Pre-encapsulation LED (light emitting diode) module dust blowing method and device

A technology of LED modules and dust removal devices, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve the problems that cannot meet the requirements of product quality and production process environment, and achieve a significant dust removal effect , high reliability, and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the invention.

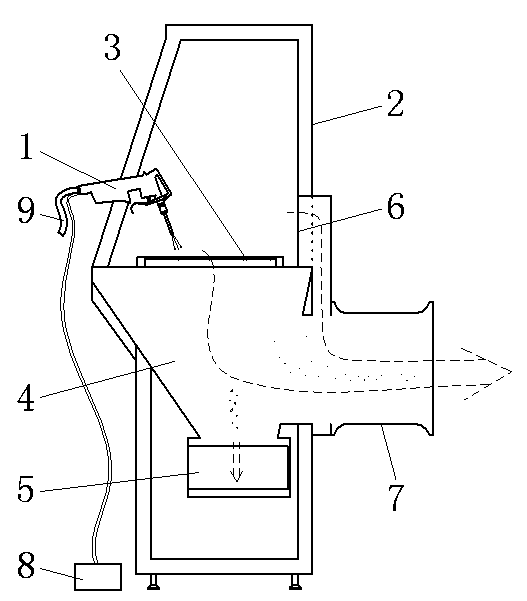

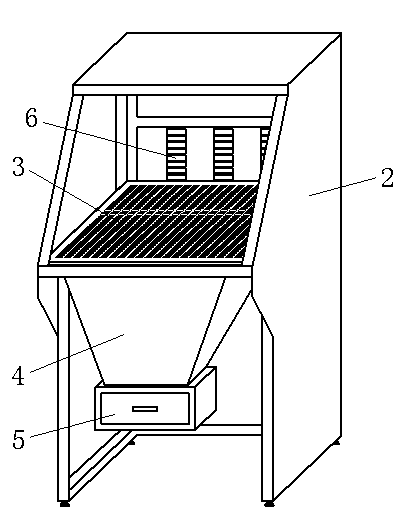

[0018] A method of blowing dust before LED module potting, such as figure 1 - As shown in Figure 4, the method is to place the filled batch of LED modules with their mouths up on the transparent glass workbench to ensure that the glue will not flow out; set a reflector under the transparent glass workbench to reflect light Use a mirror to observe the filling quality of the bottom surface of the LED module. By adjusting the angle of the reflector to achieve the best visual effect.

[0019] A device constructed according to the aforementioned method, such as figure 1 - As shown in FIG. 4 , it includes a frame 1 , a transparent glass inspection platform 2 is arranged on the frame 1 , and a mirror 3 is arranged on the frame 1 below the transparent glass inspection platform 2 . The shape and size of the reflective mir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com