A superconducting magnet vpi mold joint insulation sealing device and its technology

A technology of insulating and sealing superconducting magnets, which is applied in the manufacture of superconducting magnets/coils, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of easy dislocation of gaskets, low sealing efficiency, and scrapped coils, and achieves sealing accuracy. High, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

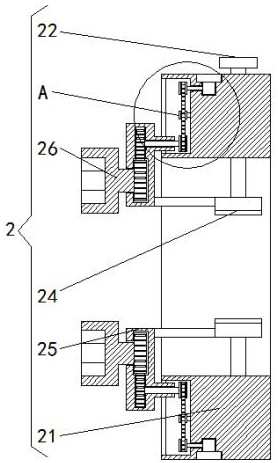

[0033] see Figure 3-Figure 6 , a superconducting magnet VPI mold joint insulation and sealing device, including a sealing mechanism 1, the outer side of the sealing mechanism 1 is sleeved with an assembly mechanism 2, the assembly mechanism 2 includes a collar 21, and the inside of the collar 21 is inserted with a screw 22, the screw 22 is connected to the drive wheel 23 through a bevel gear, so that multiple sets of splints 24 move synchronously. The outside of the screw 22 is connected to the drive wheel 23, and the outside of the screw 22 is threaded with a splint 24. The splint 24 is slidingly connected to the inside of the collar 21. , and the splint 24 is connected to the carriage 25 through a connecting rod, the left side of the collar 21 is slidably connected to the carriage 25 , and the left side of the carriage 25 is engaged with the sleeve 26 .

[0034] Turn the screw 22, the screw 22 drives the splint 24 to move towards the direction of the superconductor 12, the ...

Embodiment 2

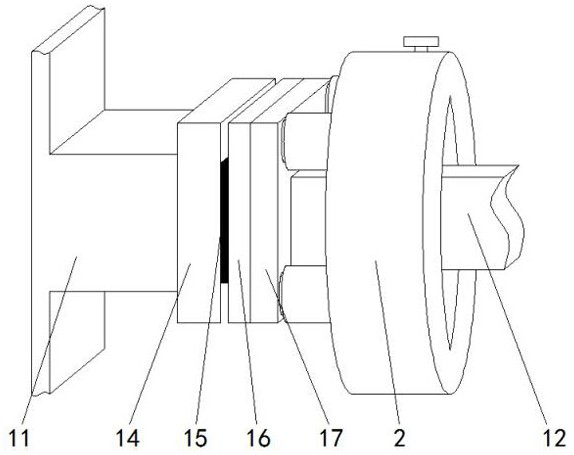

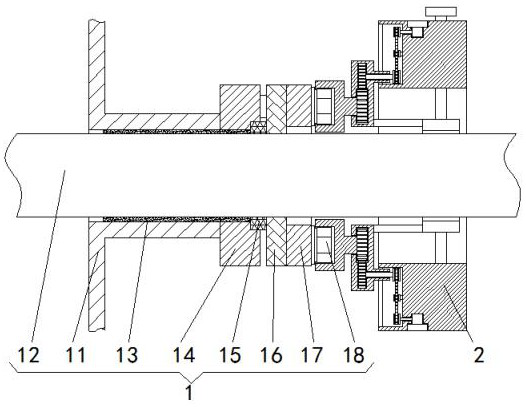

[0038] see Figure 1-Figure 2, a superconducting magnet VPI mold joint insulation sealing device, including a sealing mechanism 1, the sealing mechanism 1 includes a vacuum mold 11, the interior of the vacuum mold 11 is inserted with a superconductor 12, the outer side of the superconductor 12 is sleeved with an insulating pad 13, the vacuum mold The right side of 11 is welded with a fixed flange 14, the inside of the fixed flange 14 is clamped with a gasket 15, the outer side of the superconductor 12 and located on the right side of the gasket 15 is sleeved with an insulating flange 16, the outer side of the superconductor 12 and located in A locking flange 17 is sleeved on the right side of the insulating flange 16 , and bolts 18 are inserted into the locking flange 17 .

Embodiment 3

[0040] see Figure 1-Figure 6 , a superconducting magnet VPI mold joint insulation sealing device, including a sealing mechanism 1, the sealing mechanism 1 includes a vacuum mold 11, the interior of the vacuum mold 11 is inserted with a superconductor 12, the outer side of the superconductor 12 is sleeved with an insulating pad 13, the vacuum mold The right side of 11 is welded with a fixed flange 14, the inside of the fixed flange 14 is clamped with a gasket 15, the outer side of the superconductor 12 and located on the right side of the gasket 15 is sleeved with an insulating flange 16, the outer side of the superconductor 12 and located in The right side of the insulating flange 16 is sleeved with a locking flange 17, the inside of the locking flange 17 is inserted with bolts 18, the outer side of the sealing mechanism 1 is sleeved with an assembly mechanism 2, and the assembly mechanism 2 includes a collar 21. A screw 22 is inserted inside the ring 21, and the screw 22 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com