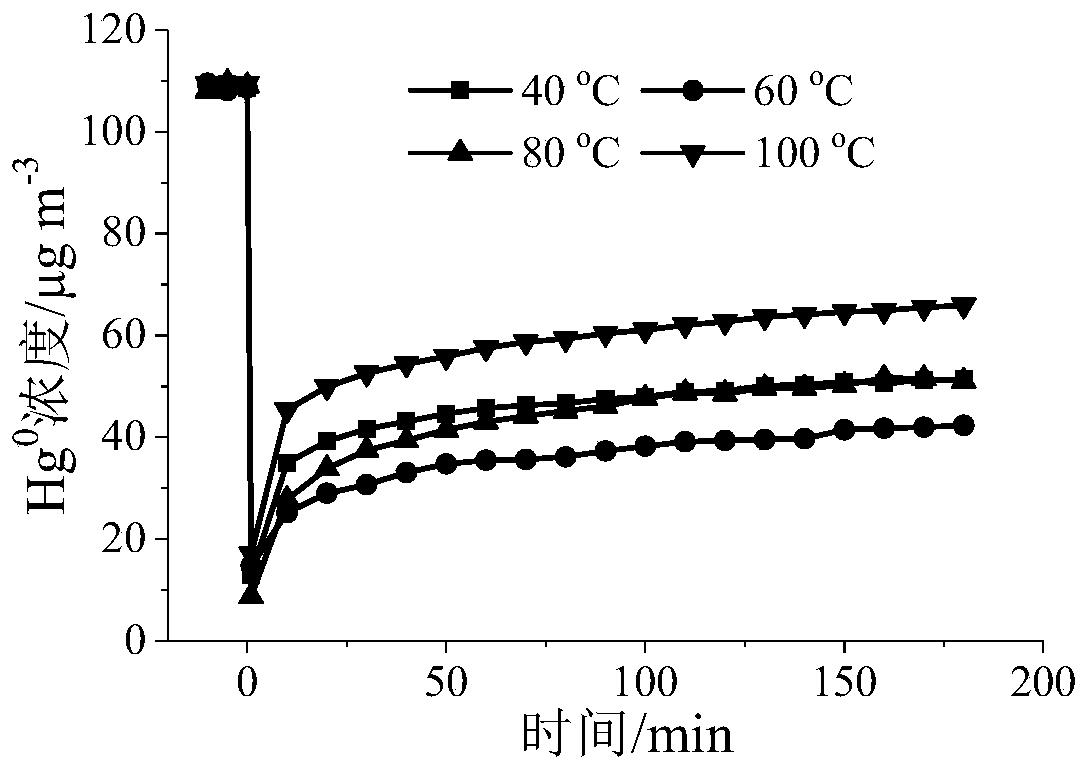

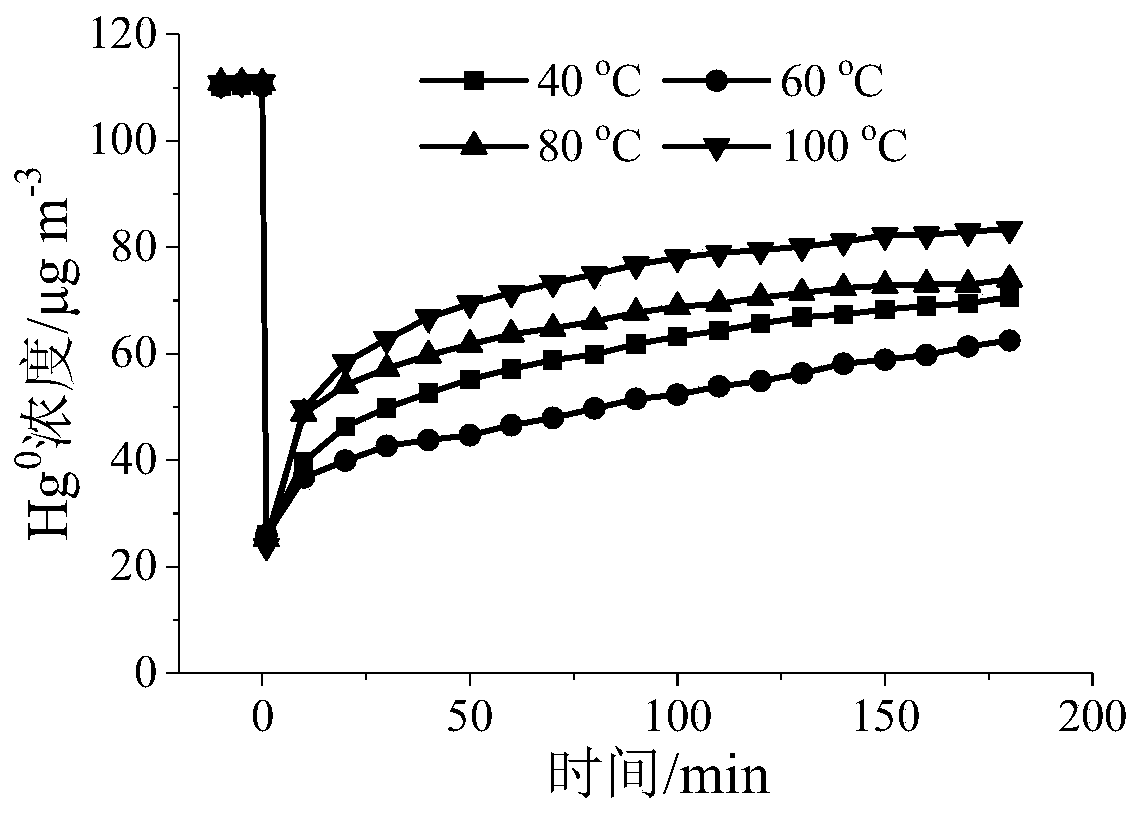

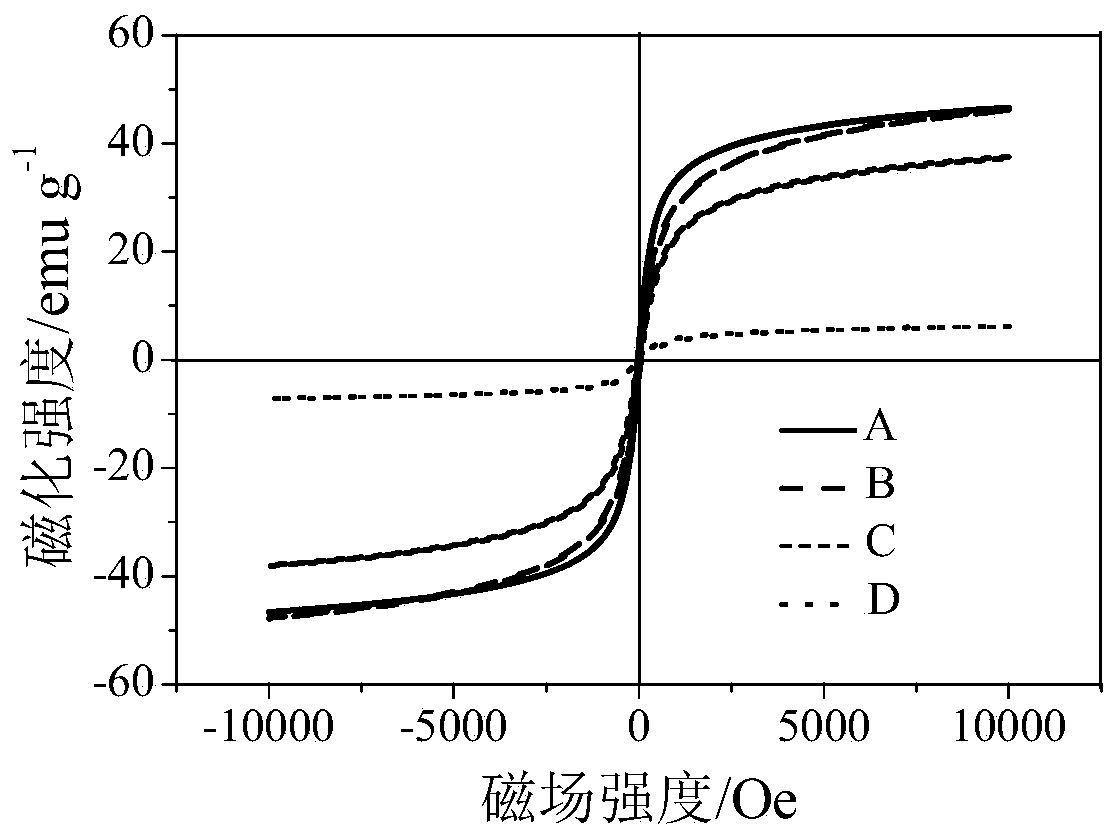

Magnetic renewable adsorbent for adsorbing gaseous zero-valent mercury and preparation method of magnetic renewable adsorbent

ActiveCN110801805AExcellent gaseous zero-valent mercury adsorption performanceStrong magneticGas treatmentOther chemical processesPhosphomolybdic acidSorbent

The invention discloses a magnetic renewable adsorbent for adsorbing gaseous zero-valent mercury and a preparation method of the magnetic renewable adsorbent, and belongs to the technical field of mercury adsorption. The adsorbent is formed by performing phosphomolybdic acid (HPMo) grafting on magnetite (Fe3O4) in a preparation process to form HPMo@Fe3O4, then performing high-temperature calcination to obtain MoO3@gamma-Fe2O3, and finally performing vulcanization modification. The phase change of maghemite is inhibited by a means of phosphomolybdic acid grafting, so as to improve the thermal stability of maghemite, and the magnetic property of maghemite is improved; meanwhile, the zero-valent mercury adsorption capacity of the phosphomolybdic acid grafted maghemite is improved by controlling the vulcanization effect of the surface of the phosphomolybdic acid grafted maghemite, the magnetic adsorbent which has excellent low-temperature zero-valent mercury adsorption capacity and can berecycled is prepared, and the magnetic adsorbent can be suitable for being combined with a wet-type electric precipitator to control mercury pollution of a coal-fired power plant in a centralized mode.

Owner:JIANGNAN UNIV

Preparation method of nano-magnetic chitin immobilized enzyme

InactiveCN1904043AStrong magneticHigh recovery rate of activityOn/in organic carrierLiquid ratioChitin formation

The present invention discloses a preparation method of nano magnetic chitosan immobilized enzyme. Said method includes the following steps: making nano magnetic chitosan particles whose surface contains acylchloro functional group be dispersed in enzyme-bearing solution, stirring them to make reaction for 2-8 hr at 20-25 deg.C, making solid-liquid separation in magnetic field, using phosphoric acid buffer solution to wash the magnetic precipitate for three times so as to obtain the required nano magnetic chitosan immobilized enzyme, the concentration of enzyme in enzyme-bearing solution is 0.01-0.1%. and the solid-liquid ratio of nano magnetic chitosan whose surface contains acylchloro functional group and enzyme-bearing solution is 1:50-1:200 g / ml.

