MOF-derived Fe0/Fe3C@ C/N magnetic mesoporous composite material and preparation method and application thereof

A composite material and mesoporous technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve problems such as ecological toxicity effects, insufficient stability, secondary pollution, etc., and achieve recovery Catalytic activity, wide adaptability, and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A MOF-derived Fe 0 / Fe 3 Preparation method 1 of C@C / N magnetic mesoporous composite material, the specific operation steps are as follows:

[0032] (1) Take 234mg (0.625mmol) [Fe(Cp)(CO 2 ) 2 ] 2 and 515 mg (2.5 mmol) H 3 Bidc was dissolved in 35mL of acetonitrile / water (v / v=4 / 3) mixed solvent, fully stirred at room temperature for 2h to obtain a uniform precursor solution, and transferred to a 100mL polytetrafluoroethylene-lined hydrothermal reactor;

[0033] (2) The reaction kettle was hydrothermally reacted at 160° C. for 24 hours, and then naturally cooled to room temperature. Alternately and repeatedly washing with methanol and deionized water, and suction filtering to obtain Fe(Hbidc) metal-organic framework material;

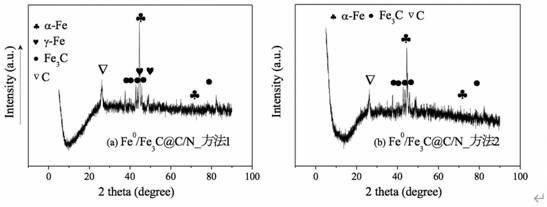

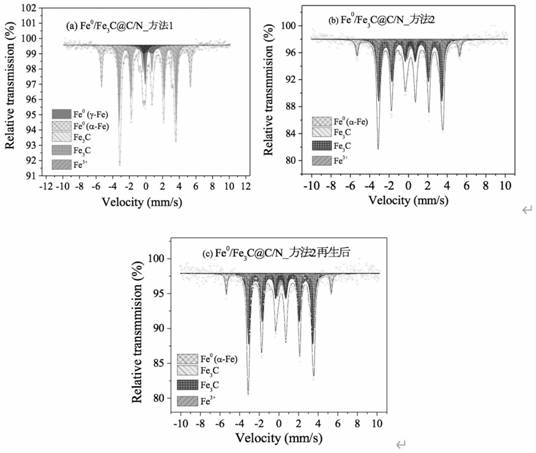

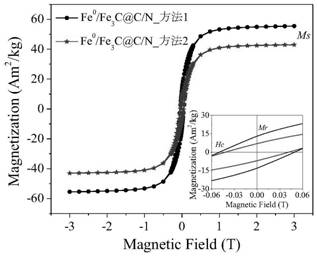

[0034] (3) Carry out vacuum drying treatment to Fe(Hbidc), and then place the powdered Fe(Hbidc) in nitrogen atmosphere at 10°C·min -1 The rate was raised to 800 °C, and calcined at this temperature for 5 h to obtain carbonization-derived F...

Embodiment 2

[0041] A MOF-derived Fe 0 / Fe 3 The preparation method 2 of C@C / N magnetic mesoporous composite material differs from that of Example 1 in that in step (1), the reactor is placed at 220°C for hydrothermal reaction. Other steps are consistent with the method of embodiment 1.

[0042] Fe 0 / Fe 3 Application of C@C / N magnetic mesoporous composites: prepare simulated organic wastewater with an initial SMX concentration of 10mg / L, and add 0.4g L to the wastewater -1 Fe prepared in embodiment 2 0 / Fe 3 C@C / N and 47.6mg·L -1 Oxidant PS, stir at room temperature to make the reaction uniform, take samples at 5, 10, 20, 30, 45, 60, 90, 120, and 180 minutes of reaction, and use HPLC to measure the remaining concentration of SMX in wastewater, and convert it into removal rate For: 37.9%, 63.0%, 84.3%, 92.1%, 95.8%, 96.9%, 97.5%, 97.8%, 98.1. Wastewater treatment efficiency is suitable with embodiment 1, it can be seen that the Fe prepared by embodiment 2 and embodiment 1 0 / Fe 3...

Embodiment 4

[0047] Fe 0 / Fe 3 The application of C@C / N magnetic mesoporous composite material is different from that in Example 2 in that the catalyst is the Fe prepared in Example 1 0 / Fe 3 C@C / N, other steps are the same as in Example 2. After the wastewater treatment reaction starts, samples are taken at regular intervals, and the remaining concentration values of PS and TOC in the wastewater are respectively measured by potassium iodide (KI) spectrophotometry and total organic carbon (TOC) analyzer, and converted into Utilization rate and removal rate, the results are shown in Table 2.

[0048] Table 2

[0049]

[0050]

[0051] What table 2 shows is the Fe that embodiment 1 prepares 0 / Fe 3 C@C / N activates PS to treat SMC system, and the concentration of residual PS and residual TOC in wastewater changes with reaction time. As can be seen from the results, when the SMX removal rate was 99.5% (Table 1) after the reaction for 180min, the PS utilization rate reached 94.7%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com