Method for assessing ultra-high cycle fatigue strength and fatigue life of steam turbine rotor

A steam turbine rotor, fatigue life technology, applied in the field of steam turbines, to achieve the effect of accurate equivalent unidirectional symmetrical stress amplitude, which is not conducive to cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

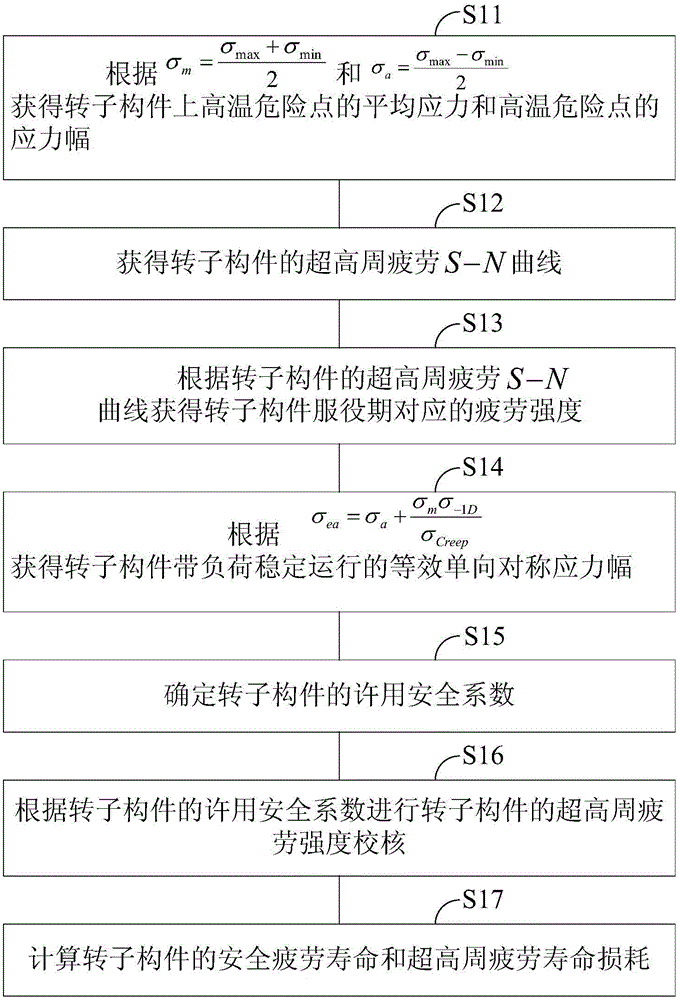

[0038] figure 1 It is a schematic flow chart of a steam turbine rotor ultra-high cycle fatigue fatigue strength and fatigue life evaluation method according to an embodiment of the present invention. The steam turbine rotor ultra-high cycle fatigue fatigue strength and fatigue life evaluation method includes:

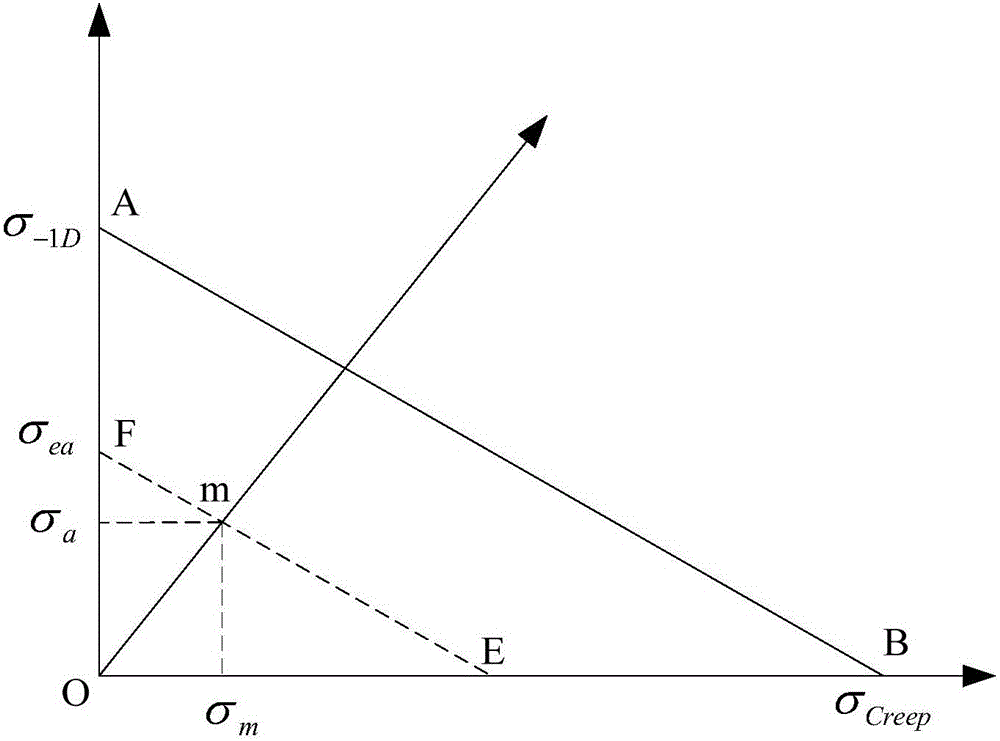

[0039] Step S11, according to and Obtain the average stress and the stress amplitude of the high temperature dangerous point on the rotor component, where, σ m is the average stress at the high temperature danger point, σ a is the stress amplitude of the high temperature danger point, σ max is the maximum stress at the high temperature danger point, σ min is the minimum stress at the high temperature danger point.

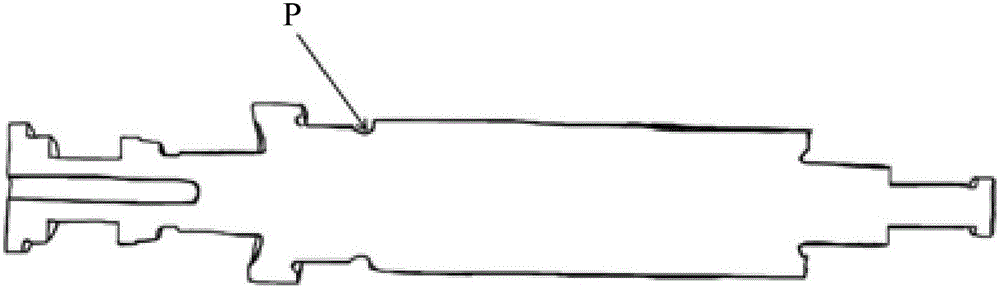

[0040] Specifically, under the action of its own gravity, the high-temperature dangerous point on the rotor component rotates to the lower surface (that is, the 270° position at the bottom of the rotor component) to receive the maximum stress, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com