Owner:SOUTH CHINA UNIV OF TECH

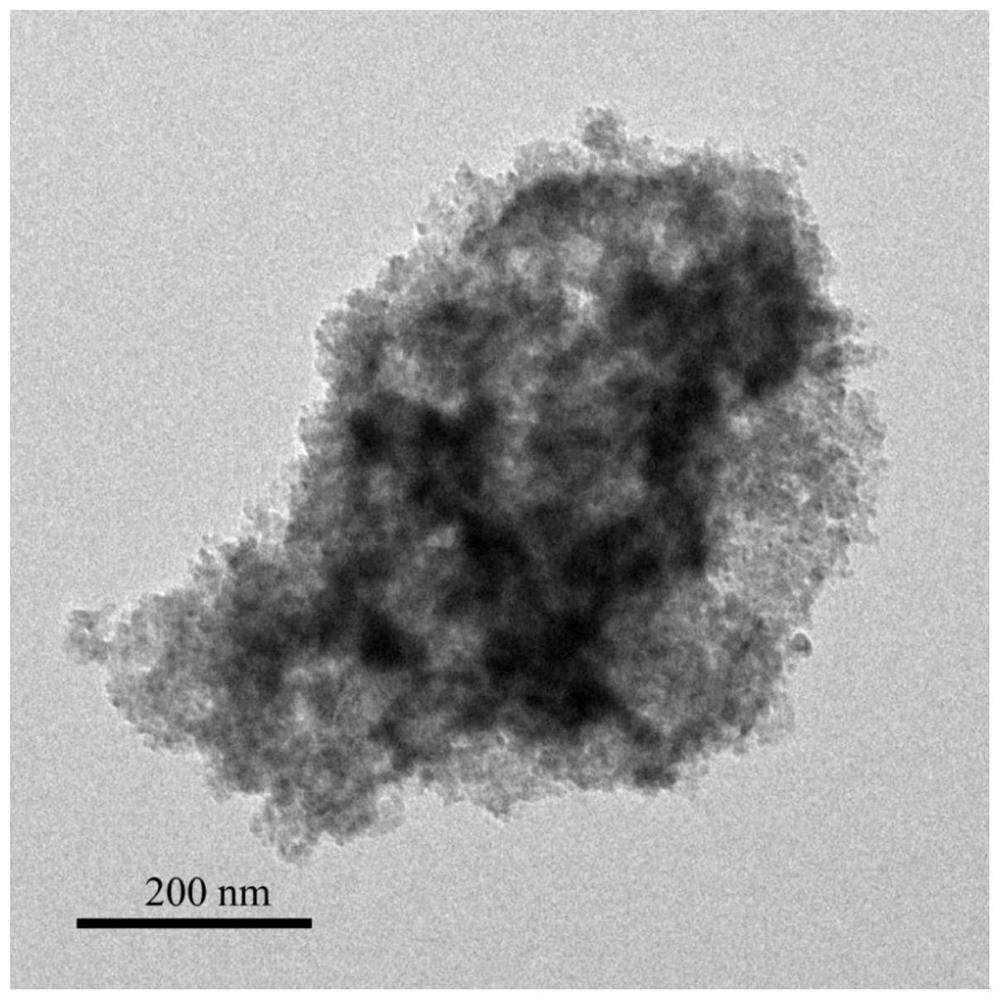

Preparation method and application of nitrogen-doped three-dimensional graphene aerogel loaded nano zero-valent iron

PendingCN111939960AHigh nitrogen contentHigh activityWater treatment compoundsWater contaminantsSulfate radicalsDoped graphene

The invention discloses a method for preparing a three-dimensional graphene aerogel loaded nano zero-valent iron material by using a calcining-liquid-phase reduction manner. The method comprises the following steps: (1) synthesizing nitrogen-doped graphene oxide; (2) synthesizing nitrogen-doped three-dimensional graphene aerogel; and (3) synthesizing the nitrogen-doped three-dimensional graphene aerogel loaded nano zero-valent iron material. According to the material disclosed by the invention, zero-valent iron particles in the obtained composite material are nano-scale, are uniformly distributed, have high catalytic activity, and interact with persulfate to generate sulfate free radicals and hydroxyl free radicals with strong oxidizing property, so as to degrade organic pollutants. Compared with conventional methods for synthesizing melamine-doped three-dimensional graphene aerogel, the method disclosed by the invention has the characteristics of higher nitrogen content, high reactionrate, high efficiency, easiness in recovery after use, no secondary pollution, simplicity, economy and high operability.

Owner:NANKAI UNIV

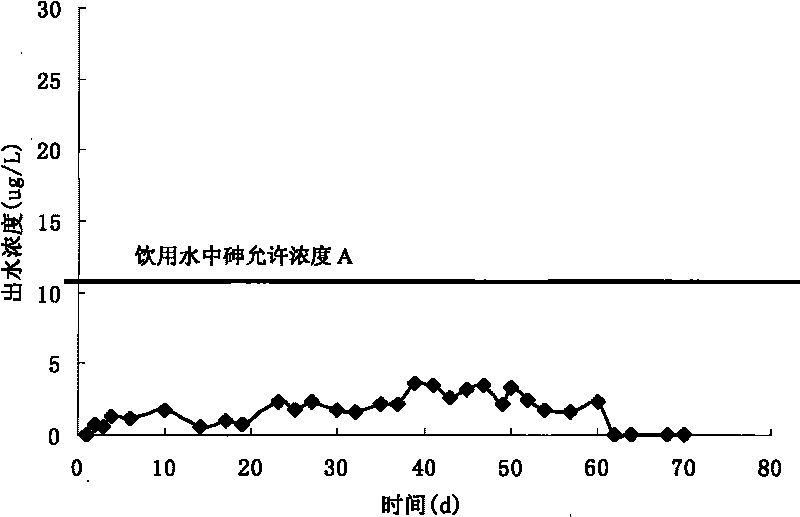

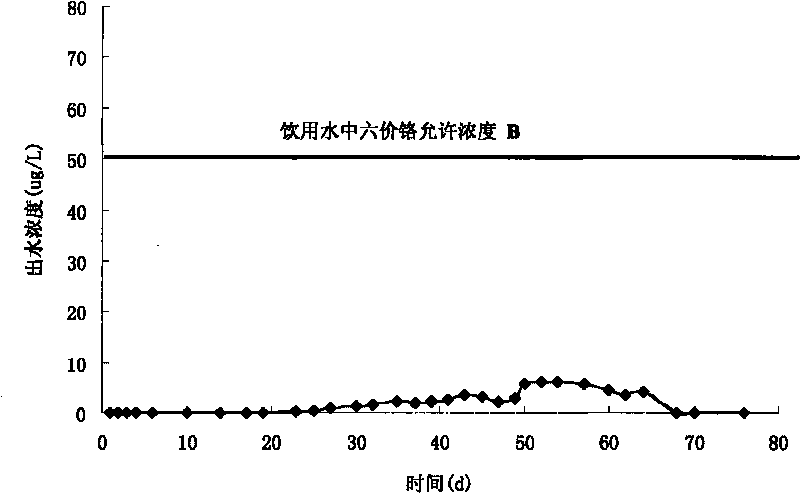

Material for purifying arsenate and chromate in drinking water and preparation method and application thereof

InactiveCN101723506AImprove adsorption capacityWide variety of sourcesWater contaminantsWater/sewage treatmentArsenateManganese

The invention relates to a material for purifying arsenate and chromate in drinking water and a preparation method and application thereof. The material is characterized in that: the material is sulfide of iron, manganese or zinc; the content of the sulfide in the material is not less than 50 weight percent; the content of arsenic is not more than 0.5 weight percent; and the concentration of the arsenate and the chromate in the drinking water is between 0.01 and 5 mg / L. The material for purifying the drinking water has the advantages of wide sources of raw materials, low cost and high adsorption activity, and capacity of being repeatedly used.

