Method for determining high-cycle fatigue life of bolt hole in complex stress state

A stress state, high cycle fatigue technology, applied in the field of mechanical fatigue life calculation, to achieve the effect of accurate fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

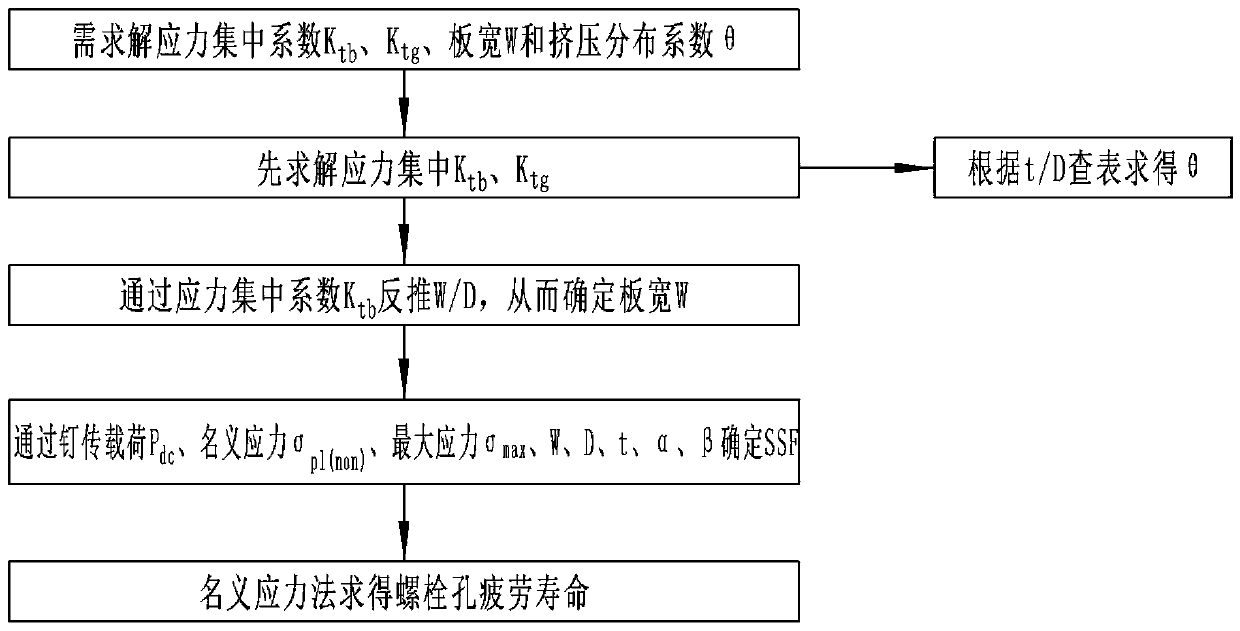

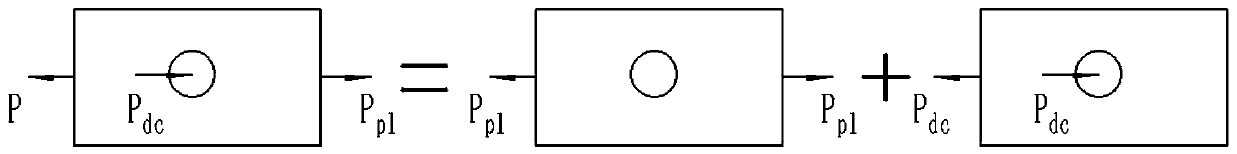

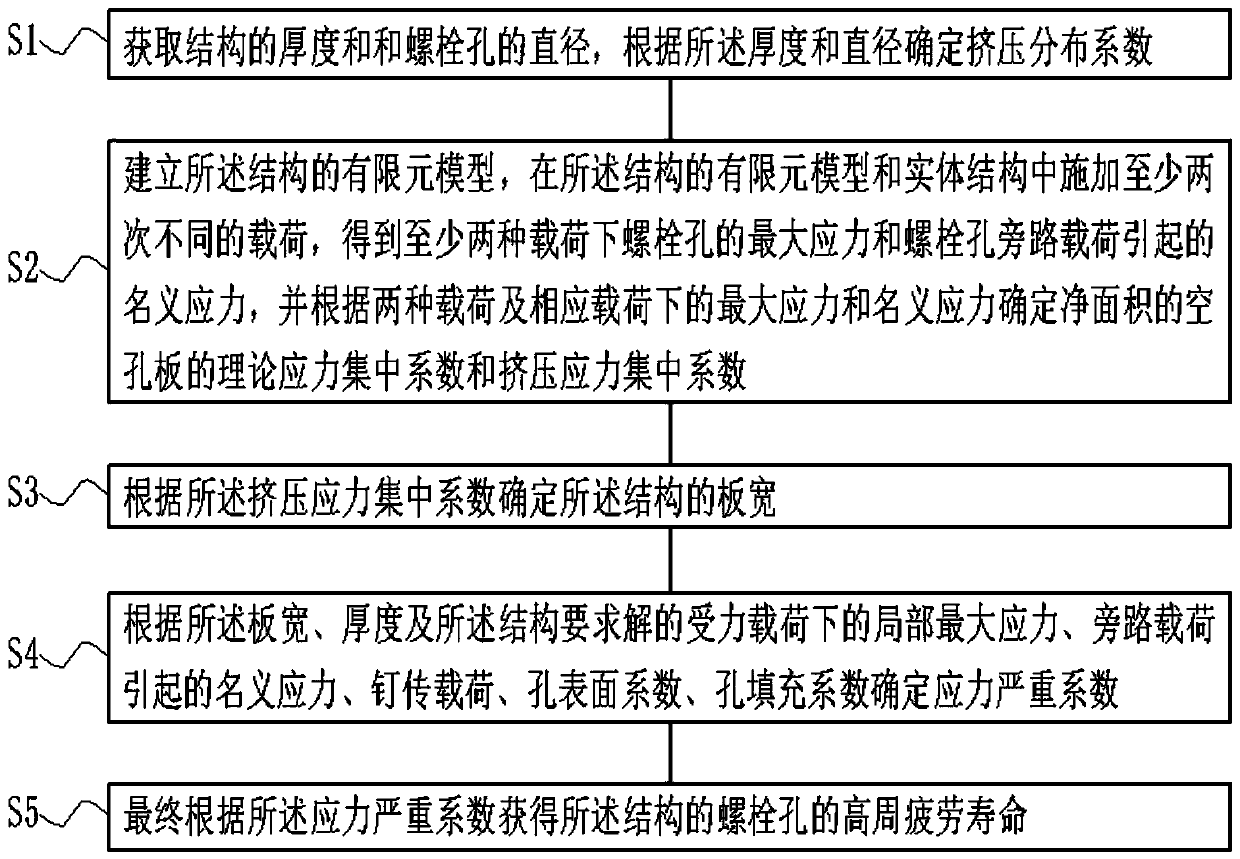

[0055]The purpose of this application is to solve the problems in the prior art that the plate width of the structure cannot be determined, and the stress concentration factor is also difficult to determine, and propose a method that can more accurately determine the fatigue life of bolt holes under complex stress states . The method of the present application is by first determining the stress concentration factor K tg and K tb , and then determine the plate width W to solve the stress severity factor SSF, and determine the nominal stress caused by the bypass load through the method of this application, so that the determination of the life of the bolt hole is more accurate.

[0056] In order to achieve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com