Freon treated by premixed combustion and method for producing said resource

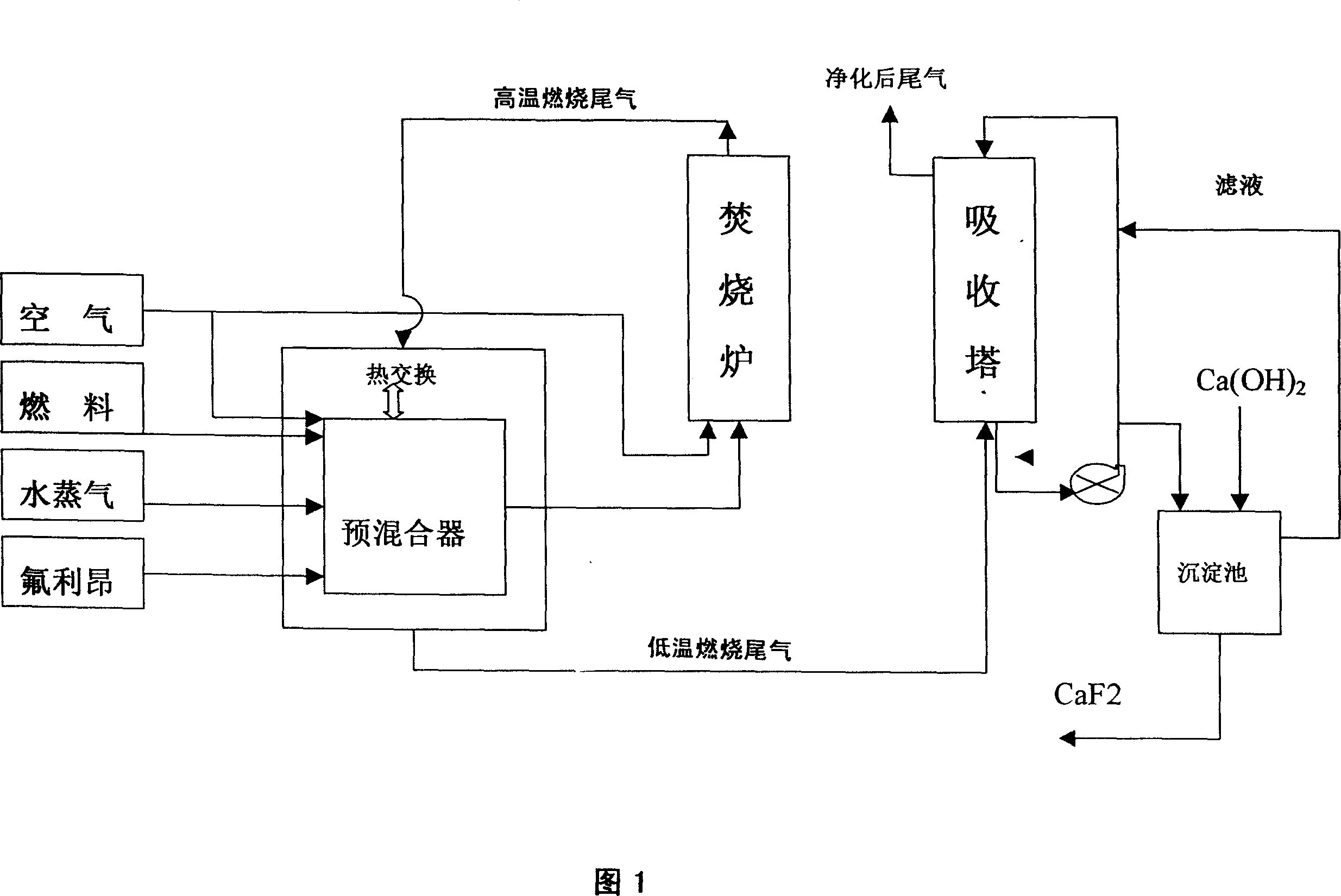

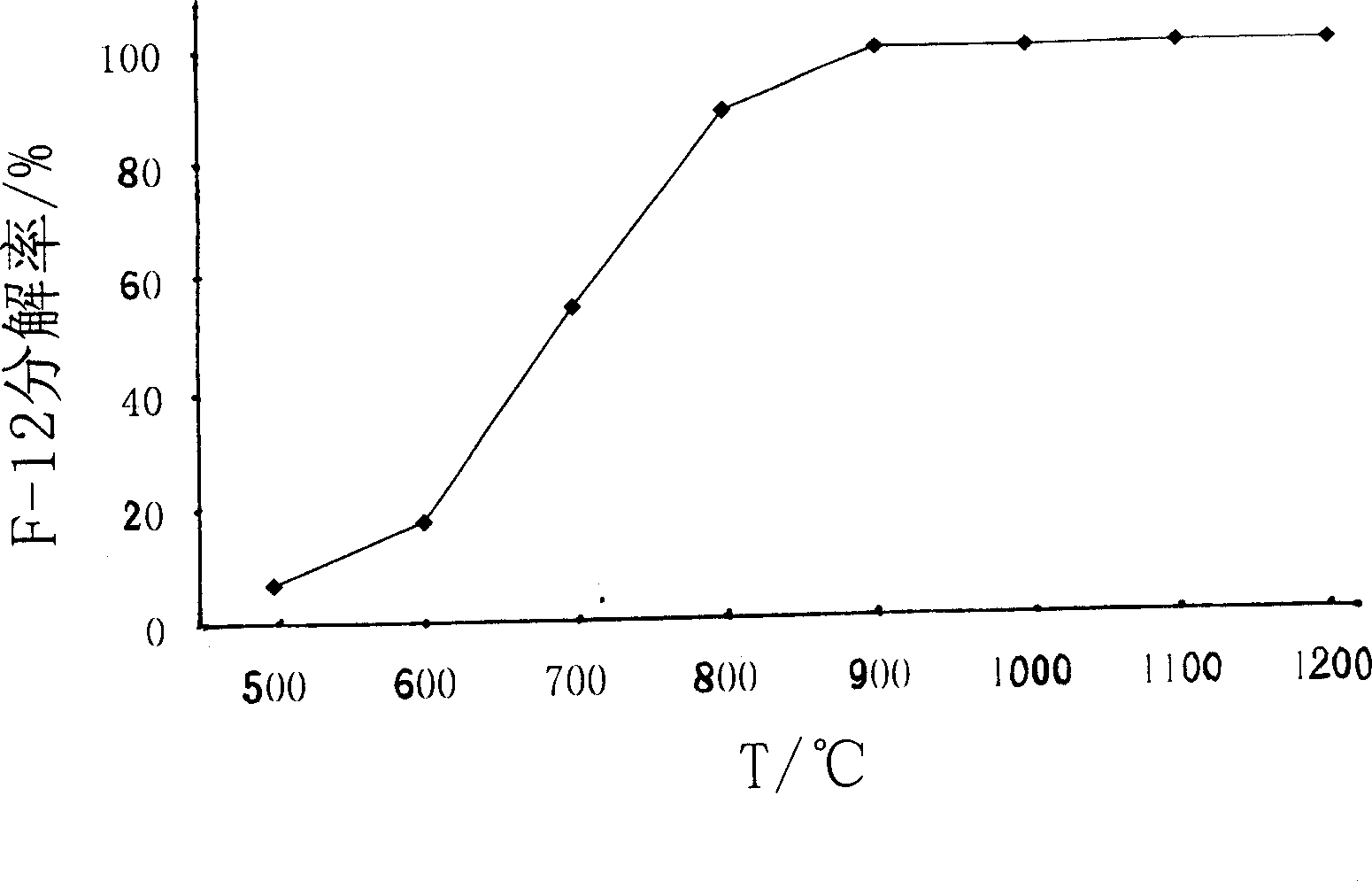

A pre-mixed combustion and Freon technology, applied in the direction of combustion methods, combustion types, incinerators, etc., can solve the problems of unstable Freon decomposition rate, reduced carbon dioxide selectivity, and incomplete Freon decomposition, so as to improve flame propagation speed and combustion Effects of increasing temperature and decomposition rate and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

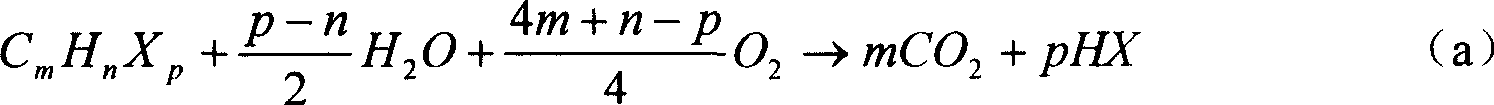

[0040] Commercially available Freon-12 (F-12, that is, difluorodichloromethane CCl 2 f 2 ). For Freon-12, m, n, and p in formula (a) are 1, 0, and 4 respectively, and then formula (a) becomes:

[0041] (c)

[0042] Use civil liquefied petroleum gas as fuel.

[0043] The incinerator cavity is a cylindrical cavity with a diameter of 120mm and a length of 1000mm.

[0044] The flow velocity of the premixed gas in the heat exchange tube is 5.6M / s, and the flow velocity of the combustion exhaust gas in the premixer is 1.5M / s.

