Multiple field sheet type piezoresistor and its producing method

A varistor, multi-layer chip technology, applied in the direction of resistance manufacturing, varistor, varistor core, etc., can solve the problems of high cost of solder paste, poor solderability, unsuitable for mass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

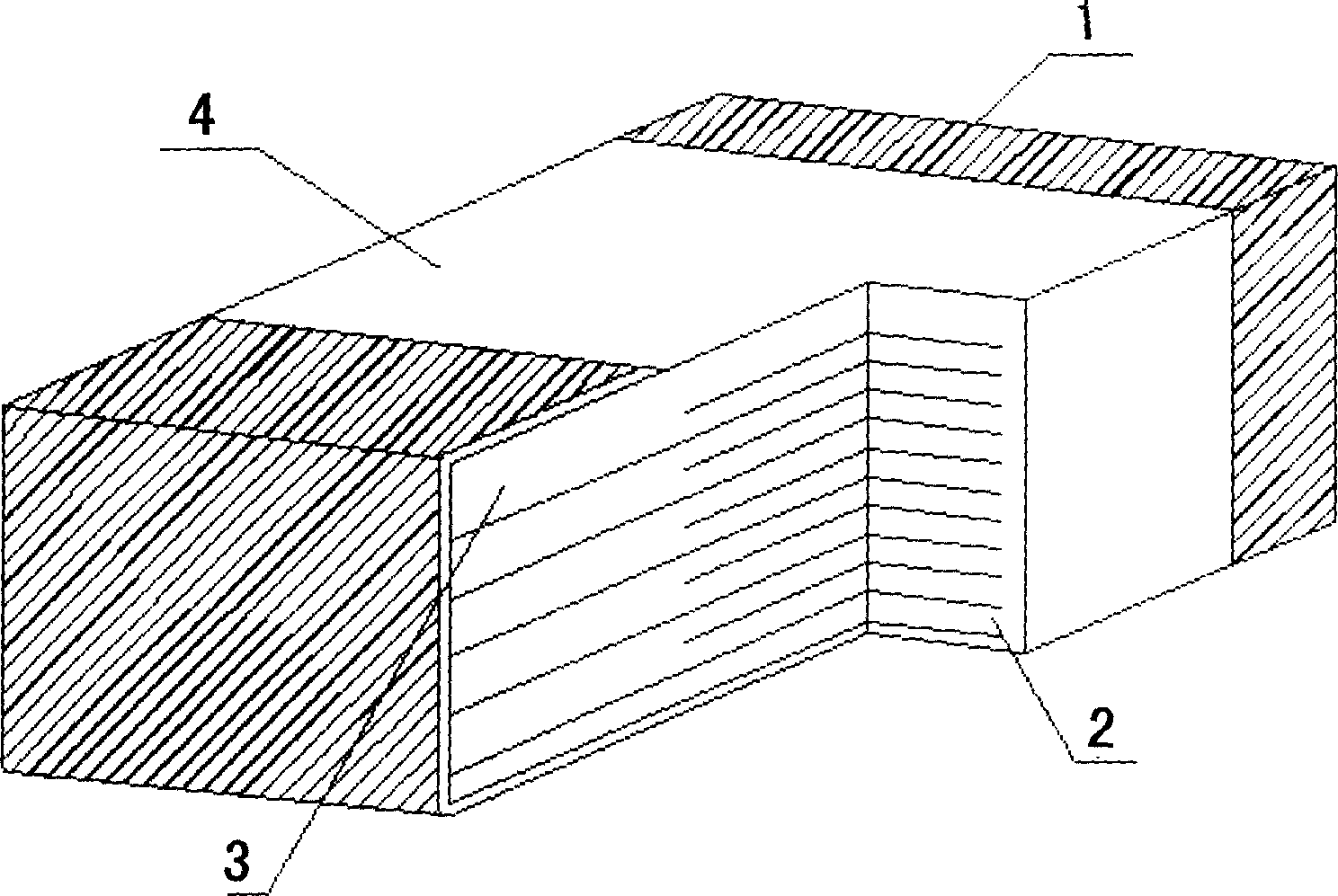

[0257] Embodiment 1: A multilayer chip varistor with an insulating layer between the internal electrodes and the terminal electrodes.