Owner:HEFEI UNIV OF TECH

Preparation method for modified activated carbon used for catalysis of hydrogen peroxide oxidation

InactiveCN105107506AIncrease loadImprove uniformityWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsActivated carbonWastewater

The invention relates to a preparation method for modified activated carbon used for catalysis of hydrogen peroxide oxidation. The preparation method mainly solves the problem that catalysts are difficult to separate and cannot be utilized repeatedly when a homogeneous system is employed to process organic waste water. The preparation method comprises the following steps: firstly, powder particles and impurities on surfaces of activated carbon are washed in water, and the activated carbon is dried for standby; secondly, an alternate magnetic reactor is employed to clean the activated carbon again; thirdly, the activated carbon after cleaning is taken, a certain amount of errous sulphate solution or ferrous chloride solution is added according to a proportion that 100g of the activated carbon is added with 200-300mL of a ferrous sulphate solution or a ferrous chloride solution with a concentration of 0.1-0.5mol / L, the reaction is carried out for 10-30min, and activated carbon and the ferrous sulphate solution are collected respectively; fourthly, ozone is pumped into the collected activated carbon for 5-15min, then pure water is added to clean the activated carbon, then the activated carbon is dried, and modified activated carbon is prepared. The provided activated carbon has advantages of high stability, low cost, stable performances and the like.

