Construction method for foundation pit supporting by dynamic compaction replacement of muddy soil

A technology of dynamic compaction replacement and foundation pit support, which is applied in the field of building foundations, can solve problems such as poor soil stability, extended construction period, complex engineering, etc., and achieve the effect of saving procedures, saving construction costs and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

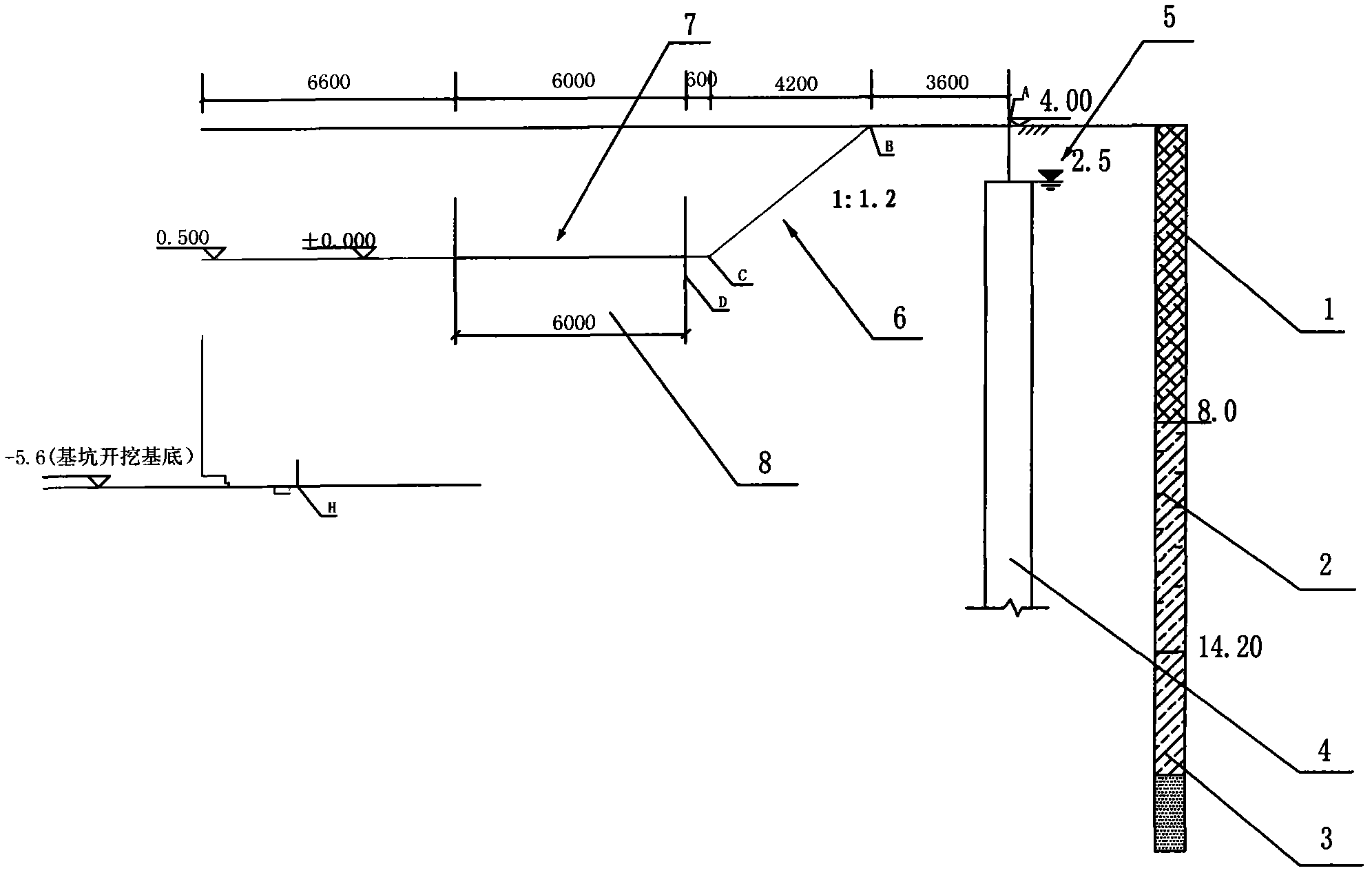

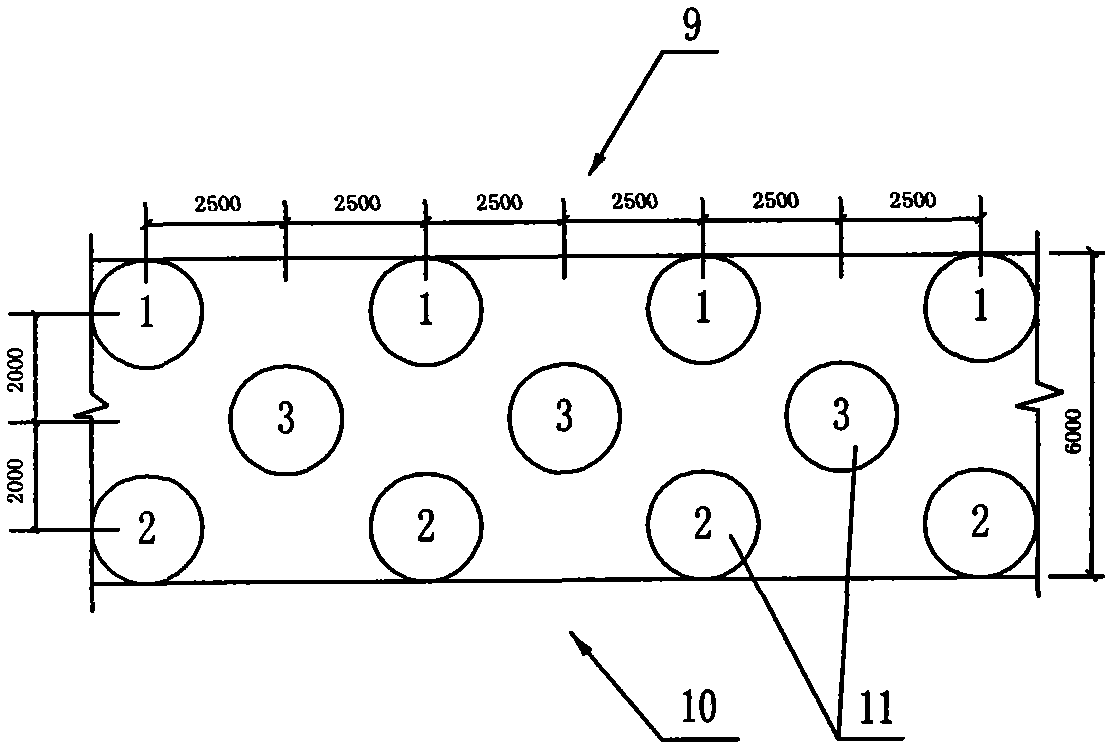

