Method for manufacturing and sealing exhaust port in vacuum glass and system thereof

A vacuum glass and exhaust port technology, applied in the physical field, can solve the problems of affecting the appearance, easy damage to the sealing port, poor sealing effect, etc., and achieve the effects of fast processing and production, high sealing precision, and improving vacuum sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

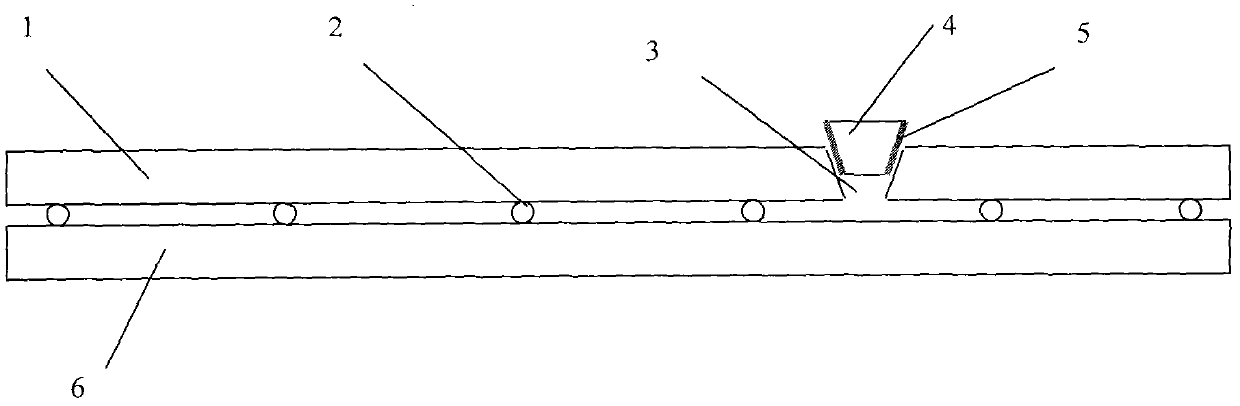

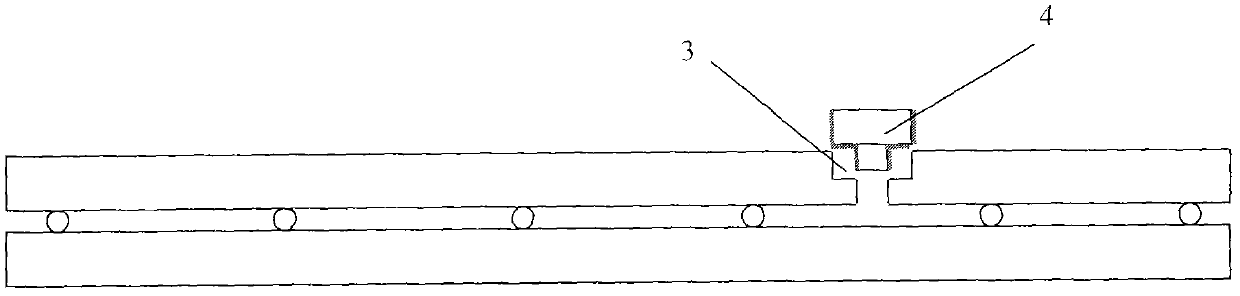

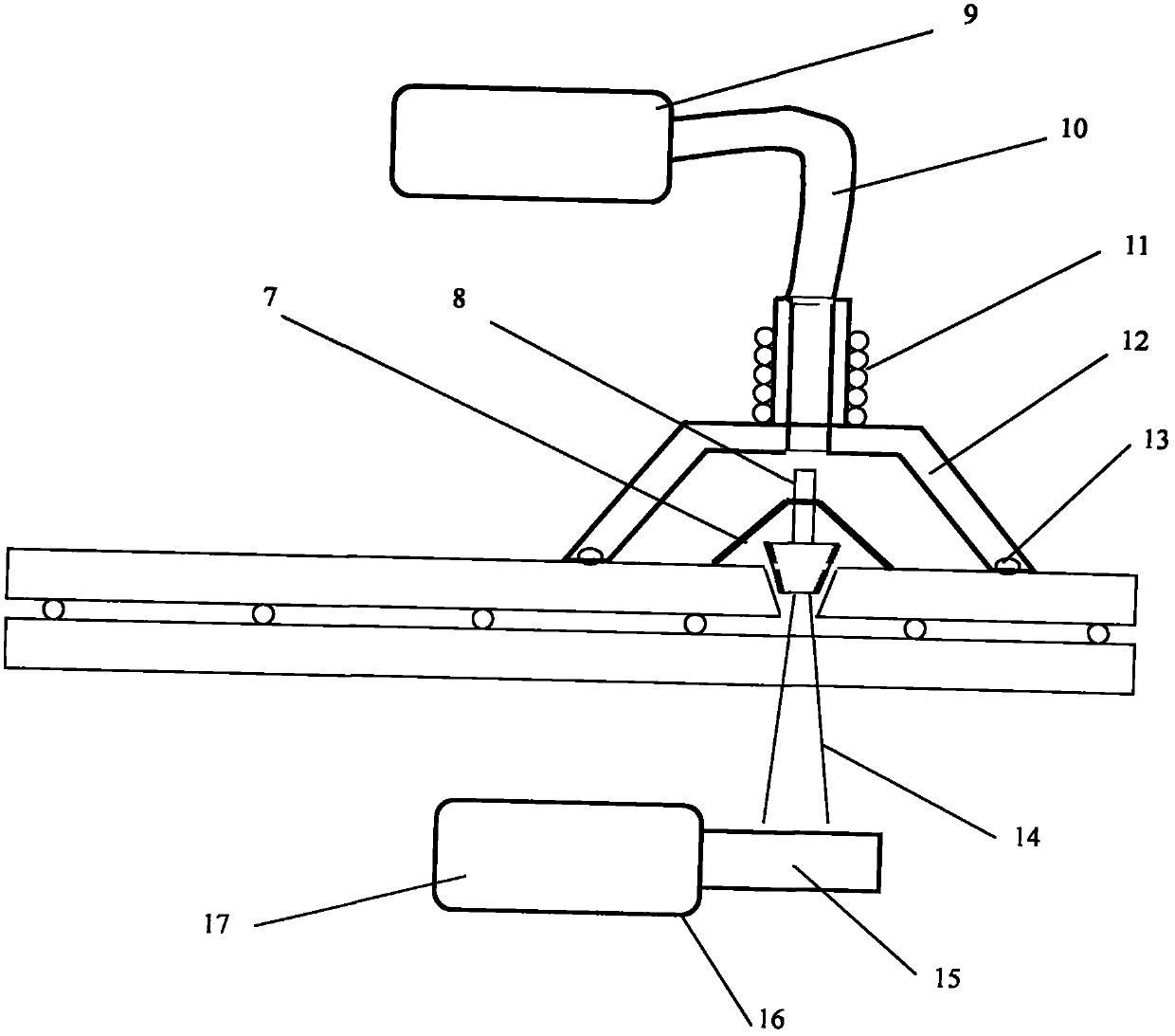

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the method for manufacturing and sealing the exhaust port 3 in the vacuum glass of the present invention includes a process of making the exhaust port 3 in the vacuum glass, a process of making the glass sealing plug 4 and a process using the described glass sealing plug 4. The process of sealing the exhaust port 3. In the process of making the exhaust port 3 in the vacuum glass, the laser is used to directly engrave the through hole layer by layer in the flat glass to form a through hole. In the process of sealing the plug 4, a laser is used to three-dimensionally engrave a plug body on the glass block, the shape of the plug body matches the shape of the through hole, and the glass sealing plug 4 is used to seal the exhaust port 3 During the process, the plug body is put into the through hole, the sealant 5 is laid between the plug body and the through hole, and then the plug body and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com