Owner:SHANXI UNIV

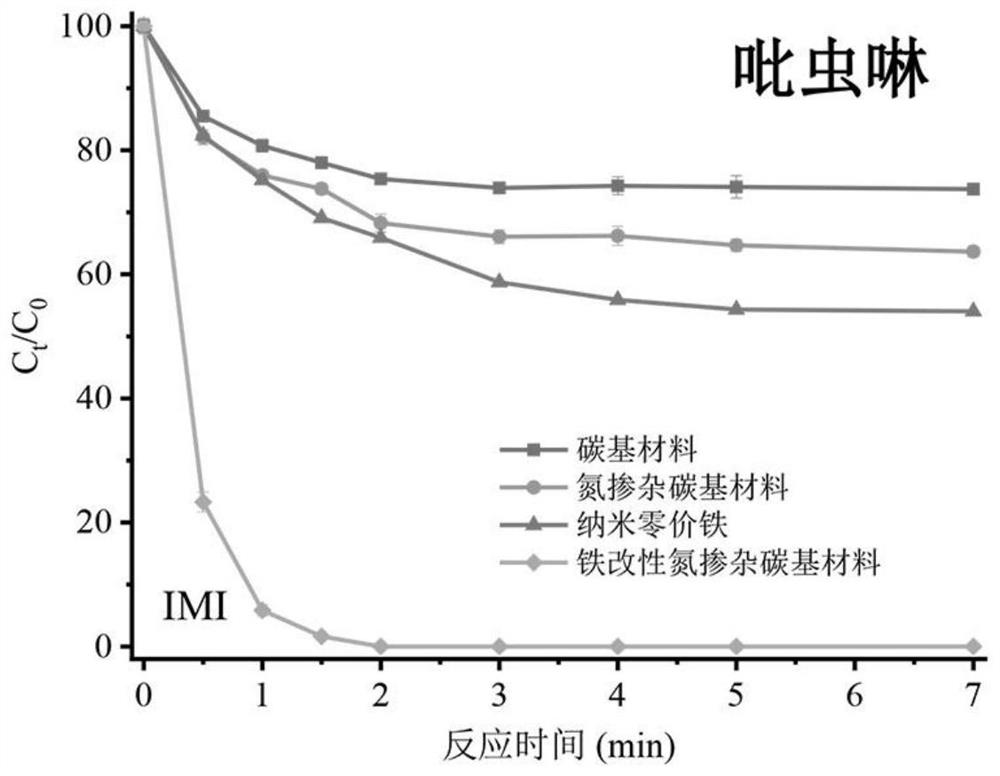

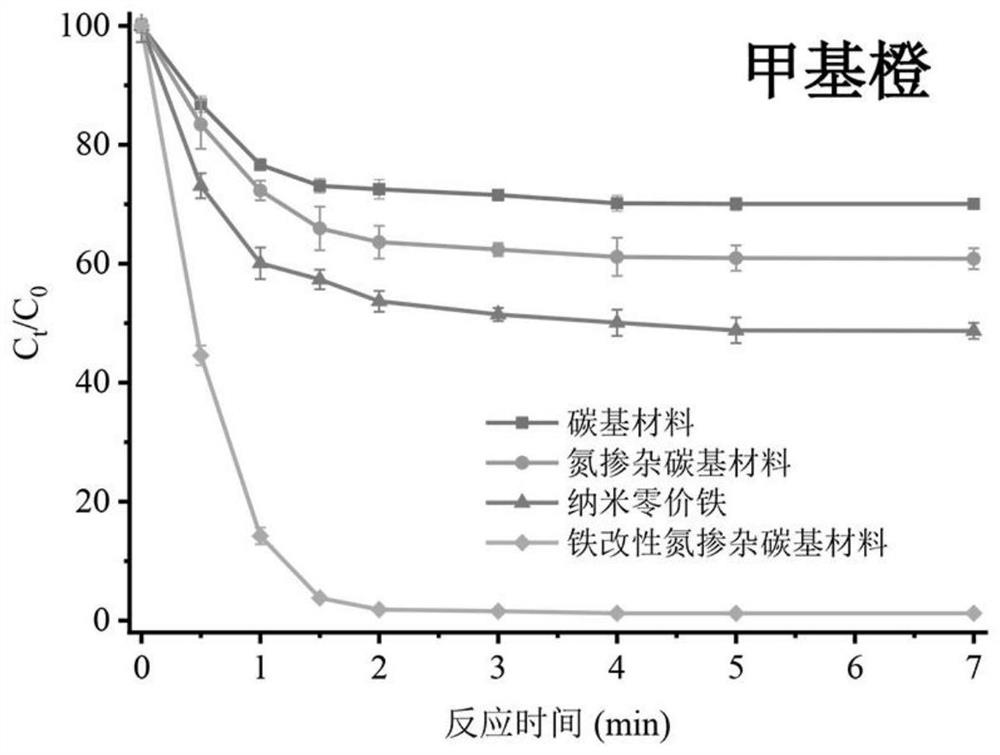

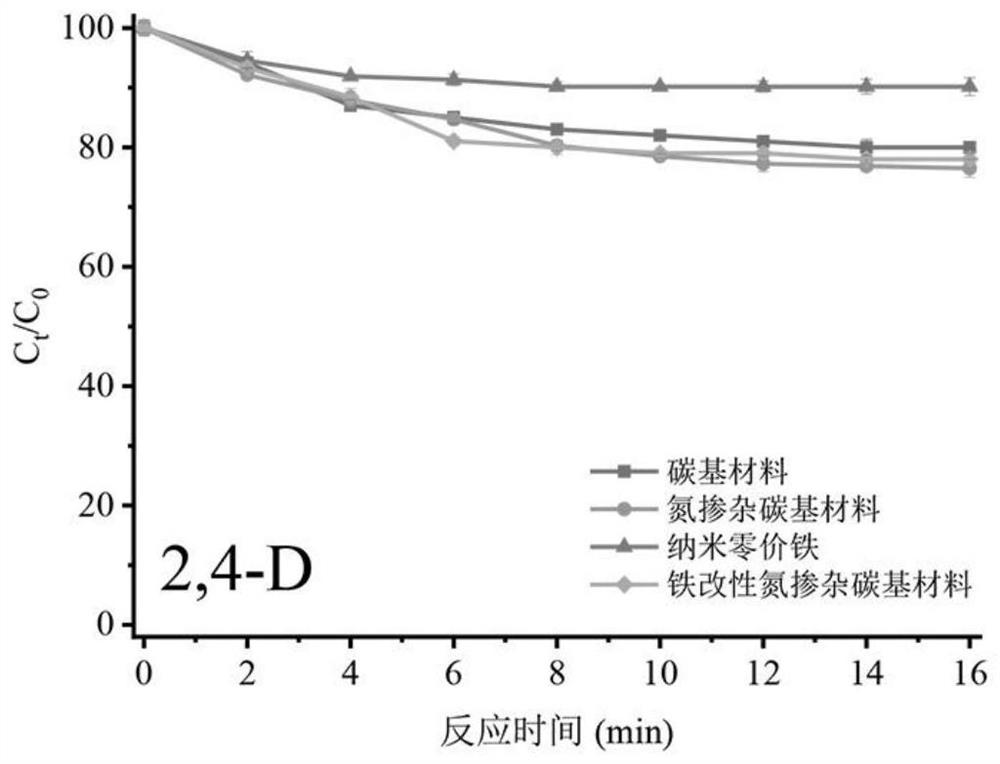

Method for degrading dye and pesticide by microwave-induced reinforced iron-modified nitrogen-doped carbon-based material

ActiveCN112897631AFast energy transferStrong penetrating powerWater/sewage treatment by irradiationWater contaminantsSoil scienceMicrowave irradiation

The invention discloses a method for degrading dye and pesticide by microwave-induced enhanced iron-modified nitrogen-doped carbon-based material. The nitrogen-doped carbon-iron composite material obtained by the method is of a three-dimensional structure, zero-valent iron particles are nanoscale and are uniformly distributed, the catalytic activity is high, the degradation reaction mainly induces the reinforced iron-modified nitrogen-doped carbon-based material to degrade high-concentration organic pollutants through a heat effect generated by microwave radiation and non-heat effects such as electricity, magnetism and chemistry, so that the absorption of microwave energy and the utilization rate of zero-valent iron are improved, and dyes and pesticides are rapidly degraded. The method for modifying the iron-modified nitrogen-doped carbon-based material through microwave coupling has the advantages of being high in reaction rate, high in efficiency, easy to recycle after being used, free of secondary pollution, simple, economical and high in operability.

Owner:NANKAI UNIV

Charged magnetic hydrophobic material and preparation method and application thereof in separation of micro-fine-particle minerals

The invention discloses a charged magnetic hydrophobic material and a preparation method and application thereof in separation of micro-fine-particle minerals. The material includes magnetic particlesand a metal organic complex loaded on the surface, has strong magnetism, is positively charged on the surface, and has high electrostatic adsorption capacity for anions and high physical adsorption performance for hydrophobic micro-fine-particle minerals, and therefore, after micro-fine-particle minerals in ore pulp are subjected to surface hydrophobic and anion modification, the micro-fine-particle minerals can be adsorbed and agglomerated by utilizing the material, then the micro-fine-particle minerals are efficiently separated from gangue minerals through magnetic separation, thus solvinga difficult problem of separation and purification of ultrafine minerals. A preparation process of the charged magnetic hydrophobic material is simple and cheap and meets industrial production requirements.

Owner:CENT SOUTH UNIV

High-magnetism high-mechanical-strength bonded neodymium iron boron (NdFeB) permanent magnet and preparation method thereof

InactiveCN102938283AImprove magnetismHigh mechanical strengthPermanent magnetsInorganic material magnetismEpoxyMaterials science

The invention relates to a high-magnetism high-mechanical-strength bonded neodymium iron boron (NdFeB) permanent magnet and a preparation method thereof and belongs to the technical field of magnets. The high-magnetism high-mechanical-strength bonded NdFeB permanent magnet comprises NdFeB magnetic powders, a thermosetting resin, a curing agent and a lubricating agent, and the magnetic powders comprise metallocene macromolecule ferromagnetic powders and stainless steel powders. The preparation method includes firstly, evenly mixing the thermosetting resin, the curing agent and acetone; secondly, evenly mixing the NdFeB magnetic powders, the metallocene macromolecule ferromagnetic powders and the stainless steel powders; thirdly, adding a mixture obtained from the step two to a mixture obtained from the step one and evenly mixing the two mixtures; fourthly, performing drying and screening, adding the lubricating agent, and evenly mixing the mixtures to obtain a magnetic powder mixture; fifthly, using a compression molding machine to press the mixtures into a magnet green body; and sixthly, curing the magnet green body at the temperature of 175-200 DEG C to obtain the magnet. The magnet has the advantages of being convenient to prepare, high in magnetic property and mechanical strength, small in dimensional tolerance, convenient to subsequently barrel and grind and low in transportation and assembly loss of finished products.

