Moisture-proof anti-cracking detachable floor

An anti-cracking and flooring technology, applied in floors, buildings, building structures, etc., can solve the problems of non-reusable use, poor floor permeability, and large stress, and achieve beautiful appearance, strong moisture resistance, and weakened tensile stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

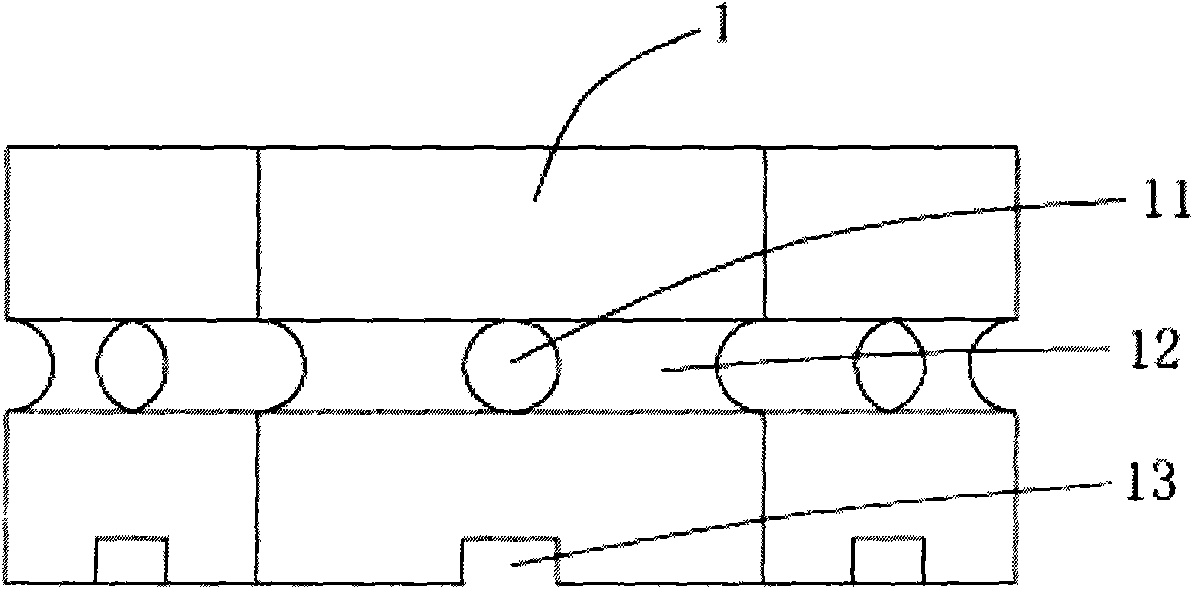

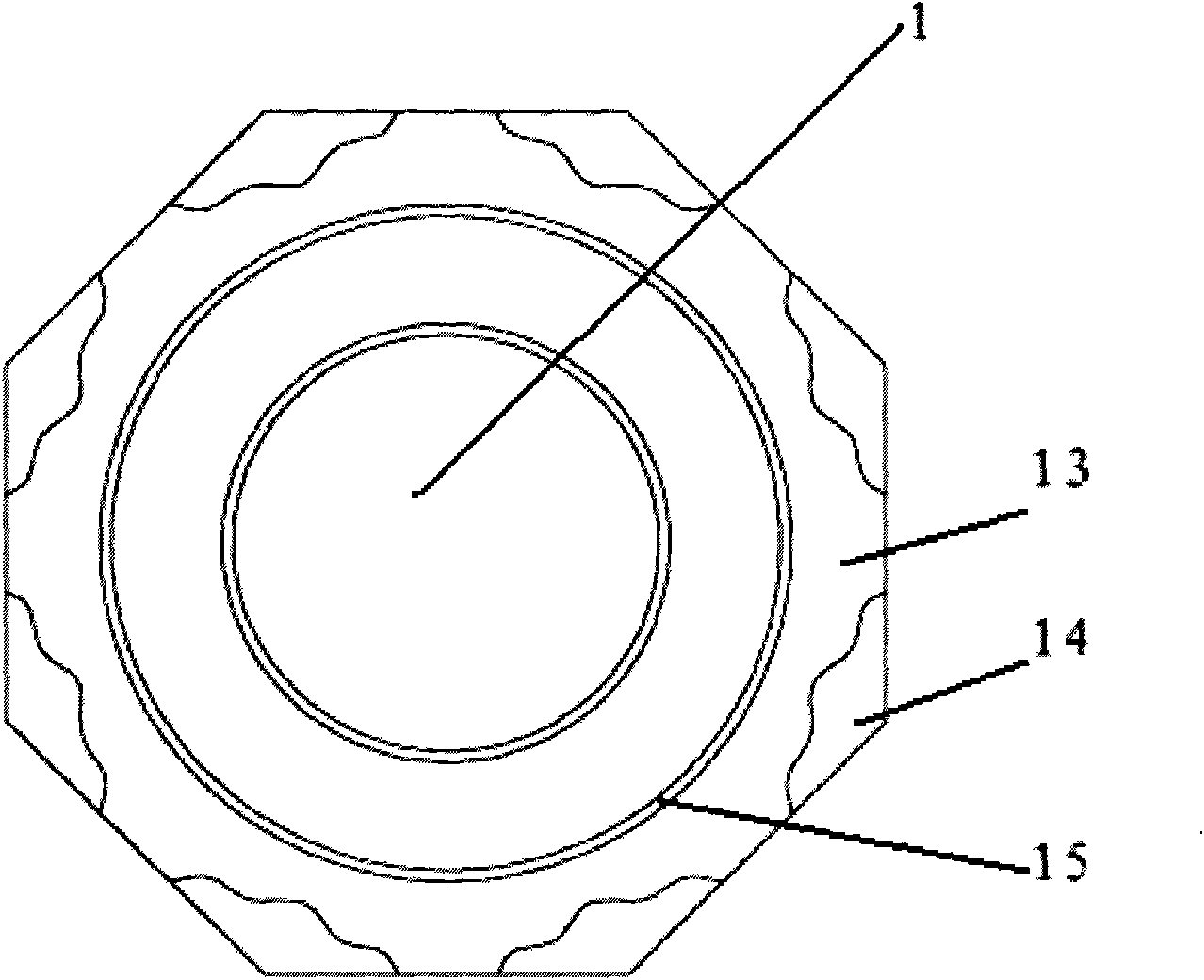

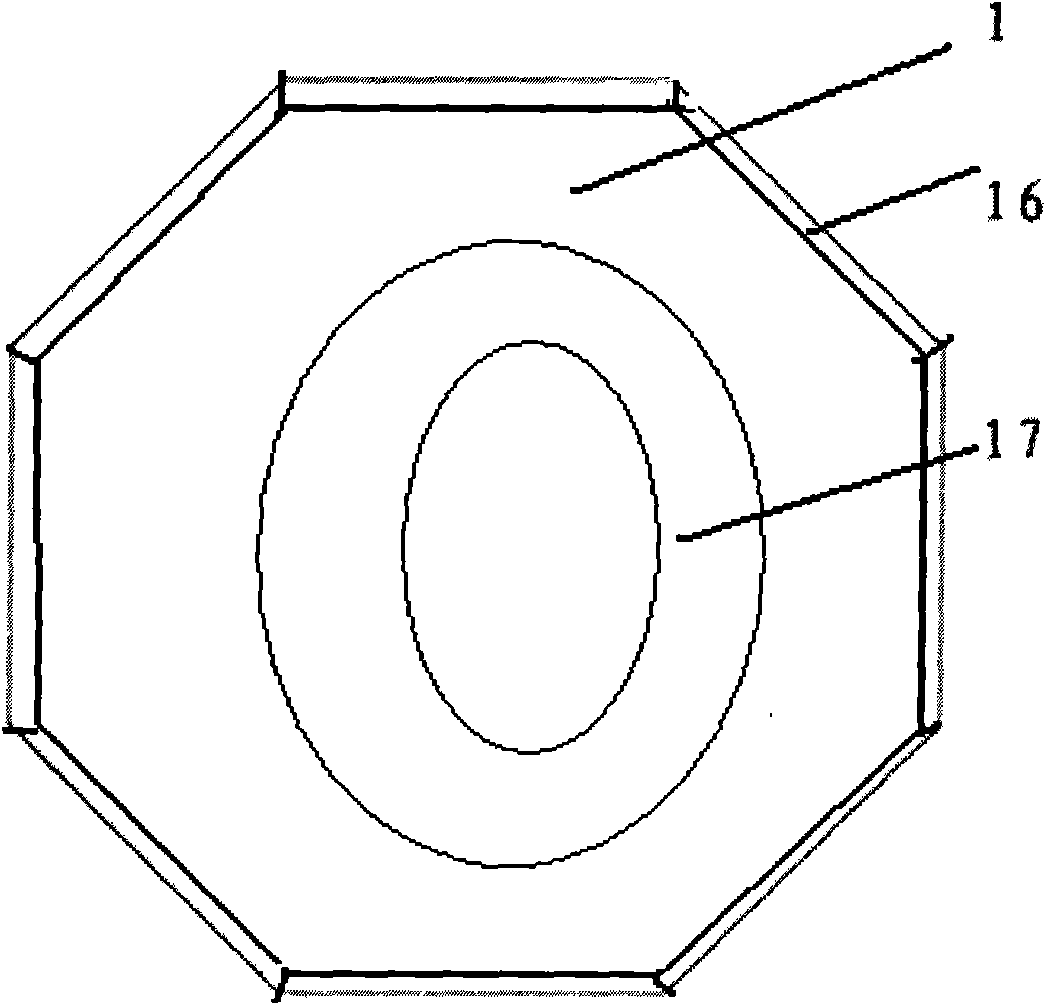

[0041] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 .

[0042] figure 1 It is an octagonal moisture-proof, crack-proof and detachable floor. The middle of the side of the floor 1 is provided with a horizontal groove 12, and a tenon 11 is arranged at the center of the horizontal groove 12, please refer to figure 2 The bottom edge of the floor 1 is provided with footings 14, air-permeable grooves 13 are formed between two footings, and a circular groove 15 is chiseled on the bottom of the floor 1. Please refer to image 3 , The edge of the surface of the floor 1 is provided with a chamfer 16 . There are carved patterns 17 in the center of the surface. Please