[0045] First of all, according to the design processing capacity range of the incinerator, the processing capacity of Freon is determined to be 0.01M 3 / min; According to formula (1), it is determined that Freon: the molar ratio of fuel = 1: 1, that is, the liquefied petroleum gas flow rate is 0.01M 3 / min; Freon is determined according to (2) formula: That is, the water vapor flow rate is 0.005M 3 / min; 1M 3 The theoretical air volume required...

Embodiment 2

[0051] Commercially available Freon-13 (F-13, that is, trifluorochloromethane CClF 3 ). For Freon-13, m, n, and p in formula (a) are 1, 0, and 4 respectively, and formula (a) is:

[0052] (d)

[0053] Use artificial gas (the main component is carbon monoxide) as fuel.

[0054] Incinerator is the same as embodiment 1.

[0055] First of all, according to the design processing capacity range of the incinerator, the processing capacity of Freon is determined to be 0.012M 3 / min, according to formula (1) to determine Freon: fuel molar ratio = 1: 7.5, that is, the artificial gas flow rate is 0.09M 3 / min, according to formula (2) to determine Freon: That is, the water vapor flow rate is 0.036M 3 / min, 1M 3 The theoretical air volume required for artificial gas combustion is 18.51M 3 , taking the excess air coefficient of liquefied petroleum gas combustion as 1.1, and the primary air volume accounts for 70% of the total air volume, the total air vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com