Ultra-pure alloy and method for manufacturing turbine rotor forging by using same

A steam turbine rotor and rotor body technology, applied in the manufacture of tools, quenching agents, heat treatment equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

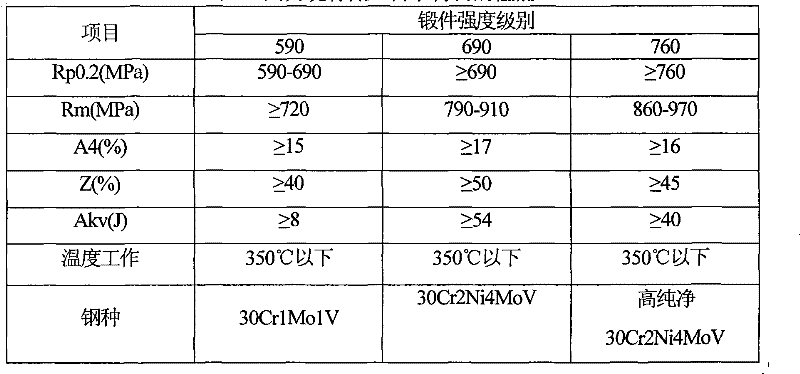

Examples

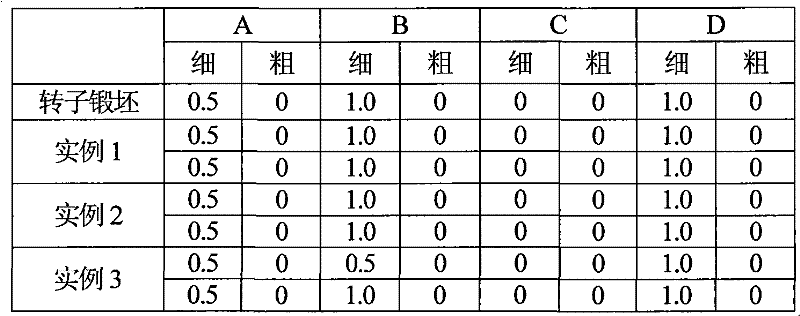

Embodiment 1

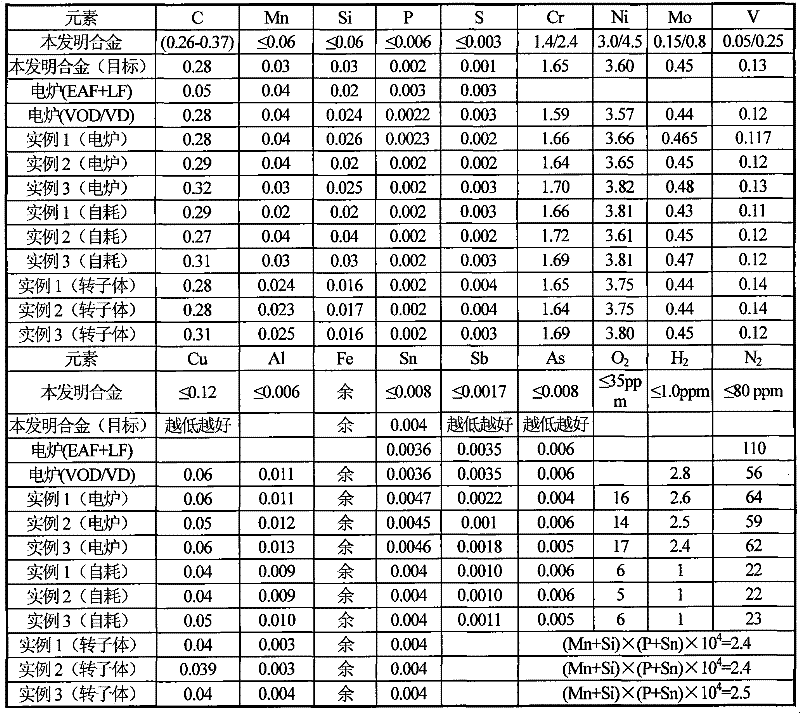

[0051] The chemical composition mass percent of the alloy material in this example is: C: 0.28; Mn: 0.024; Si: 0.016; P: 0.002; S: 0.004; Cr: 1.65; Ni: 3.75; : 0.04; Al: 0.003; Sn: 0.004; Sb: 0.0010; As: 0.006; O≤35ppm, H≤1.0ppm, N≤80ppm; the rest are Fe and unavoidable impurities.

[0052] Select Fe, Cr, Mo, Ni, V-Fe and other raw materials with low S, P, As, Sb, Sn and other impurities, smelt alloys in EAF (electric arc furnace) + LF (refining furnace), add Al, lime, fluorescent Stone and other materials, and ensure a certain amount of decarburization during the oxidation period, fully dephosphorize, degas, and remove inclusions, fully deoxidize and desulfurize during the reduction period, and control Mn, Si≤0.05% and S, P≤0.03% by furnace analysis before the furnace. As, Sb, Sn≤0.005%, Al≤0.02%; slag flow + slag removal at least twice before tapping, add Cr, Mo, Ni, V-Fe, adjust each alloy element to reach the above composition content; refining outside the furnace ( LF), ...

Embodiment 2

[0057] The mass percent of the chemical composition of the alloy material in this example is: C: 0.28; Mn: 0.023; Si: 0.017; P: 0.002; S: 0.004; Cr: 1.64; Ni: 3.75; : 0.039; Al: 0.003; Sn: 0.004; Sb: 0.0010; As: 0.006; O≤35ppm, H≤1.0ppm, N≤80ppm; the rest are Fe and unavoidable impurities.

[0058] The vacuum degassing time is 28 minutes; the forging heating temperature is 1200°C; the forged rotor body is hydrogen-expanded and annealed, the first stage is heated at 925°C for 15 hours and air-cooled, and the second stage is heated at 660°C for 105 hours and slowly cooled; The finished rotor required for machining after the overall heat treatment of the forging, the finished rotor required for machining after the overall heat treatment of the forging, the heat treatment process of the forging is 860°C / 5h / water quenching+580°C / 20h / furnace cooling. Others are the same as embodiment 1.

Embodiment 3

[0060] The mass percent of the chemical composition of the alloy material in this example is: C: 0.31; Mn: 0.025; Si: 0.016; P: 0.002; S: 0.003; Cr: 1.69; Ni: 3.80; : 0.04; Al: 0.004; Sn: 0.004; Sb: 0.0011; As: 0.005; O≤35ppm, H≤1.0ppm, N≤80ppm; the rest are Fe and unavoidable impurities.

[0061] The vacuum degassing time is 30 minutes, and the forging heating temperature is 1170°C; the forged rotor body is hydrogen-expanded and annealed, the first stage is heated at 900°C for 15 hours and air-cooled, and the second stage is heated at 660°C for 105 hours and slowly cooled; The finished rotor required for machining after the overall heat treatment of the forging, the finished rotor required for machining after the overall heat treatment of the forging, the heat treatment process of the forging is 850°C / 6h / water quenching+600°C / 16h / furnace cooling. Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com