Damage repair method for marine steam turbine rotor

A steam turbine rotor, damage repair technology, applied in coating, arc welding equipment, metal material coating process, etc., can solve the problems of deep corrosion pits, temperature accumulation, rotor balance damage, etc., to prolong the service life and prolong the service life , Solve the effect of easy wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

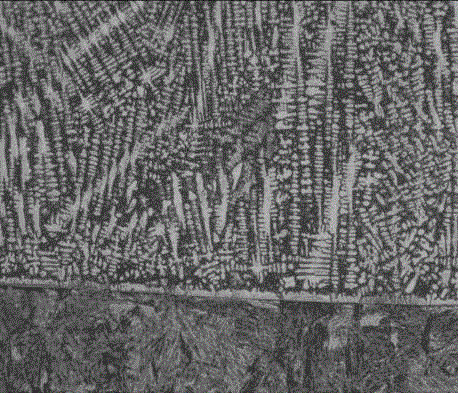

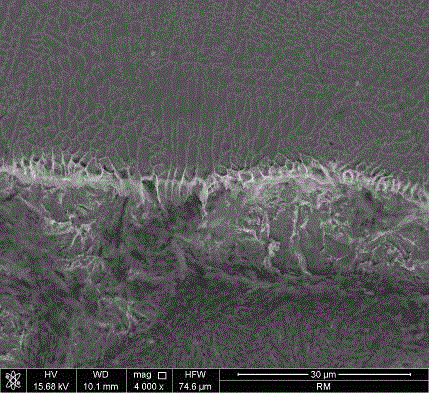

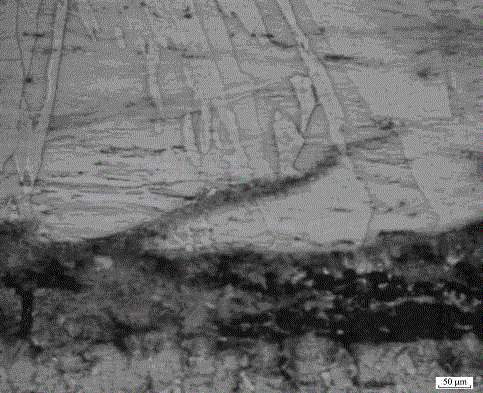

[0038]This example proposes a method for repairing damage to a marine steam turbine rotor, which is suitable for corrosion pits on the surface of the steam turbine rotor seal journal with a large depth (not less than 0.3 mm) and steam with a large depth (not less than 0.3 mm) on the impeller disk surface. The erosion pits are repaired, and the specific repair steps are as follows:

[0039] (1) Use resistance heat energy micro-arc surfacing welding technology to repair the damage defects of the steam seal journal surface and impeller disk surface of the marine steam turbine rotor workpiece. The specific repair process is as follows:

[0040] (11) Surface pretre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com