Coal mine anchor drilling robot autonomous anchor drilling device and method

A technology of robots and drilling anchors, which is applied in mining equipment, earth-moving drilling, bolt installation, etc., can solve the problems of poor working environment, high labor intensity and high safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

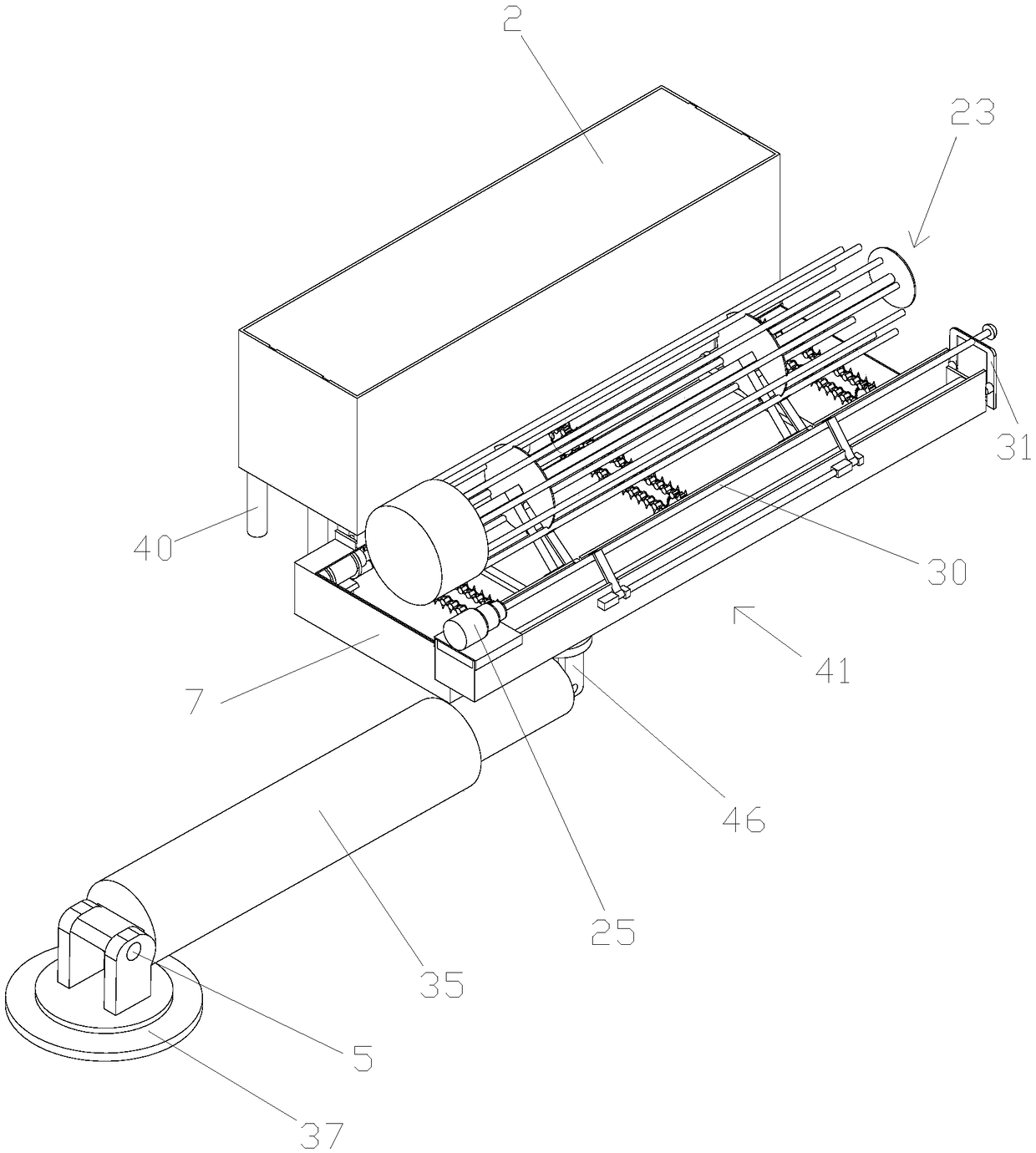

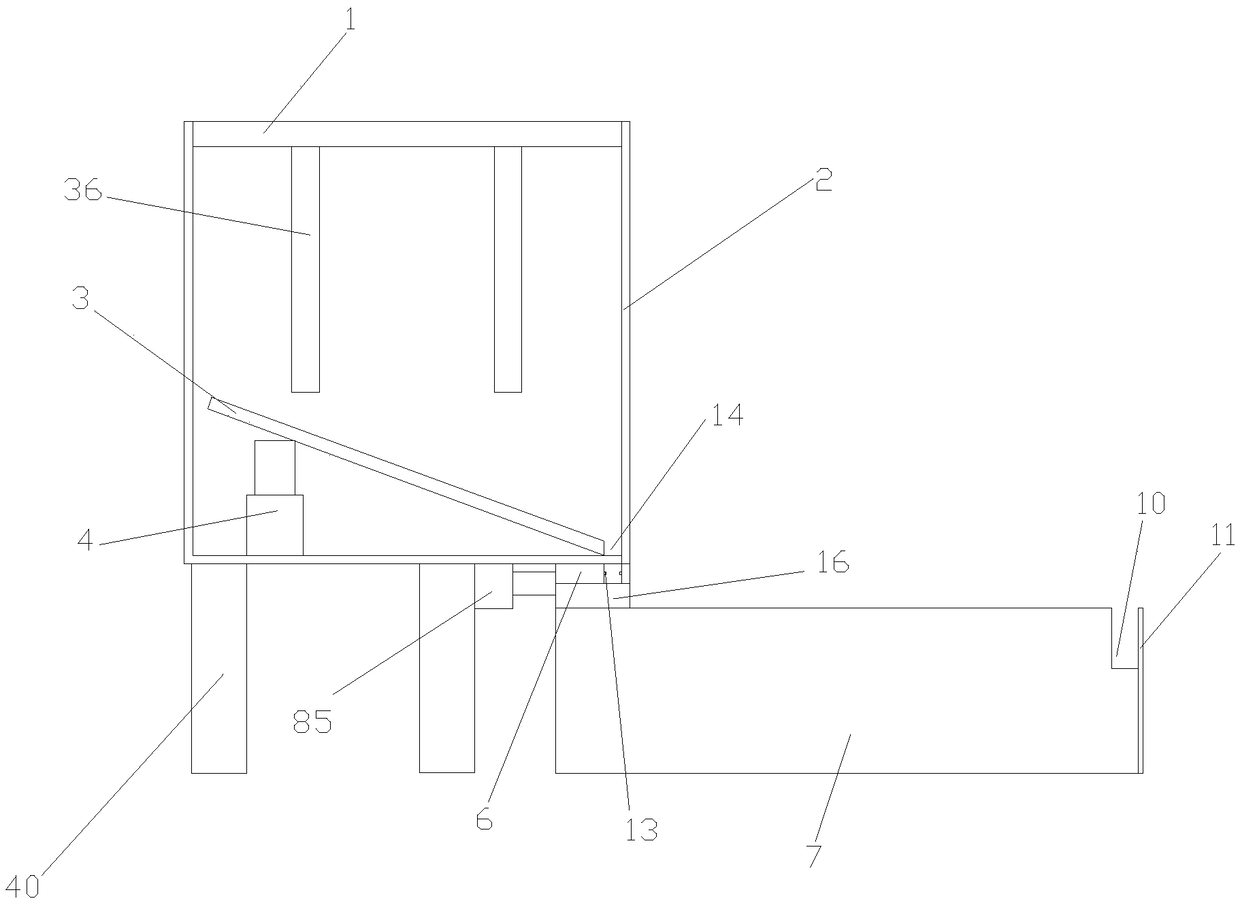

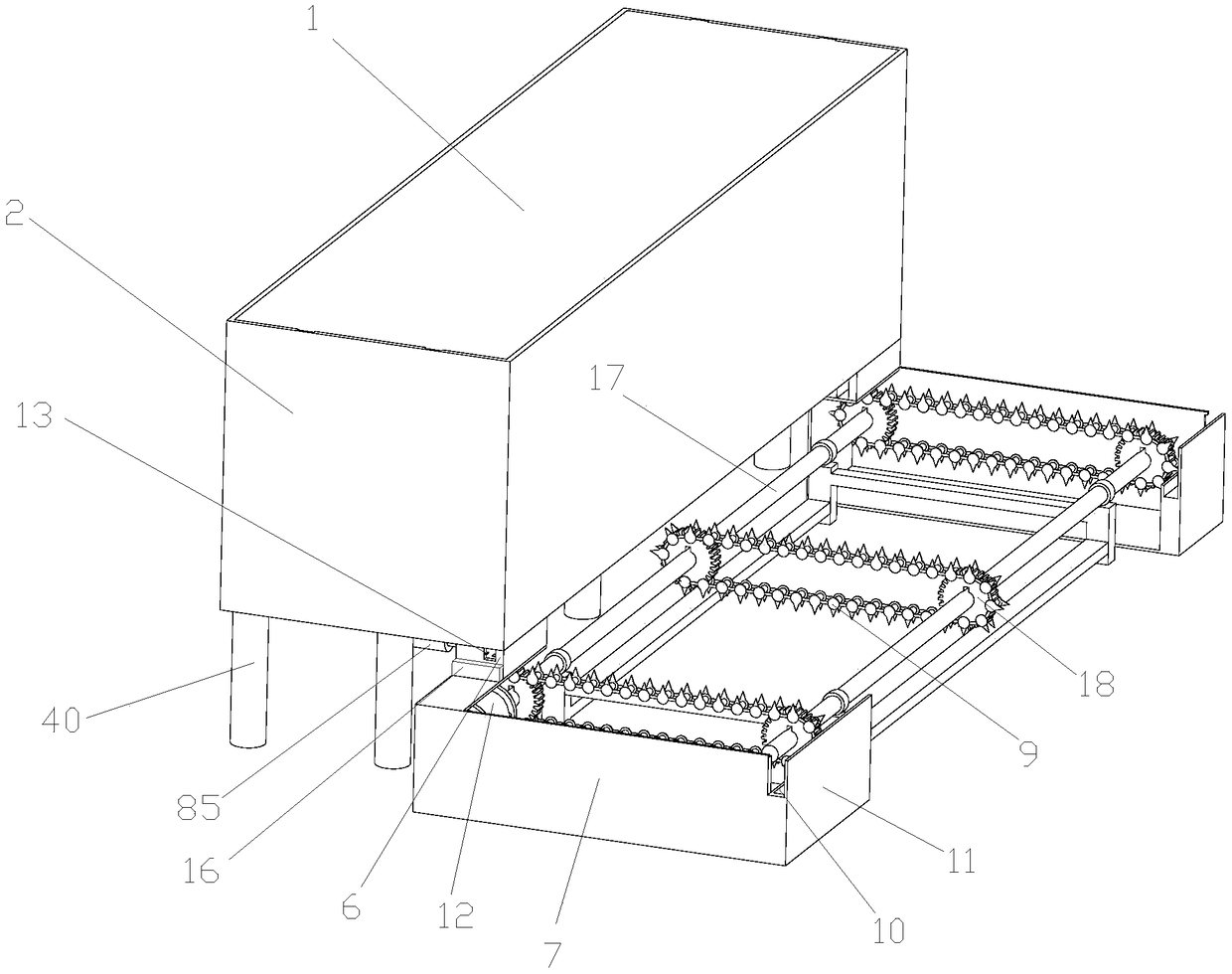

[0093] Such as figure 1 , image 3 and Figure 8 The self-drilling and bolting device of a coal mine bolting robot shown includes a control module, a bolt storehouse, a bolt conveying mechanism for transporting the bolts slid out of the bolt storehouse, and drilling and installation at the position to be supported. The drilling and anchor mechanism of the anchor rod, the drilling and anchor mechanism includes a hydraulic telescopic mechanism, a drilling mechanism 41 installed on the hydraulic telescopic mechanism, and a bolt frame 23 installed on the drilling mechanism 41, and the The anchor rod on the anchor rod conveying mechanism is clamped on the upper anchor rod mechanism on the anchor rod frame 23 and the anchor rod loading mechanism is used to drill the anchor rod on the anchor rod frame 23, and the hydraulic telescopic mechanism includes a base 37 , the hydraulic arm 35 installed on the base 37 and the hydraulic arm driving mechanism that drives the hydraulic arm 35 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com