Novel CoFe2O4/CNFs cathode catalytic membrane coupling microbial fuel cell two-stage tandem system and application thereof

A cathode catalysis and fuel cell technology, which is applied in the direction of electrochemical and biological combination treatment, biological water/sewage treatment, water/sewage treatment, etc., can solve the problem of microbial fuel cell effluent water quality not up to standard, high concentration coking wastewater difficult to process complex process and other problems, to achieve the effect of good operation stability, excellent anti-pollution performance, and excellent ORR activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

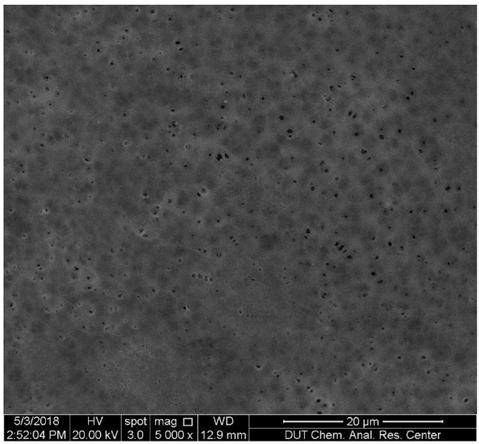

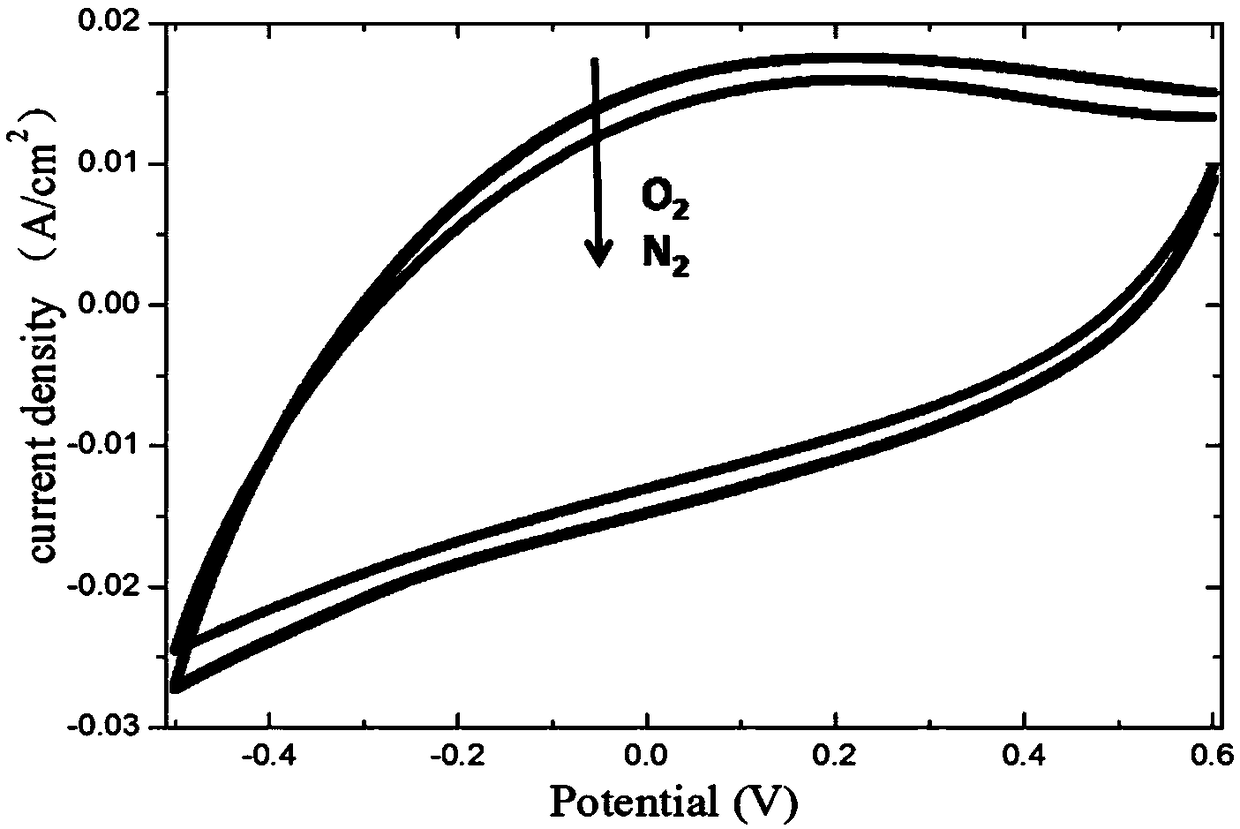

[0024] (1) Cathode CoFe 2 o 4 / CNFs catalytic membrane preparation: Weigh 2g PVDF, 0.8g PVP, 0.5g carbon nanofiber, 0.3g CoFe 2 o 4 / CNFs catalyst and 16.4g DMF were mixed, after stirring for 6h, ultrasonic defoaming for 30min, using carbon nanofiber cloth as the substrate, the coating thickness was 300μm, and CoFe was obtained after phase inversion for 12h 2 o 4 / CNFs catalytic membrane cathode. figure 1 CoFe prepared for 2 o 4 / CNFs membrane SEM image, showing that the pores on the surface of the membrane are evenly distributed and the pore size is uniform; figure 2 It is to test the ORR performance of the catalytic membrane. The test scan range is -0.5V-0.5V in oxygen and nitrogen respectively. Compared with nitrogen, the current response value in oxygen is more significant.

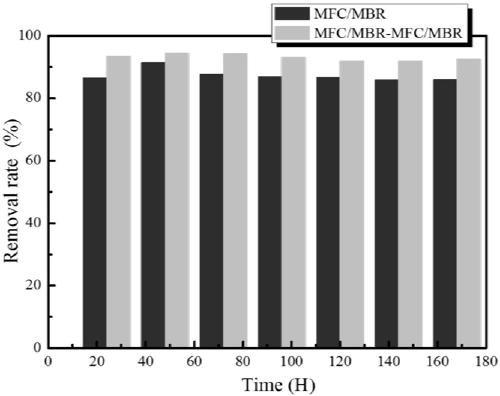

[0025] (2)CoFe 2 o 4 / CNFs cathode catalytic membrane coupling microbial fuel cell secondary series system to treat coking wastewater Operation: take the high-concentration wastewater of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com