Preparation method of magnetic graphene ternary composite material based on click chemistry

A technology of magnetic graphene and composite materials, applied in the field of graphene, can solve problems such as difficult solid-liquid phase separation, uneven particle size, and irregular shape, and achieve regular shape, uniform particle size, and good dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Magnetic Fe 3 o 4 preparation of

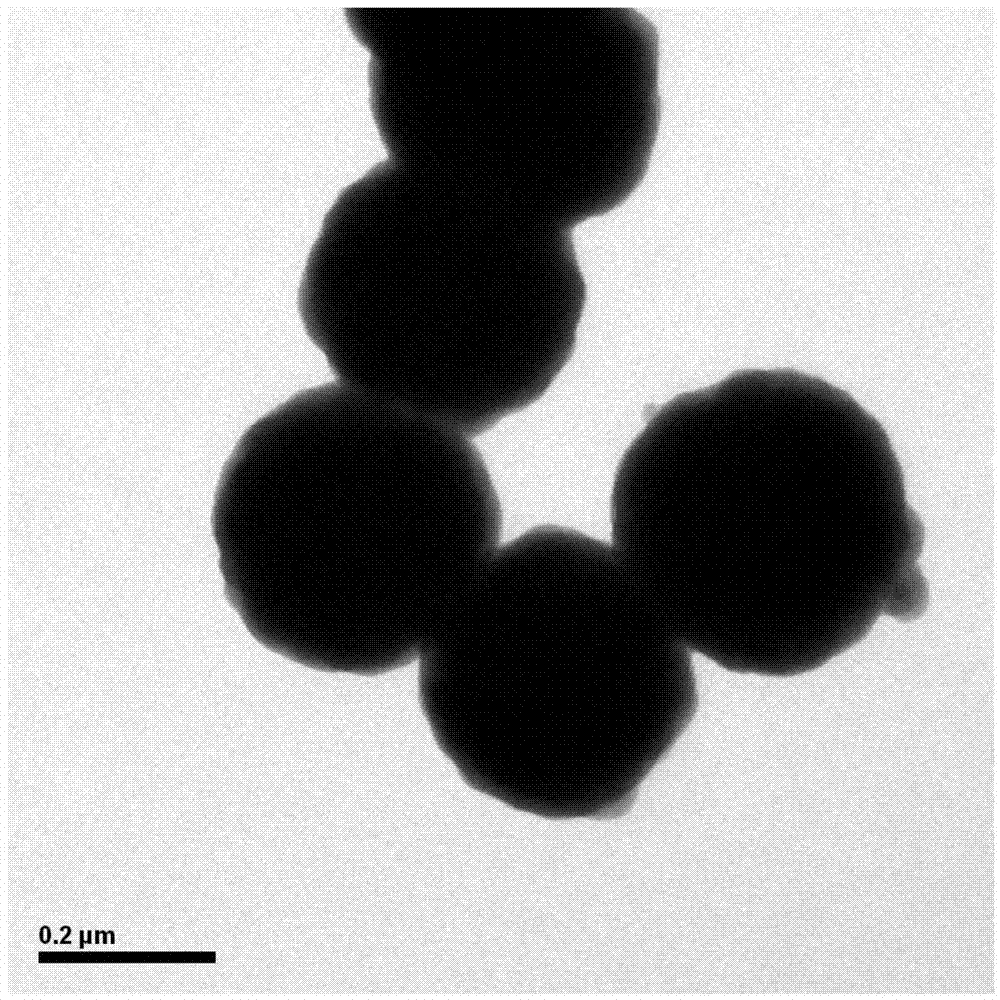

[0023] 1.0g FeCl 3 ·6H 2 O was added to 20mL of ethylene glycol, ultrasonically dispersed at 50°C for 0.5h until the solution was clear; then 3.0g of anhydrous sodium acetate was added, ultrasonically dispersed at 50°C for 0.5h, and then the mixed solution was added to a polytetrafluoroethylene autoclave Reaction at 200°C for 6h. Cool to room temperature, magnetically separate, wash several times with ultrapure water to pH 7.0, then wash several times with ethanol, and vacuum dry at 60°C for 6 hours to obtain magnetic Fe 3 o 4 . Produced Fe 3 o 4 The TEM image of figure 1 As shown, Fe prepared by traditional solvothermal method 3 o 4 The particle size is 300-500nm.

