Multiferroic Bi0.83Pr0.15Sr0.02Fe0.97-xMn0.03CuxO3-CuFe2O4 composite film and preparation method thereof

A technology of bi0.83pr0.15sr0.02fe0.97-xmn0.03cuxo3-cufe2o4 and composite film is applied in the direction of coating to achieve the effects of improving ferroelectric and ferromagnetic properties, suppressing volatilization, and reducing leakage current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

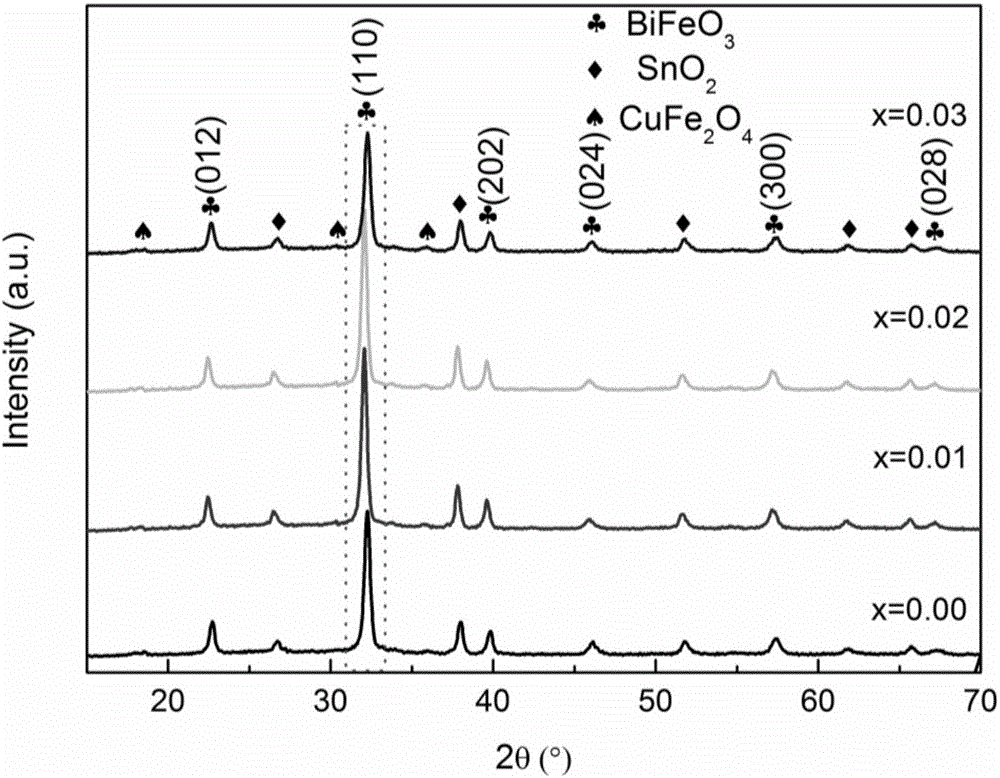

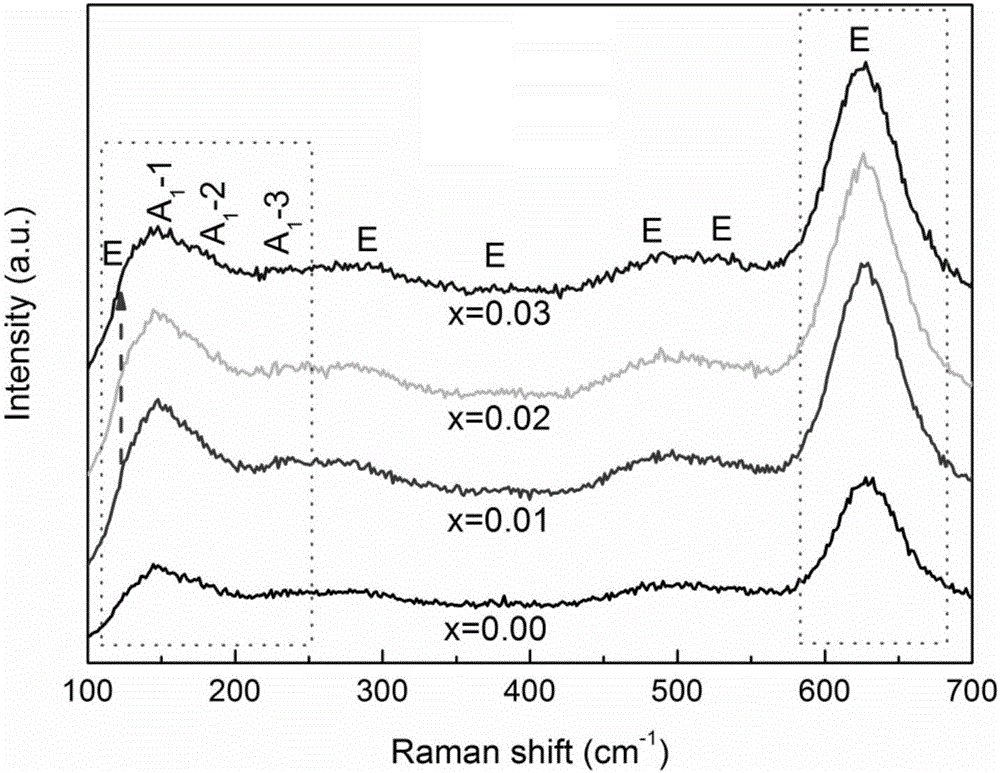

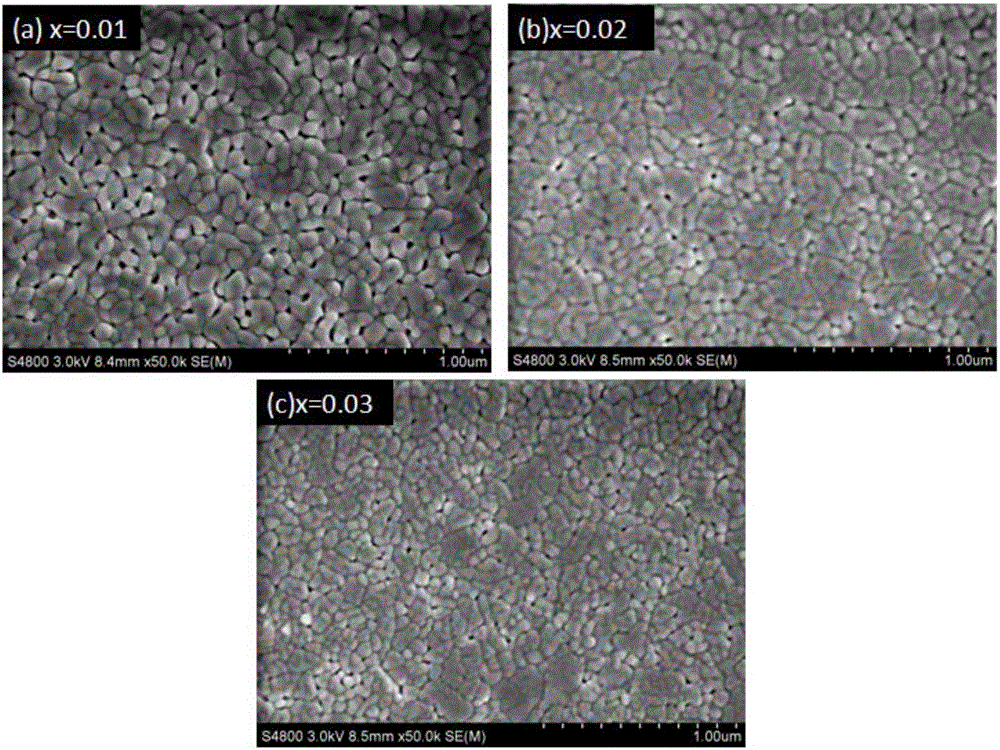

Embodiment 1

[0039] Step 1: Dissolve ferric nitrate and copper nitrate in ethylene glycol methyl ether at a molar ratio of 1:2, stir for 30 minutes, then add acetic anhydride and stir for 90 minutes to obtain stable CuFe with a Cu ion concentration of 0.15mol / L 2 o 4 Precursor, CuFe 2 o 4 The volume ratio of ethylene glycol methyl ether and acetic anhydride in the precursor solution is 3:1;

[0040] Step 2: Dissolve bismuth nitrate, praseodymium nitrate, strontium nitrate, ferric nitrate, manganese nitrate and copper nitrate in a solvent in a molar ratio of 0.88:0.15:0.02:0.96:0.03:0.01 (x=0.01, 5% bismuth nitrate excess ), to obtain a stable Bi with a total concentration of metal ions of 0.25mol / L 0.83 PR 0.15 Sr 0.02 Fe 0.96 mn 0.03 Cu 0.01 o 3 Precursor solution; the solvent is a mixed solution of ethylene glycol methyl ether and acetic anhydride with a volume ratio of 3:1;