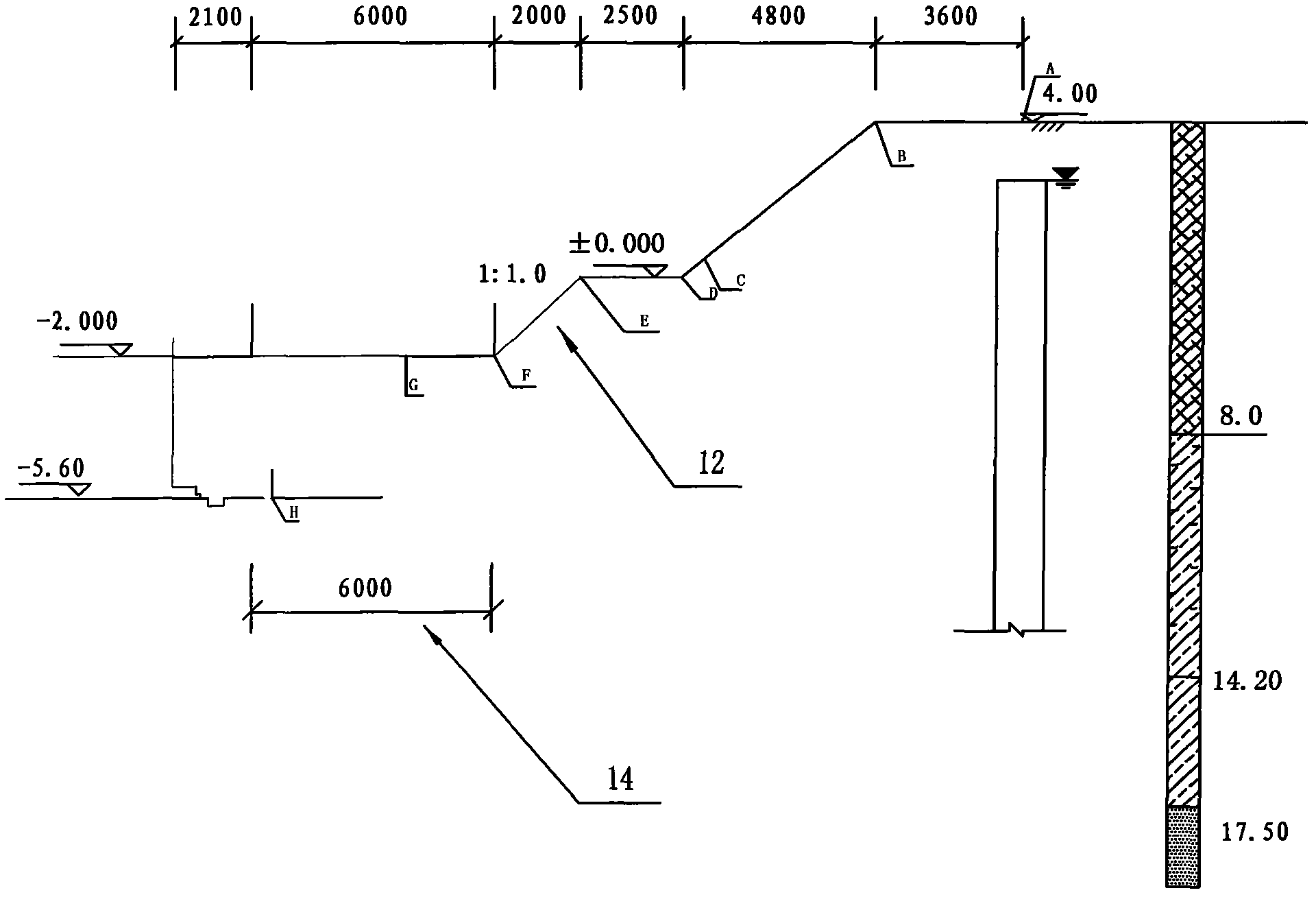

[0033] The following takes Qingdao Ruihai Xinyuan Foundation Pit Excavation and Support Project as an object to give a comprehensive description of this technology: The project is located on the west side of Huanwan Avenue, and the soil layers exposed in the site are as follows from top to bottom:

[0034] (1) Filling soil 1: The thickness of the layer is 7.00-9.7 meters, which is mainly backfilled with sand and large stone bricks, and partially filled with plain soil.

[0035] (2) Fine sand with silt: layer thickness of 0.50-3.00 meters, mainly fine sand

[0036] (3) Muddy soil 2: layer thickness 0.60-6.40 meters, flow plastic ~ soft plastic, poor toughness

[0037] (4) Silty clay 3: layer thickness 0.20-2.90 meters, soft plastic to flow plastic, with medium compressibility

[0038] The safety level of the foundation pit support project is level two. Considering the temporary slope, the normal service life of the foundation pit is one year. According to the different environ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com