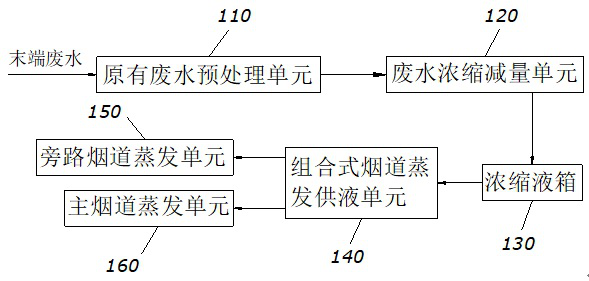

Coal-fired power plant wastewater zero-discharge combined flue evaporation system and method thereof

A coal-fired power plant and evaporation system technology, applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve problems such as large environmental risks, adverse effects of boilers, etc., to reduce sensitivity, eliminate environmental hidden dangers, and reasonable transformation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

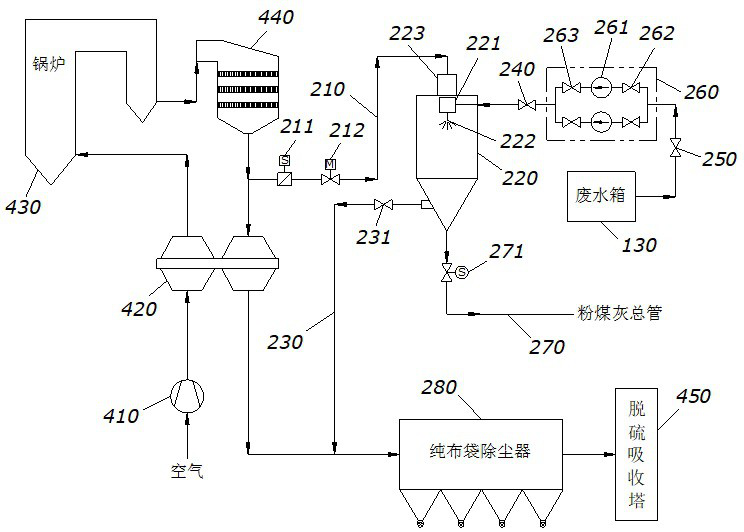

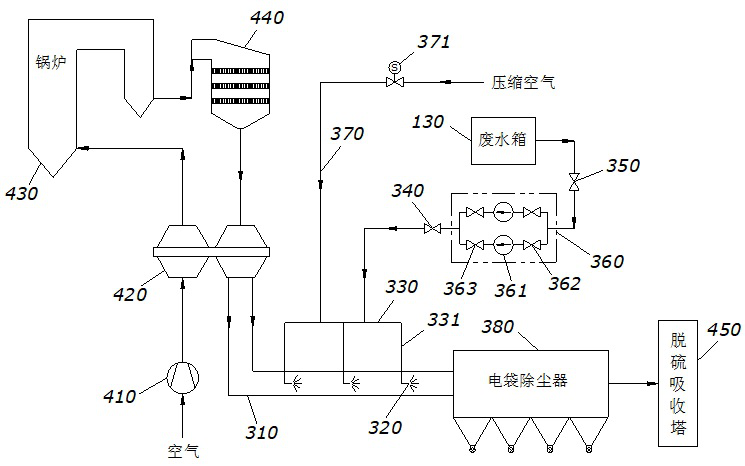

[0026] The specific implementations and examples of the present invention will be described in detail below in conjunction with the accompanying drawings. The described specific examples are only used to explain the present invention, and are not intended to limit the specific implementations of the present invention.

[0027] At present, the general idea of most coal-fired power plants to treat wastewater is to pass the wastewater into the channel between the air preheater and the dust collector, and use the SCR (Selective Catalytic Reduction, selective catalytic reduction) reactor and the air preheater to (i.e. air preheater) high-temperature flue gas is used as a heat source, and the separated pollutants are transported to the standby ash storage through the ash conveying system inside the dust collector, and the separated water vapor is transported to the desulfurization absorption tower; and now Some dust collectors are divided into two types: electric bag dust collector...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com