Liquid crystal cleaning and production equipment

A technology for production equipment and liquid crystal, applied in the field of liquid crystal cleaning production equipment, can solve problems such as affecting the performance of the liquid crystal screen, scrapping the whole machine, and increasing the cost of liquid crystal production, and achieve the effect of eliminating hidden dangers of environmental protection, meeting environmental protection requirements, and enhancing the removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

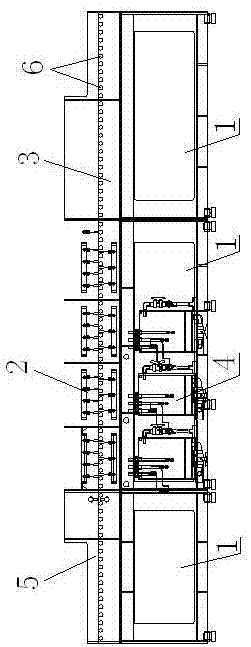

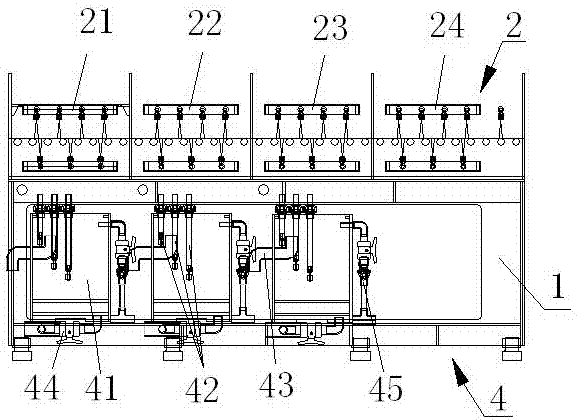

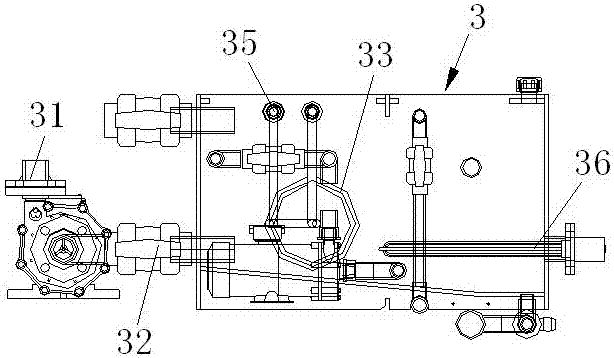

[0019] refer to Figure 1~4 , a liquid crystal cleaning production equipment, including a base support 1, a cleaning device 2, a water tank 3, a cleaning liquid circulation system 4, a feeding device 5, and a conveyor belt 6, and the base support 1 is a plurality of sequentially arranged on a production line. A feeding device 5 is installed on the top plane of a base support 1, and then a cleaning device 2 is installed on the top plane of the next base support 1, and a cleaning liquid circulation system 4 is installed inside the base support 1, and the cleaning liquid circulation system 4 and The cleaning device 2 is assembled together. A water tank 3 is installed on the top plane of the last base bracket 1. The water tank 3 and the cleaning liquid circulation system 4 are connected together through pipelines. The conveyor belt 6 is installed through the feeding device 5 and the cleaning device 2. Furthermore, an air knife (not shown) is installed in the feeding device 5. Sinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com