A low-cycle fatigue life analysis method for generator structures

A low-cycle fatigue and life analysis technology, applied in electrical digital data processing, special data processing applications, instruments, etc., it can solve the problem that formula calculation of structural life does not realize process analysis, cannot effectively deal with multi-axial stress problems, and the results are not obvious enough. To reduce the cost of design and development, achieve standardization, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

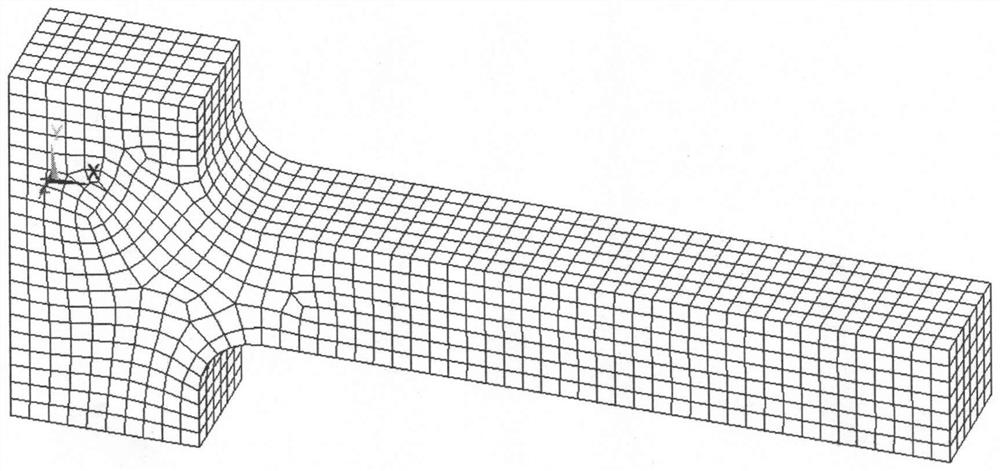

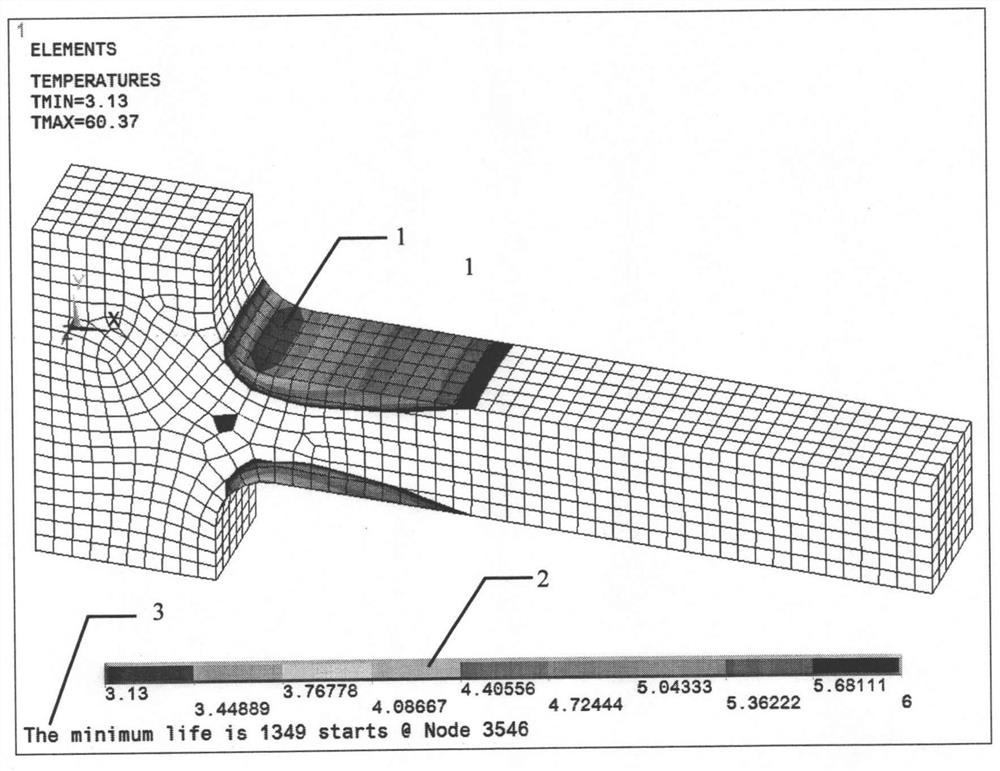

[0040] like figure 1 As shown, it is a finite element numerical simulation model of a cantilever beam structure. The specific size parameters are 120mm in length, 20mm in section width, 20mm in height, and a fillet radius of 10mm. Copper material is used, and the applied load is an alternating force of ±5kN at the free end. Take it as the analysis object of this embodiment.

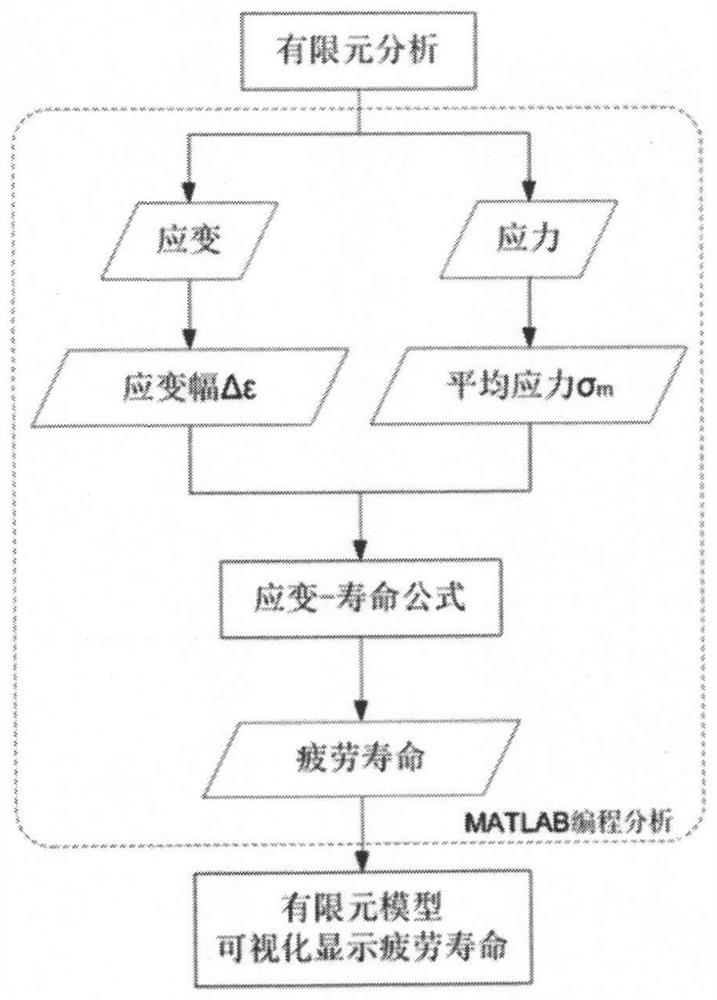

[0041] like image 3 As shown, firstly, the stress and strain of the cantilever beam under 5kN and -5kN loads are obtained by finite element elastoplastic analysis (step 1). Then import the stress and strain results into the self-edited MATLAB program (step 2-3) for low-cycle fatigue analysis, and calculate the fatigue life of the cantilever beam finite element model at each node. Finally, the fatigue life at each node is loaded on each node as a temperature load and displayed (step 4).

[0042] The described low cycle fatigue life analysis method for generator structure is:

[0043] Step 1: Establish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com