Preparation method of graphene-rare earth doped zinc oxide nano ceramic microfiltration membrane composite material

A zinc oxide nano- and ceramic micro-filtration technology, which is applied in chemical instruments and methods, separation methods, membranes, etc., can solve problems such as secondary pollution, achieve high safety, good stability, and solve the effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A graphene-cerium, yttrium co-doped zinc oxide ceramic microfiltration membrane composite material, comprising:

[0029] (1) Preparation of cerium and yttrium co-doped zinc oxide: In this experiment, 9.3 grams of zinc acetate was dissolved in 50 milliliters of ethylene glycol and in the stabilizer ethanolamine solution equimolar with zinc acetate, stirred while heating, at 70 Stir at ℃ for 1 hour to form a uniform transparent solution, then add 0.5 g of yttrium acetate, continue stirring for 2 hours, and let it stand for 12 hours. Dissolve 0.2 g of cerium acetate in 10 ml of ethylene glycol and stir while heating , stirred at 80°C for 1 hour to prepare solution A. Add a certain amount of A solution to B solution dropwise at 70°C and stir for 1 hour to obtain a solution of cerium and yttrium co-doped with zinc oxide, and bake it in a 100°C oven Dry in medium for 10-60 minutes, then put it into a muffle furnace and slowly heat it to 400-600°C, keep it for 2 hours, then co...

