Magnetic visible-light-driven photocatalyst for treating hexavalent chromium wastewater and preparation method of magnetic visible-light-driven photocatalyst

A visible light and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of fast photogenerated charge recombination rate, high temperature, and large particle size problems, achieve high visible light catalytic activity, easy magnetic separation and recovery, and simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

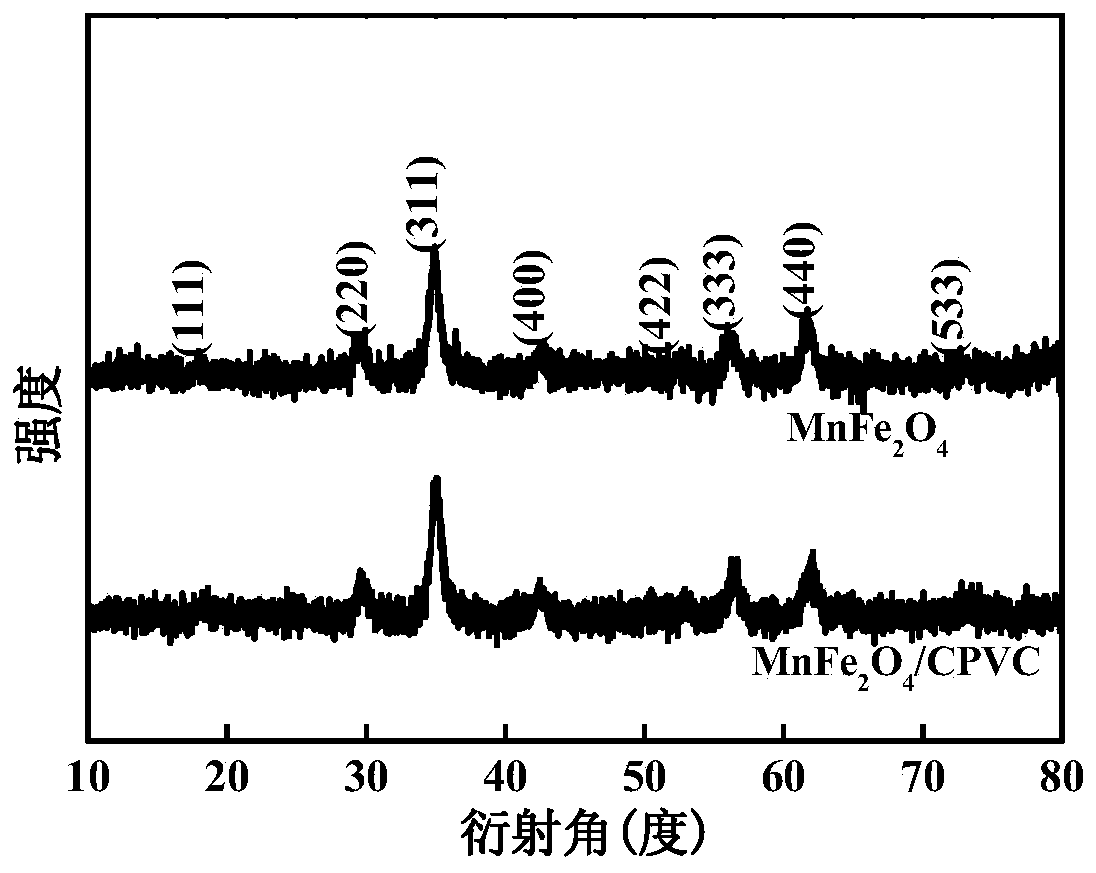

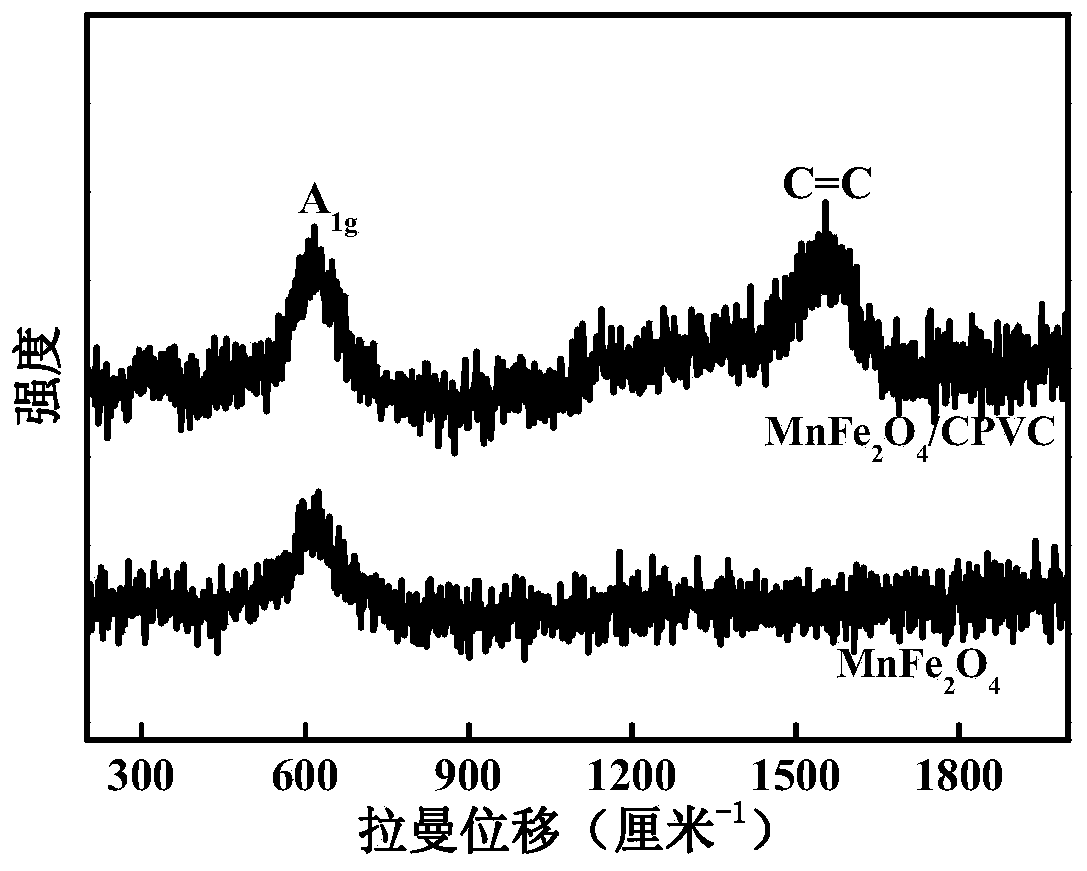

[0036] 1. MnFe 2 o 4 / Synthesis of CPVC composites:

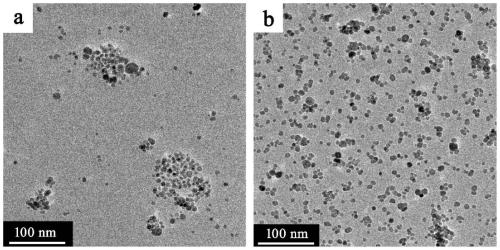

[0037] 1) MnFe 2 o 4 Synthesis of nanoparticles: Measure 70ml of benzyl alcohol in a 150ml beaker, weigh 2mmol of manganese acetate and add it, ultrasonically dissolve it completely for 1h, then add 4mmol of iron acetylacetonate, stir magnetically for 1h, and then transfer to a 100ml volume polystyrene In a stainless steel autoclave lined with vinyl fluoride, seal it, heat it at 200°C for 24h, cool it down to room temperature naturally, wash and dry the obtained precipitate.

[0038] 2) MnFe 2 o 4 / Synthesis of CPVC nanocomposite material: Weigh 20mg of PVC powder and dissolve it in 25ml THF, then add 1000mg of the above solvothermally synthesized MnFe 2 o 4 powder, and then ultrasonically for 2 hours to make it evenly dispersed, put it in an oven and heat it at 65°C for 5 hours to evaporate the tetrahydrofuran solvent to dryness, take out the solid and grind it to obtain MnFe 2 o 4 / PVC nanocomposite. The complex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com