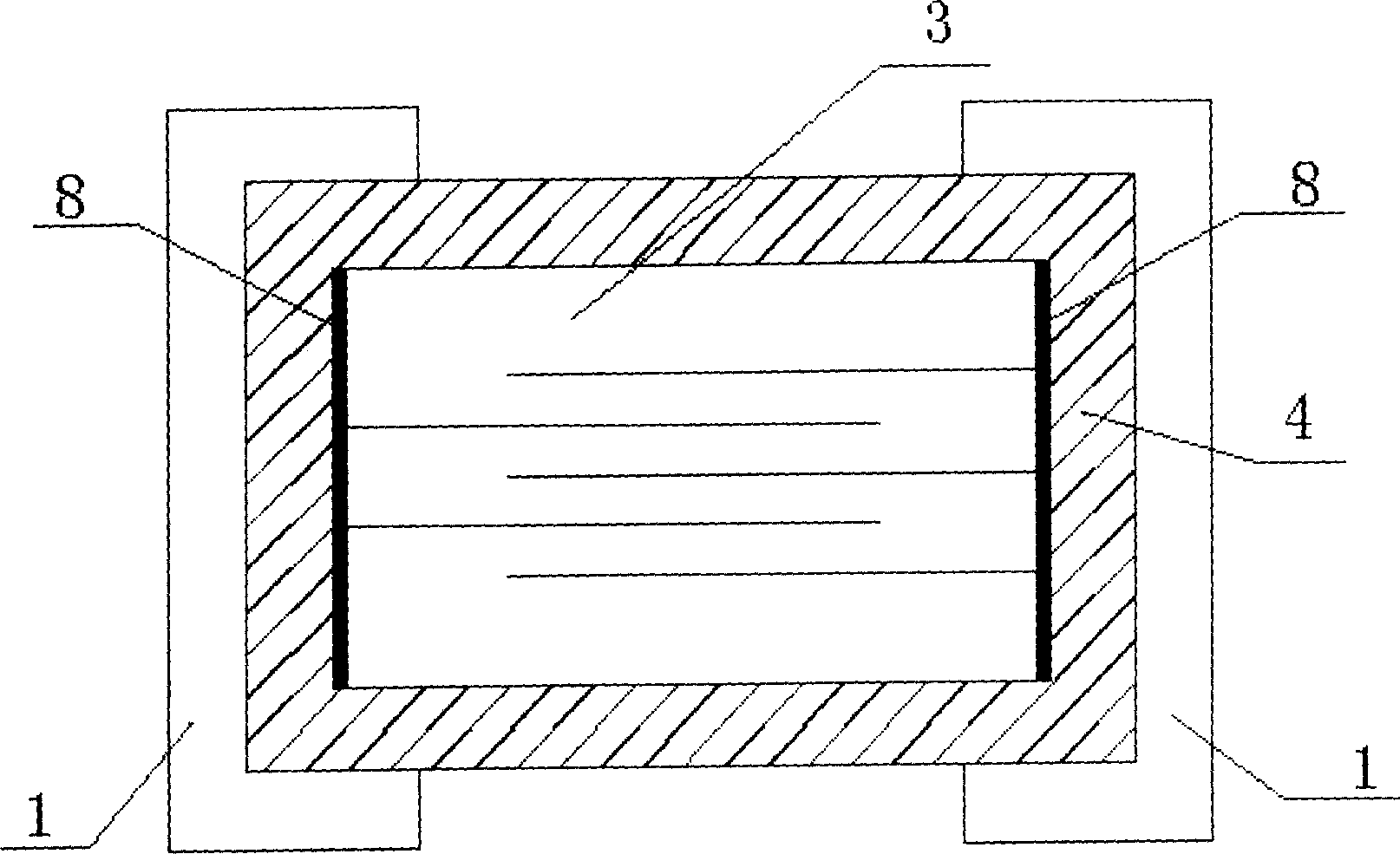

[0258] Such as image 3 The shown varistor with an insulating layer between the inner electrode and the terminal electrode is composed of a varistor substrate 3 , a terminal electrode 8 , a glass insulating layer 4 and a terminal electrode 1 .

[0259] The two ends of the varistor substrate 3 are respectively provided with a terminal electrode 8 connected to a terminal electrode 1, and the internal electrode 2 at one end of each chip varistor unit is connected with the terminal electrode 8 at the corresponding end, The internal electrode 2 at the other end of each chip varistor unit is connected to the termination electrode 8 at the corresponding other end.

[0260] Its manufacture method comprises the following steps:

[0261] (1) Preparation of slurry

[0262] (1) The material components and weight percentages of the varistor film are res...