[0041] Step 3: Select the FTO / glass substrate, place the cut FTO / glass substrate in detergent, acetone...

Embodiment 2

[0047]Step 1: Dissolve ferric nitrate and copper nitrate in ethylene glycol methyl ether at a molar ratio of 1:2, stir for 30 minutes, then add acetic anhydride and stir for 90 minutes to obtain stable CuFe with a Cu ion concentration of 0.15mol / L 2 o 4 Precursor, CuFe 2 o 4 The volume ratio of ethylene glycol methyl ether and acetic anhydride in the precursor solution is 3:1;

[0048] Step 2: Dissolve bismuth nitrate, praseodymium nitrate, strontium nitrate, ferric nitrate, manganese nitrate and copper nitrate in a solvent in a molar ratio of 0.88:0.15:0.02:0.95:0.03:0.02 (x=0.02, bismuth nitrate excess 5% ), to obtain a stable Bi with a total concentration of metal ions of 0.25mol / L 0.83 PR 0.15 Sr 0.02 Fe 0.95 mn 0.03 Cu 0.02 o 3 Precursor solution; the solvent is a mixed solution of ethylene glycol methyl ether and acetic anhydride with a volume ratio of 3:1;

[0049] Step 3: Select the FTO / glass substrate, place the cut FTO / glass substrate in detergent, acetone,...

Embodiment 3

[0055] Step 1: Dissolve ferric nitrate and copper nitrate in ethylene glycol methyl ether at a molar ratio of 1:2, stir for 30 minutes, then add acetic anhydride and stir for 90 minutes to obtain stable CuFe with a Cu ion concentration of 0.15mol / L 2 o 4 Precursor, CuFe 2 o 4 The volume ratio of ethylene glycol methyl ether and acetic anhydride in the precursor solution is 3:1;

[0056] Step 2: Dissolve bismuth nitrate, praseodymium nitrate, strontium nitrate, ferric nitrate, manganese nitrate and copper nitrate in a solvent in a molar ratio of 0.88:0.15:0.02:0.94:0.03:0.03 (x=0.03, bismuth nitrate excess 5% ), to obtain a stable Bi with a total concentration of metal ions of 0.25mol / L 0.83 PR 0.15 Sr 0.02 Fe 0.94 mn 0.03 Cu 0.03 o 3 Precursor solution; the solvent is a mixed solution of ethylene glycol methyl ether and acetic anhydride with a volume ratio of 3:1;

[0057] Step 3: Select the FTO / glass substrate, place the cut FTO / glass substrate in detergent, acetone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation polarization | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

| Coercive field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com