Preparation and application of floatable magnetic hollow material for removing heavy metal in water and soil

A heavy metal and soil technology, applied in the fields of nanomaterials and environmental protection, can solve the problem of inability to remove heavy metals from the source, and achieve the effects of safe and non-toxic degradation products, low production cost, and efficient adsorption and reduction of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

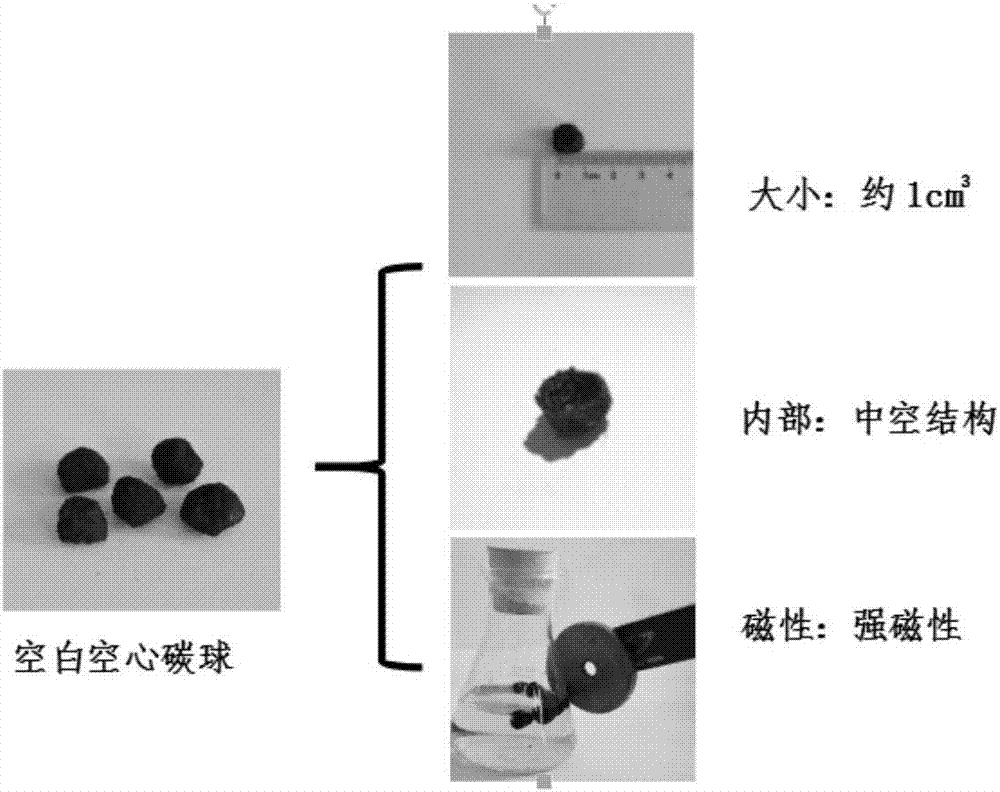

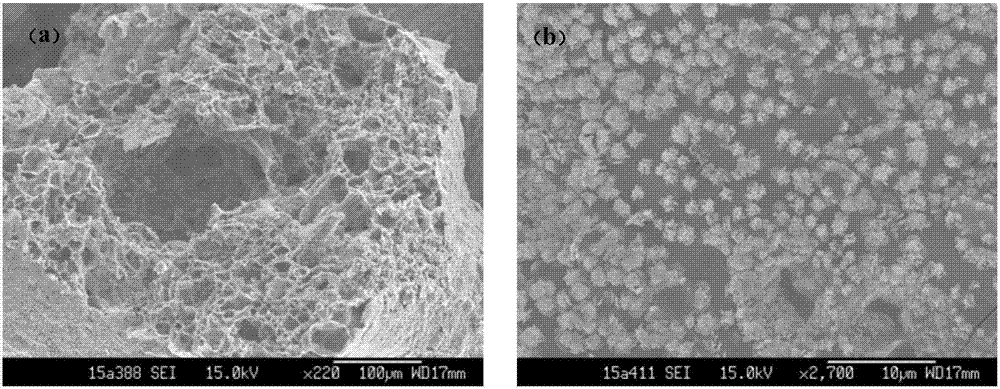

[0047] Preparation and application of a floatable magnetic hollow material for heavy metal removal in water and soil