experiment example 1

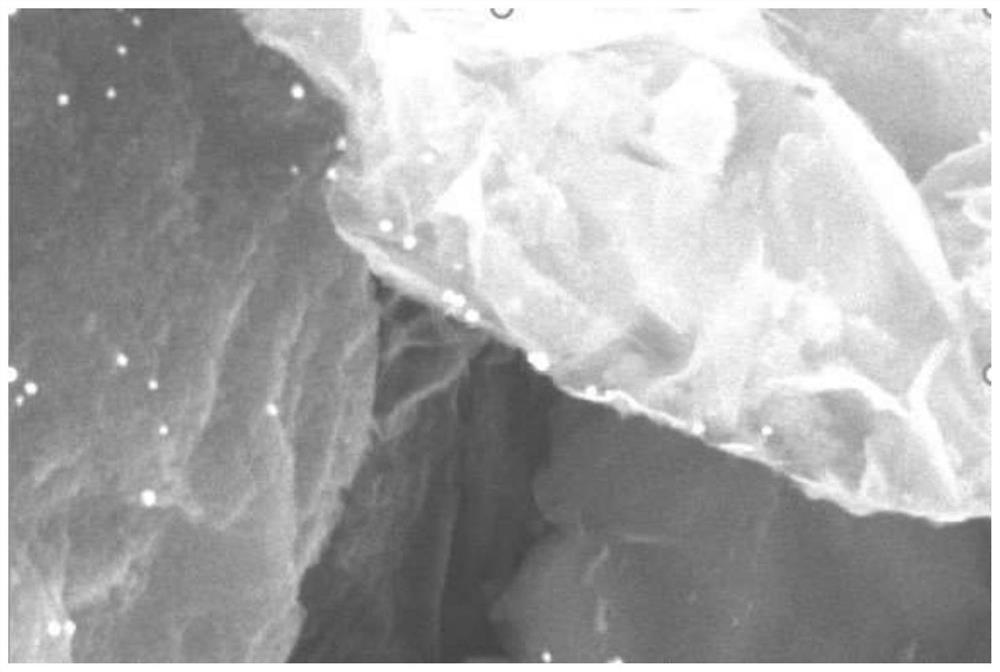

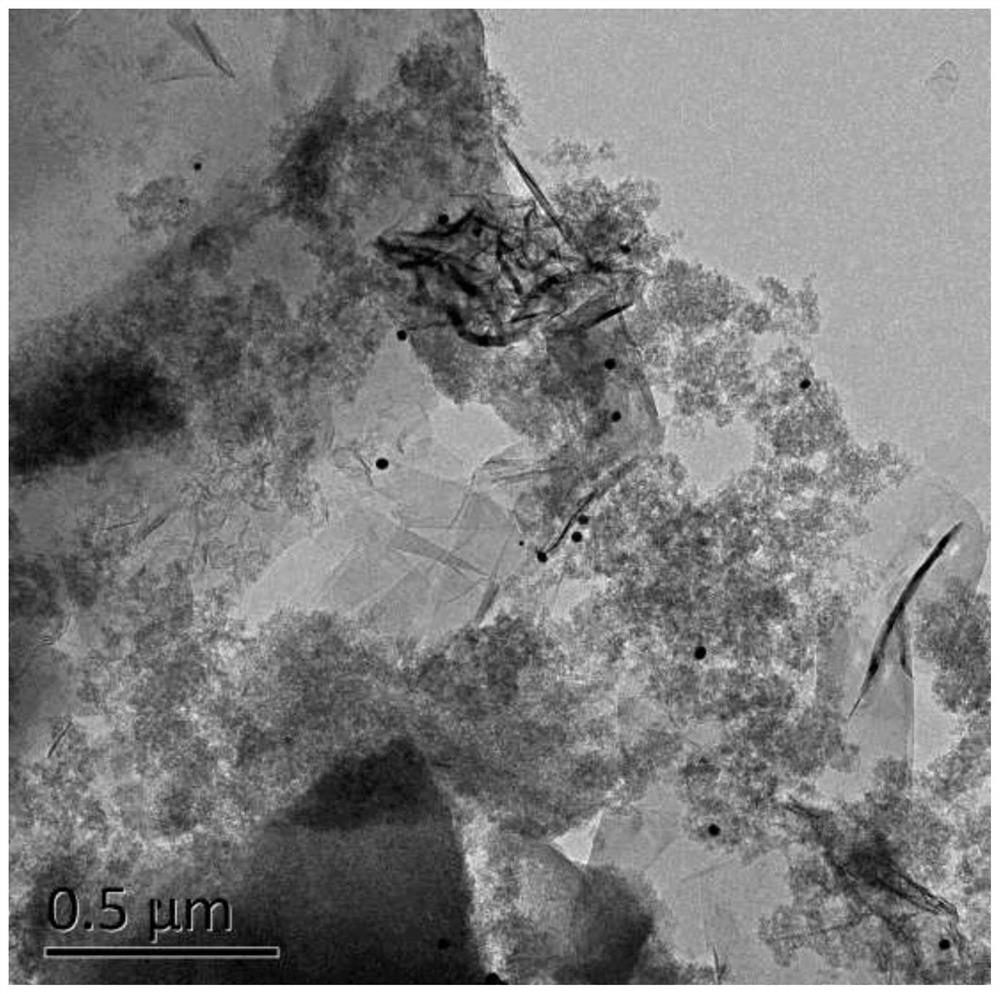

[0039] Observe the SEM of the prepared graphene-cerium, yttrium co-doped zinc oxide ( figure 1 ) and TEM ( figure 2 ) shape. It can be seen that cerium and yttrium co-doped zinc oxide are uniformly distributed on the surface of graphene.

experiment example 2

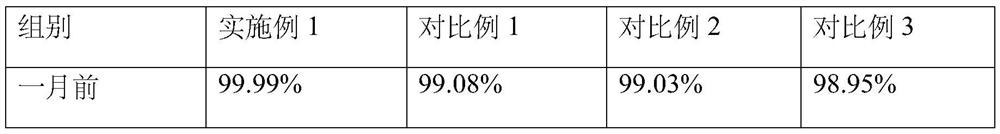

[0041] The water from the same water source was filtered by using the microfiltration membrane obtained in each embodiment and comparative example. Measure the content of Escherichia coli in the water after one month of filtration, and judge the filtration effect of the filter membrane by the content of Escherichia coli, the results are shown in the table below.

[0042]

[0043]

[0044] It can be seen from the above table that the degree of filtration of water by each group of filter membranes is the same one month ago. However, after one month of sunlight exposure, the filtering effect of Escherichia coli in the comparison group decreased to a higher degree than that in the example group. It shows that due to the strong photocatalytic degradation and sterilization effect of graphene / rare earth doped zinc oxide in the filter membrane of the implementation group, no secondary pollution will be generated, while the secondary pollution of the filter membrane will be gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com