Swing vortex check valve

A check valve, swing type technology, applied in the direction of lift valve, valve detail, control valve, etc., can solve the problems of high-density medium backflow, high processing cost, complex process, etc., to achieve high processing technology, low cost, high technology easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

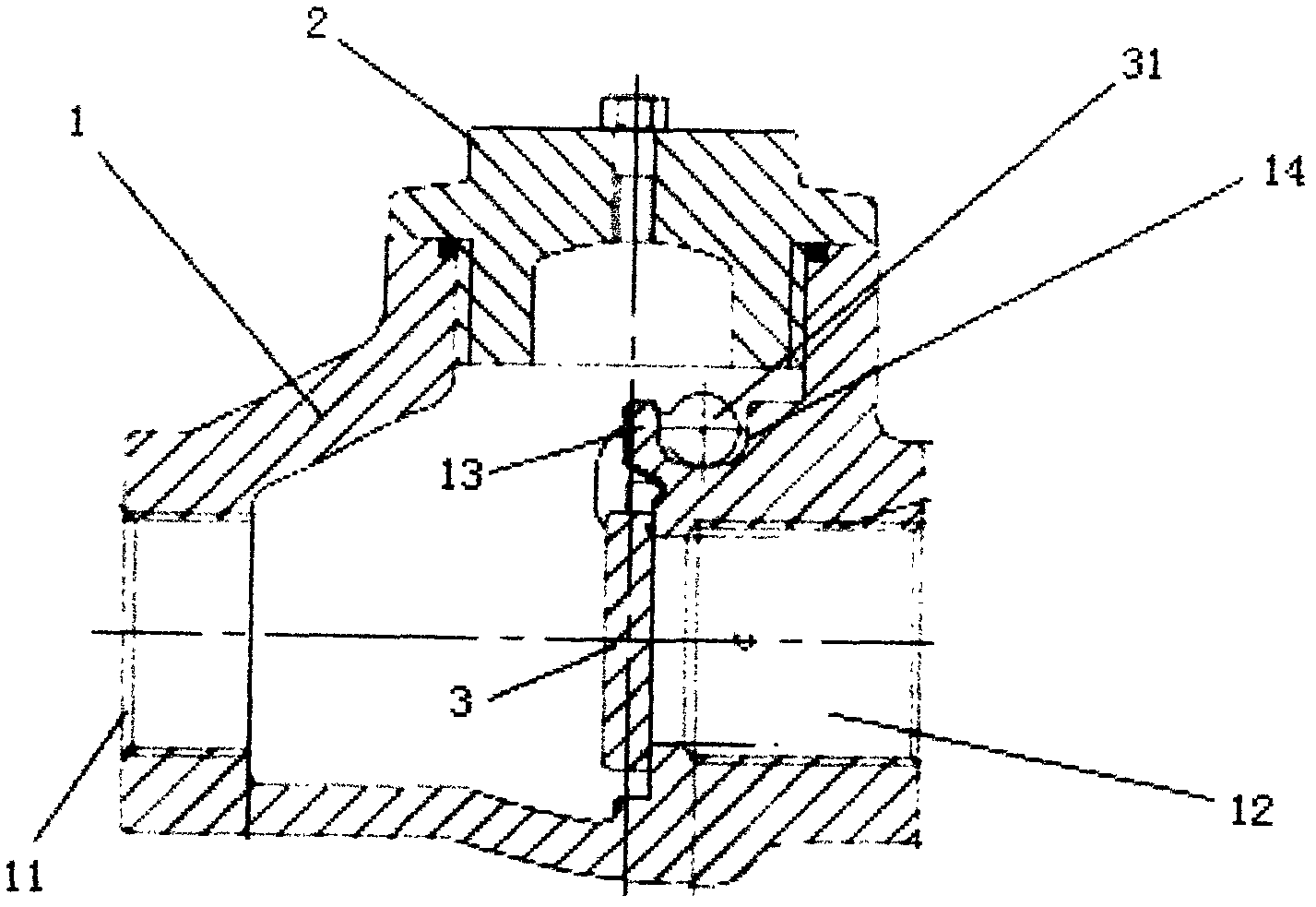

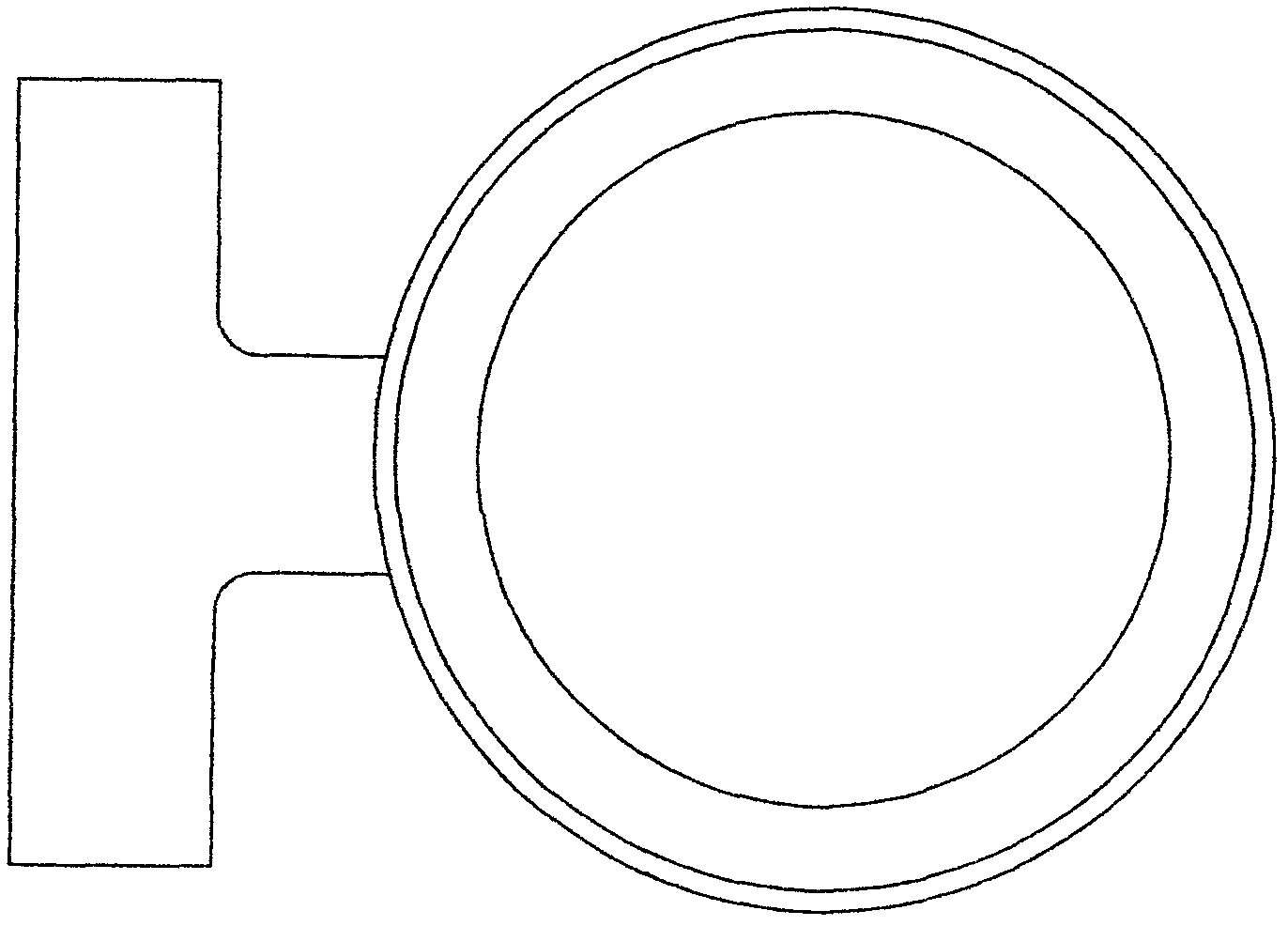

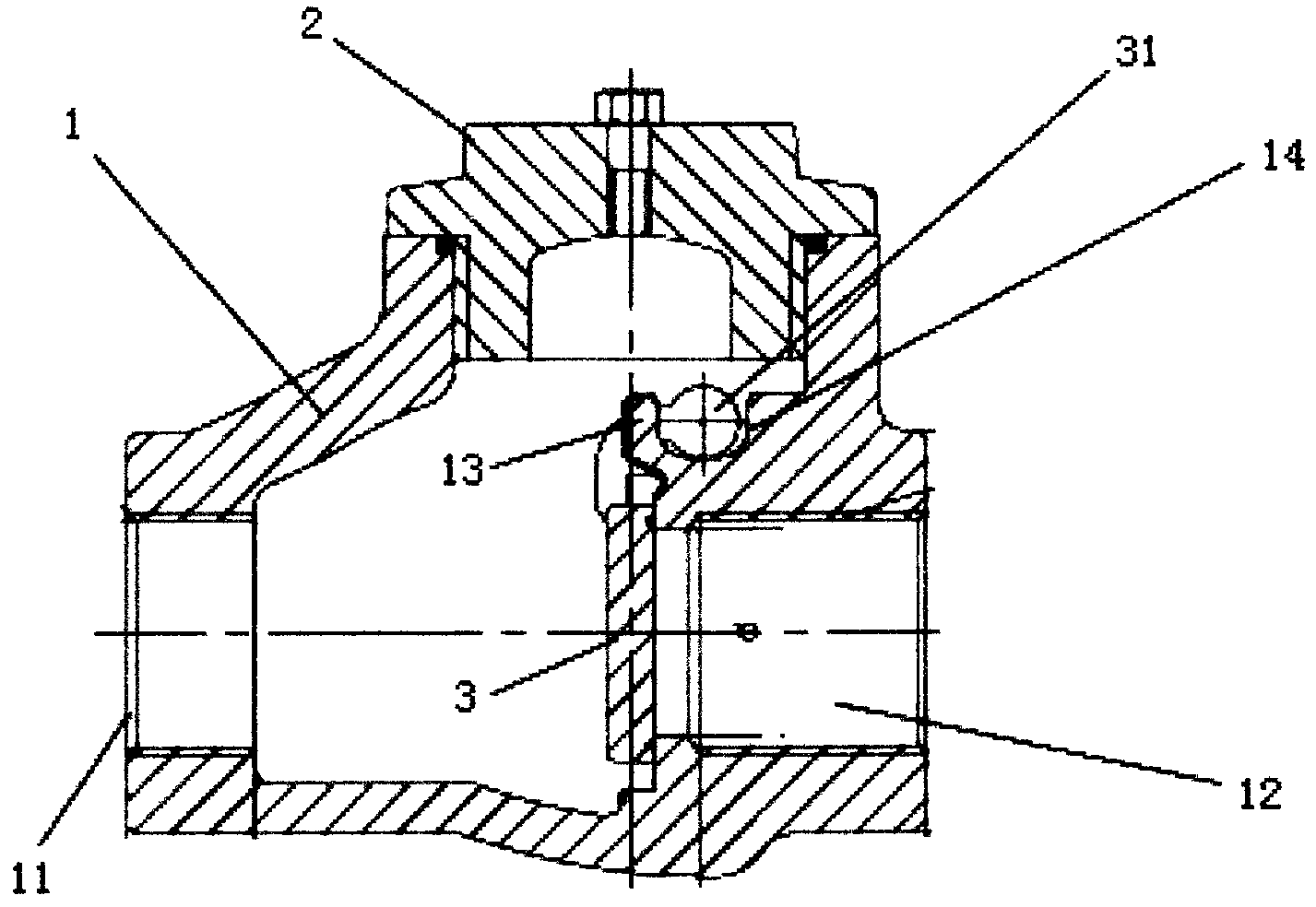

[0015] A check valve, comprising a valve body 1, a valve cover 2 and a valve plate 3, the upper and lower inner walls of the inlet part 11 of the valve body 1 are of asymmetric structure, the upper inner wall is a slope, the lower inner wall is a plane, the fluid flows from the inlet part 11 After entering, a vortex field is formed to increase the sealing torque on the valve plate 3, the sealing effect of the valve plate is better, and the service life is longer.

[0016] Furthermore, the upper end of the valve plate 3 is connected with an integrated shaft 31, the shaft 31 and the valve plate 3 are of an integral structure, and the shaft 31 is parallel to the plane of the valve plate 3, and the inside of the valve cover 2 on the valve body 1 is provided with a placement shaft. The groove 4, the groove 4 is located at the top of the fluid outlet part 12, there is a raised edge 13 beside the groove 4, and there is a gap on the edge, the connecting piece between the valve plate sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com