Groove valve

The technology of a valve body and a tubular valve is applied in the field of wine filling devices on a wine production line, which can solve the problems of easy leakage and inconvenient opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

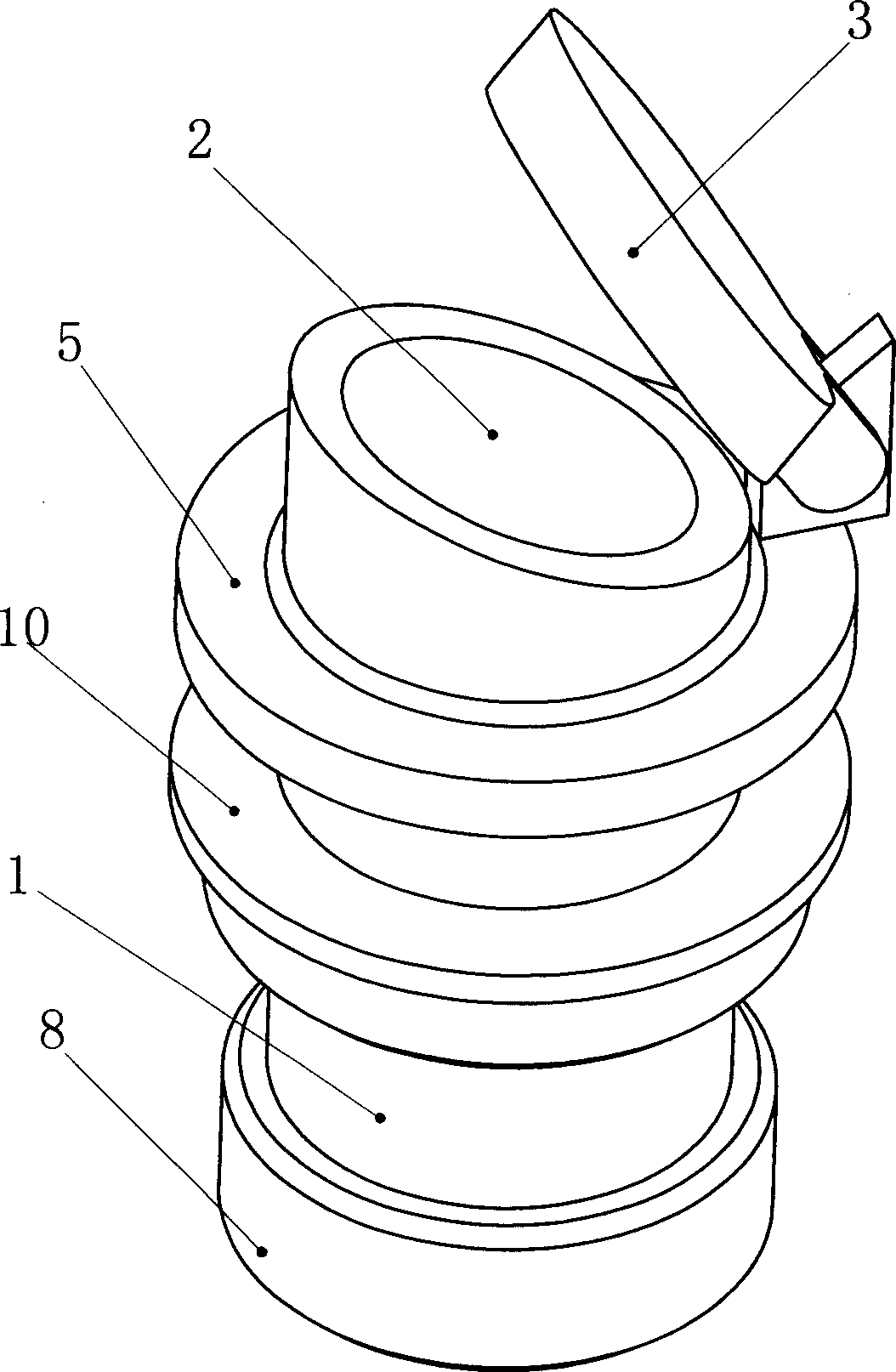

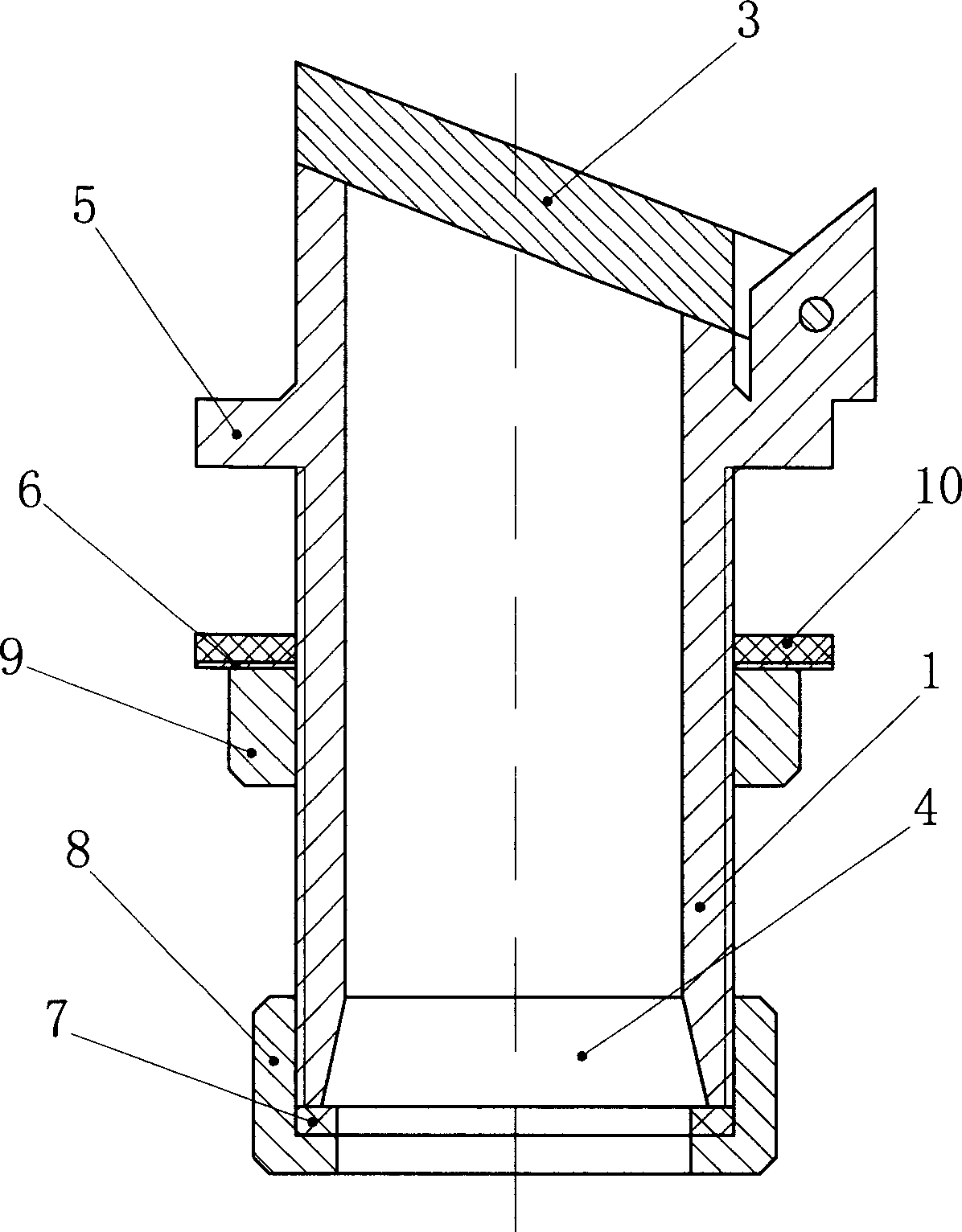

[0011] Such as figure 1 , figure 2 As shown: the valve body 1 of the groove valve is in the shape of a straight pipe, the upper end of the valve body 1 is the injection port 2, the lower end of the valve body 1 is the connection port 4, the end surface of the valve body 1 injection port 2 intersects the axis of the valve body 1 obliquely, and the injection port 2 The end face generally intersects the axis of the valve body 1 at 15° to 30°. The middle part of the outer wall of the valve body 1 is provided with a protruding annular step 5. In this specific embodiment, the annular step 5 is formed by annular ribs. In the vicinity of the lower edge of the injection port 2, the valve cover 3 is hinged on the annular step 5 near the lower edge of the injection port 2. The inclination angle of the valve cover 3 is the same as that of the injection port 2. The inner hole of the connection port 4 is a horn-shaped conical surface with a taper Between 10° and 20°, the end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com