Embodiment 2

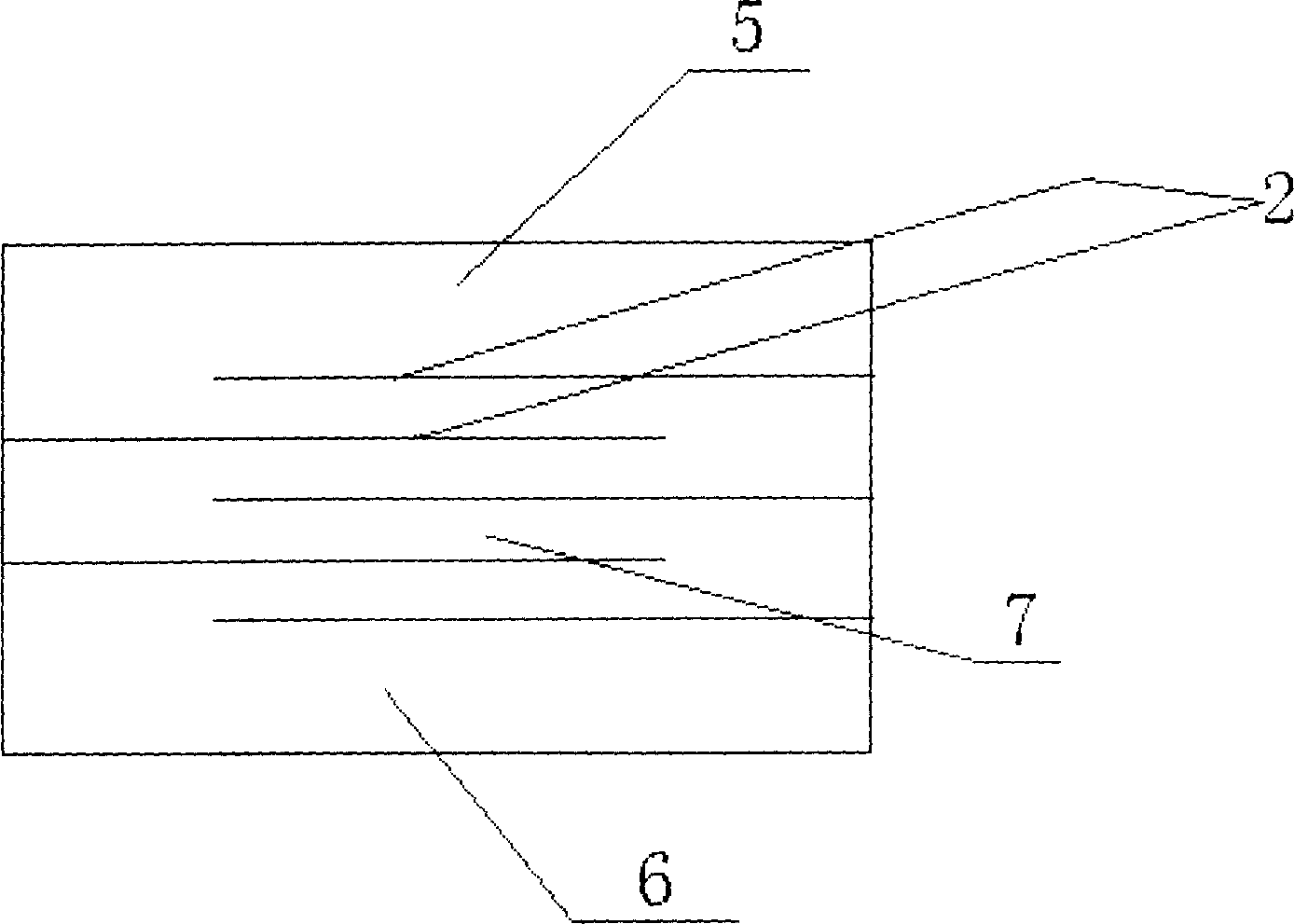

[0305] Embodiment 2: A multilayer chip varistor in which internal electrodes and terminal electrodes are directly connected.

[0306] Such as Figure 4 The piezoresistor in which the inner electrode and the terminal electrode are directly connected is composed of a piezoresistor substrate 3 , a glass insulating layer 4 and a terminal electrode 1 .

[0307] The internal electrode at one end of each chip varistor unit is directly connected to the terminal electrode 1 at the corresponding one end, and the internal electrode at the other end of each chip varistor unit is directly connected to the terminal electrode 1 at the corresponding other end.

[0308] Its manufacture method comprises the following steps:

[0309] (1) prepare slurry, with embodiment 1 (one);

[0310] (2) lamination, with (two) of embodiment 1;

[0311] (3) cutting, with (3) of embodiment 1;

[0312] (4) degumming, with (four) of embodiment 1;

[0313] (5) sintering, with (five) of embodiment 1;

[0314]...

Embodiment 3

[0318] Embodiment 3: A multilayer chip varistor in which terminal electrodes are directly connected to a varistor substrate.

[0319] Such as Figure 5 The piezoresistor in which the terminal electrodes are directly connected to the piezoresistor substrate is composed of a piezoresistor substrate 3 , an organic material insulating layer 9 and a terminal electrode 1 .

[0320] The two ends of the varistor substrate are respectively directly connected to the two terminal electrodes 1;

[0321] The internal electrode at one end of each chip varistor unit is directly connected to the terminal electrode 1 at the corresponding one end, and the internal electrode at the other end of each chip varistor unit is directly connected to the terminal electrode 1 at the corresponding other end.

[0322] Its manufacture method comprises the following steps:

[0323] (1) Preparation of slurry

[0324] (1) The material of piezoresistive film is made into slurry, same as (1) (1) of embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com