Turbine Rotor

a turbine rotor and rotor body technology, applied in the field of turbine rotors, can solve the problems of difficult to meet the requirements of both properties of only one material, inability to apply oxidation, excessive oxidation of penetration beads, etc., and achieve the effect of improving the reliability of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

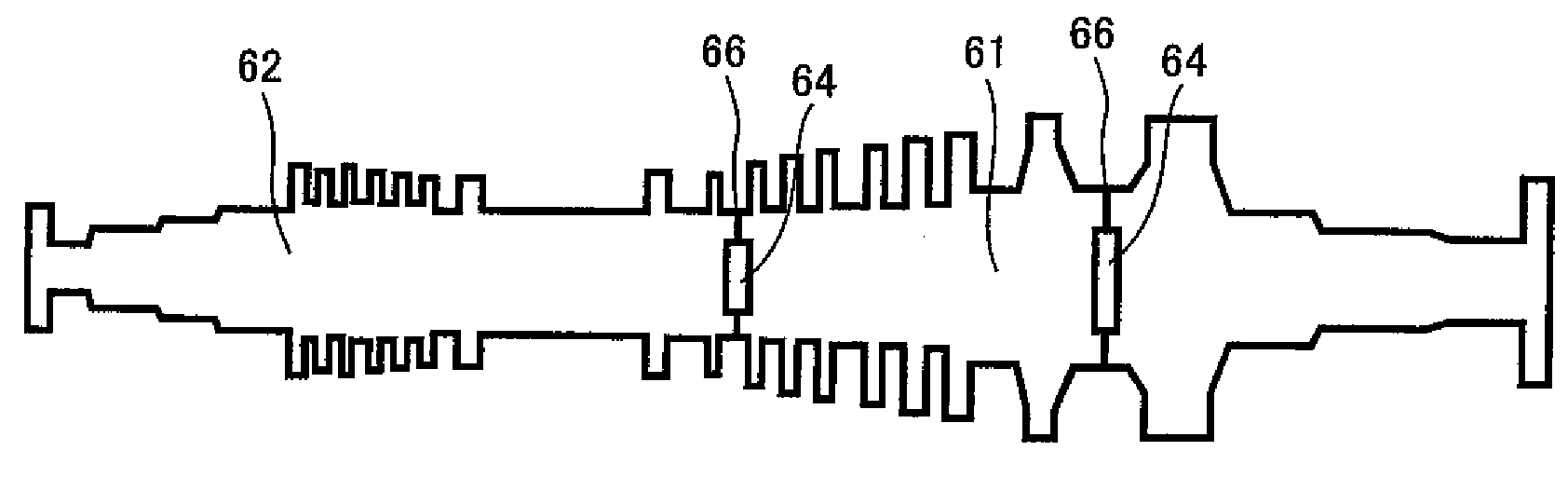

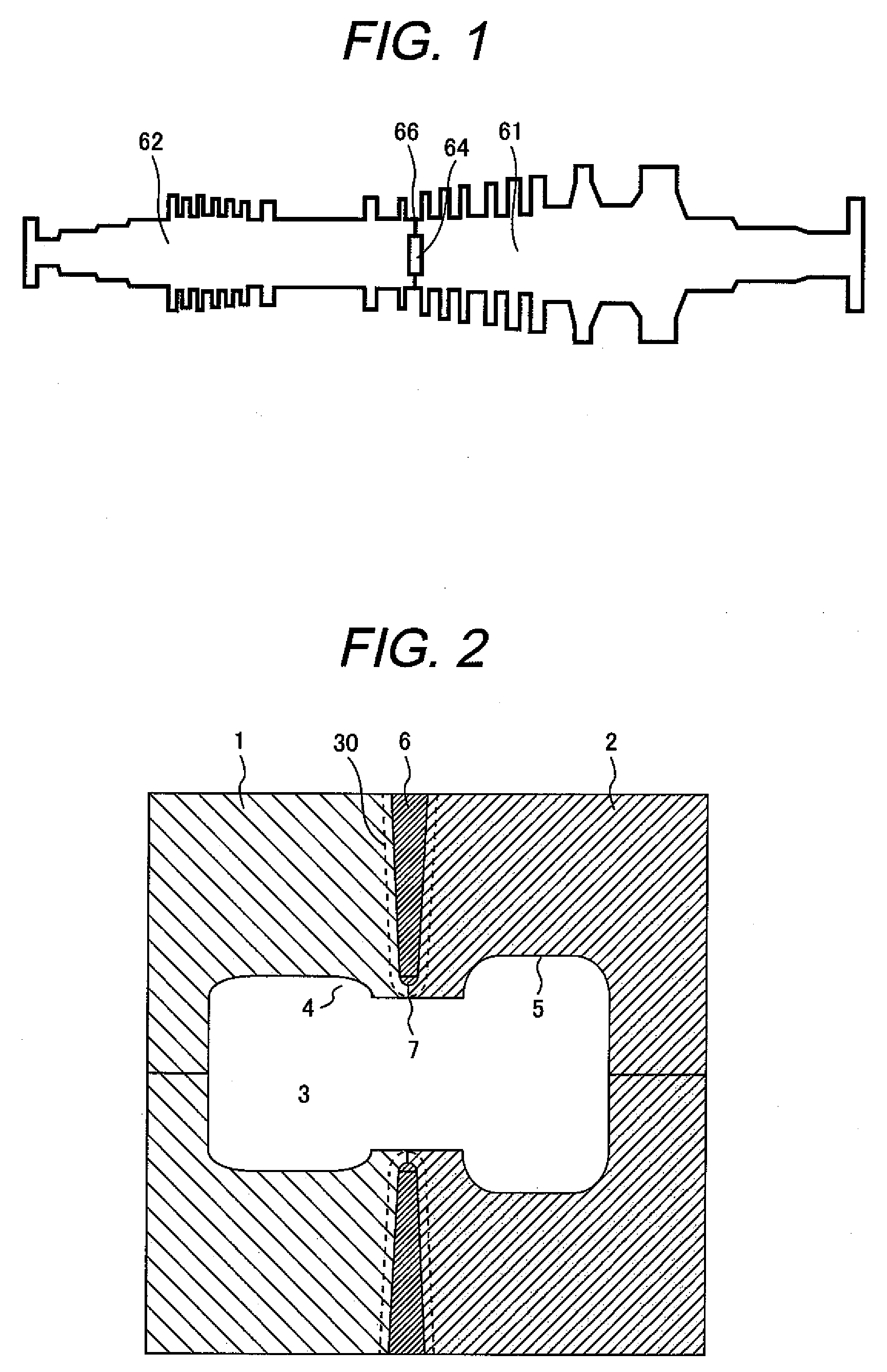

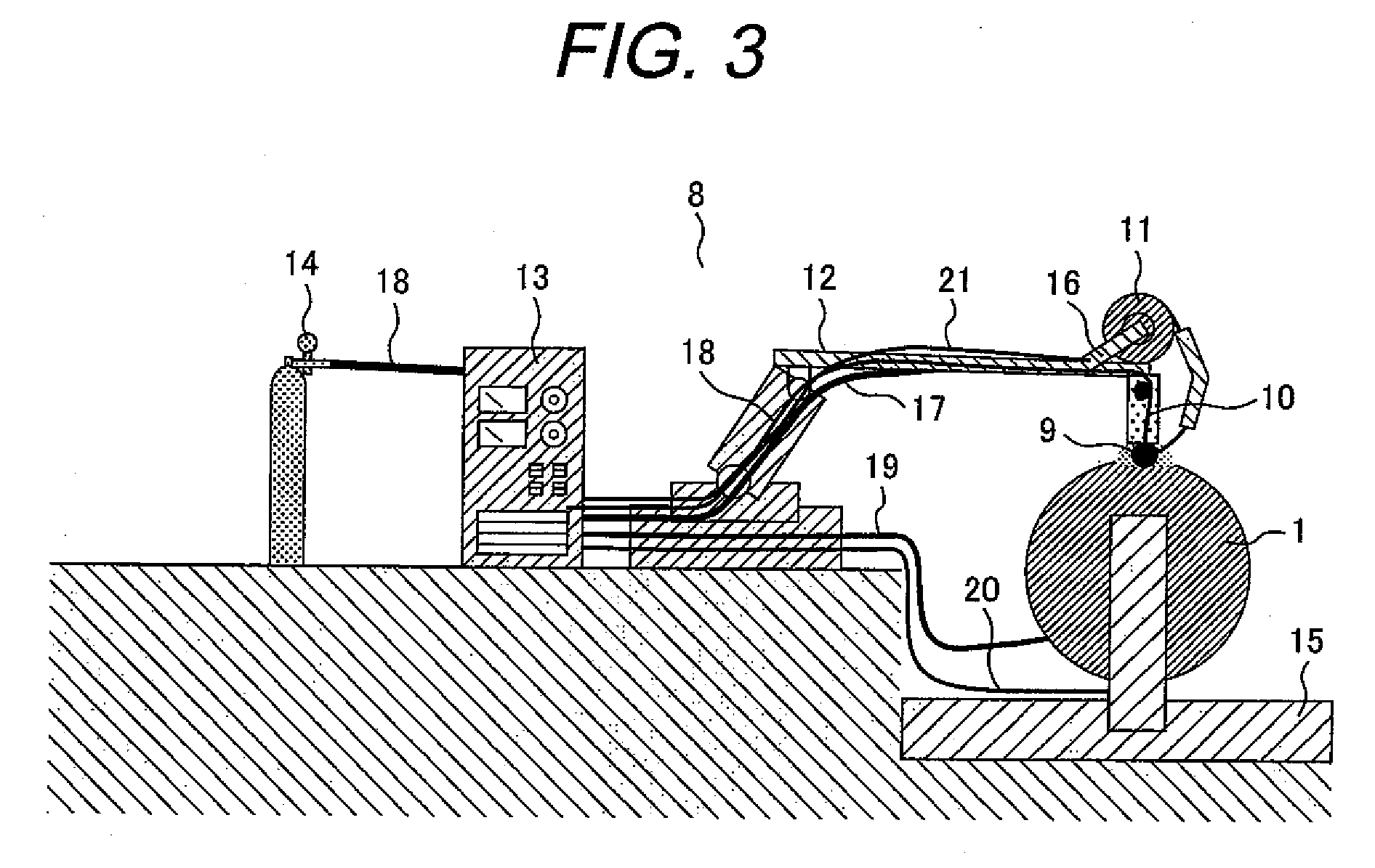

[0047]Example 1 of the present invention will be described below using FIGS. 1 to 11. FIG. 1 is a sectional view of the turbine rotor for high and low pressure steams according to the present invention. The turbine rotor for high and low pressure steam shown in FIG. 1 is divided into two components, that is, a rotor 62 for high pressure and a rotor 61 for low pressure, which are connected to each other by a weld 6 (weld metal 66) to construct the turbine rotor. A joint connected by the weld 6 has a hollow portion 64, which decreases the weight of the turbine rotor. The rotor 62 for high pressure includes 1% Cr—Mo—V steel. The rotor 61 for low pressure includes 3 to 4% Ni—Cr—Mo—V steel. Table 1 shows chemical compositions (weight percent) of weld wires and materials constituting the rotor of a typical turbine rotor, the rest of the compositions being Fe.