[0048] a. Dissolve 1g of sodium alginate in 100mL of water at 25°C (room temperature), and stir until clear and transparent;

[0049] b. Add dried and pulverized dried banana leaves with a mass percentage concentration of 0.5% and kaolin with a mass percentage concentration of 5%, and stir thoroughly to obtain a mixed system;

[0050] c. Pour the mixed system into the mould, and carry out freeze molding treatment for 4 hours;

[0051] d. Pour the hardened cube in the above step c into a 1% ferric chloride solution and soak for 20 hours;

[0052] e. Pick up the cube soaked in the ferric chloride solution, dry it slightly, put it into a pottery crucible, and carbonize it in a muffle furnace at 250°C for 150 minutes;

[0053] f. After carbonization, a floatable magnetic hollow material for removing heavy metals in water and soil can be obtained, and sealed for ...

Embodiment 2

[0060] Preparation and application of a floatable magnetic hollow material for heavy metal removal in water and soil

[0061] a. Dissolve 2g of potassium alginate in 100mL of water at 25°C (room temperature), and stir until clear and transparent;

[0062] b. Add dried and pulverized chaff with a concentration of 0.8% by mass and kaolin with a concentration of 5% by mass, and fully stir to obtain a mixed system;

[0063] c. Pour the mixed system into the mould, and carry out freeze molding treatment for 6 hours;

[0064] d. Pour the hardened cube in the above step c into a 4% iron sulfate solution by mass and soak for 12 hours;

[0065] e. Pick up the cube soaked in the ferric persulfate solution, dry it slightly, put it into a pottery crucible, and carbonize it in a muffle furnace at 350°C for 90 minutes;

[0066] f. After carbonization, a floatable magnetic hollow material for removing heavy metals in water and soil can be obtained, and sealed for storage.

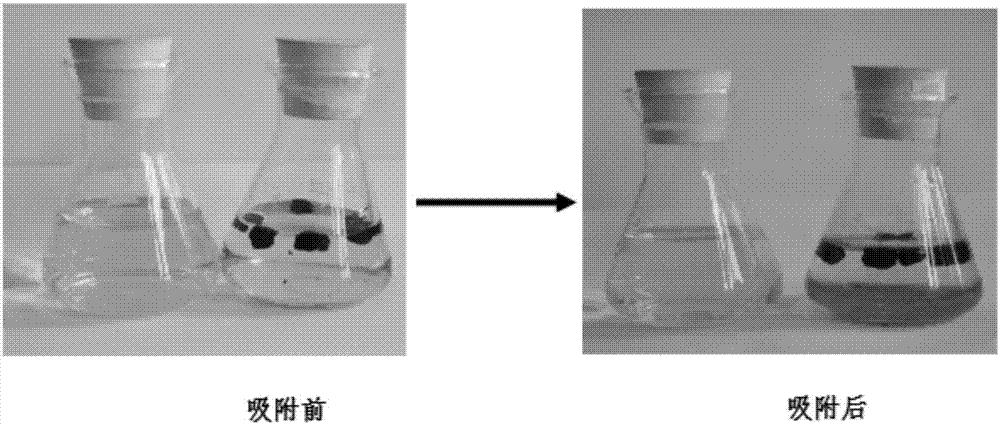

[0067] Applica...

Embodiment 3

[0073] Preparation and application of a floatable magnetic hollow material for heavy metal removal in water and soil

[0074] a. Dissolve 2g of sodium alginate in 100mL of water at 25°C (room temperature), stir well until clear and transparent;

[0075] b. Add dried and pulverized corn leaves with a concentration of 0.8% by mass and kaolin with a concentration of 5% by mass, and fully stir to obtain a mixed system;

[0076] c. Pour the mixed system into the mould, and carry out freeze molding treatment for 8 hours;

[0077] d. Pour the hardened cube in the above step c into a 4% iron sulfite solution by mass and soak for 12 hours;

[0078] e. Pick up the cube soaked in the ferric sulfite solution, dry it slightly, put it into a pottery crucible, and carbonize it in a muffle furnace at 350°C for 90 minutes;

[0079] f. After carbonization, a floatable magnetic hollow material for removing heavy metals in water and soil can be obtained, and sealed for storage.

[0080] Applic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com