Owner:TIANJIN NIBBOH MAGNETS

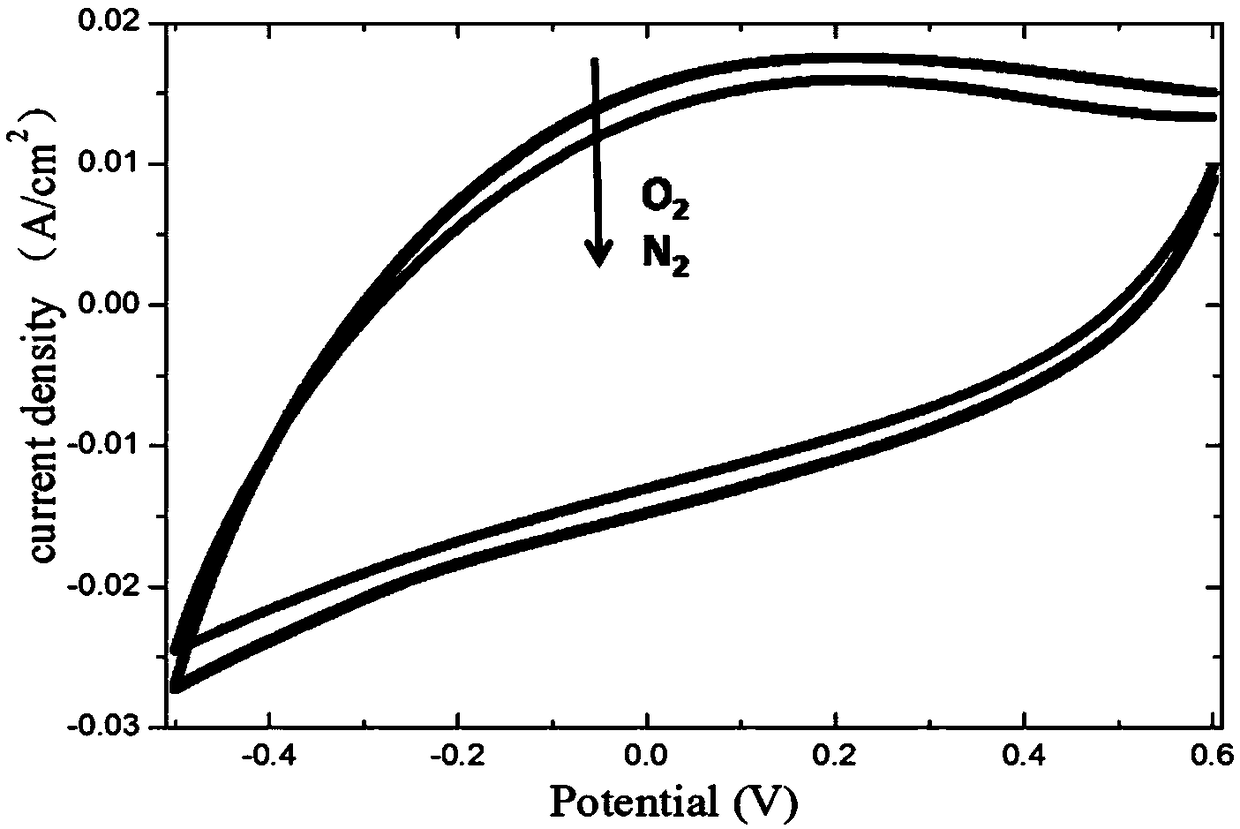

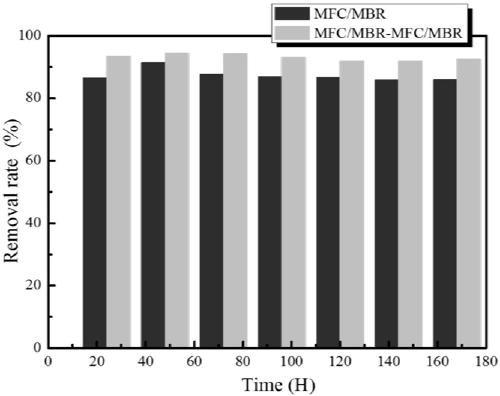

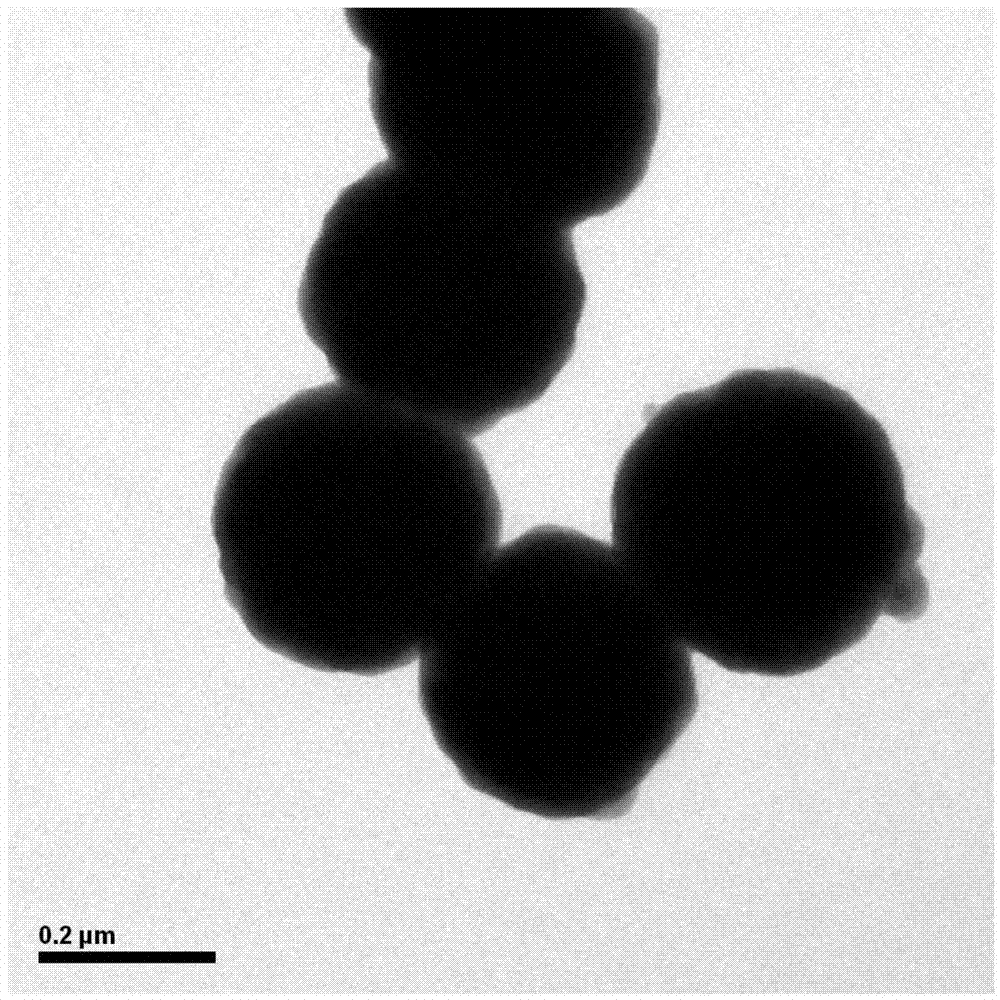

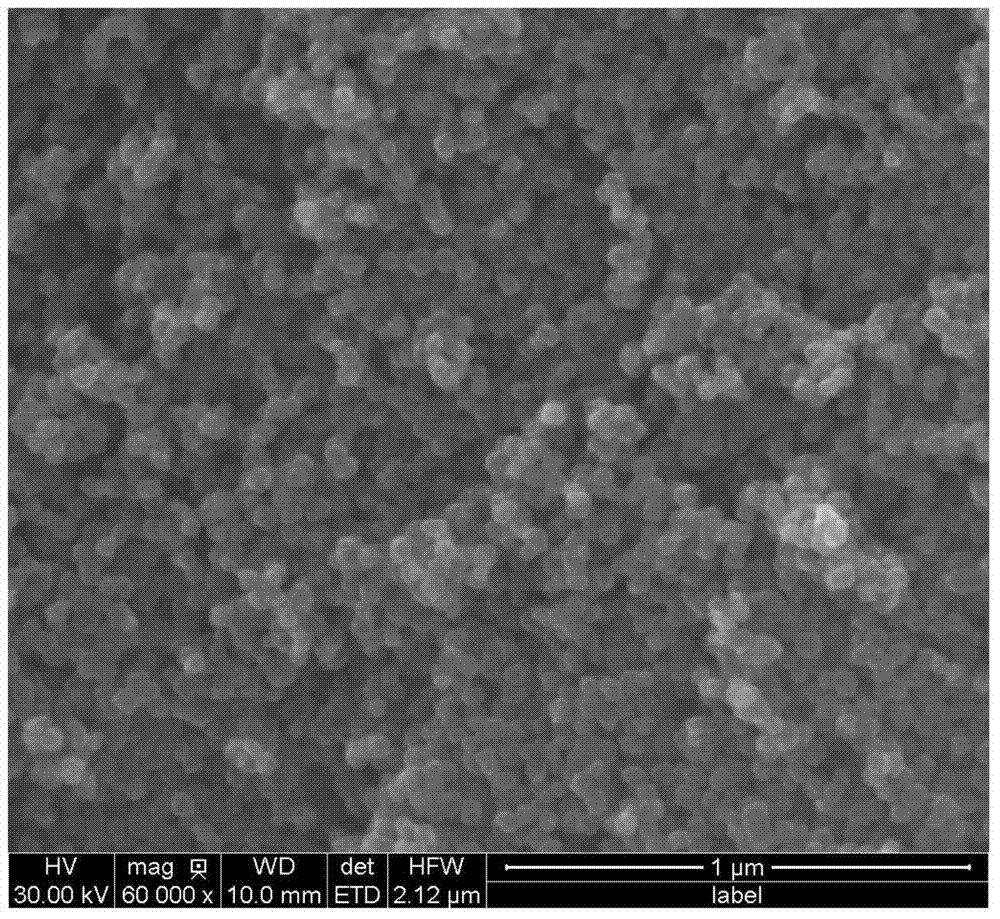

Novel CoFe2O4/CNFs cathode catalytic membrane coupling microbial fuel cell two-stage tandem system and application thereof

ActiveCN108928931AStrong magneticEasy to recycleTreatment by combined electrochemical biological processesWater/sewage treatmentHigh concentrationFiltration

The invention belongs to the technical fields of sewage purification and wastewater recycling, and discloses a novel CoFe2O4 / CNFs cathode catalytic membrane coupling microbial fuel cell two-stage tandem system and an application thereof. The system is used to treat non-degradable practical coking wastewater. High-efficiency treatment of the coking wastewater is realized through cooperating the oxidation effect of anode chamber microbes on organic matters, the catalysis effect of a CoFe2O4 / CNFs catalytic membrane and membrane filtration. The system uses the good stability and excellent pollution resistance of the CoFe2O4 / CNFs composite membrane having high ORR activity, and has the advantages of good running stability, improvement of the quality of outlet water, realization of standard-reaching discharging of the coking wastewater, facilitation of development of amplified and pilot scale test experiments, and promotion of the industrialization of the accomplishment when applied to the two-stage tandem continuous treatment of the high-concentration coking wastewater.