refer to Figure 4 , Figure 4 It is a square floor that is moisture-proof, crack-proof, and detachable. A horizontal groove 22 is arranged at the middle of the side of the floor 2 , and a tenon 21 is arranged at the center of the horizontal groove 22 . Pleas...

Embodiment 2

[0045] Production of octagonal moisture-proof, crack-proof, removable floor with a side length of 60 mm:

[0046] Choose the side length as 160 millimeters, and the height is the rosewood of 55 millimeters cube, and the rosewood of above-mentioned cube is cut into the floor that side length is the octagon of 60 millimeters with wood cutting machine. A width of 10 mm and a depth of 10 mm horizontal grooves are chiseled out in the middle of the eight sides of the floor of the octagon. Drill a tenon with a diameter of 10 mm and a depth of 20 mm at the center of the horizontal groove. The pattern is carved in the center of the surface of the floor, and the chamfered structure is cut at the edge of the surface. Glue the feet with wood paint glue on the eight edges of the bottom surface of the floor, and cut out a circular groove on the bottom surface. The sides and bottom of the floor are glued with aluminum film. Then the above-mentioned floor is dried, painted, dried in the su...

Embodiment 3

[0048]Lay the floor on a square ground with a side length of 260 mm: take out 4 pieces of octagonal moisture-proof, crack-proof, detachable floor 1 with a side length of 60 mm, and a square moisture-proof and crack-proof floor with a side length of 60 mm 2. Detachable floors 2, 4 pieces of isosceles triangle with side lengths of 60, 60, and 70 mm respectively Moisture-proof, crack-proof, detachable floors 5, 4 pieces of right angles with side lengths of 35, 35, and 60 mm Triangular moisture-proof, crack-proof, detachable floor 4. Take out the 4 wooden tenons, insert one end of the four wooden tenons 3 into the tenons of the square moisture-proof, crack-proof, and detachable floor 2, and insert the other ends into the octagonal moisture-proof, crack-proof, and detachable floor 1 respectively. to splice. After splicing, an isosceles triangle gap is formed between two octagonal moisture-proof, crack-proof, and detachable floors 1, and one end of two wooden tenons is inserted int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com