Fatigue analysis method of wind turbine blade coating considering raindrop erosion

A wind turbine, fatigue analysis technology, applied in wind turbines, monitoring of wind turbines, wind power generation, etc., can solve the problem that the impact method is difficult to consider the raindrop fluid-solid interaction, the fatigue life of the fan blade coating cannot be calculated, and it is difficult Quantify the total transfer energy of fan blade coating and other issues to achieve the effect of accurate fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention will be described in detail below according to the accompanying drawings and preferred embodiments, the purpose and effect of the present invention will become more clear, and it should be understood that the specific embodiments described herein are only used to explain the present invention, not to limit the present invention.

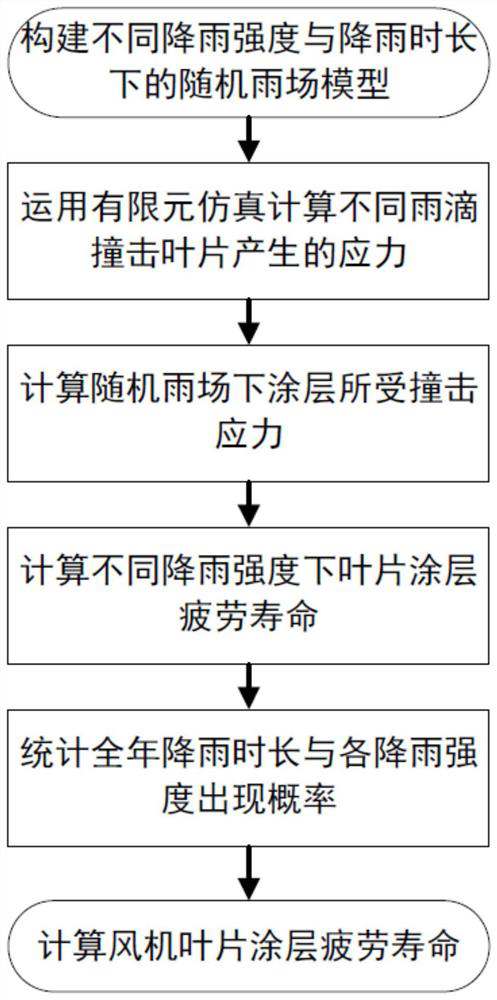

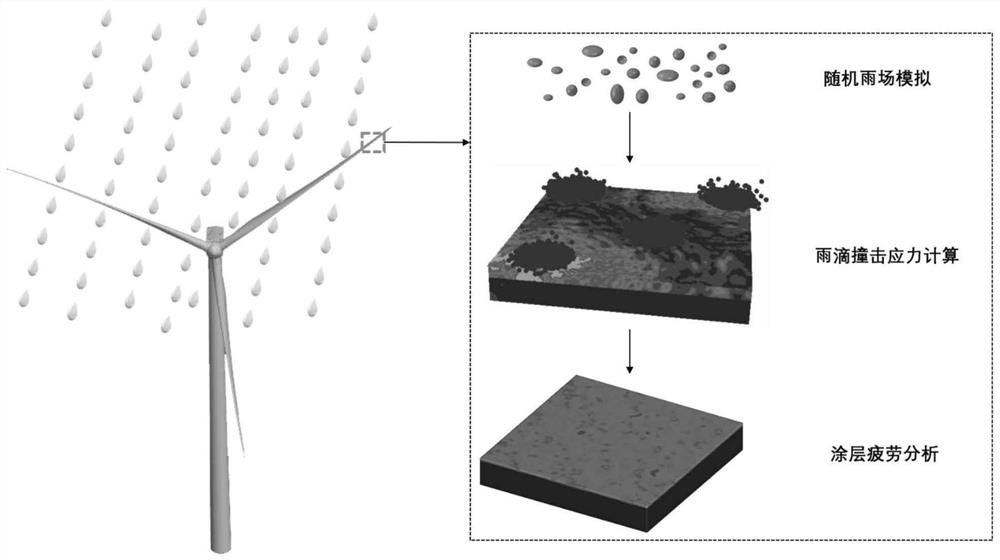

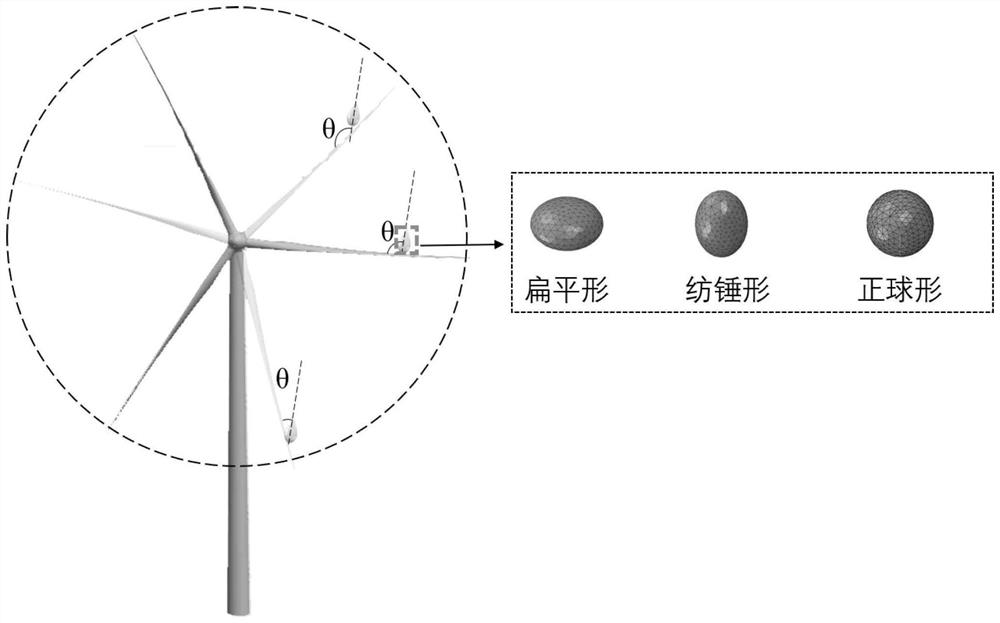

[0089] The wind turbine blade coating fatigue analysis method of the present invention considers raindrop erosion, uses the random rain field model to effectively model the natural rainfall condition, uses smooth fluid dynamics and stress interpolation to accurately analyze the raindrop impact on the blade stress, and uses fatigue The fatigue life of the blade coating is comprehensively calculated by the crack propagation theory, and the fatigue life of the wind turbine blade coating in Miami, Florida is predicted and calculated. The specific flow chart is as follows: figure 1 shown, the schematic diagram is as figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com