Embodiment 2

[0024] Embodiment 2: magnetic nanometer Fe 3 o 4

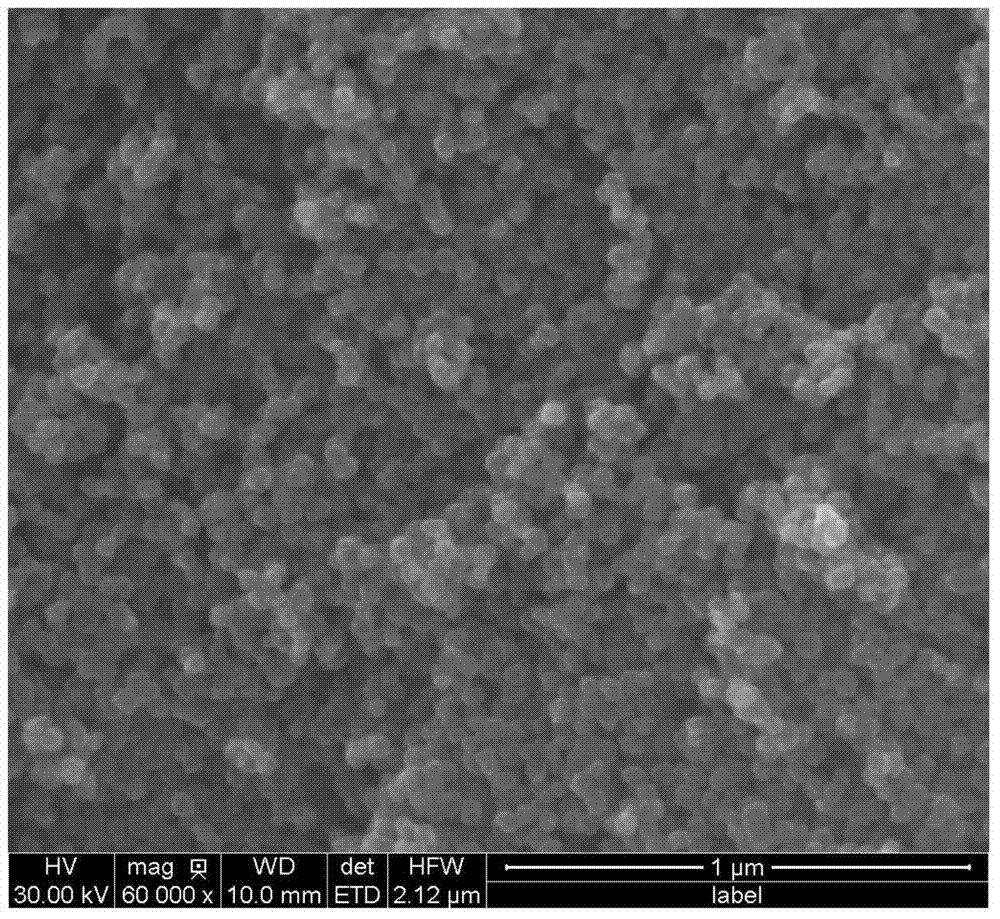

[0025] 1.0g FeCl 3 ·6H 2 Add O to 20mL of ethylene glycol, ultrasonically disperse at 50°C for 0.5h until the solution is clear; then add 3.0g of anhydrous sodium acetate, ultrasonically disperse at 50°C for 0.5h, then add 0.4g of sodium hydroxide and 10.0mL of ethylenediamine , ultrasonically disperse at 50°C for 0.5h until the solution is clear; then add the mixed solution into a polytetrafluoroethylene autoclave and react at 200°C for 6h. Cool to room temperature, magnetically separate, wash several times with ultrapure water until the pH is 7.0, then wash several times with ethanol, and vacuum dry at 60°C for 6 hours to obtain magnetic nano-Fe 3 o 4 . The prepared magnetic nano-Fe 3 o 4 The scanning electron microscope image of figure 2 As shown, the Fe prepared by the modified solvothermal method 3 o 4 The particle size is 50-60nm, with regular shape, uniform particle size and good dispersion.