TABLE 1Steel gradeCSiMnNiCrMoNbVMaterial for high0.290.040.770.521.131.353—0.27pressure 1: 1%Cr—Mo—V steelWeld(1) 1.25%0.060.500.99—...

example 2

[0069]With reference to FIG. 14, example 2 of the present invention will be described. This example is the same as Example 1 except for the length of the outer contact face 32 in the axial direction, and therefore a description of the same other components as Example 1 will be omitted below.

[0070]The result of a preliminary verification test performed prior to this example will be described below. The length L2 of the outer contact face 32 in the axial direction was 2.5 mm before and after the welding. That is, the penetration tip of the weld metal 6 did not reach the outer contact face 32 in the axial direction. In this case, the effect was not obtained of preventing the spouting of the metal by compression of the outer contact face 32 in the axial direction as described in FIG. 11. This result shows that in order to obtain the effect of preventing the spouting of the weld metal 6, the penetration tip of the weld metal 6 needs to be located on the outer contact face 32 in the axial...

example 3

[0071]With reference to FIG. 15, example 3 of the present invention will be described. This example is the same as Example 1 except for the length of the outer contact face 32 in the axial direction, and therefore a description of the same other components as Example 1 will be omitted below.

[0072]The result of a preliminary verification test performed prior to this example will be described below. The length L2 of the outer contact face 32 in the axial direction was 2.5 mm before the welding and 0 mm after the welding. That is, the weld metal 6 included the entire area of the outer contact face 32 in the axial direction. In this case, since the outer contact face 32 in the axial direction disappeared, the effect of preventing the spouting of the weld metal was not obtained. This result shows that in order to obtain the effect of preventing the spouting of the metal, it is essential to leave a part of the outer contact face 32 in the axial direction. The section of the vicinity of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| steam temperature | aaaaa | aaaaa |

| steam temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com