Owner:DALIAN UNIV OF TECH

Preparation method of magnetic graphene ternary composite material based on click chemistry

The invention relates to a preparation method of a magnetic graphene ternary composite material based on click chemistry. The preparation method comprises the following steps: adding 1.0-5.0 g of trivalent ferric salt to 10-50 ml of reactive solvent, and carrying out ultrasonic dispersion until a solution is clear; then adding 1.0-5.0 g of a stabilizer, carrying out ultrasonic dispersion for 0.1-0.5 h at the temperature of 50-60 DEG C, then adding 0.2-1.0 g of strong alkaline reagent and 5-20.0 mL of amine functional reagent, and carrying out ultrasonic dispersion until the solution is clear; adding 50-100 mg of graphene, carrying out ultrasonic dispersion for 0.3-1 h at the temperature of 50-60 DEG C, and then adding the mixed solution in a polytetrafluoroethylene high-pressure autoclave for reacting for 4-10 h; cooling to room temperature, carrying out magnetic separation, washing with ultrapure water for several times until the pH is 7.0, then washing with ethyl alcohol for several times, and drying to obtain the amino-modified magnetic graphene ternary composite material. The preparation method is simple in technology, controllable in functional group proportion, high in repeatability and the like, the prepared amino-modified magnetic graphene ternary composite material has the advantages of high magnetism, multiple functions and the like, and the prepared amino-modified magnetic graphene ternary composite material is relatively higher in application value and wide in application prospect.

Owner:NINGBO MUNICIPAL CENT FOR DISEASE CONTROL & PREVENTION

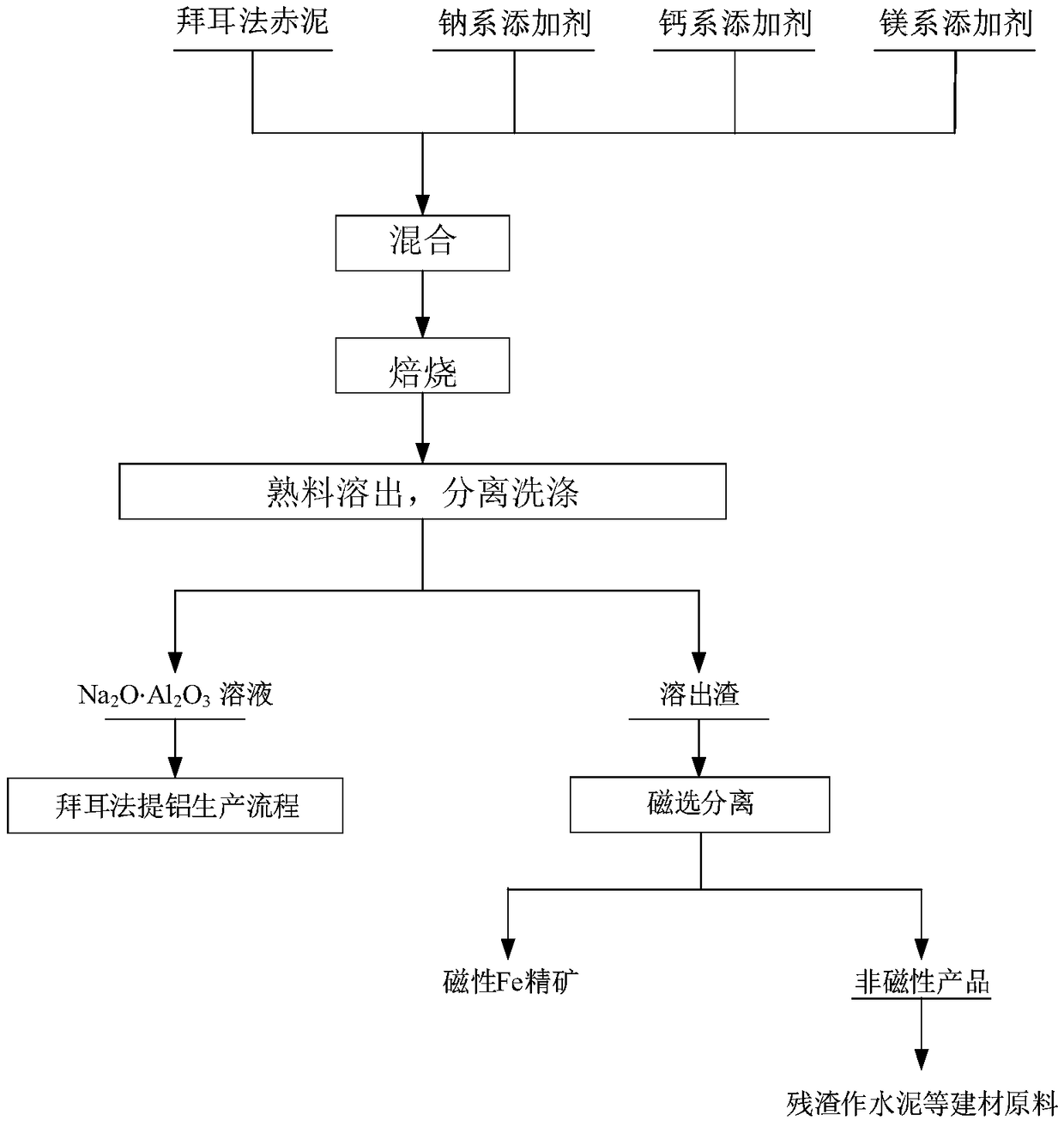

Method for comprehensively recycling sodium, aluminum and iron from red mud

ActiveCN108950212ASimple control conditionsEliminate environmental hazardsProcess efficiency improvementAluminiumMagnesium

The invention discloses a method for comprehensively recycling sodium, aluminum and iron from red mud. The red mud is mixed with an additive to obtain a raw material, the mixed raw material is subjected to calcination to obtain clinker, the clinker is added to an alkaline adjustment liquid for leaching, slid-liquid separation is performed, and leachate containing aluminum and sodium and magnetic leaching residues are obtained; the additive is a mixed additive composed of a calcium-series additive, a magnesium-series additive and a sodium-series additive. According to the technical scheme, no reducing agent needs to be added, hematite or hematite is converted as magnesioferrite with high magnetism through the magnesium-series additive and enters the leaching residues, and then an iron ore concentrate product is obtained through magnetic separating. In the technical scheme, the atmosphere control process and generation of a great quantity of polluting atmosphere in the current iron recycling process are avoided. In the method, the aluminum recycling rate is 85%, the sodium recycling rate is 92% or above, the sodium content in final residues is lowered to 1% or below, the iron grade of the iron ore concentrate is 50-55%, and the recycling rate is about 70%.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com