Embodiment 3

[0026] Example 3: Preparation of Amino-modified Magnetic Graphene Ternary Composite Material

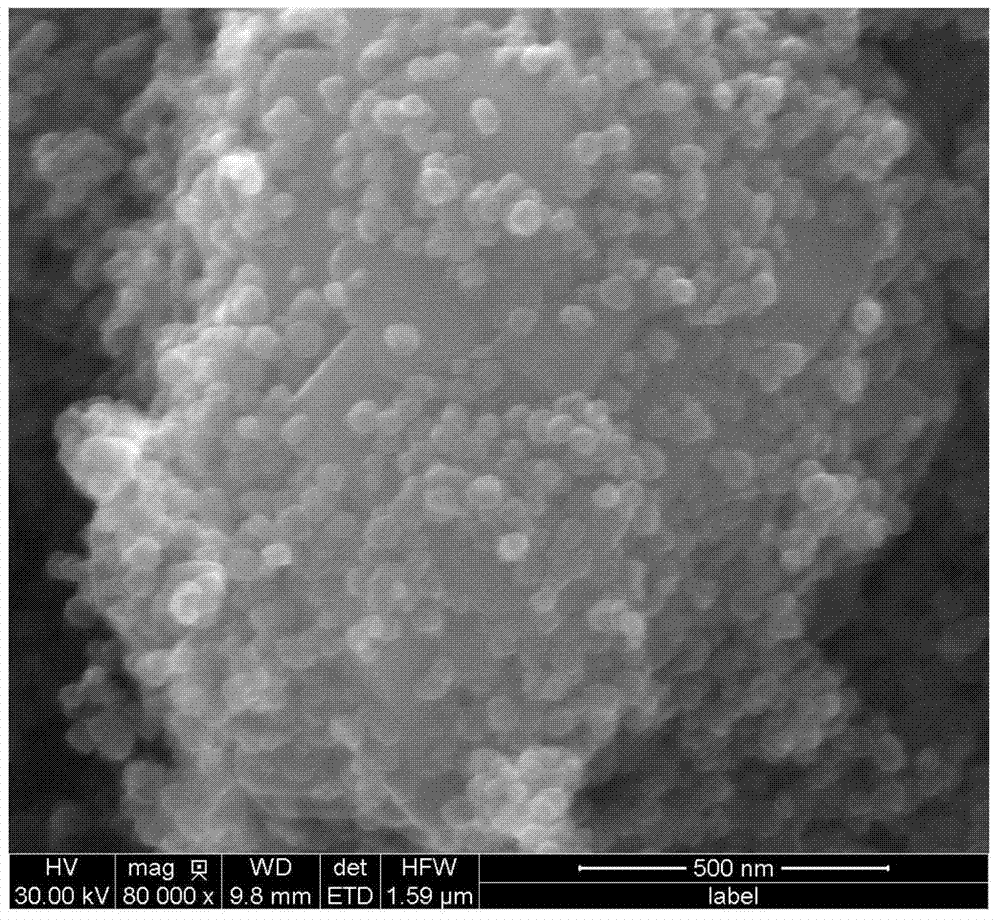

[0027] 1.0g FeCl 3 ·6H 2Add O to 20mL of ethylene glycol, ultrasonically disperse at 50°C for 0.5h until the solution is clear; then add 3.0g of anhydrous sodium acetate, ultrasonically disperse at 50°C for 0.5h, then add 0.4g of sodium hydroxide and 10.0mL of ethylenediamine , ultrasonically disperse at 50°C for 0.5h until the solution is clear; add 50mg of carboxylated graphene, ultrasonically disperse at 50°C for 1h, then add the mixed solution into a polytetrafluoroethylene autoclave at 200°C for 6h. Cool to room temperature, magnetically separate, wash several times with ultrapure water until the pH is 7.0, then wash several times with ethanol, and vacuum-dry at 60°C for 6 hours to obtain an amino-modified magnetic graphene ternary composite. The scanning electron microscope picture of the above-mentioned amino modified magnetic graphene ternary composite material is as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com